Bamboo Charcoal Polylactic Acid Particle Spinning System

A spinning system and polylactic acid technology, applied in the field of bamboo charcoal polylactic acid particle spinning system, can solve the problems that impurities cannot be effectively filtered, affect the use effect, affect the spinning quality, etc., and achieve simple structure, cost saving, function and The effect of indicator improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

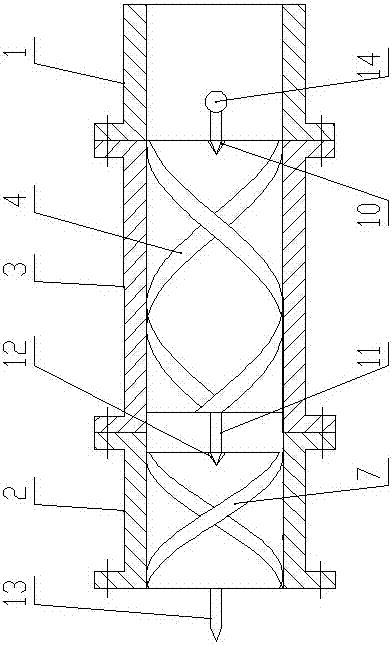

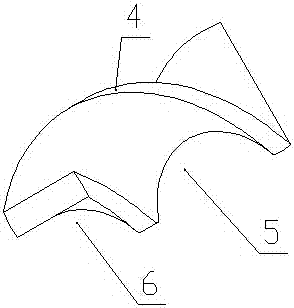

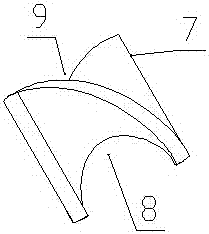

[0021] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Shown, the bamboo charcoal polylactic acid particle spinning system of the present invention comprises mixing tank 16, granulation screw extruder 17, the first feed bin 18, the second feed bin 19, spinning screw extruder 20 and spinning box Body 24, the discharge port of the mixing tank 16 is connected with the feed port of the granulation screw extruder 17, the discharge port of the granulation screw extruder 17 is connected with the feed port of the first feed bin 18, the second material The discharge port of the warehouse 19 is connected with the feed port of the spinning screw extruder 20 through the main feeding pipe 21, and the discharge port of the first feed bin 18 is connected with the main feeding pipe 21 through the mixing pipe 22, and the mixing material The pipe 22 is provided with a micrometer 23, and the discharge port of the spinning screw extruder 20 is connected with the spinning box 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com