Downwards-pressing pressing piece device for smooth and clean spinning

A tableting device and smooth technology, applied in textiles and papermaking, etc., can solve the problems of high maintenance cost and high cost, and achieve the effect of improving yarn quality, low cost and reducing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

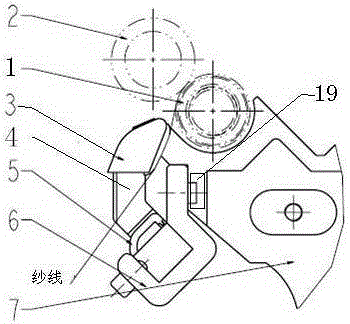

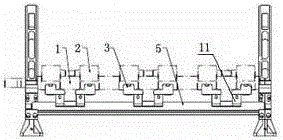

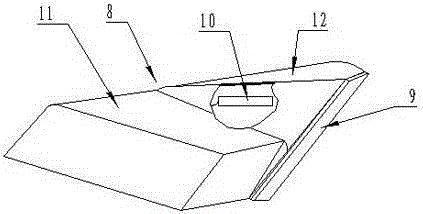

[0016] Such as figure 1 As shown, the down-pressing tablet pressing device for smooth and smooth spinning includes a front roller 1, a front top roller 2, a tablet pressing assembly 3, a connecting section 4, a power control assembly 5, a support seat 6 and a roller seat 7, The tablet pressing assembly 3 is composed of a housing 8, a heating plate 9, and a heater 10, wherein the housing 8 includes a connection end 11, and a heating part 12 integrally formed on one side of the upper end of the connection end 11. The front end of the heating part 12 is One opening, the heating plate 9 is fixed on the opening of the heating part 12 of the housing 8, and the heater 10 is fixed inside the heating part 12 of the housing 8; the power control assembly 5 includes a mounting seat 13, a mounting groove 14 and a The circuit control board 15 of the heater 10, the circuit control board 15 is installed in the installation groove 14, and is tightly installed in the installation groove 14 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com