Low-cost bio-based composite fiber as well as preparation method and application thereof

A composite fiber, bio-based technology, used in fiber processing, conjugated synthetic polymer rayon, final product manufacturing, etc. The effect of low volume, good hand feeling and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

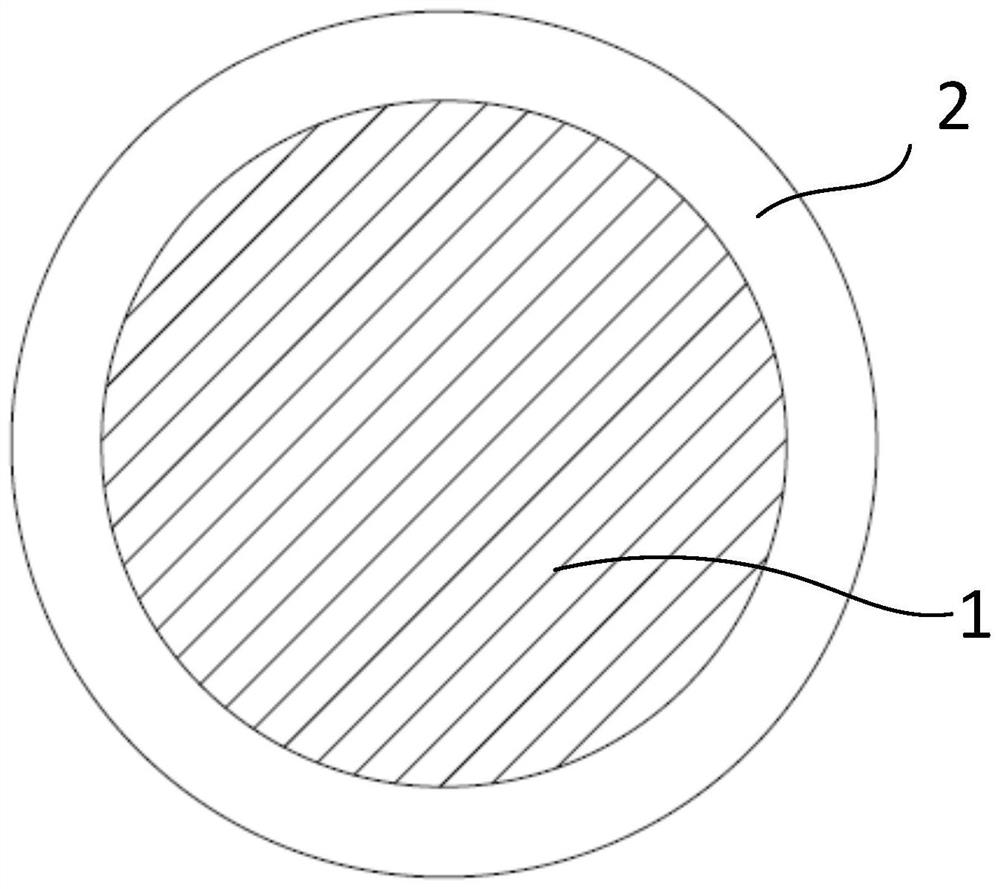

Image

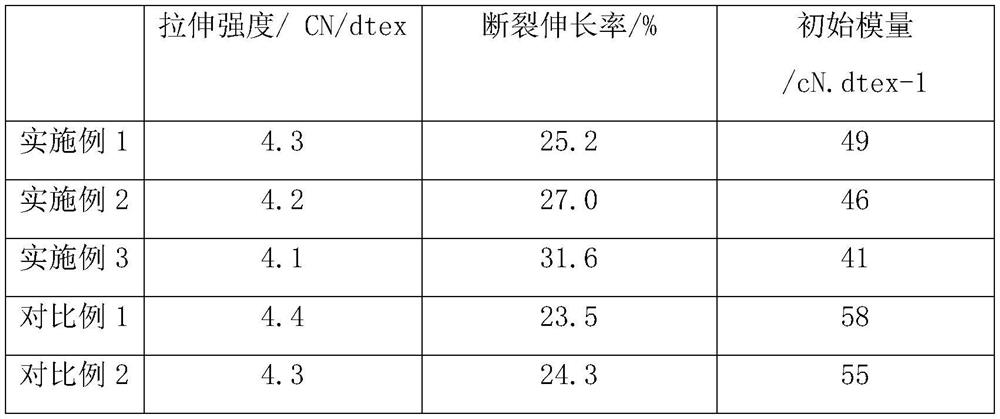

Examples

Embodiment 1

[0066] 1.1 Preparation of semi-dull nylon 66 slices

[0067] (1) Weigh the raw nylon 66 slices (white particles, relative viscosity 2.40), put them into a high-speed mixer, add a matting agent titanium dioxide (purity 99.9%, type is anatase, particle size 300nm), the amount of titanium dioxide added is nylon 0.2% of the mass of 66, stir at a low speed of 100rpm for 10 minutes, take it out, and set aside;

[0068] (2) Place the mixed material in the above (1) on the main feeding port of a twin-screw extruder with an aspect ratio of 42:1, melt extrusion and granulation, and the extruded material is cooled, air-dried, pelletized, and vacuumized. After drying, a dried semi-matte nylon 66 was obtained.

[0069] The temperature setting range of the twin-screw extruder is 255-270°C, the screw speed is 450rpm, and the temperature of each zone of the twin-screw extruder is: the temperature of the first zone: 255°C, the temperature of the second zone: 260°C, and the temperature of the ...

Embodiment 2

[0085] 2.1 Preparation of semi-dull nylon 66 slices

[0086] (1) Weigh the raw nylon 66 slices (white particles, relative viscosity 2.40), put them into a high-speed mixer, add a matting agent titanium dioxide (purity 99.9%, type is anatase, particle size 300nm), the amount of titanium dioxide added is nylon 0.3% of the mass of 66, stir at a low speed of 100rpm for 10 minutes, take it out, and set aside;

[0087] (2) Place the mixed material in the above (1) on the main feeding port of a twin-screw extruder with an aspect ratio of 42:1, melt extrusion and granulation, and the extruded material is cooled, air-dried, pelletized, and vacuumized. After drying, a dried semi-matte nylon 66 was obtained.

[0088] The temperature setting range of the twin-screw extruder is 255~270℃, the screw speed is 500rpm, the temperature of each zone of the twin-screw extruder is: the temperature of the first zone: 255°C, the temperature of the second zone: 260°C, and the temperature of the third...

Embodiment 3

[0104] 3.1 Preparation of semi-dull nylon 66 slices

[0105](1) Weigh the raw nylon 66 slices (white particles, relative viscosity 2.40), put them into a high-speed mixer, add a matting agent titanium dioxide (purity 99.9%, type is anatase, particle size 300nm), the amount of titanium dioxide added is nylon 0.4% of the mass of 66, stir at a low speed of 100rpm for 10 minutes, take it out, and set aside;

[0106] (2) Place the mixed material in the above (1) on the main feeding port of a twin-screw extruder with an aspect ratio of 42:1, melt extrusion and granulation, and the extruded material is cooled, air-dried, pelletized, and vacuumized. After drying, a dried semi-matte nylon 66 was obtained.

[0107] The temperature setting range of the twin-screw extruder is 255~270℃, the screw speed is 550rpm, and the temperature of each zone of the twin-screw extruder is: the temperature of the first zone: 255°C, the temperature of the second zone: 260°C, and the temperature of the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com