Preparing method of normal-temperature normal-pressure deeply-dyeable polyester filament

A technology of polyester filament and normal pressure, applied in the field of preparation of deep dyeable polyester filament at normal temperature and pressure, can solve the problems of difficult to obtain color development, fastness, increased production cost, high equipment requirements, etc., to achieve dyeing effect Good, high production efficiency, high color fastness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of deep dyeable polyester filament at normal temperature and pressure, comprising the following steps:

[0038] (1) Drying: Dry deep-dyed polyester chips under normal temperature and pressure, the drying temperature is 100~120℃, and the drying time is 24~48 hours;

[0039] (2) Extrusion: The normal temperature and pressure deep dyeable polyester chips after normal drying are sent to the extruder to be heated and melted, compressed into a melt, and extruded by a rotating screw with a screw pressure of 150~220kg / cm 2 ;

[0040] (3) Spinning: spinning at a temperature of 250~280°C and a speed of 2500~3000m / min;

[0041] (4) Winding: Stretching, twisting and winding, it is suitable for deep dyeing of polyester fibers at room temperature and pressure;

[0042] (5) Texturing: use a texturing machine to process deep-dyeable polyester fibers at room temperature and pressure to obtain deep-dyeable polyester filaments at room temperature and pressure; the dra...

Embodiment 2

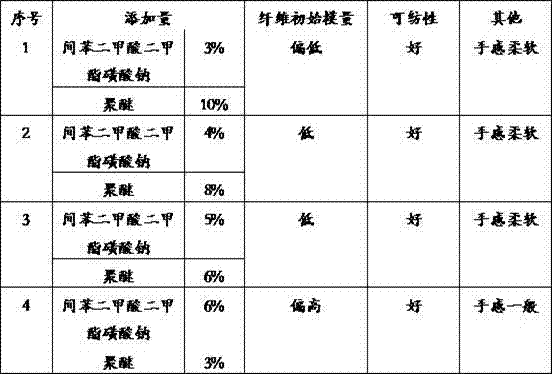

[0056] The difference from Example 1 is that the normal temperature and pressure deep dyeable polyester chip in step (1) includes the following components: polyester, the third monomer and the fourth monomer, and the polyester includes normal temperature and pressure cations Dye-dyeable polyester, the third monomer includes diethyl isophthalate sulfonate, the fourth monomer includes aliphatic dibasic acid, the weight ratio of each component is as follows: normal temperature and pressure cationic dyeable 80~95% polyester, 2~8% diethyl isophthalate sulfonate, 3~12% aliphatic dibasic acid. Put the cationic dye-dyeable polyester at normal temperature and pressure into the reaction kettle, carry out esterification at 180-270°C, control the external temperature of the fractionating column at 150-180°C, and the top temperature at 130-160°C; Diethyl isophthalate sulfonate and aliphatic dibasic acid are stirred together, and after stirring for 4-20 minutes, the temperature in the kettl...

Embodiment 3

[0058] The normal temperature and pressure deep dyeable polyester chip in step (1) includes the following components: polyester, the third monomer and the fourth monomer, the polyester includes normal temperature and pressure cationic dye-dyeable polyester, the third monomer The body includes diethylene glycol isophthalate sulfonate, and the fourth monomer includes polyether. The weight ratio of each component is as follows: polyester 80-95% dyeable with cationic dyes at normal temperature and pressure, isophthalic acid Diethylene glycol formate sulfonate 3~5%, polyether 6~10%. Put the cationic dye-dyeable polyester at normal temperature and pressure into the reaction kettle, carry out esterification at 180-270°C, control the external temperature of the fractionating column at 150-180°C, and the top temperature at 130-160°C; Diethylene glycol isophthalate sulfonate and polyether are stirred together, and after stirring for 4-20 minutes, the temperature in the kettle is lowered...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com