Method for dyeing slubby yarn cotton fabrics into raindrop or silk rain style

A technology for slub yarns and fabrics, applied in dyeing, textile and papermaking, etc., can solve the problems of single color, impossible to obtain raindrop or rain silk dyeing style, etc., and achieves simple and easy method, excellent dyeing fastness, bright color and luster. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Cotton fabrics that have been pre-treated by boiling, bleaching, etc., are padded with anti-dyeing agent (10-20 g / L), and dried in a dryer; padding with dyeing solution containing reactive dyes and alkali agents (soda ash or baking soda), with liquid The rate is 80-100%; the fabric is steamed in saturated steam for 60-90 seconds at a temperature of 100-102°C, and then washed in cold water, hot water (70-90°C), soaping (90-95°C), and hot water (70-90℃), cold water washing, drying and other post-treatment.

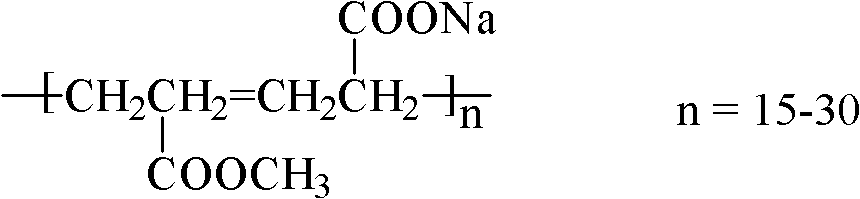

[0020] The chemical structure of the anti-dyeing agent is as follows:

[0021]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com