Bamboo Charcoal Micropowder Polylactic Acid Chip Production Fiber System

A bamboo charcoal micropowder and polylactic acid technology, which is applied in fiber processing, single-component polyester rayon, and filament forming processing, etc., can solve the problems that impurities cannot be effectively filtered, affect the spinning quality, and affect the use effect, etc. Achieve the effect of simple structure, improved functions and indicators, and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

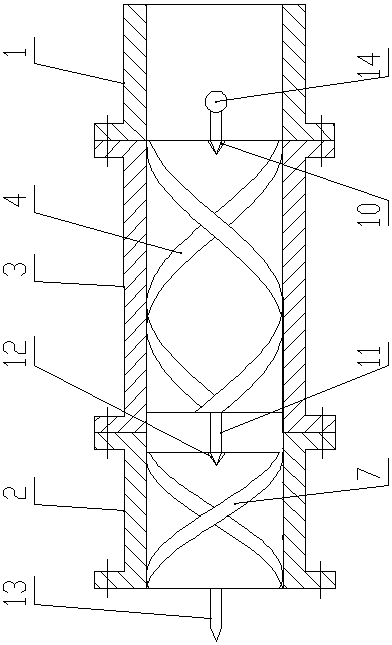

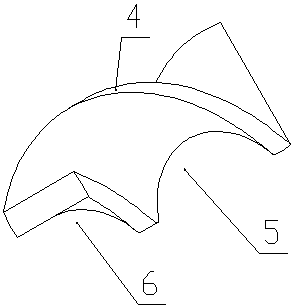

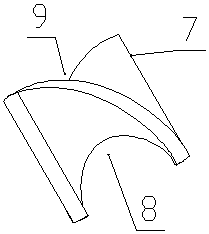

[0021] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the bamboo charcoal micropowder polylactic acid chip production fiber system of the present utility model comprises the first feed bin 16, the second feed bin 17, compressed air system 18, spinning screw extruder 19 and spinning casing 20, the second The discharge port of the feed bin 17 is connected with the feed port of the spinning screw extruder 19 through the main feeding pipe 21, and an air duct 22 is inclined between the air outlet of the compressed air system 18 and the main feeding pipe 21, and the wind The position of the connecting end of the pipe 22 and the compressed air system 18 is higher than the position of the connecting end of the air pipe 22 and the main feeding pipe 21, and the air pipe 22 is provided with a regulating air valve 30 adjacent to the compressed air system 18, and the discharge of the first feed bin 16 The mouth is connected with the air pipe 22 through the mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com