Patents

Literature

55results about How to "Initial modulus reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of antibacterial anti-flaming protein viscose fiber

InactiveCN102304783AImprove flame retardant performanceHigh strengthMonocomponent cellulose artificial filamentWet spinning methodsViscoseSlurry

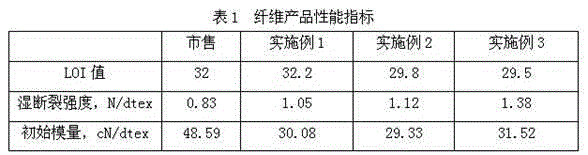

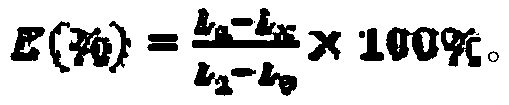

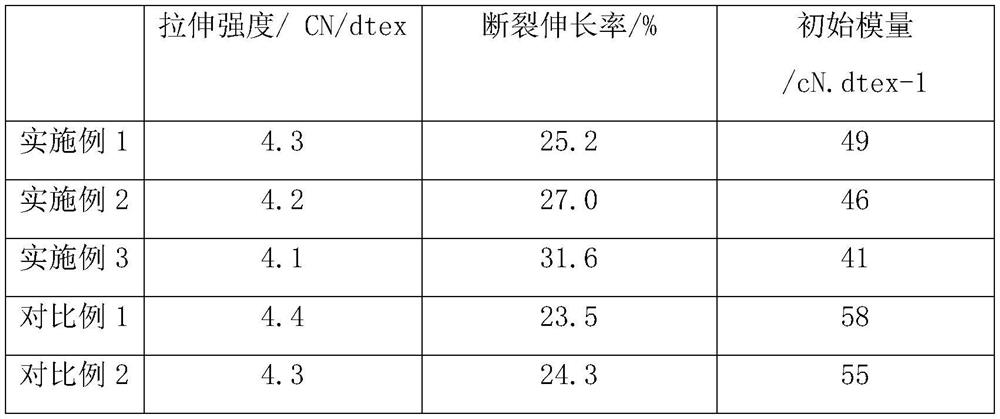

The invention discloses a preparation method of an antibacterial anti-flaming protein viscose fiber. The preparation method comprises the following steps of preparing fire retardant slurry, a protein glue liquid and a chitosan solution, mixing uniformly the fire retardant slurry, the protein glue liquid and the chitosan solution with a viscose spinning solution before spinning, preparing the antibacterial anti-flaming protein viscose fiber through wet spinning, and carrying out soft arrangement on the prepared fiber. According to the preparation method of the antibacterial anti-flaming protein viscose fiber, disclosed by the invention, the antibacterial anti-flaming protein viscose fiber is prepared from hexaphenoxy cyclotriphosphazene as a fire retardant, alkyl polyglycoside as an emulsifier of the fire retardant, animal protein as a protein raw material, and chitosan as an antibacterial agent, has excellent flame retardant property and is up to the national textile anti-flaming standard; and meanwhile, the service performance and antibacterial property are excellent, the wet strength of the fiber is improved by more than 20%, the initial modulus is reduced by more than 30%, and the bulking intensity is improved by more than 8%.

Owner:TAIYUAN UNIV OF TECH

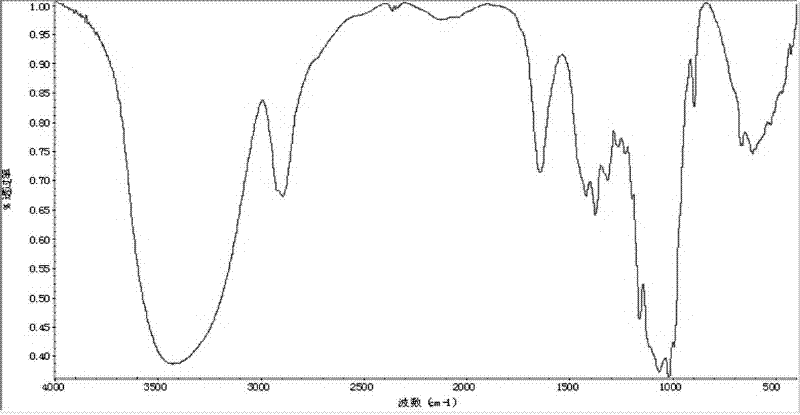

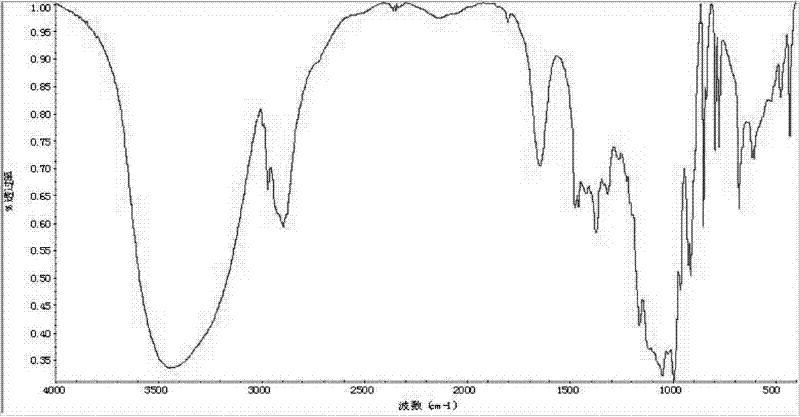

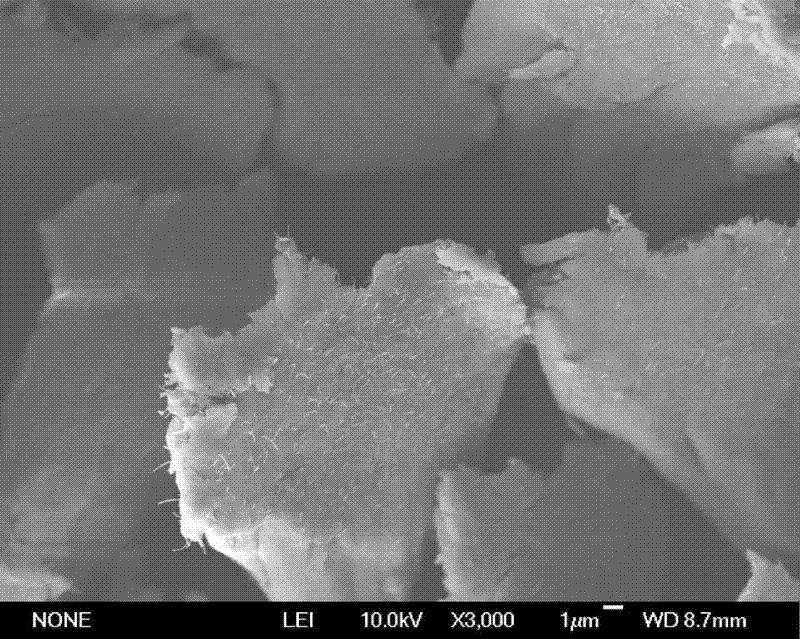

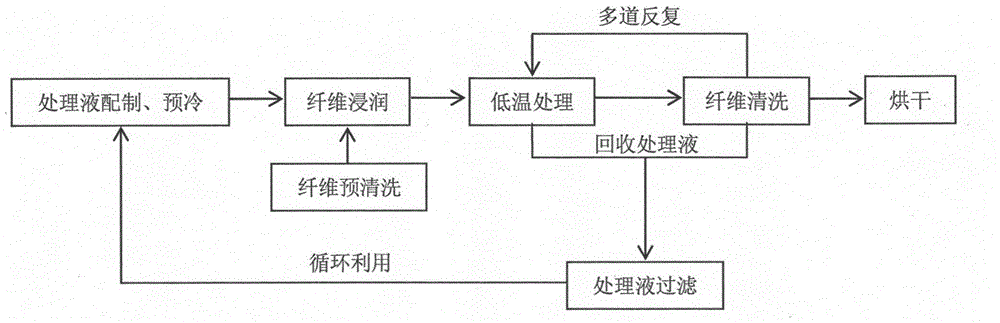

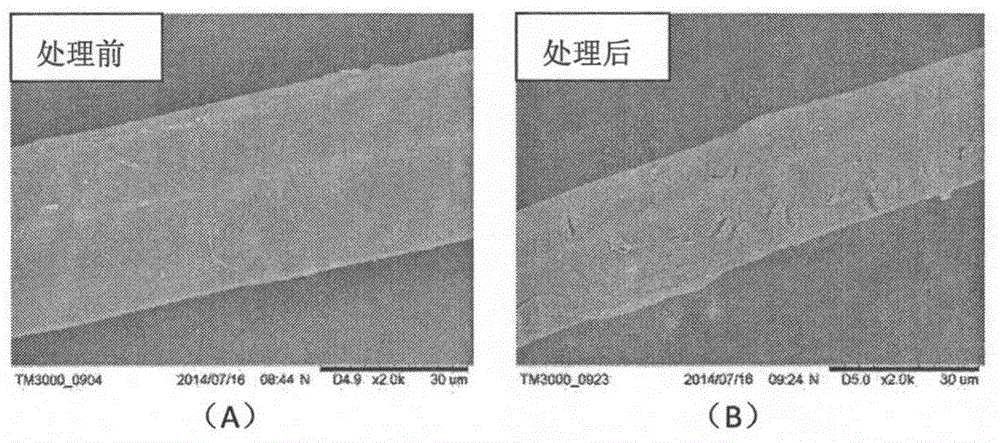

Low-temperature softening treatment method for jute fibers

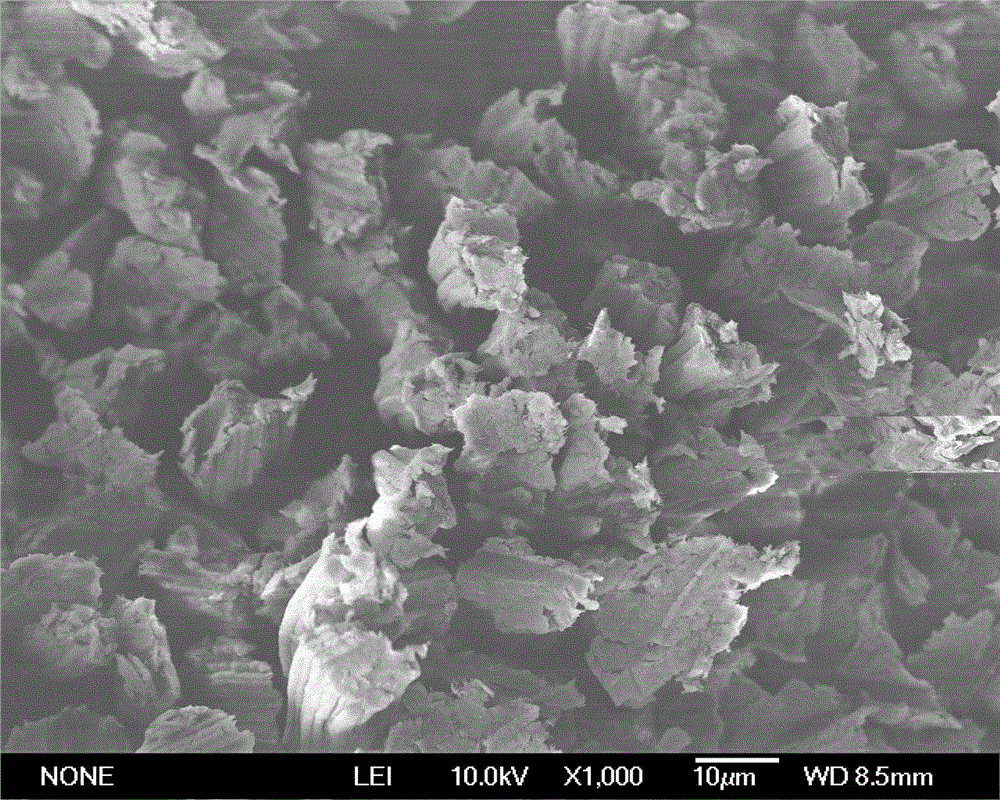

The invention provides a low-temperature softening treatment method for jute fibers. The low-temperature softening treatment method for jute fibers is characterized by concretely comprising the following steps: prewashing jute fibers to remove surface impurities, performing one to ten times of softening treatment, and drying to obtain softened jute fibers; wherein softening treatment comprises the following steps: infiltrating the jute fibers in a softening treatment fluid or spraying the softening treatment fluid onto the jute fibers, wherein the softening treatment fluid contains alkali and urea or thiourea; and treating for 10s-3h at 5DEG C to -195DEG C under low-temperature state, and taking out and washing the jute fibers. The treatment method is simple, high-efficiency and clean, the treated jute fibers are low in crystallinity, low in rigidity, and soft in hand feeling, and the prepared fabric is not itchy; and the fibers have low crystallinity, the surfaces of the fibers have partial holes and grooves, and the dyeing performance and hygroscopic property of the fibers can be obviously improved.

Owner:DONGHUA UNIV

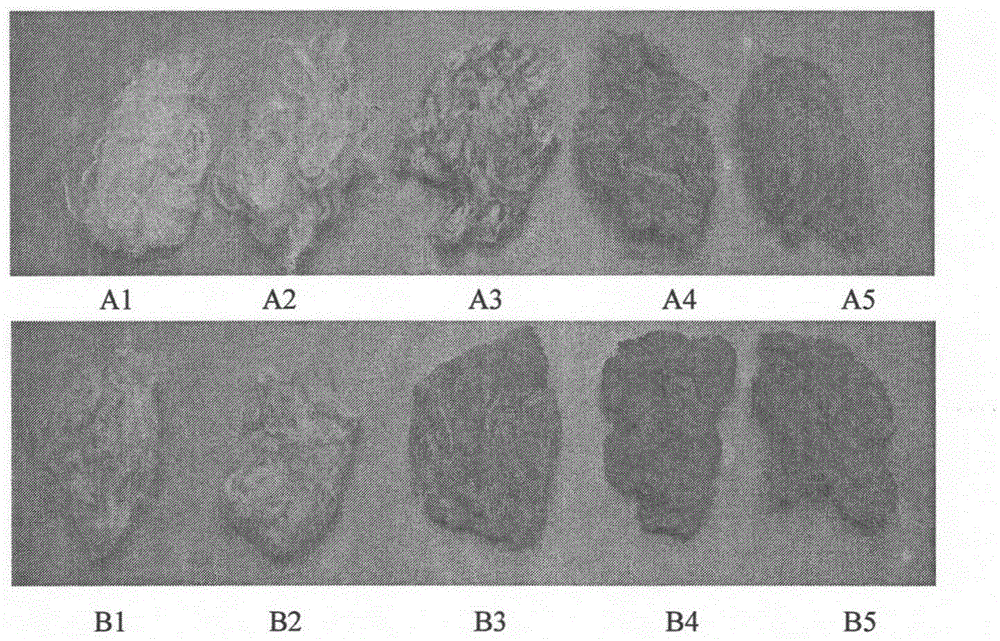

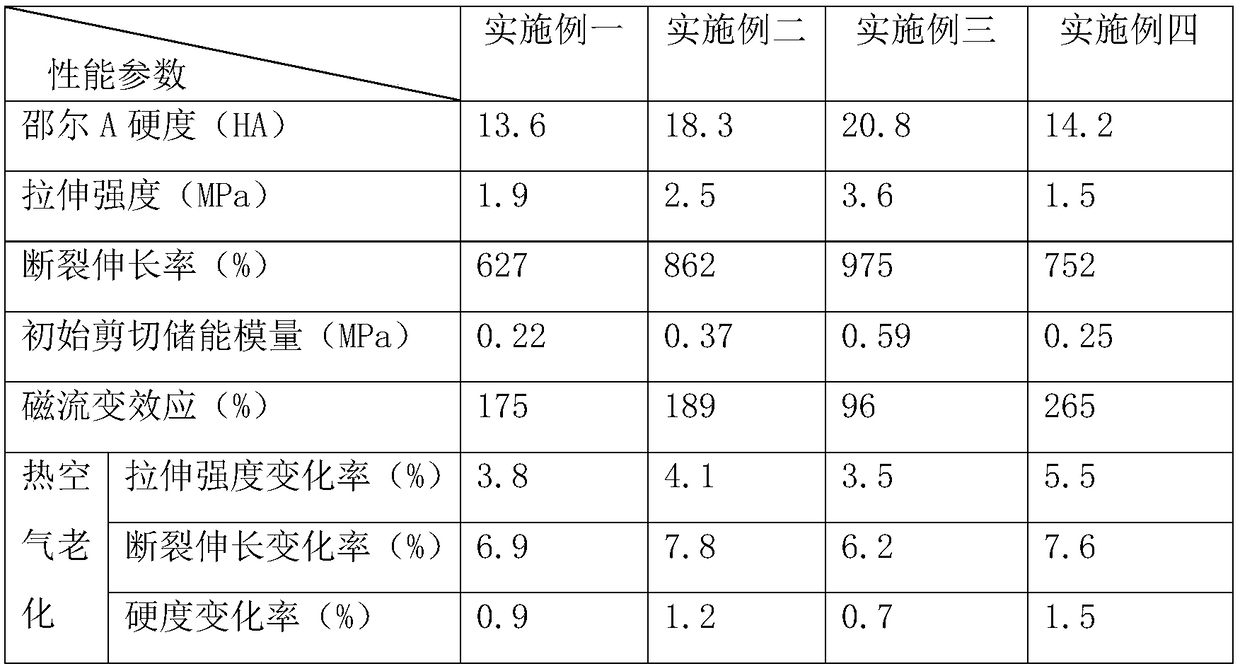

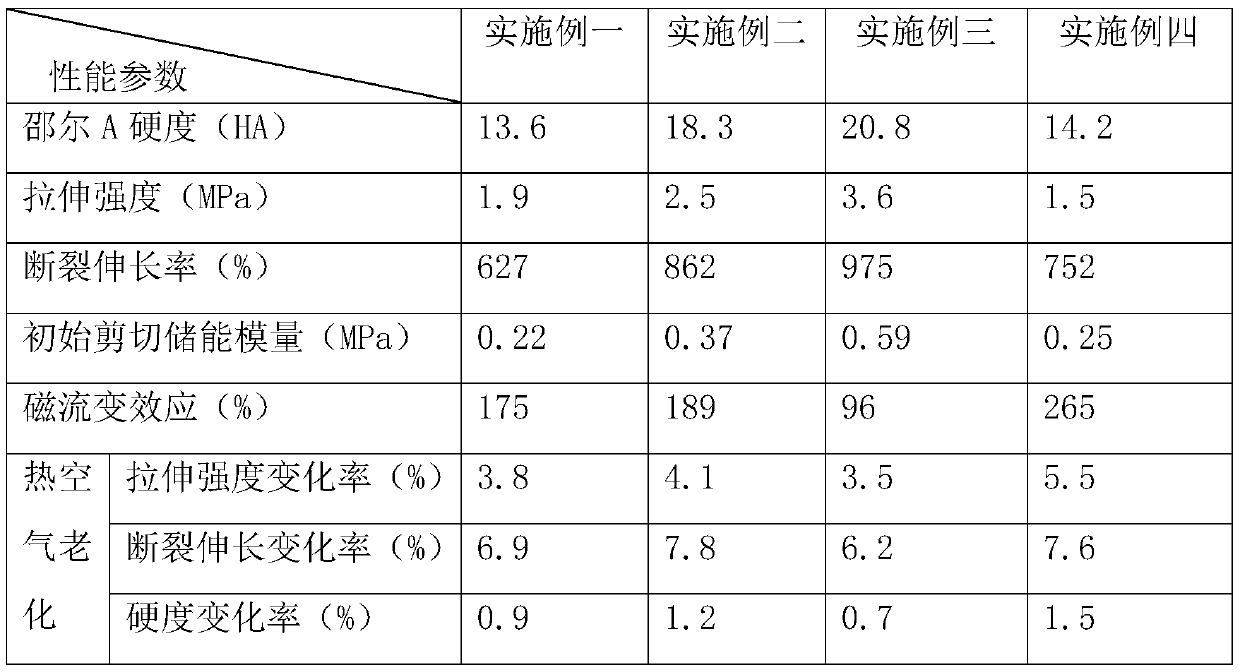

Preparation method of magnetorheological elastomer with high heat resistance and good tensile property

ActiveCN108727710AImprove slip characteristicsGood compatibilityMagnetic materialsElastomerHigh resistance

The invention provides a preparation method of magnetorheological elastomer with high heat resistance and good tensile property, comprising the steps of a, mixing well modified carbonyl iron powder, asilane coupling agent, and methyl vinyl silicone rubber; covering the surface of the carbonyl iron powder with a polymer layer composed of methyl vinyl silicone rubber and a silane coupling agent, adding ethylene propylene diene monomer rubber, a plasticizer and reinforcing particles, and mixing well to obtain mixed rubber; b, adding the mixed rubber in an open mill, adding an antiaging agent anda vulcanizing agent, performing open milling and rubber covering, injecting the obtained material into a mold, performing pre-structural treatment under a magnetic field, and vulcanizing on a plate vulcanizing press so as to obtain the magnetorheological elastomer with high heat resistance and good tensile property. The preparation method herein overcomes the technical difficulty in the preparation of magnetorheological elastomer by ethylene propylene diene monomer rubber, and excellent properties of the magnetorheological elastomer can be exerted.

Owner:CHONGQING UNIV

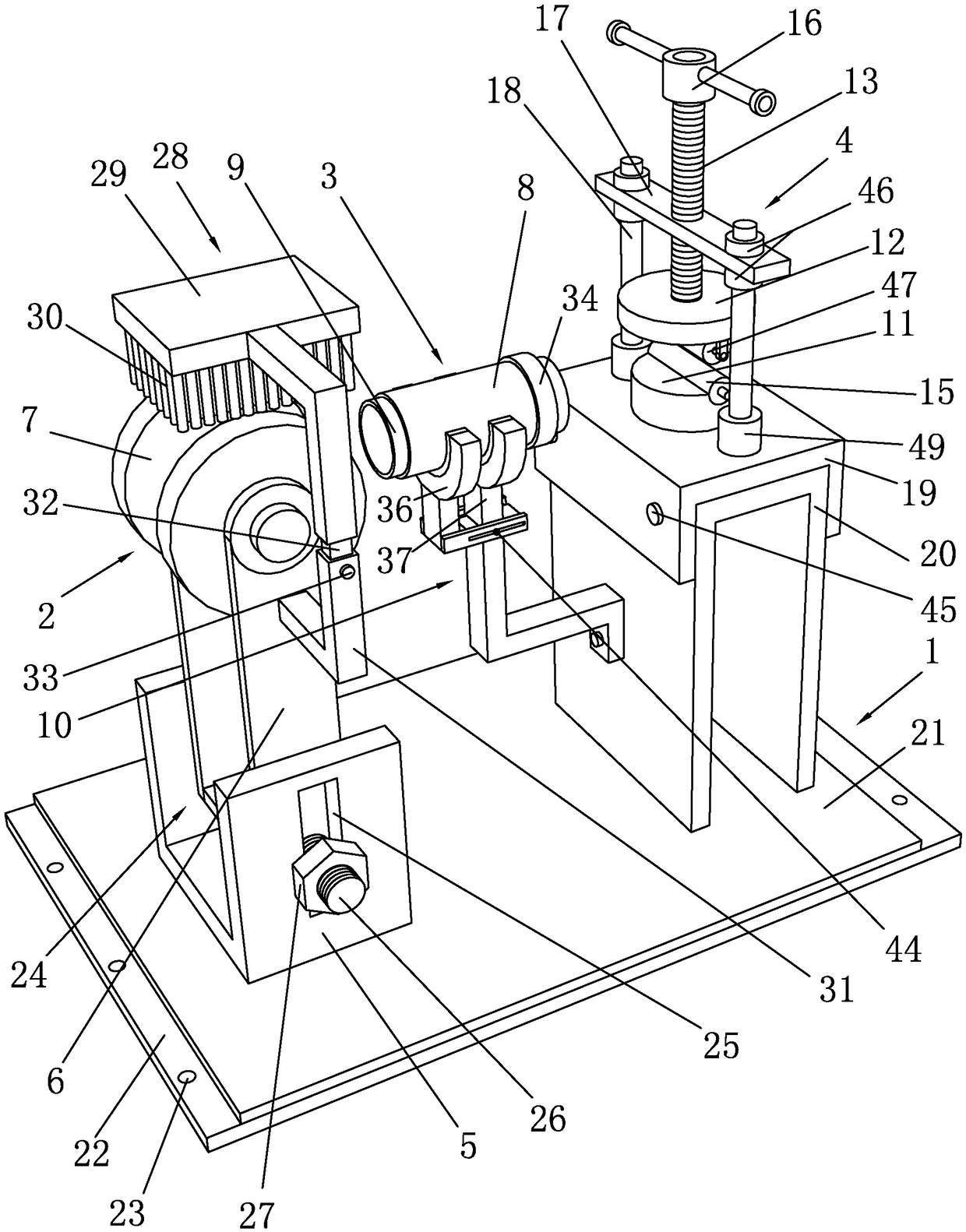

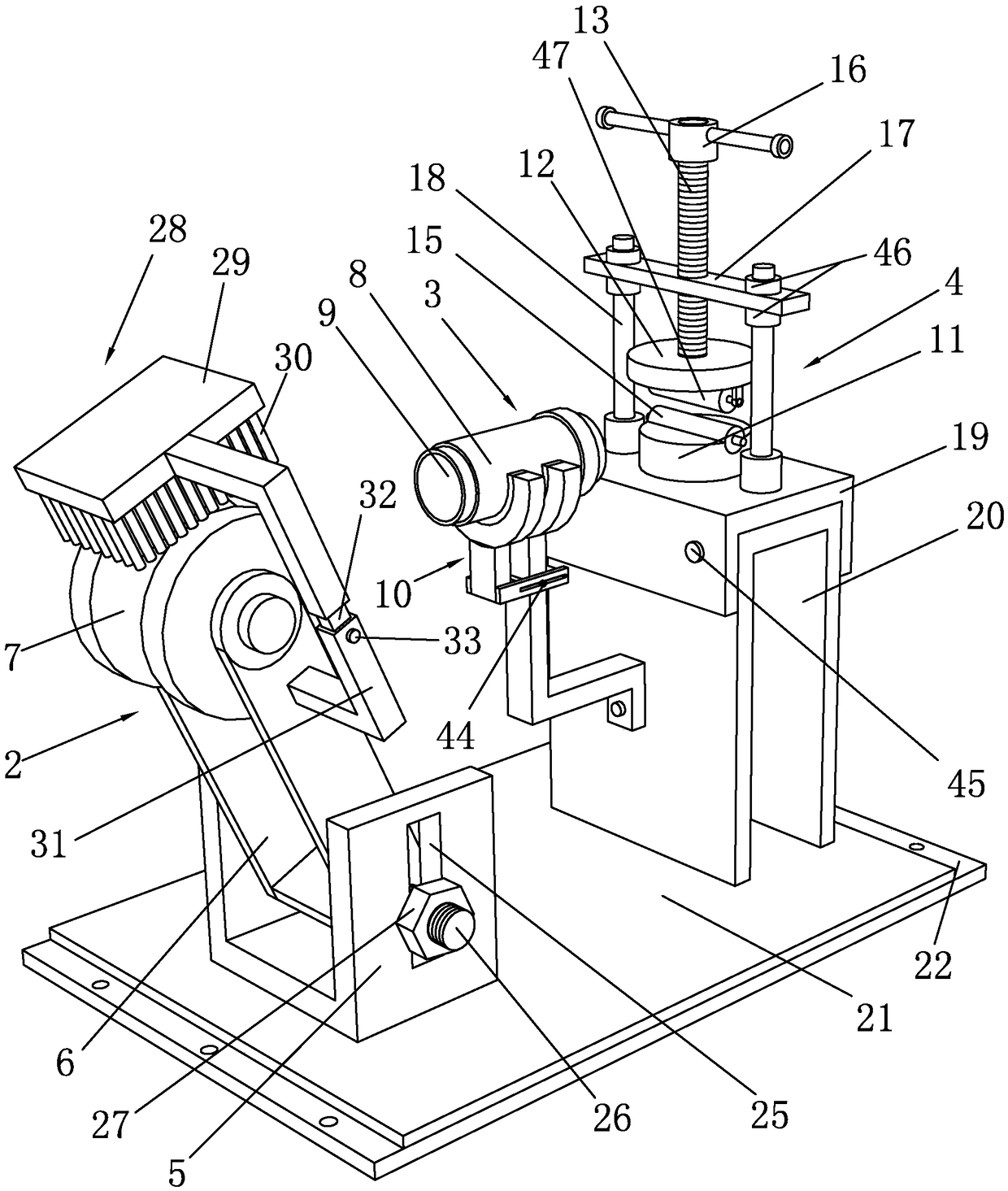

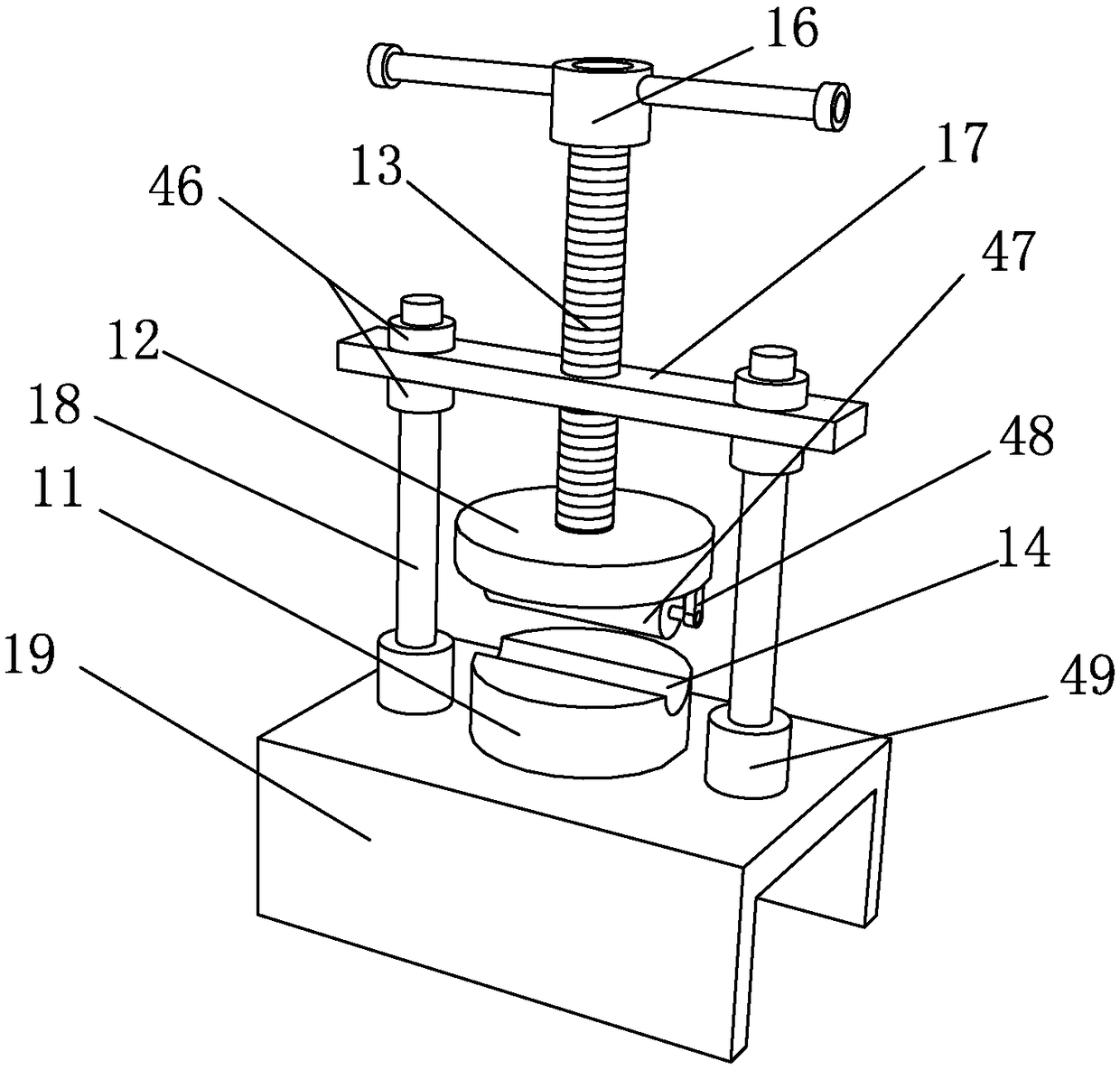

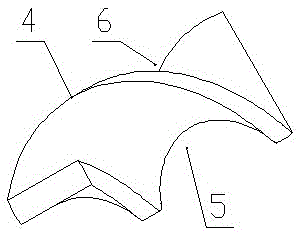

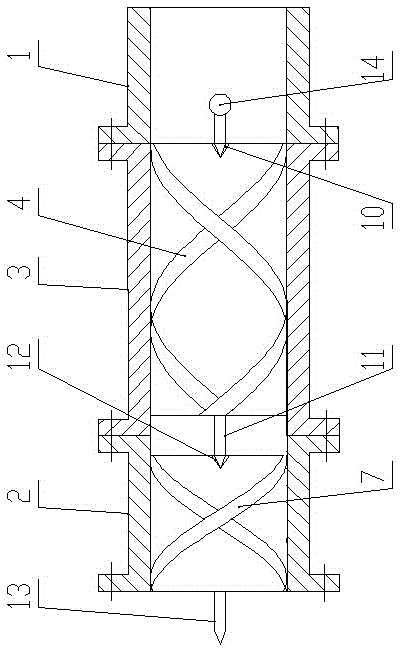

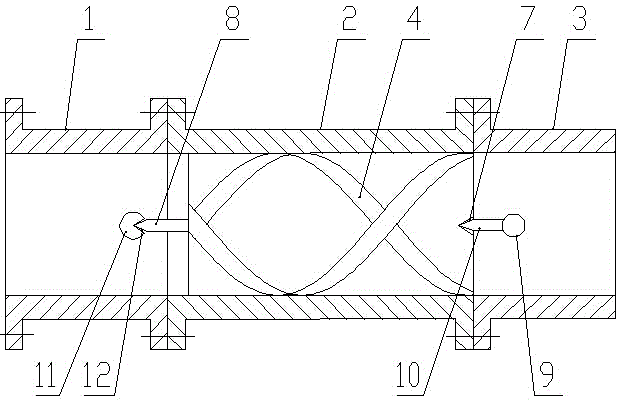

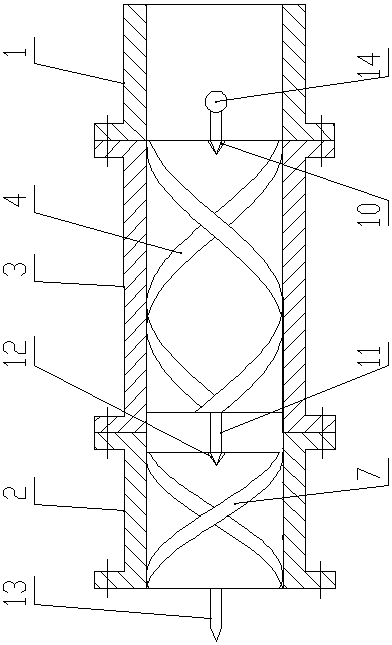

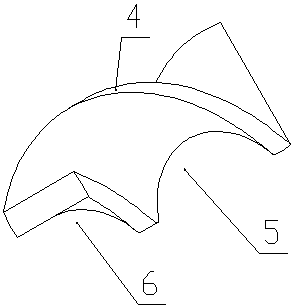

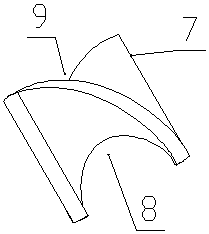

Yarn guiding device for textile product production

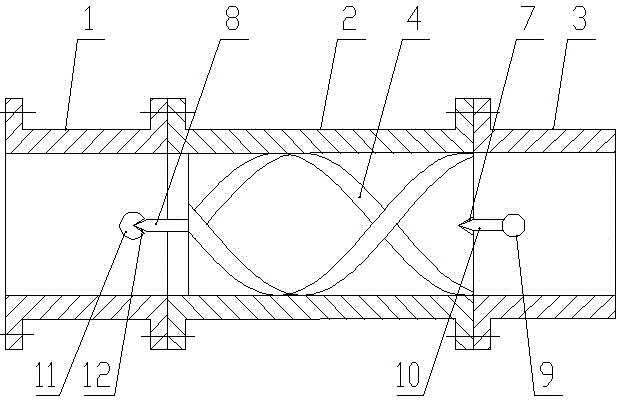

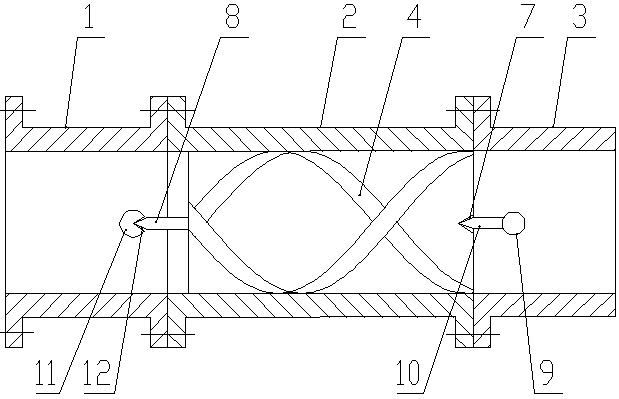

InactiveCN109281021AReduce mechanical vibrationEasy to assemble and disassembleYarnYarnPulp and paper industry

The invention discloses a yarn guiding device for textile product production. The device comprises a fixing bottom plate, a guiding assembly, a burr removing assembly and an adjusting assembly, the burr removing assembly comprises a guiding tube, a heating sleeve tube and a supporting frame, the heating sleeve tube is sleeved with the guiding wire, a heating wire is arranged in the heating tube, the adjusting assembly comprises a fixing plate, an adjusting plate and a pressurizing screw rod, the fixing plate is located on the limiting frame, a tensioning roller is arranged below the bottom ofthe adjusting plate, and the pressurizing screw rod is sleeved with the limiting plate. According to the yarn guiding device, yarns can be welled guided to prevent the yarns from breaking in the conveying process, the adjustment of the angle of the yarns can be conducted according to the conveying angle of the yarns, the using range of the guiding device is expanded, burrs, impurities and the likeon the yarns are removed through the burr removing mechanism to improve the quality of the yarns, and tensioning force in the yarn conveying process can be conducted by the adjusting assembly according to the conveying demands of the yarns to help the conveying of the yarns.

Owner:SHENGZHOU WENDA TEXTILE CO LTD

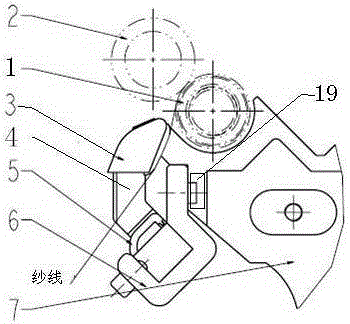

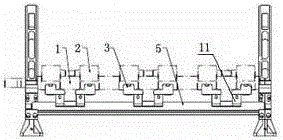

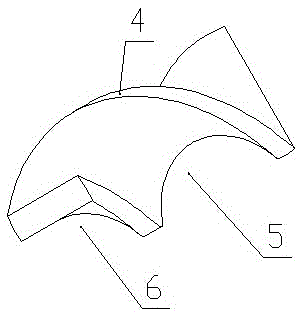

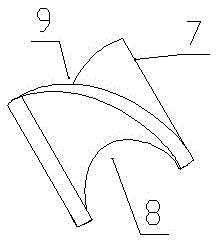

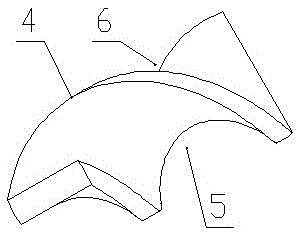

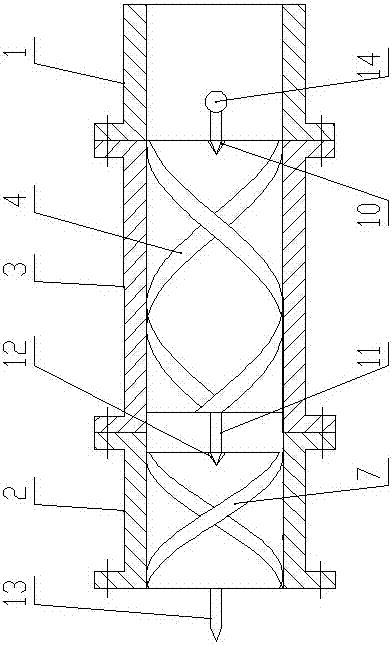

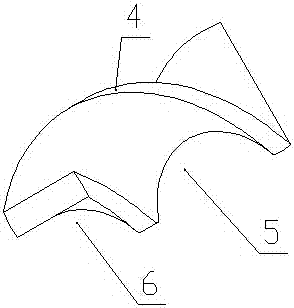

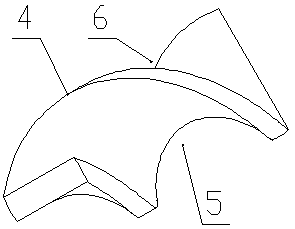

Downwards-pressing pressing piece device for smooth and clean spinning

The invention relates to a downwards-pressing pressing piece device for smooth and clean spinning. A pressing piece assembly is composed of a shell, a heating piece and a heater, wherein the shell comprises a connecting end and a heating part, the heating part is arranged at one side of the upper end of the connecting end and is formed integrally, an opening is formed in the front end of the heating part, the heating piece is fixed to the opening of the heating part of the shell, and the heater is fixed in the heating part of the shell. A power control assembly comprises an installing base, an installing groove and a circuit control panel, and the circuit control panel is closely installed in the installing groove through the installing base. A supporting base comprises a connecting piece and an inserting groove which are formed integrally, a certain included angle is formed between the connecting piece and the side face of the inserting groove, and vertical oblong holes are formed in the connecting piece; a connecting section is of a V-shaped structure, and the included angle between the two planes at the inner side of the V-shaped structure is equal to that formed between the connecting piece and the side face of the inserting groove. The rigidity of fibers is reduced, harmful hairiness is reduced, and resultant yarn quality is improved.

Owner:JINGWEI TEXTILE MASCH CO LTD

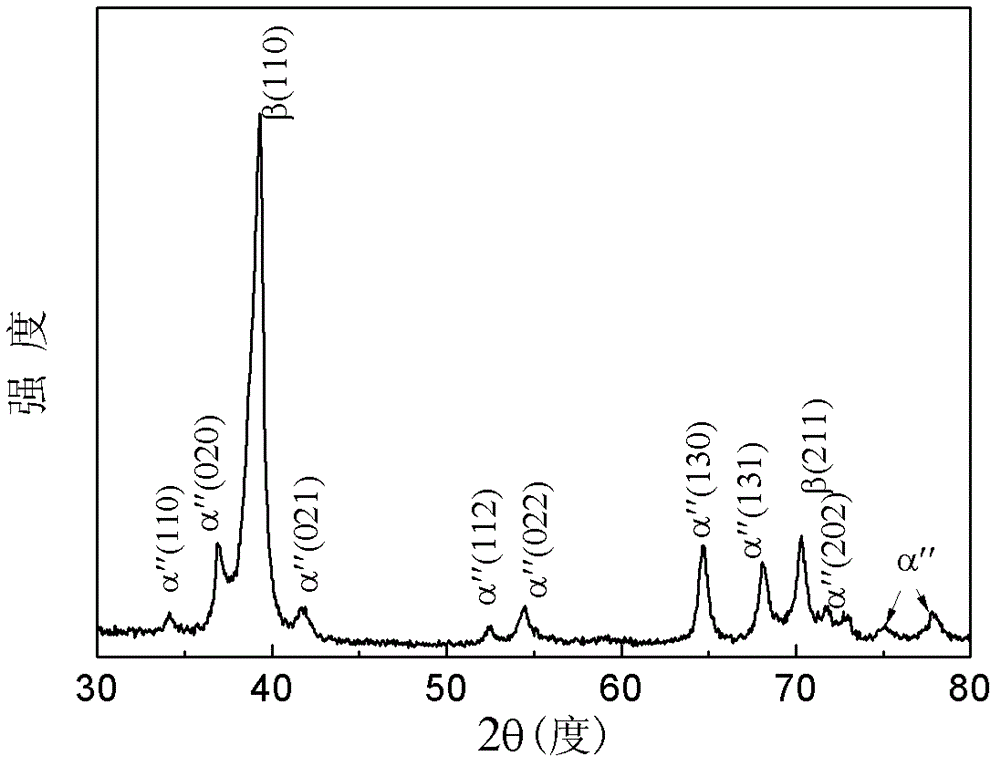

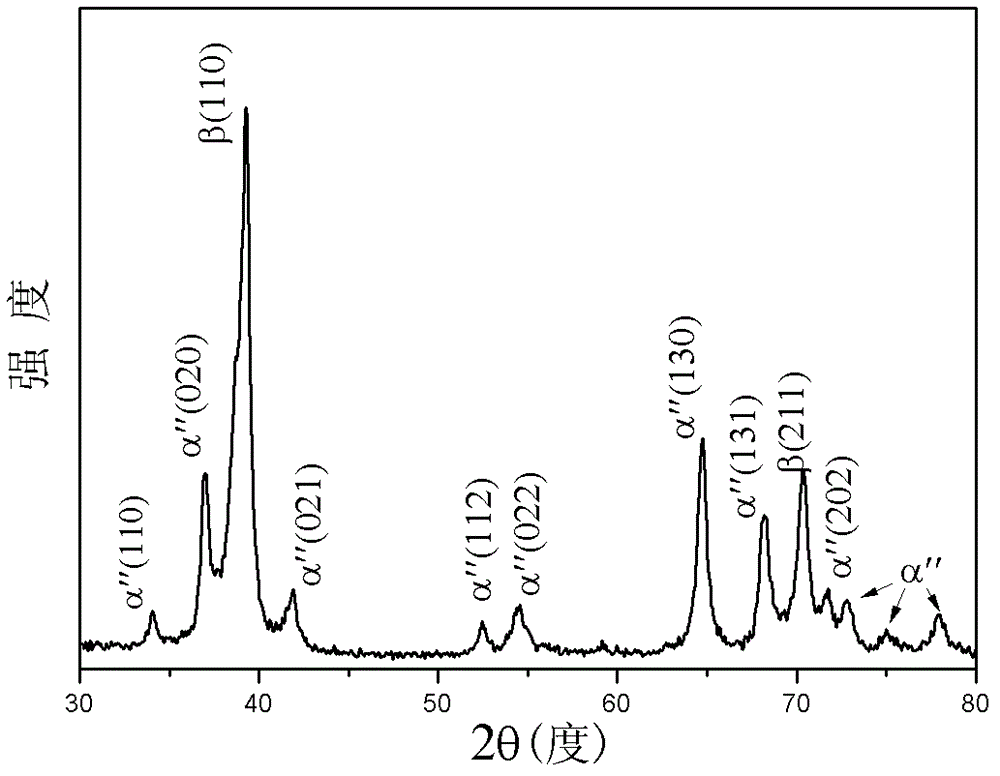

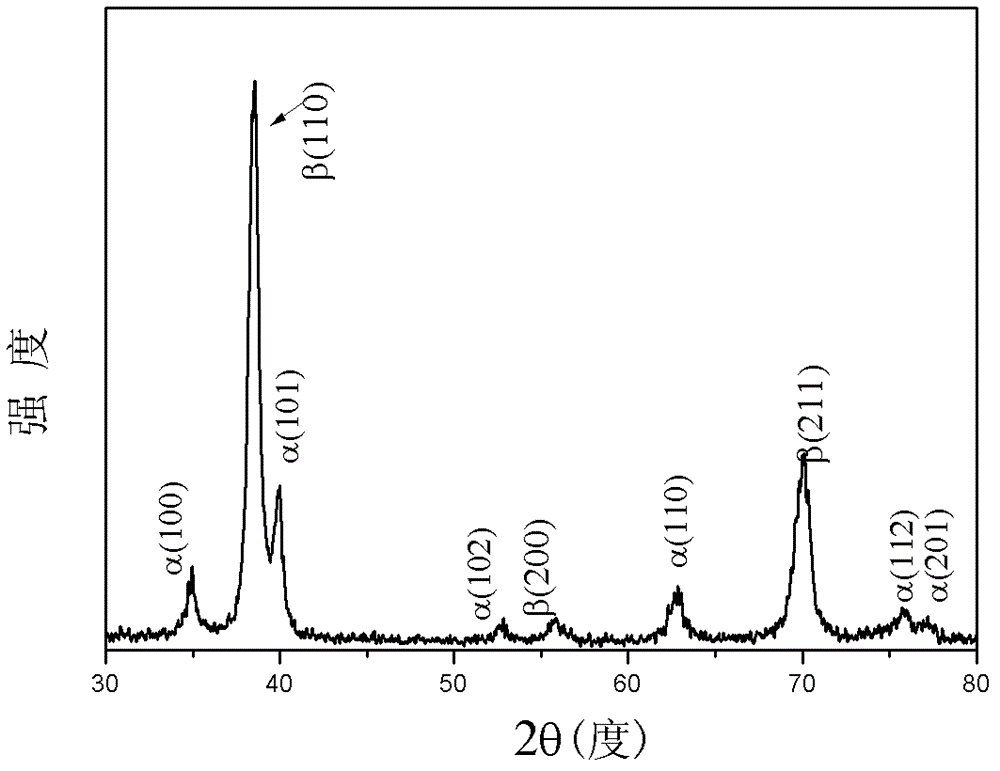

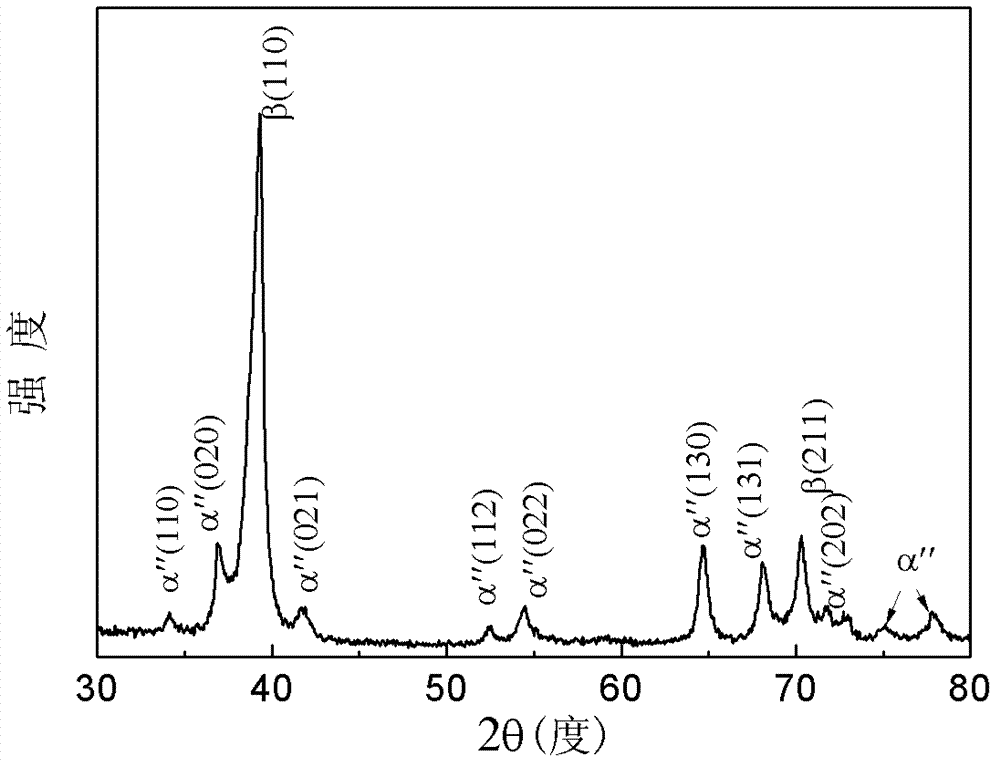

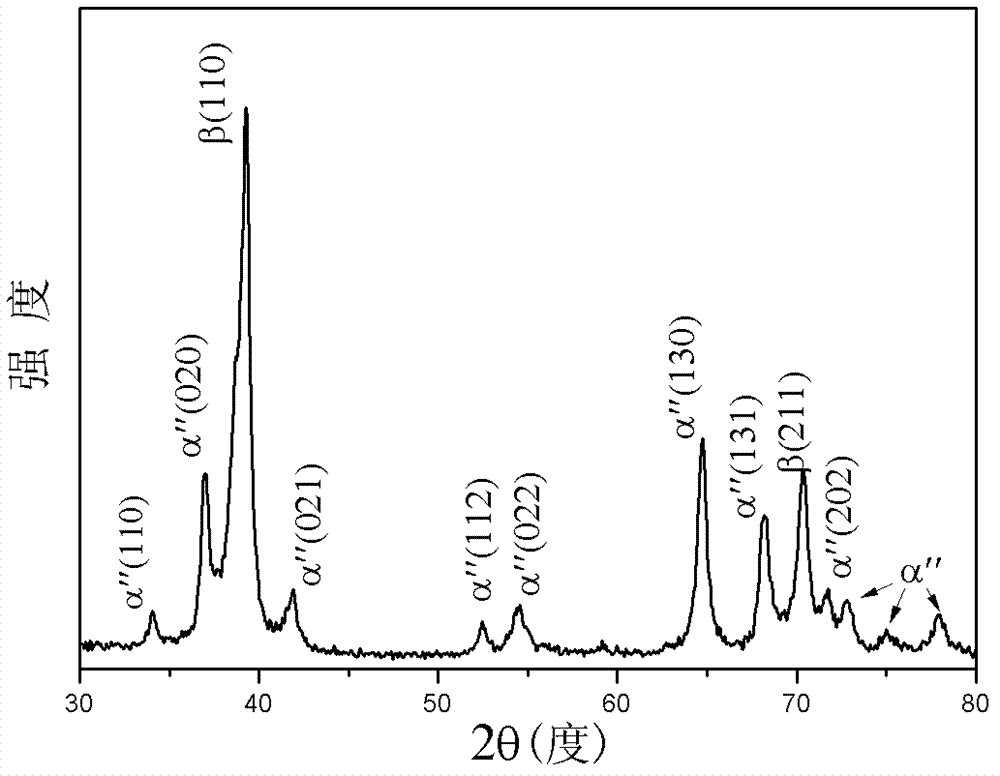

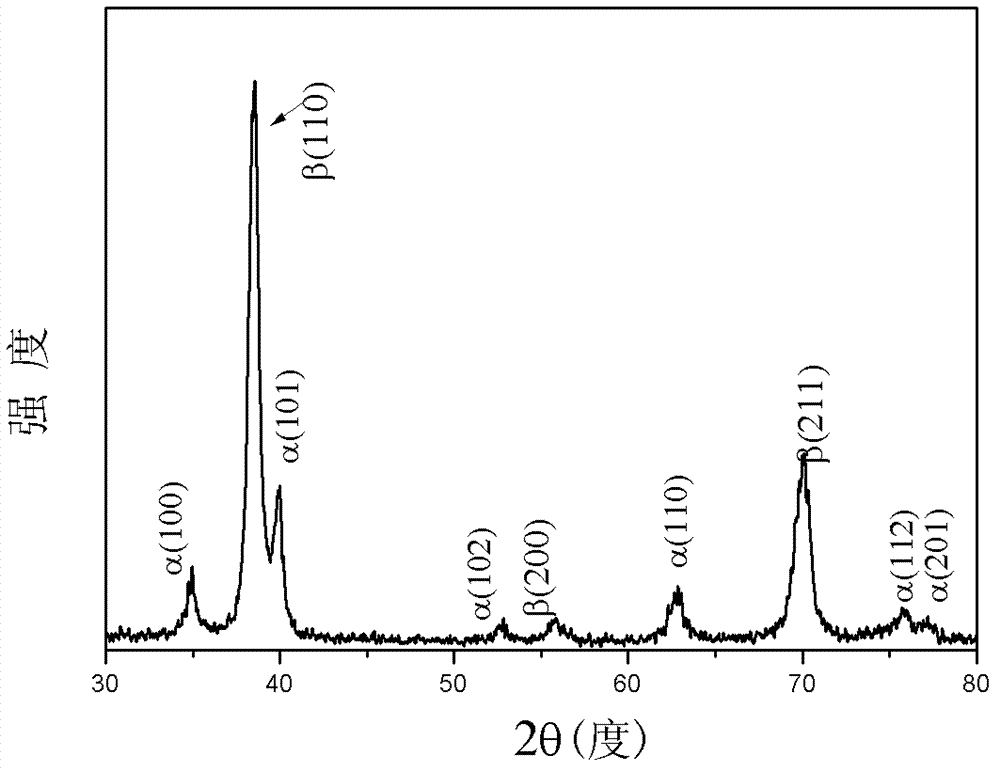

Near-beta titanium alloy with low elastic modulus and high strength and preparation method of near-beta titanium alloy

InactiveCN103060609AImproved cold working propertiesLow work hardening rateMedical equipmentNonlinear deformation

The invention provides a Ti-Nb-Mo-Sn near-beta titanium alloy with low elastic modulus and high strength. The alloy comprises the following chemical components in percentage by weight: 15-35% of niobium, 1-8% of molybdenum, 1-8% of stannum and 0-1.2% of titanium dioxide powder. The Ti-Nb-Mo-Sn near-beta titanium alloy with low elastic modulus and high strength has the beneficial effects that the systemic alloy has good cold machining performance and a low machining cementation index and can coldly deform in a large scale by using cold machining processes such as cold rolling, cold wire drawing and the like; the systemic alloy has the characteristic of nonlinear deformation after being thermally machined or coldly machined and has large restorable elastic strain, low initial modulus and average modulus and high strength; the systemic alloy has low elastic modulus, high yield strength and breaking strength and high linear elasticity after being smelted, thermally machined or coldly machined and thermally treated; and the systemic alloy can be used for preparing medical equipment, physical training equipment and industrial equipment, and can be used for biomedical applications such as artificial bones, bone joints, implanted tooth roots, bony plates and the like.

Owner:BEIHANG UNIV

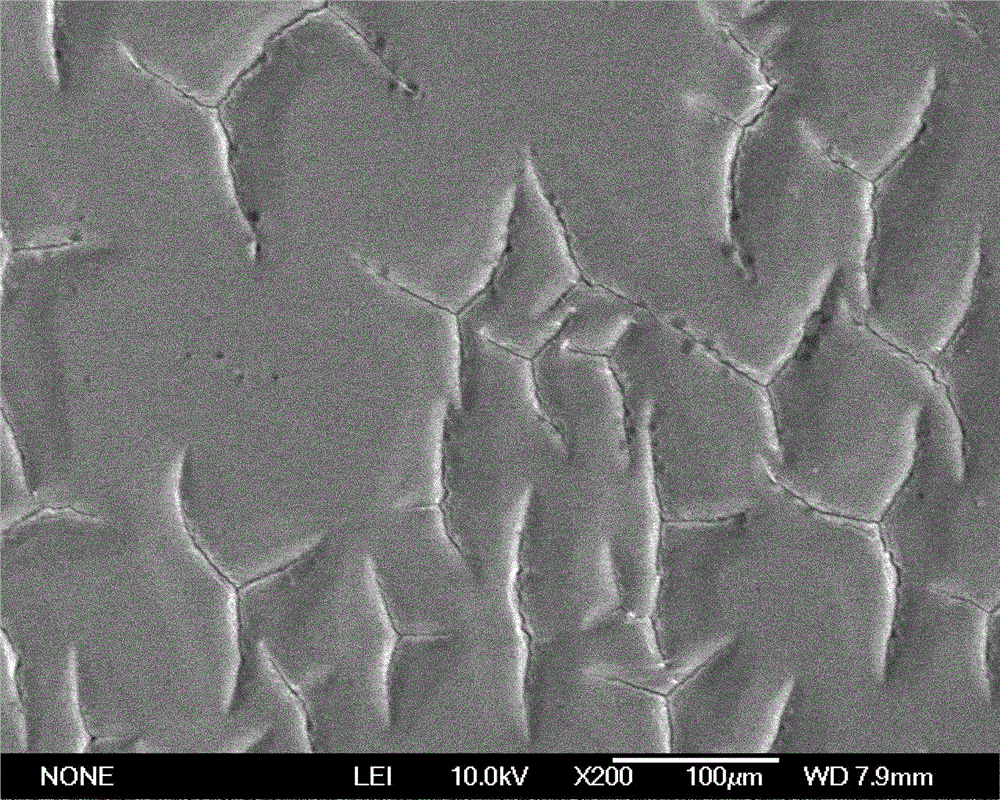

Polyamide monofilament, and production method and application thereof

ActiveCN106555249AChanging the ratio of hydrogen bondsChange the spatial structureBristleArtificial filament heat treatmentCarbon numberPolyamide

The invention provides a polyamide monofilament, and a production method and an application thereof. A raw material for producing the polyamide monofilament comprises polyamide resin, and the polyamide resin is produced from 1,5-pentamethylenediamine and aliphatic long-carbon chain diacid. The production method of the polyamide monofilament is characterized in that polyamide monofilament is obtained through spinnereting, cooling molding, drawing and winding setting of dried polyamide resin. The raw material for producing the polyamide monofilament contains a monomer with the carbon number being an odd number, so a hydrogen bond proportion formed among molecules of an amido group, the crystal form and molecular chain space arrangement are different from those of conventional polyamide monofilaments produced from a monomer with the carbon number being an odd number; and the polyamide monofilament provided by the invention has a lower initial modulus and a higher bending resilience than the conventional polyamide monofilaments, and can be used to produce super soft filament and prolong the service life of the super soft filaments.

Owner:CATHAY R&D CENT CO LTD +2

Composite flame retardant sizing agent for regenerated cellulose fiber

ActiveCN104357935AImprove surface activityGood ecological safety and compatibilityFlame-proof filament manufactureArtificial filaments from viscoseRegenerated celluloseMother liquor

The invention discloses a composite flame retardant sizing agent for regenerated cellulose fiber, and the regenerated cellulose fiber produced by applying the composite flame retardant sizing agent. The composite flame retardant sizing agent is prepared by the following steps: mixing cellulose ether, chlorocyclotriphosphazene derivatives and alkyl polyglucoside according to the mass ratio of 1:(1-20):(0.1-5) and then dissolving in industrial soft water, wherein the cellulose ether is taken as an enhancer, chlorocyclotriphosphazene derivatives are taken as a flame retardant and alkyl polyglucoside is taken as an emulsifier. The regenerated cellulose fiber is prepared by the following steps: adding the 0.5-30wt% of the prepared composite flame retardant sizing agent into regenerated cellulose fiber spinning mother liquor, evenly stirring, defoaming for 30-180min and preparing by adopting a wet-process spinning method of the conventional regenerated cellulose fiber, and the regenerated cellulose fiber has excellent flame-retardant property and higher strength and wearability, the wet fracture strength is improved by more than 20% compared with the conventional flame-retardant viscose fiber, and the initial modulus is reduced by more than 35%.

Owner:SHANXI RUISAIGE TEXTILE TECH CO LTD +1

Bamboo charcoal polylactic acid particle spinning technology

ActiveCN105463589AImprove scraping efficiencyEasy to manufactureSpinning head liquid feederMelt spinning methodsHigh wear resistanceMoisture regain

A bamboo charcoal polylactic acid particle spinning technology comprises the steps that bamboo charcoal micro powder and polylactic acid particles are mixed and then sent to a granulation screw extruder to be produced into a bamboo charcoal polylactic acid master batch; the bamboo charcoal polylactic acid master batch is dried; the bamboo charcoal polylactic acid master batch is subjected to quantitative metering of a micro-meter and then sent into a spinning screw extruder together with polylactic acid dry chips to be processed into a bamboo charcoal polylactic acid melt; the bamboo charcoal polylactic acid melt is filtered through a melt filter; the filtered bamboo charcoal polylactic acid melt is sent into a spinning manifold through a melt pipeline; the bamboo charcoal polylactic acid melt is spun into bamboo charcoal polylactic acid fiber through a spinning component in the spinning manifold. According to the spinning technology, polylactic acid is modified through nanoscale bamboo charcoal micro powder, so that the prepared fiber has lower initial modulus, higher moisture regain, higher wear resistance, higher air permeability and better hand feeling.

Owner:HENAN LONGDU BIOLOGY TECH

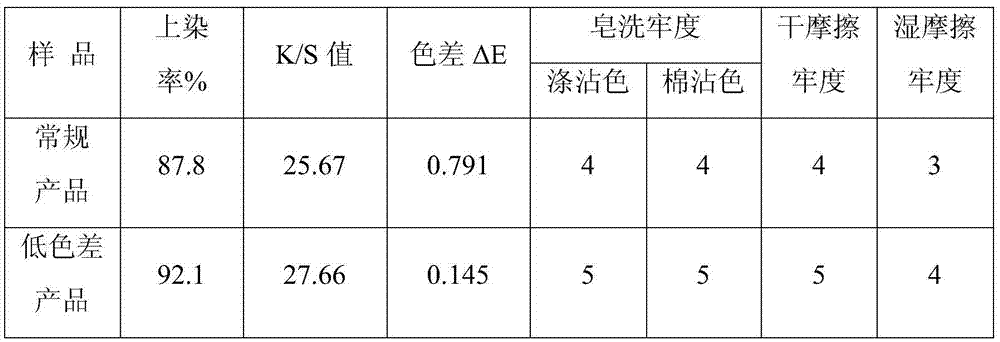

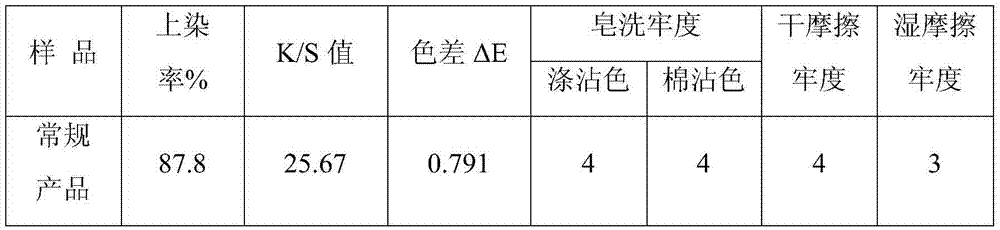

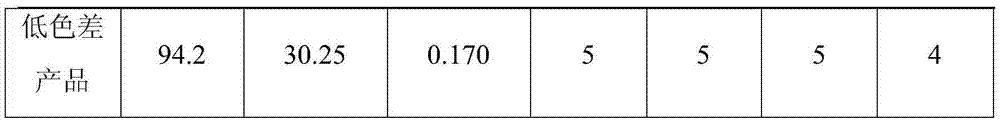

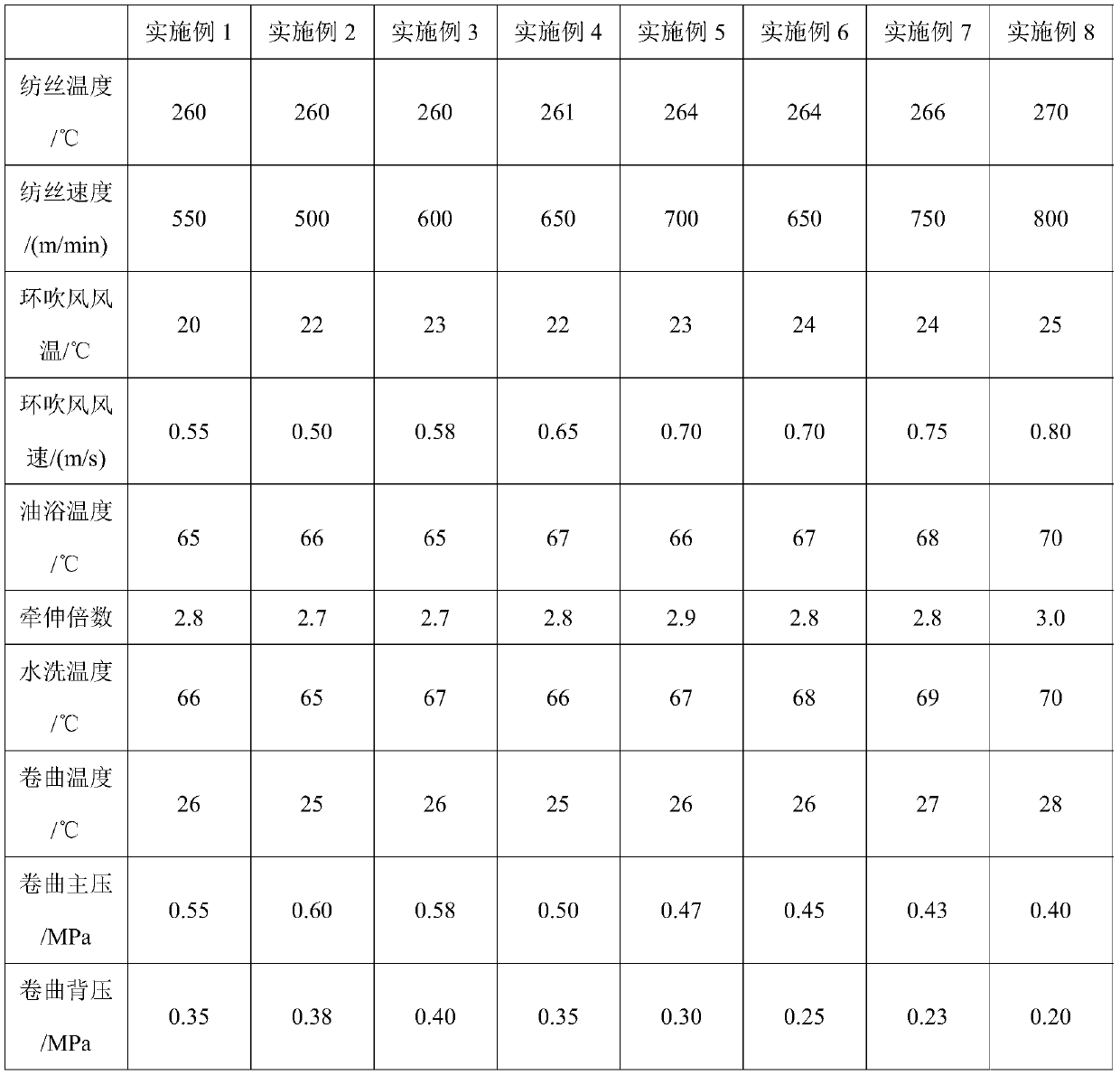

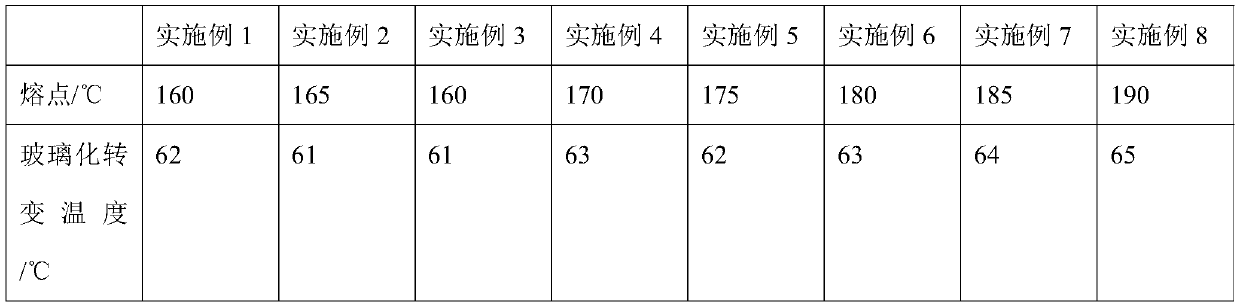

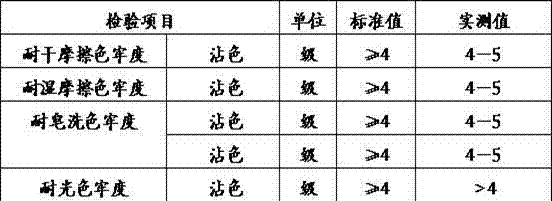

Low-color-difference polyester HOY (high oriented yarn) fibers and preparation method thereof

ActiveCN105442082ASmall coefficient of thermal degradationReduce generationNew-spun product collectionMelt spinning methodsYarnPolyester

The invention relates to low-color-difference polyester HOY (high oriented yarn) fibers and a preparation method thereof. The low-color-difference polyester HOY fibers are prepared from spun polyester yarn, and the breaking strength of the polyester HOY fibers with high dye uptake is larger than or equal to 3.0 cN / dtex; the elongation at break is 50.0% plus or minus 4.0%, and the color difference delta E is smaller than 0.200. Ethylene glycol magnesium is relatively mild, the thermal degradation coefficient is small, fewer side reactions are caused in the reaction process, and generation of oligomers is reduced in the processing process; the mass percentage of oligomers is smaller than 0.5%, and the mass percentage of diethylene glycol is smaller than 0.5%; the oligomers are reduced in the polymerization process and further reduced in the dissolving process, accordingly, the quantity of the oligomers transferred from the inside of the fibers to the outside of the fibers is reduced in the processes of polyester fiber dyeing and post-processing thermal setting, colored patches and streaks are reduced, and the fiber leveling property and the rubbing fastness are guaranteed. The HOY fibers have lower crystallinity, the breaking elongation is larger and the initial modulus of the fibers is smaller, so that the fibers have good flexibility.

Owner:JIANGSU HENGLI CHEM FIBER

Cationic sliver and its making technology

InactiveCN1382845AInitial modulus reductionReduce intensityMonocomponent polyesters artificial filamentArtifical filament manufactureEngineeringVacuum drying

A technology for producing cationic sliver includes vacuum drying CDP chips with 0.23-0.3% of SIPM content which controlling the precrystallizing temp and time, screw smelting and spinning, cooling while winding to obtain primary fibres (7-17 dtex), bundling, oil-bath drafting, two-pass steam stretching, curling while finishing oil, thermal shape fixation, making ribbons (88 mm in average length), carding, and making sliver. Its advantages are soft handle, high antistatic nature, and high dyeability.

Owner:孔森根

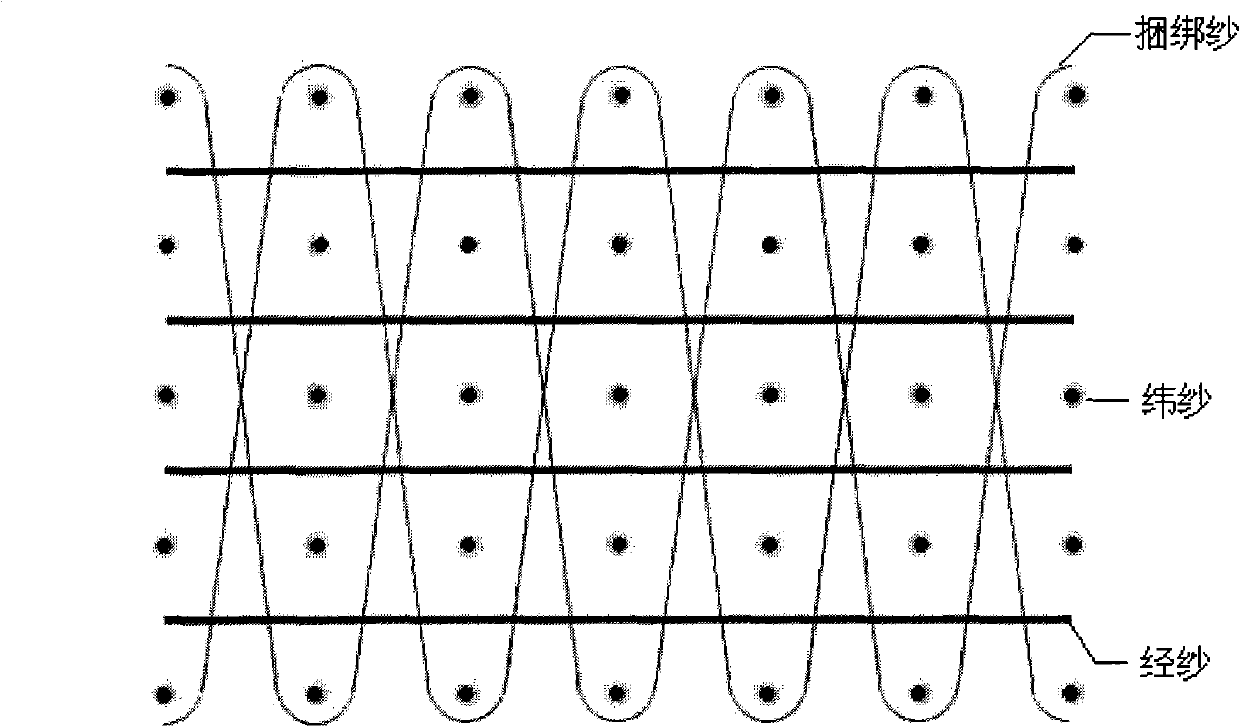

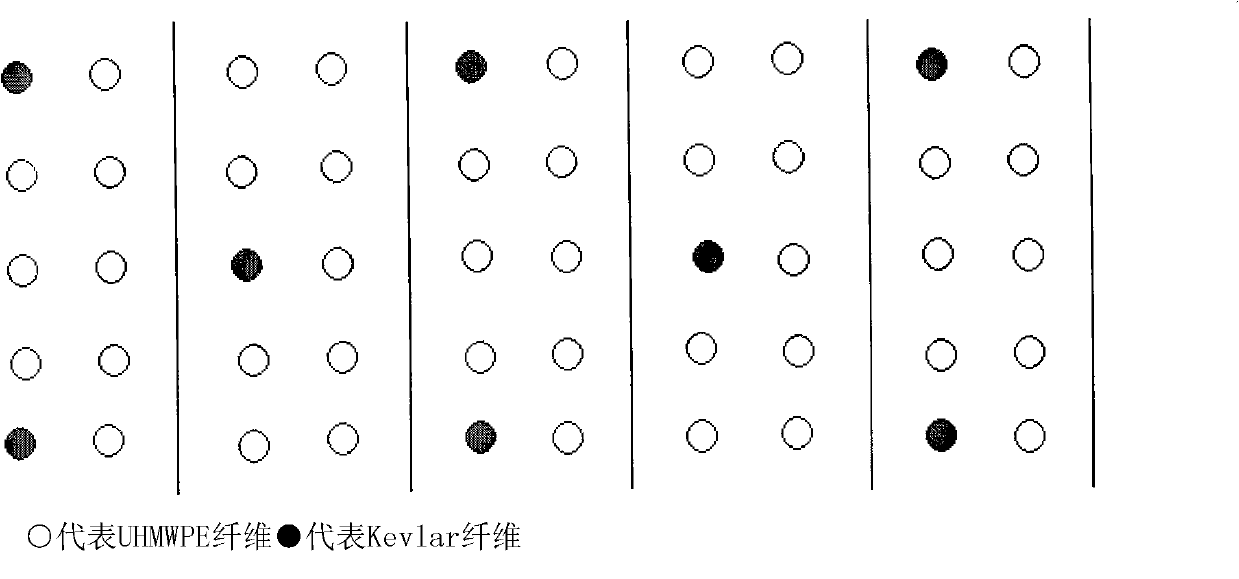

Novel three-dimensional orthogonal woven hybrid puncture-proof clothes

InactiveCN102485989AResistance to stretchingResistance to shearing and other forcesWoven fabricsProtective garmentFiberEngineering

The invention relates to a novel three-dimensional orthogonal woven hybrid puncture-proof clothes which is a mixture of ultra-high molecular weight polyethylene (UHMWPE) fiber and Kevlar fiber and is formed by interweaving in a three-dimensional orthogonal structure. Compared with the traditional puncture-proof clothes, the novel three-dimensional orthogonal woven hybrid puncture-proof clothes is interleaved from the mixture of UHMWPE fiber and Kevlar fiber, and thus the excellent puncture-proof performance and wearability of the material are ensured; and meanwhile, as a three-dimensional orthogonal weaving processing method, the material weight is greatly reduced, and the production cost of the material is lowered. The development of the three-dimensional orthogonal woven hybrid puncture-proof clothes lays foundation for the development of clothes toward light weight, low cost and flexibility.

Owner:JIANGNAN UNIV

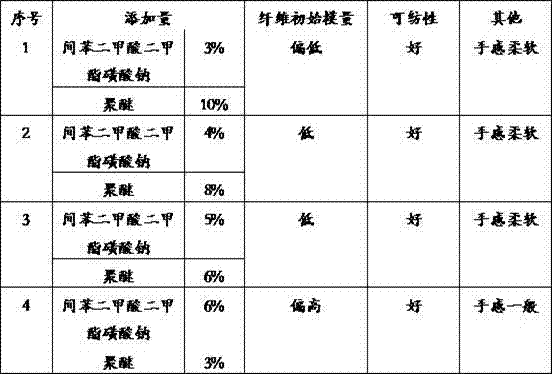

Elastic polyester fiber with low melting point and preparation method of elastic polyester fiber

ActiveCN110952161AReduce contentLow costMonocomponent copolyesters artificial filamentAldehydeFatty acid ester

The invention relates to an elastic polyester fiber with a low melting point and a preparation method of the elastic polyester fiber. After elastic polyester is prepared by using phthalic acid (terephthalic acid and isophthalic acid), glycol, polytetrahydrofuran, a glass-transition temperature modifier (M-phthalate sulfonate) and a macromolecular modulus modifier (aliphatic ester or long-chain diol of which the number of carbon atoms is more than or equal to 5) as main reaction raw materials, the elastic polyester fibers with the low melting point is prepared by spinning, and when in spinning,the material of metal sand in a spinning component is Ni. The prepared elastic polyester fibers with the low melting point are made of elastic polyester, and molecular chains of the elastic polyesterare composed of phthalic acid chain segments, glycol chain segments, polytetrahydrofuran chain segments, glass-transition temperature modifier chain segments and macromolecular modulus modifier chainsegments; and the total content of acetaldehyde and butenal in the elastic polyester fibers with the low melting point is less than 0.5ppm. According to the elastic polyester fiber with the low melting point and the preparation method of the elastic polyester fiber, occurrence of an adhesion phenomenon can be avoided while fiber softness is improved, and the content of aldehyde compounds in the fiber is reduced.

Owner:扬州富威尔复合材料有限公司

Preparing method of normal-temperature normal-pressure deeply-dyeable polyester filament

ActiveCN108003333AImprove flexibilityEasy to dye under normal pressureMonocomponent copolyesters artificial filamentDyeing processFiberSulfonate

The invention relates to a preparing method of a polyester fiber, and discloses a preparing method of a normal-temperature normal-pressure deeply-dyeable polyester filament. The problems that due to the limitation of a preparing method, the dyeing temperature of a polyester fiber is high, the requirement of high-temperature dyeing for equipment is high, energy consumption is high, and production cost is improved are solved. According to the technical scheme, the method is characterized in that raw materials include polyester, a third monomer and a fourth monomer, the third monomer is one of sodium dimethyl isophthalate sulfonate, diethyl isophthalate sulfonate and diethylene glycol isophthalate sulfonate, and the fourth monomer is fatty binary acid or polyether. The aims of dyeing the polyester filament at normal temperature and normal pressure and being good in dyeing effect, small in energy consumption in the dyeing process and low in cost are achieved.

Owner:SHAOXING GLOBAL CHEM FIBER

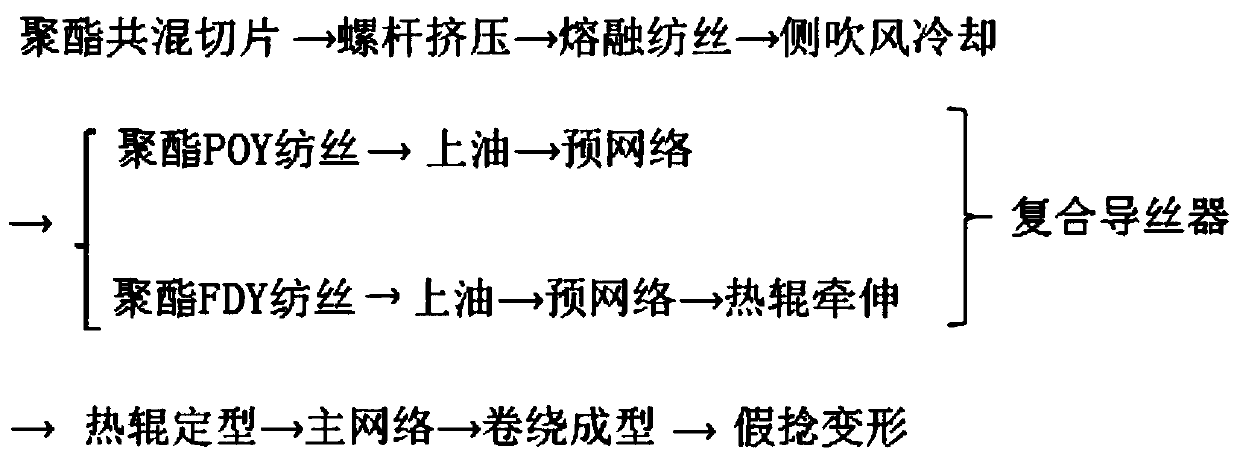

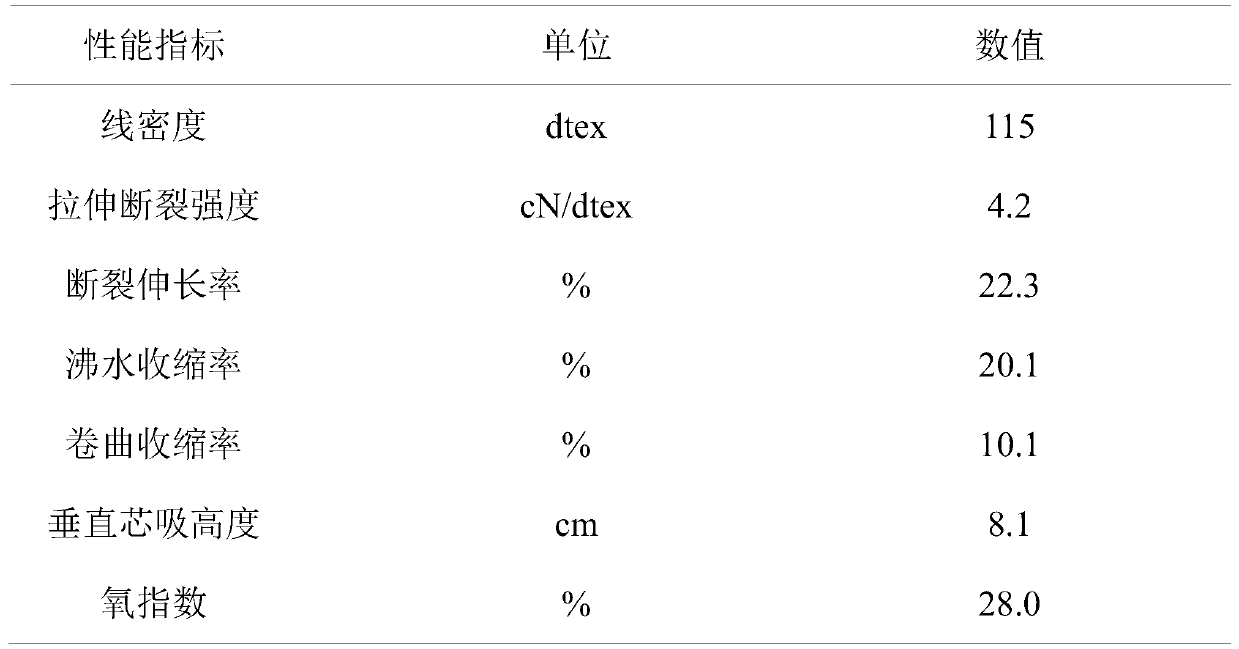

Preparation process of multifunctional polyester low-elasticity composite filament

InactiveCN110965165AVersatileImprove flame retardant performanceFlame-proof filament manufactureSpinning head liquid feederPolyesterPolymer science

The invention discloses a preparation process of a multifunctional polyester low-elasticity composite filament. The preparation process comprises the following steps that (1) blending of a pre-crystallized PET slice, a flame-retardant master batch, a hydrophilic master batch and an antibacterial master batch is carried out, and then extrusion granulation is performed to obtain a polyester blendedslice; (2) two parallel melt spinning processes are adopted, wherein one melt spinning processes is a POY melt spinning process, and the other is an FDY melt spinning process; the POY melt spinning process obtains polyester POY spinning, and the FDY melt spinning process obtains polyester FDY spinning; (3) the polyester FDY spinning is subjected to drafting to obtain polyester FDY drafting filaments; the polyester FDY drafting filaments and the polyester POY spinning are compounded to form composite filaments, and the composite filaments are shaped to obtain mixed filaments; and (4) the mixedfilaments are subjected to false twisting deformation to obtain the polyester low-elasticity composite filaments. The polyester low-elasticity composite filament not only has a high moisture absorption and sweat releasing effect, a flame retardant effect and an antibacterial effect, but also has high dyeing rate during dyeing, meanwhile, the filament has a fluffy and soft hand feeling, has certainelasticity, and expands the application range thereof.

Owner:苏州君辉纺织有限公司

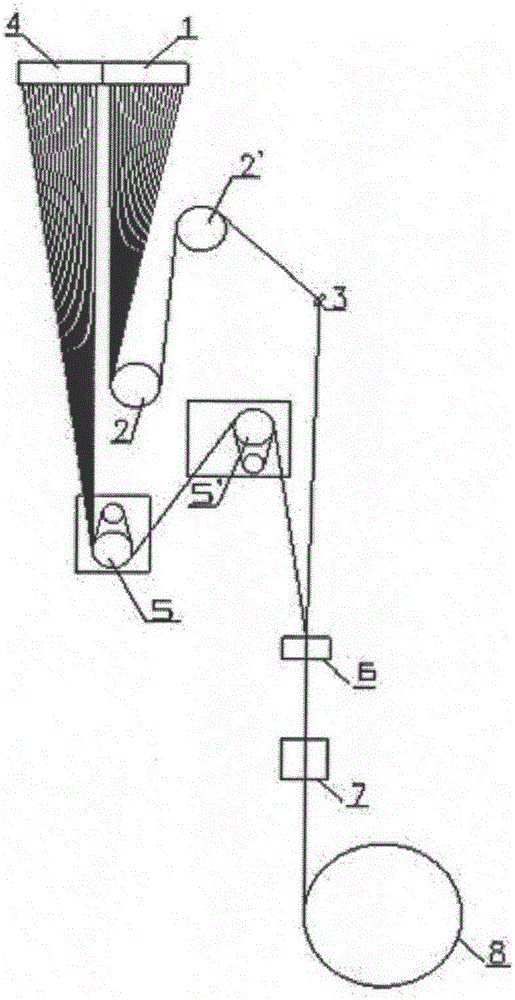

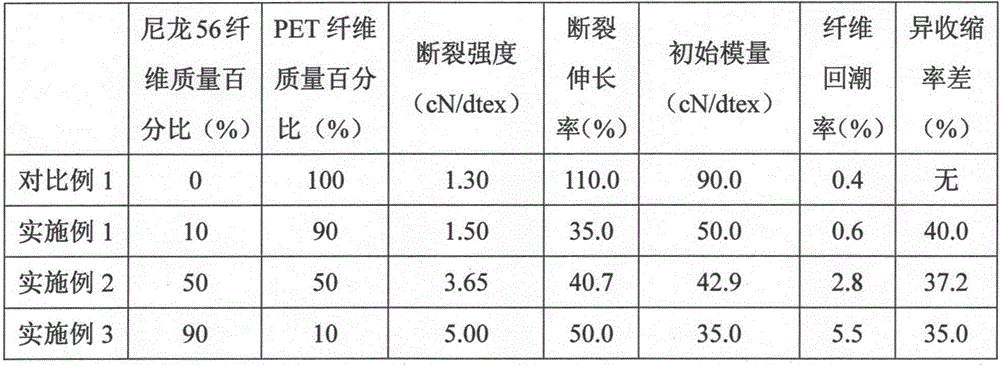

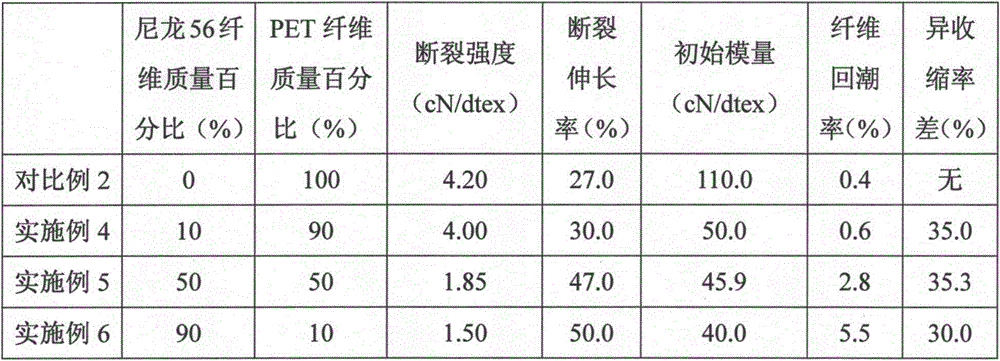

FDY/POY different shrinkage combined filament yarn of biomass nylon 56 fiber/PET fiber and preparing method thereof

InactiveCN105803571AGood hydrophilicGood flexibilityConjugated synthetic polymer artificial filamentsMaterials scienceBiomass

The invention discloses FDY / POY different shrinkage combined filament yarn of biomass nylon 56 fiber / PET fiber.The combined filament yarn is characterized by being prepared by spinning biomass nylon 56 fiber slices and PET slices; the biomass nylon 56 fiber is FDY fiber and the PET fiber is POY fiber, or the biomass nylon 56 fiber is POY fiber, and the PET fiber is FDY fiber.The difference between the boiling water shrinkage of the biomass nylon 56 fiber and that of the PET fiber is equal to or larger than 30%.According to the obtained FDY / POY different shrinkage combined filament yarn of the biomass nylon 56 fiber / PET fiber, the surfaces of tows curl slightly and naturally, hydrophily and softening property of the tows are obviously improved, and the FDY / POY different shrinkage combined filament yarn can be used for developing imitated cotton and imitated silk fabric.

Owner:DONGHUA UNIV +2

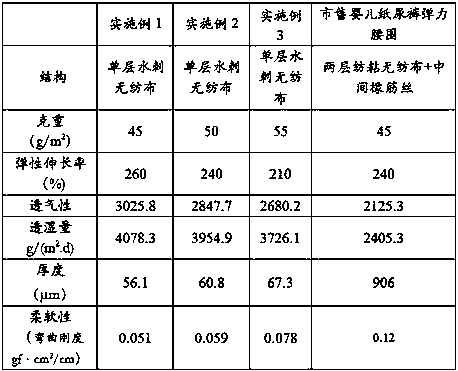

Paper diaper and preparation method thereof

ActiveCN108309571AReduce usageReduce investmentHeating/cooling textile fabricsAbsorbent padsPolyethylene terephthalate glycolCarding

The invention discloses a paper diaper and a preparation method thereof, and relates to the technical field of disposable sanitary products. PTT (polytrimethylene terephthalate) fibers and PTT / PET (polyethylene terephthalate) two-component fibers are selected, opening, carding and spunlace fixing processes are adjusted, special shrinkage and folding processes are selected, a prepared elastic non-woven fabric has excellent elasticity, further has good softness and breathability of a spunlace non-woven fabric and has better safety, and the elastic non-woven fabric is arranged at an elastic backposition of the paper diaper. Compared with a traditional paper diaper, the paper diaper has the advantages that a rubber band is omitted, and the prepared paper diaper applies more uniform elastic force to the body of an infant, so that the paper diaper has better conformity and helps good development of the hip of the infant to a certain degree.

Owner:JIAXING UNIV

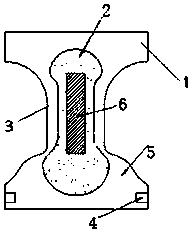

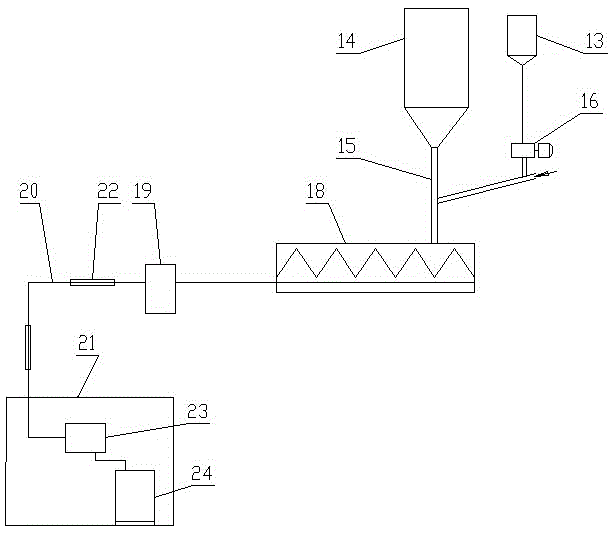

Direct spinning system for mixed melt of bamboo charcoal and polylactic acid

ActiveCN105603550AAvoid cloggingExtended service lifeSpinning solution de-aeratingArtificial thread manufacturing machinesAutomatic controlEngineering

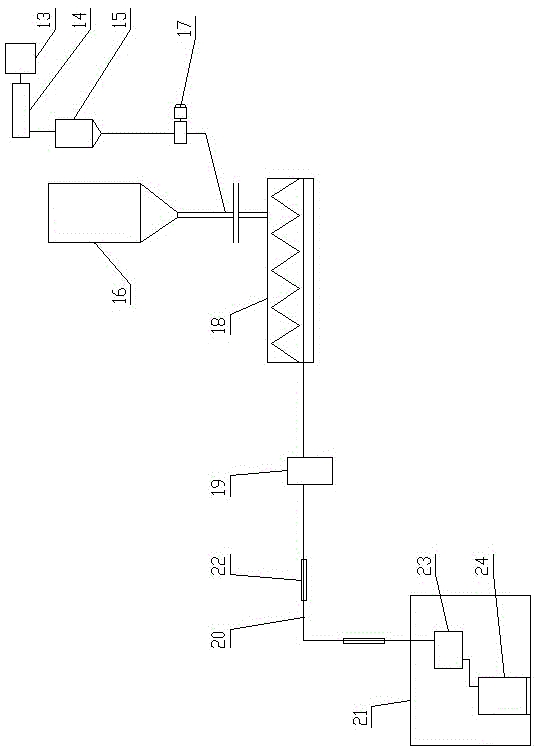

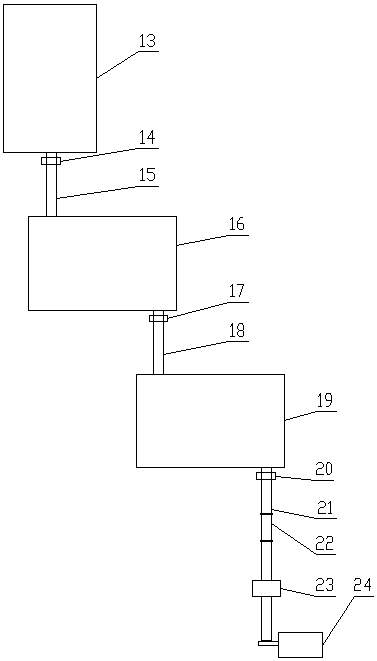

The invention provides a direct spinning system for mixed melt of bamboo charcoal and polylactic acid, comprising a polymerization framework and a spinning box body, wherein a stirring tank, a primary polymerization tank and a final polymerization tank are arranged on the polymerization framework in turn from top to bottom, the bottom of the stirring tank is in connection with the top of the primary polymerization tank through a first material conveying pipe, a first automatic control valve and a first metering pump are arranged on the first material conveying pipe, the bottom of the primary polymerization tank is in connection with the top of the final polymerization tank through a second material conveying pipe, a second automatic control valve and a second metering pump are arranged on the second material conveying pipe, a third material conveying pipe is connected to the bottom of the final polymerization tank, a third metering pump, a filtering and impurity removing device and a dynamic / static integrated pipeline type material mixing device are arranged on the third material conveying pipe in turn in a melt flowing direction, and a spinning metering pump and a spinning component are arranged in the spinning box body. According to the direct spinning system for the mixed melt of the bamboo charcoal and the polylactic acid provided by the invention, nanoscale bamboo fragrance charcoal micro powder is employed to modify the polylactic acid, and therefore fiber which is prepared from the modified polylactic acid has the advantages of reduced initial modulus, rising moisture regain, increased wear resistance and obviously improved air permeability and hand feeling.

Owner:HENAN LONGDU BIOLOGY TECH

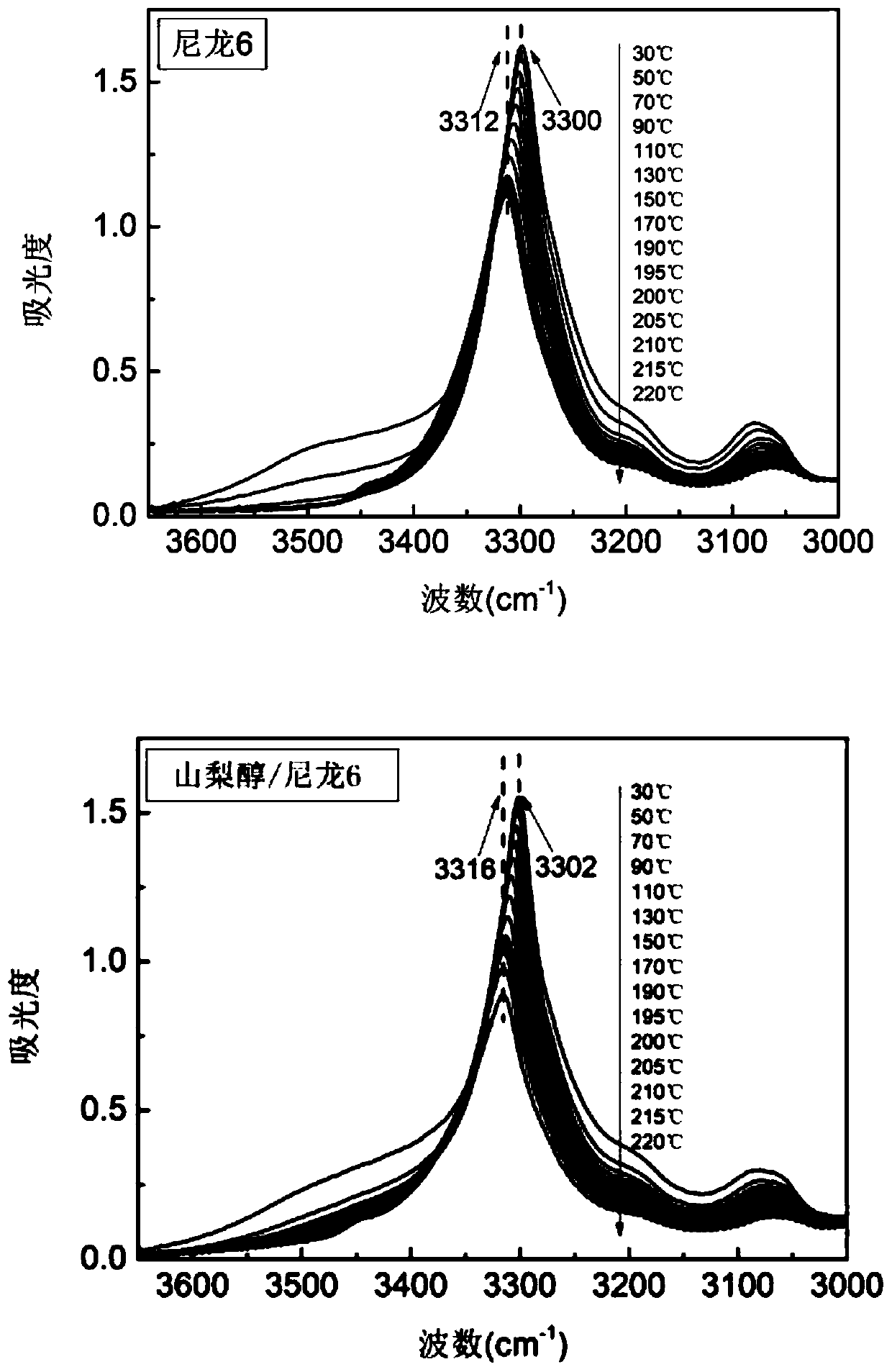

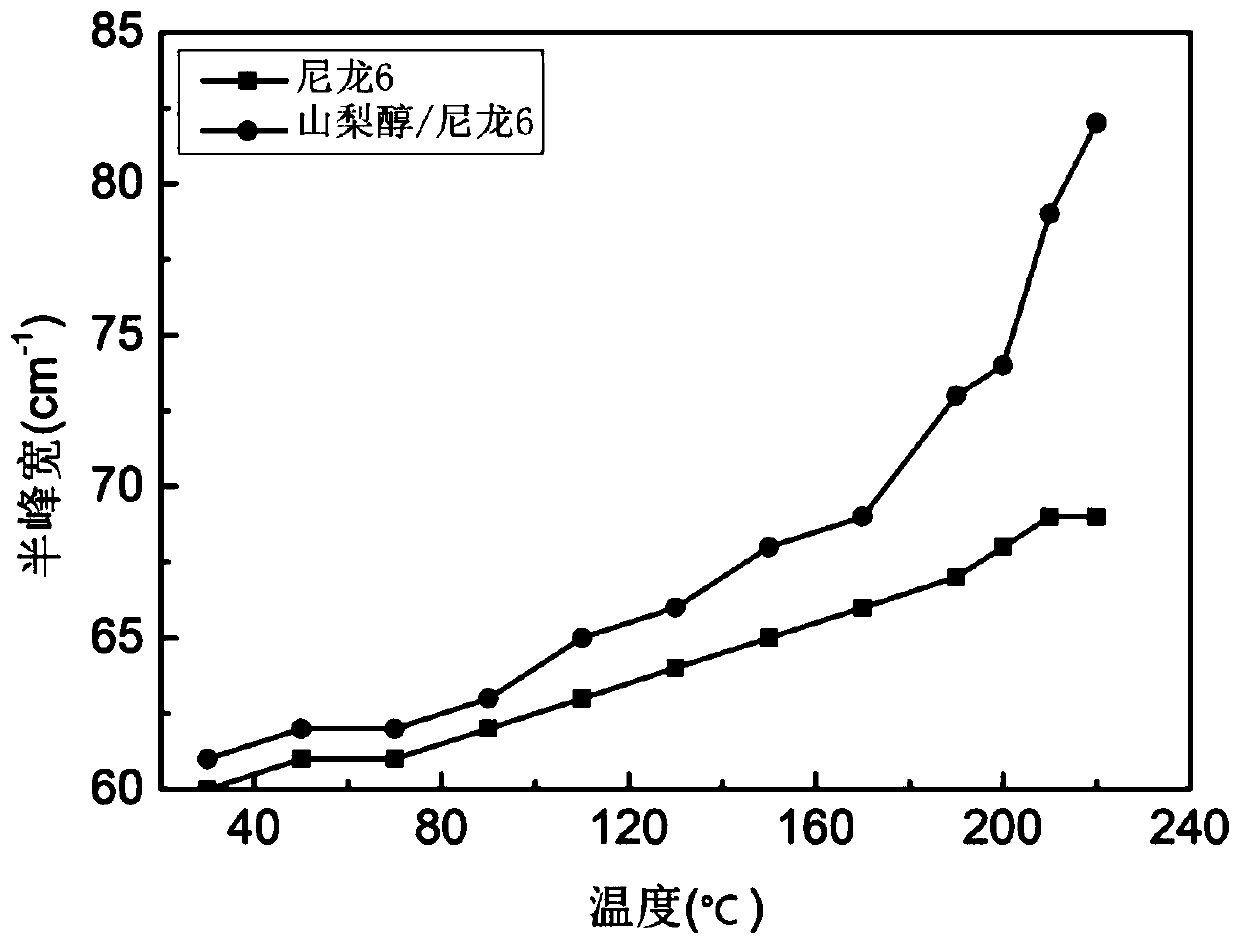

High-strength nylon 6 filaments based on one-step drafting process and preparation method of high-strength nylon 6 filaments

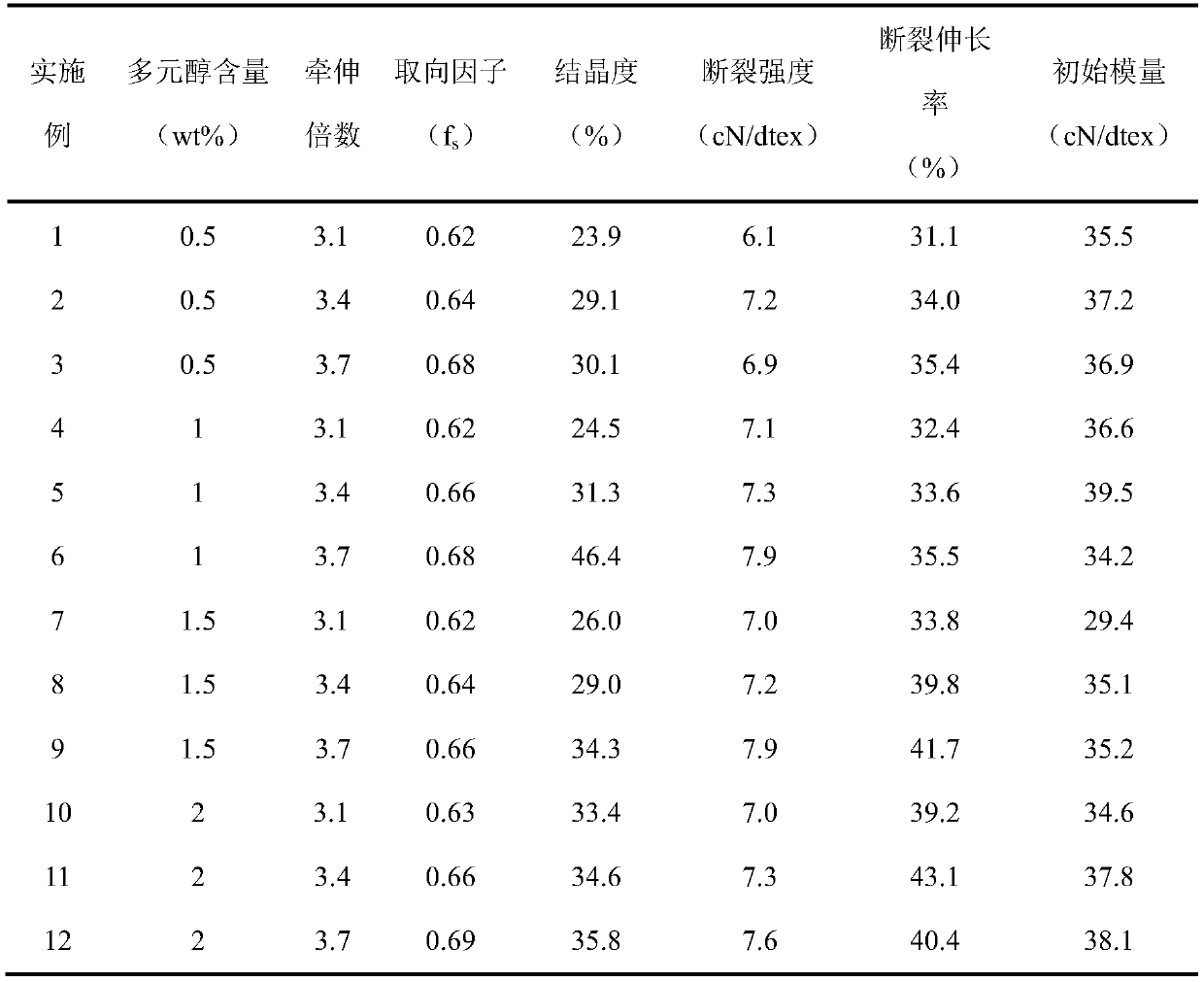

ActiveCN110387597AWeakening of hydrogen bondsImprove mechanical propertiesArtificial filament heat treatmentMelt spinning methodsBreaking strengthPolyol

The invention provides a preparation method of high-strength nylon 6 filaments based on a one-step drafting process. The preparation method is characterized by comprising following steps: step 1, polyol and nylon 6 slices are mixed in proportion, mixed polyol / nylon 6 slices are fed into a twin-screw extruder for melt blending, extruded melt is pelletized by a pelletizer, and polyol modified nylon6 masterbatches are obtained; step 2, the nylon 6 masterbatches obtained in step 1 and the nylon 6 slices are mixed in proportion, the mixture is dried and then subjected to melt extrusion by the twin-screw extruder and enters a spinning manifold, melt is sprayed out through spinneret orifices, then enters a spinning channel and is subjected to air cooling, bundling, oiling, drafting, heat settingand coiling, and the high-strength nylon 6 filaments are prepared. Polyol is added for plasticizing modification of nylon 6, high-strength nylon 6 is prepared with the one-step drafting process, andthe prepared product has excellent thermodynamic properties, higher breaking strength and elongation at break and lower initial modulus.

Owner:DONGHUA UNIV

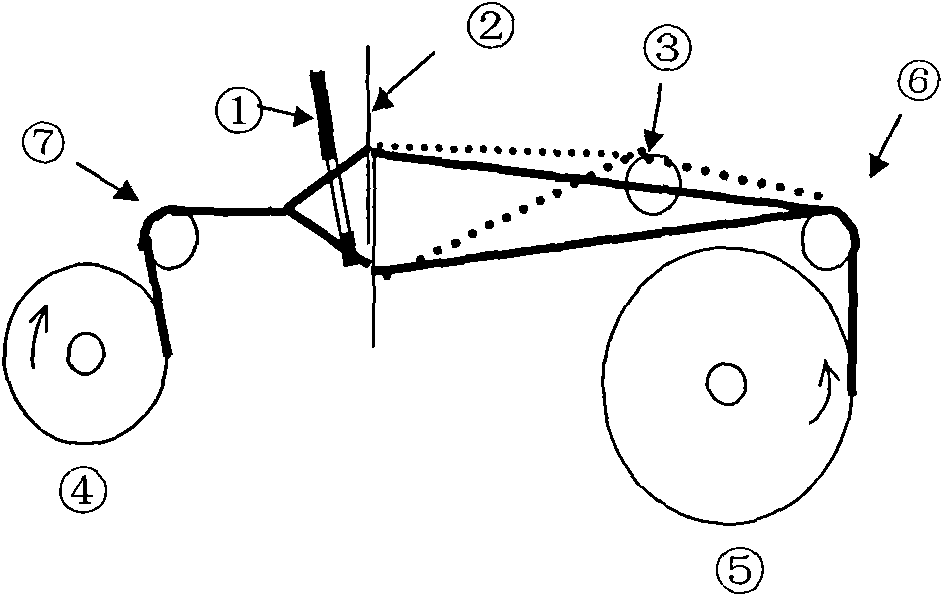

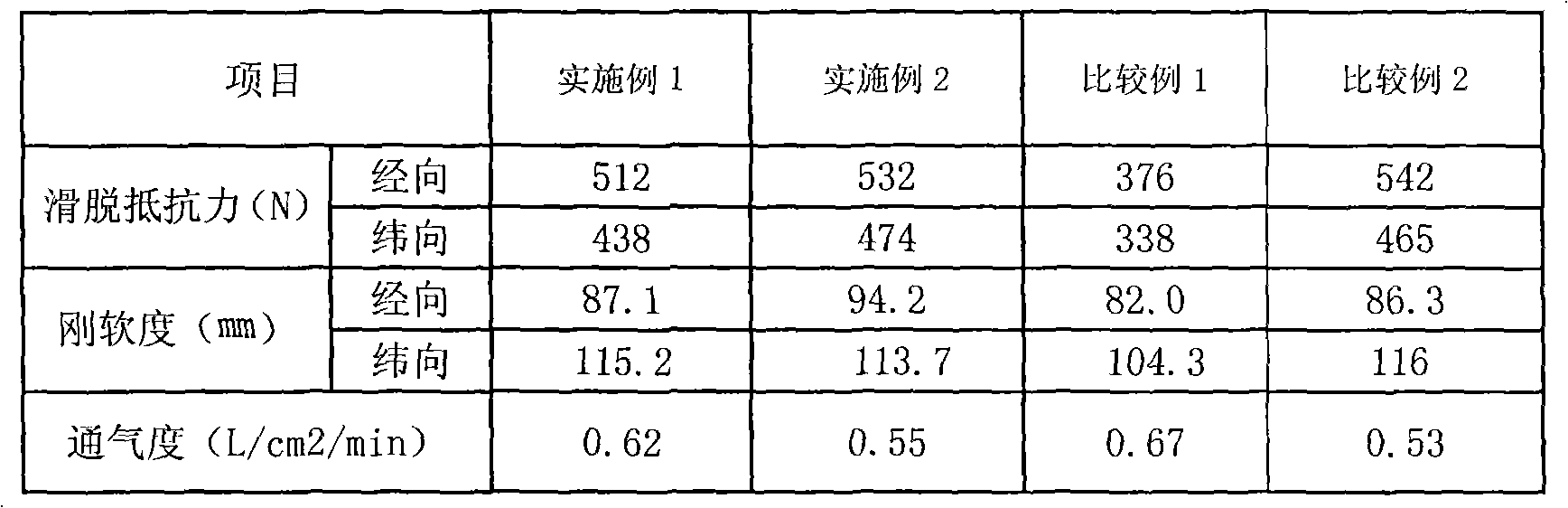

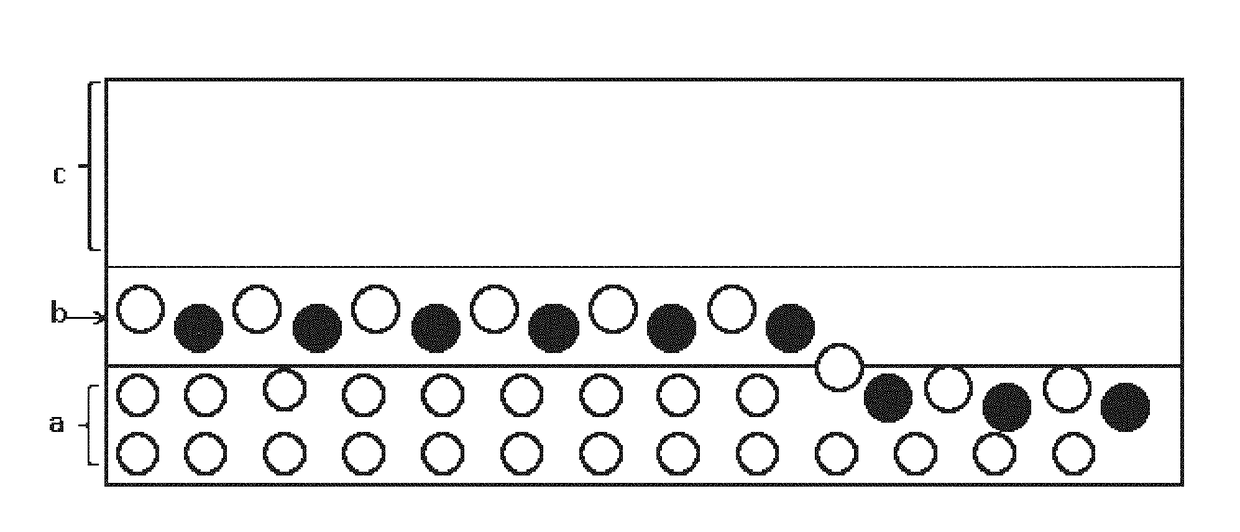

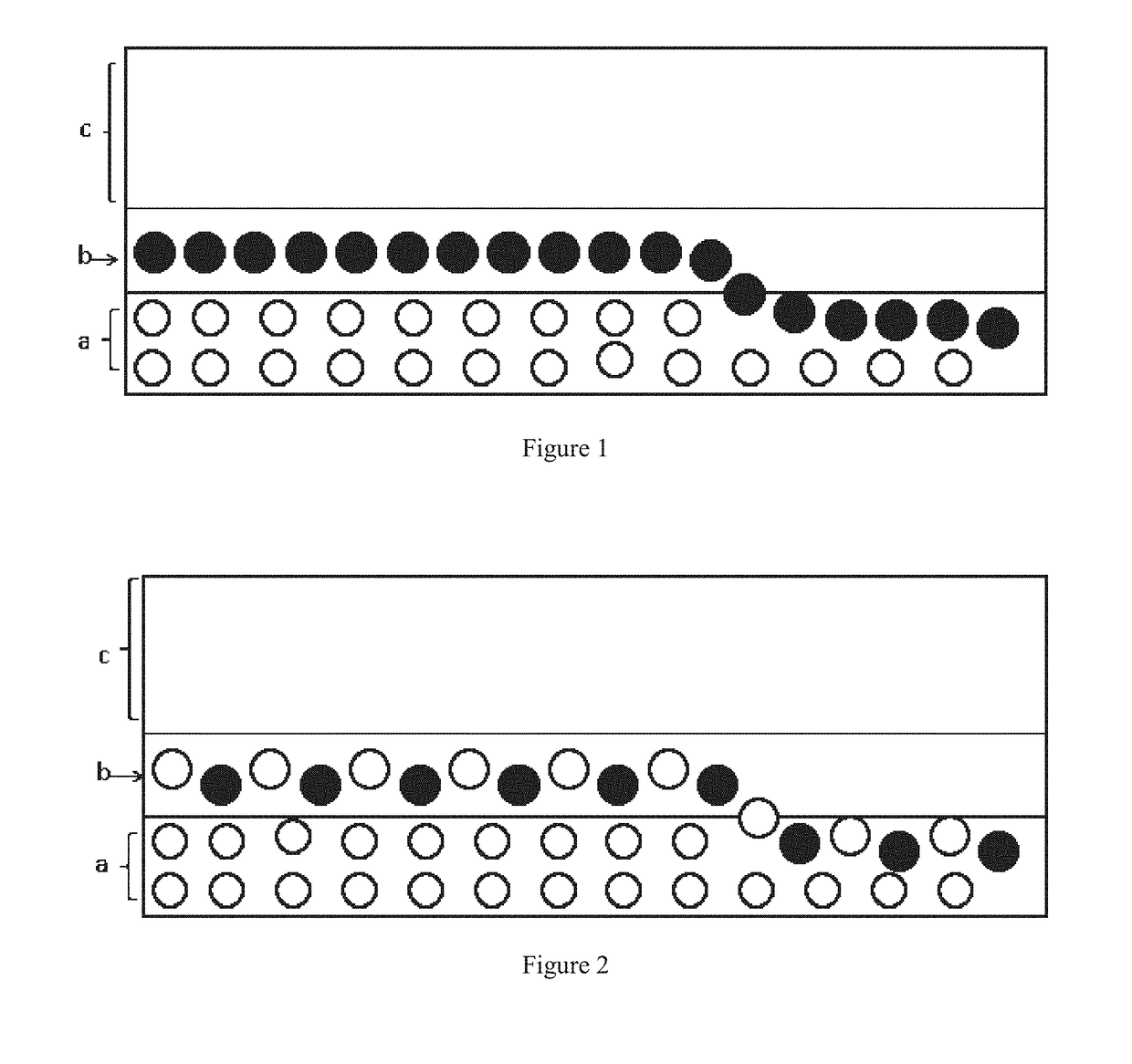

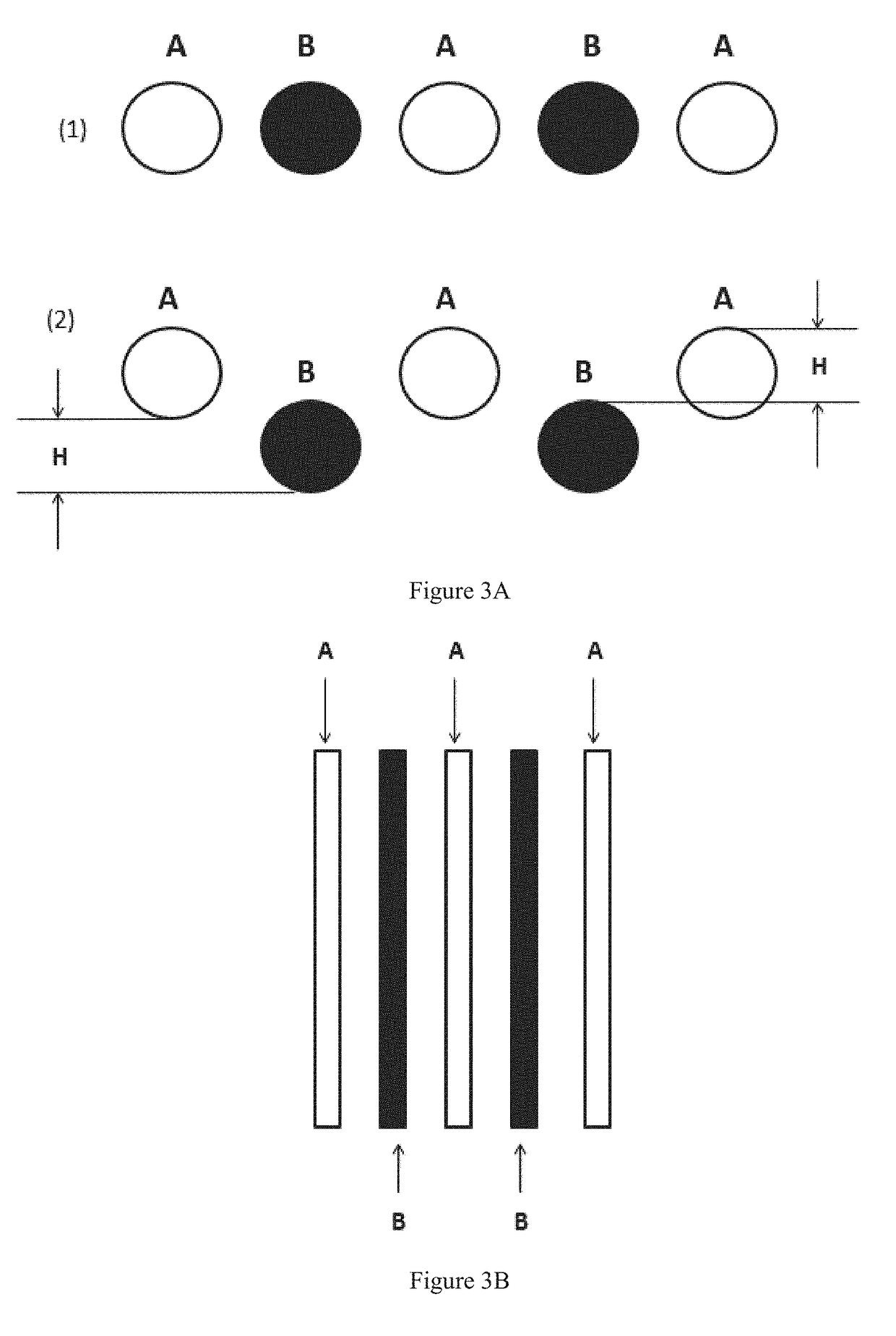

Production method of fabric for gas bag

InactiveCN101886307AReduce air permeabilityHigh slip resistanceLoomsWoven fabricsAfter treatmentEngineering

The invention discloses a production method of fabric for a gas bag, which comprises the step of weaving. In the fabric weaving process, a presser bar is additionally arranged below lamella warp between the heald frame of a weaving machine and the back beam of the weaving machine. The fabric obtained by the invention has no need of after-treatment and has good flexibility, low gas permeability and high slip resistance.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Technology for producing fibers from bamboo charcoal micropowder and polylactic acid slices

ActiveCN105671648AImprove scraping efficiencyEasy to manufactureSpinning head liquid feederMelt spinning methodsMoisture regainMetering pump

The invention discloses a technology for producing fibers from bamboo charcoal micropowder and polylactic acid slices. The technology comprises the following steps that the bamboo charcoal micropowder contained in a first stock bin falls into a color powder metering device by depending on the gravity, and the color powder metering device meters the bamboo charcoal micropowder; the bamboo charcoal micropowder metered by the color powder metering device is blown to a discharging pipe through dry compressed air while the dry polylactic acid slices contained in a second stock bin fall in the discharging pipe by depending on the gravity, and the bamboo charcoal micropowder and the dry polylactic acid slices are mixed in the discharging pipe and then fall into a spinning screw extruder; a melt filter filters bamboo charcoal-polylactic acid melt; the filtered bamboo charcoal-polylactic acid melt is delivered into a spinning box through a melt pipeline; a spinning metering pump and a spinning assembly which are arranged in the spinning box spin the bamboo charcoal-polylactic acid melt into the bamboo charcoal-polylactic acid fibers. According to the technology, polylactic acid is modified with the nanoscale bamboo aroma charcoal micropowder, and therefore the prepared fibers have the advantages that the initial modulus is decreased, the moisture regain is increased, the abrasive resistance is improved, and the air permeability and the handfeel are both obviously improved.

Owner:HENAN LONGDU BIOLOGY TECH

Cationic wool top and its making technology

InactiveCN1180145CInitial modulus reductionReduce intensityMonocomponent polyesters artificial filamentArtifical filament manufactureVacuum dryingMechanical engineering

A technology for producing cationic sliver includes vacuum drying CDP chips with 0.23-0.3% of SIPM content which controlling the precrystallizing temp and time, screw smelting and spinning, cooling while winding to obtain primary fibres (7-17 dtex), bundling, oil-bath drafting, two-pass steam stretching, curling while finishing oil, thermal shape fixation, making ribbons (88 mm in average length), carding, and making sliver. Its advantages are soft handle, high antistatic nature, and high dyeability.

Owner:孔森根

Preparation method of magnetorheological elastomer with high heat resistance and tensile properties

ActiveCN108727710BImprove slip characteristicsGood compatibilityMagnetic materialsElastomerPolymer science

The invention provides a method for preparing a magnetorheological elastomer with high heat resistance and tensile properties, comprising the following steps: a. Mixing modified carbonyl iron powder, silane coupling agent and methyl vinyl in an internal mixer The silicone rubber is mixed evenly, so that the surface of carbonyl iron powder is coated with a polymer composed of methyl vinyl silicone rubber and silane coupling agent, and then EPDM rubber, plasticizer and reinforcing particles are added for full mixing. Refining to obtain the mixed rubber; b. Put the mixed rubber in the open mill, add anti-aging agent and vulcanizing agent to carry out the rolling and rolling, and then inject the obtained material into the mold, and carry out pre-structural treatment under the magnetic field , and then vulcanized on a flat vulcanizer to obtain a magnetorheological elastomer with high heat resistance and tensile properties. The preparation method of the invention can overcome the technical difficulties in preparing the magnetorheological elastomer by using the EPDM rubber, and exert its excellent performance.

Owner:CHONGQING UNIV

Bamboo Charcoal Micropowder Polylactic Acid Chip Production Fiber System

ActiveCN105525369BAvoid cloggingExtended service lifeSpinning solution de-aeratingSpinning head liquid feederLaccaic acidEngineering

A system for producing fibers from bamboo charcoal micro powder and polylactic acid slices comprises a first material bin, a second material bin, a compressed air system, a spinning screw extruder and a spinning box, wherein a discharging port of the second material bin is connected with a feeding port of the spinning screw extruder through a main discharging pipe; an air pipe is obliquely arranged between an air outlet of the compressed air system and the main discharging pipe; a discharging port of the first material bin is connected with the air pipe through a mixing pipe; a toner meter is arranged on the mixing pipe; a discharging port of the spinning screw extruder is connected with the spinning box through a melt pipeline; a filtering and impurity removal device and a dynamic and static integrated pipeline type mixing device are sequentially arranged on the melt pipeline in the melt flowing direction. Polylactic acid is modified with nano bamboo charcoal micro powder, the initial modulus of the manufactured fibers is reduced, the moisture regain rate is increased, the wear resistance is improved, and the air breathability and the hand feeling of the fibers are remarkably improved.

Owner:HENAN LONGDU BIOLOGY TECH

Near-beta titanium alloy with low elastic modulus and high strength and preparation method of near-beta titanium alloy

InactiveCN103060609BImproved cold working propertiesLow work hardening rateMedical equipmentNonlinear deformation

Owner:BEIHANG UNIV

Bamboo Charcoal Polylactic Acid Particle Spinning System

ActiveCN105543992BAvoid cloggingExtended service lifeSpinning solution de-aeratingFilament forming substance formingEngineeringMoisture regain

Owner:HENAN LONGDU BIOLOGY TECH

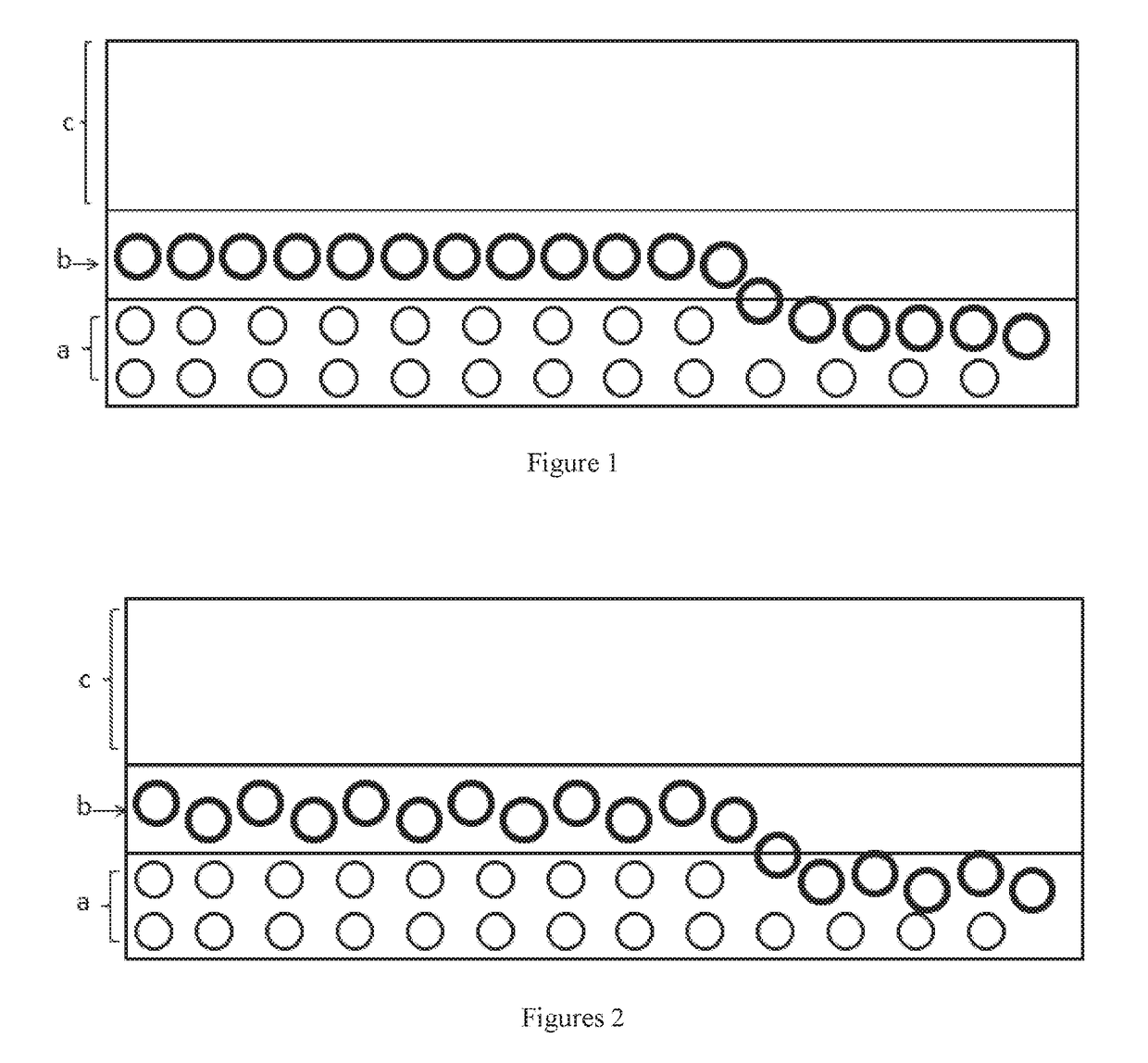

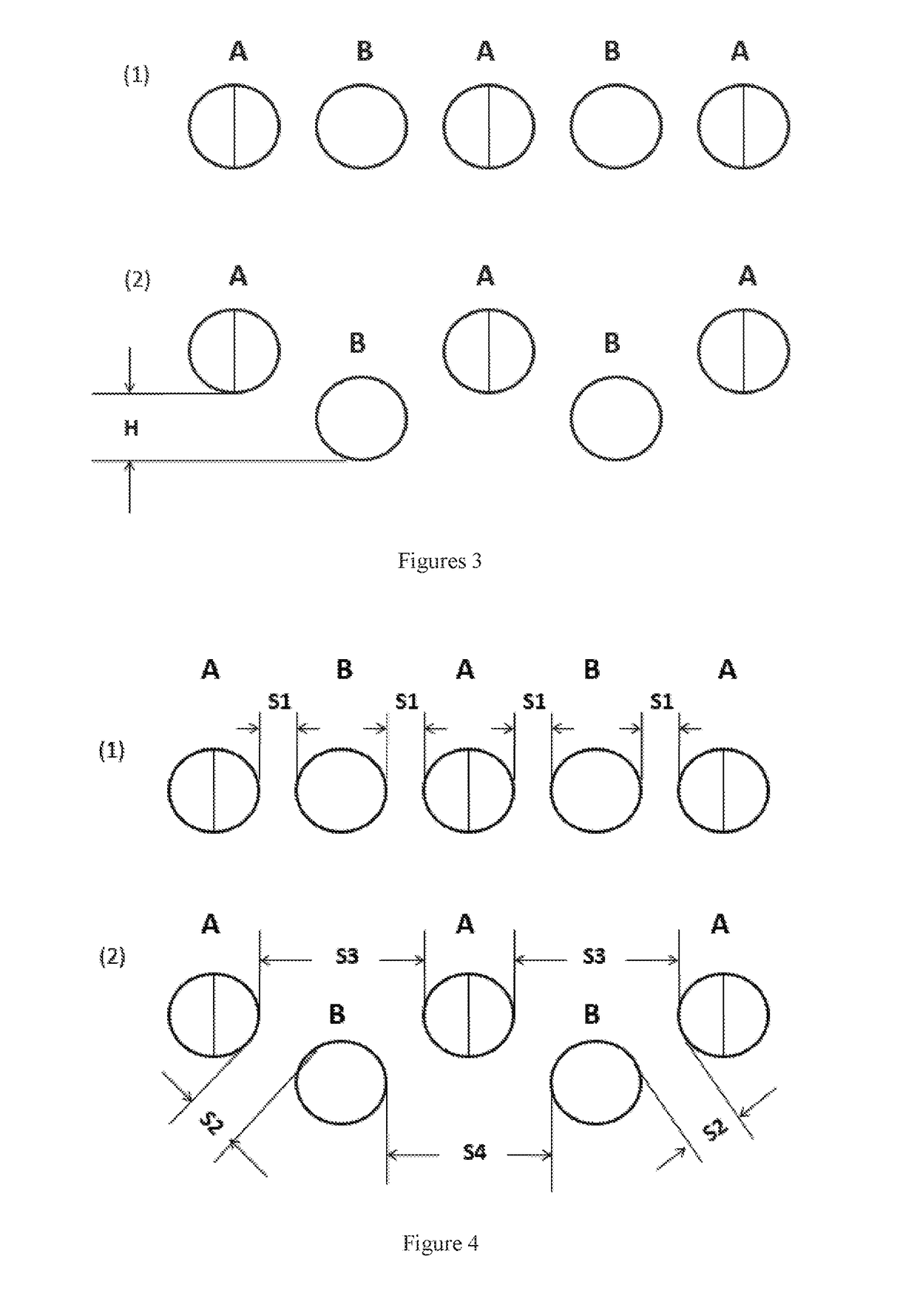

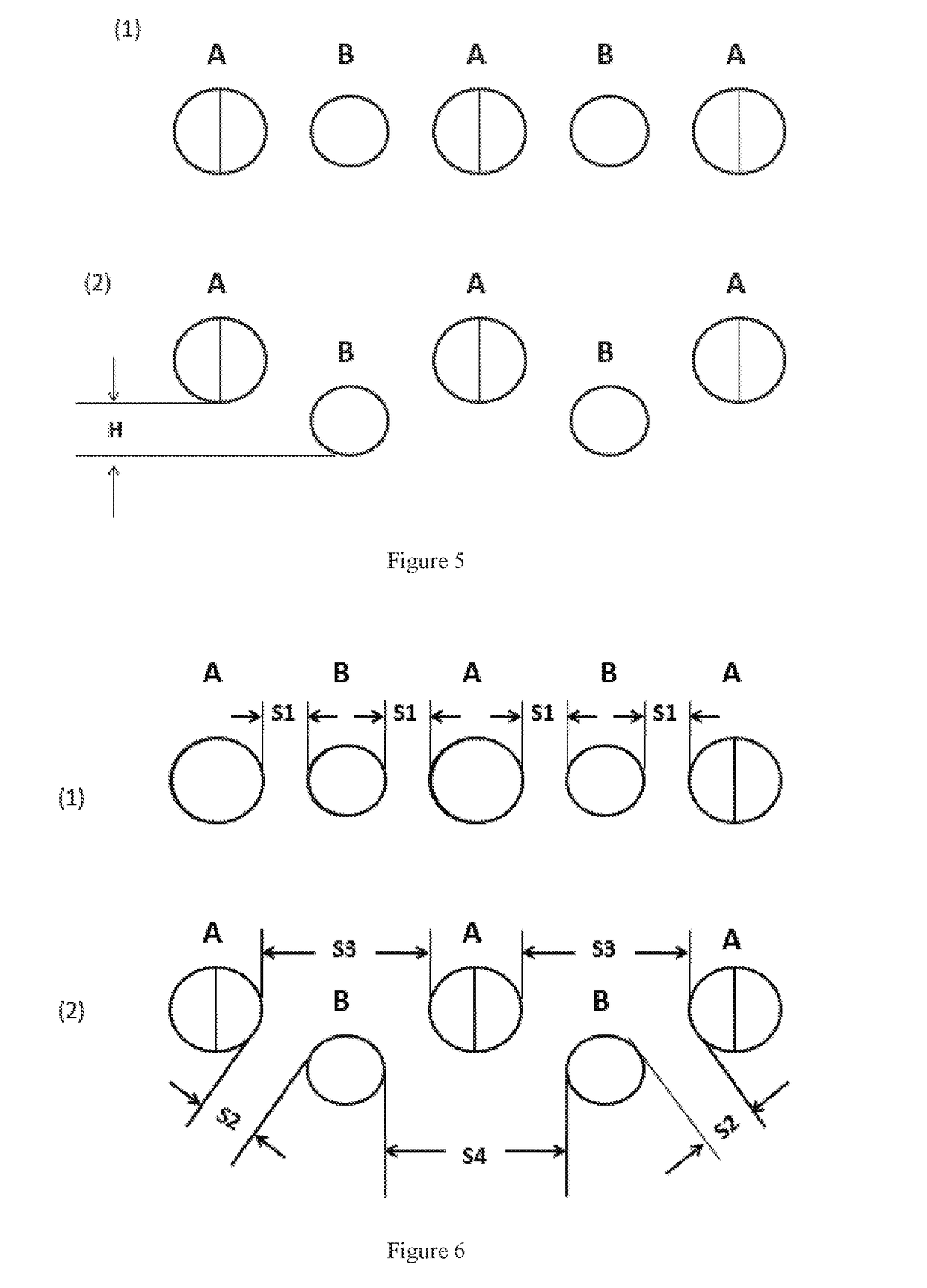

Cap ply strip with alternate nylon 6,6 and pet cords

ActiveUS20180333989A1Improve high speed durabilityImprove tread separation resistancePneumatic tyre reinforcementsTyre tread bands/patternsNylon 6Engineering

The present invention relates to a novel tire cord fabric or strip made of alternating PET and nylon 6.6 warp cords which is used as tire reinforcement. Such a novel tire cord fabric or strips improve high speed durability, tread separation resistance and impact resistance when used as zero degree spirally wound cap ply in pneumatic radial tires.

Owner:KORDSA TEKNIK TEKSTIL ANONIM SIRKETI

Cap ply strip with different nylon 6,6 constructions

InactiveUS20180339554A1Improve fatigue resistanceSufficient restraining forcePneumatic tyre reinforcementsYarnNylon 6Engineering

The present invention relates to a novel tire cord fabric or strip made of alternating nylon cords having different constructions. Such a novel cord fabrics or strips improves high speed durability and tread separation resistance when used as zero degree spirally wound cap ply on the belt package in pneumatic radial tires.

Owner:KORDSA TEKNIK TEKSTIL ANONIM SIRKETI

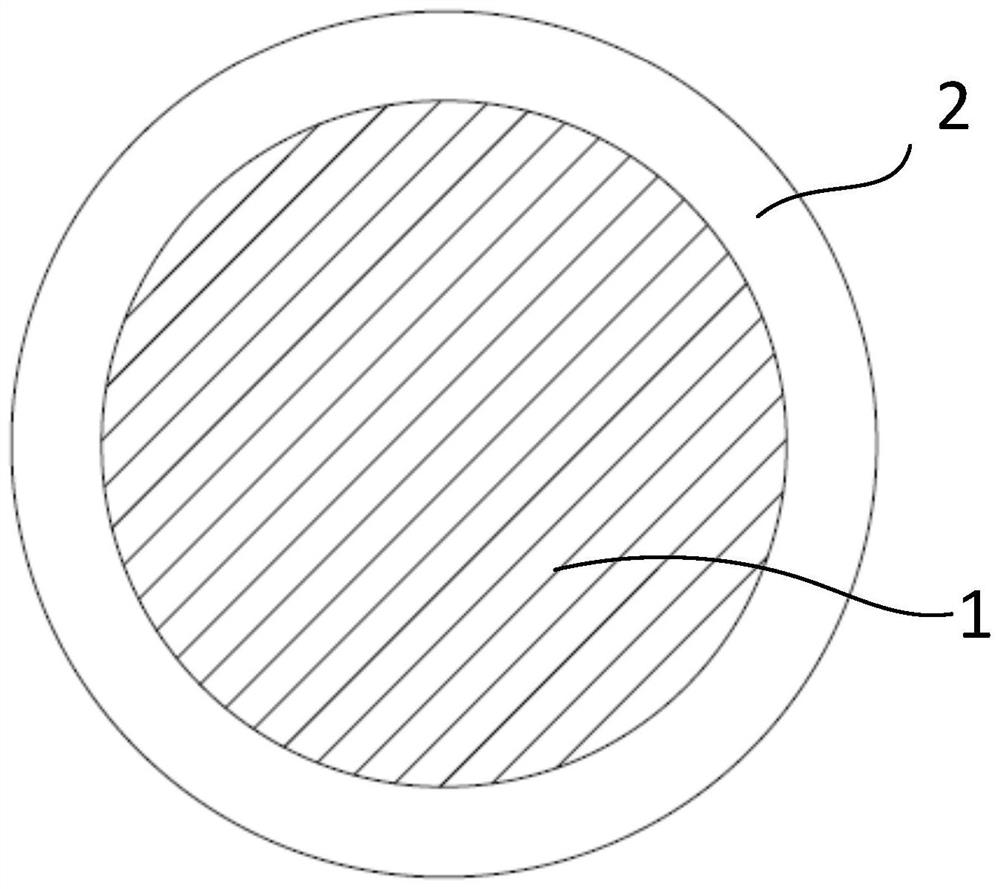

Low-cost bio-based composite fiber as well as preparation method and application thereof

PendingCN114574994AHigh strengthImprove rigidityFilament/thread formingTextile/flexible product manufacturePolymer scienceSpinning

The invention discloses a low-cost bio-based composite fiber as well as a preparation method and application thereof. The composite fiber comprises a core layer and a skin layer wrapping the core layer, the core layer is made of nylon 56, the skin layer is made of nylon 66, and in the cross section of the composite fiber, the ratio of the cross section area of the core layer to the cross section area of the skin layer is (20-80): (20-80). The preparation method comprises the following steps: respectively preparing nylon 66 slices and nylon 56 slices; the nylon 66 slices and the nylon 56 slices are subjected to melt extrusion composite spinning, so that the nylon 56 forms a core layer, the nylon 66 forms a skin layer, and the low-cost bio-based composite fiber is obtained. The mechanical property of the composite fiber is equivalent to that of nylon 66 fiber, the flexibility is better, the production cost is low, and the composite fiber can meet some low-cost nylon 66 fiber application occasions, such as the fields of automobile safety airbags, nylon industrial yarns and the like; and the fiber also belongs to bio-based composite fiber, and accords with the current low-carbon and environment-friendly development trend.

Owner:CHINESE TEXTILE ACAD

Polylactic acid bamboo charcoal slice production process

ActiveCN105504236BImprove scraping efficiencyEasy to manufactureMonocomponent polyesters artificial filamentArtifical filament manufactureLactideWater cooling

The invention provides a production process for polylactic acid bamboo charcoal slices. The production process includes the following steps that 1, lactide and bamboo incense charcoal micro-powder are added to a stirring tank to be stirred; 2, a mixture of lactide and the bamboo incense charcoal micro-powder drops in a preliminary polymerization tank through a first pipeline to be preliminarily polymerized; 3, polylactic acid bamboo charcoal melt drops in a final polymerization tank through a second pipeline to be finally polymerized; 4, a third valve at the bottom of the final polymerization tank is switched on, the polylactic acid bamboo charcoal melt is extruded out of a spinneret plate and metered through a third metering pump, and the polylactic acid bamboo charcoal melt is cooled through water; 5, the polylactic acid bamboo charcoal melt is cooled through the water, solidified to normal temperature and then sliced. Polylactic acid is modified through the nano-scale bamboo incense charcoal micro-powder, the initial modulus of fibers produced through the production process is reduced, the moisture regain is increased, abrasion resistance is improved, and the breathability and hand feeling of the fibers are obviously improved.

Owner:HENAN LONGDU BIOLOGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com