Polylactic acid bamboo charcoal slice production process

A production process and polylactic acid technology, applied in the field of polylactic acid bamboo charcoal chip production process, can solve the problems of high polymer melt viscosity, affecting the use effect, affecting the spinning quality, etc., and achieves an increase in moisture regain and cost savings. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

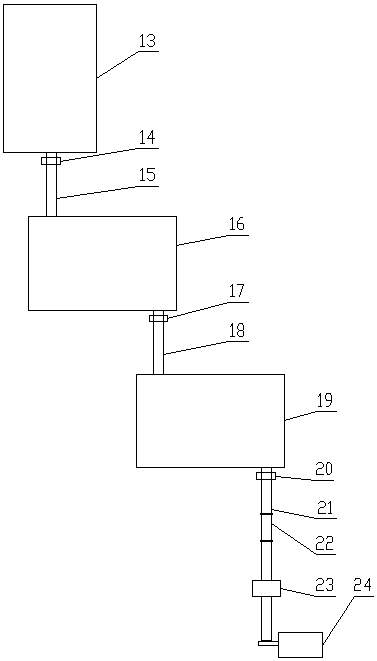

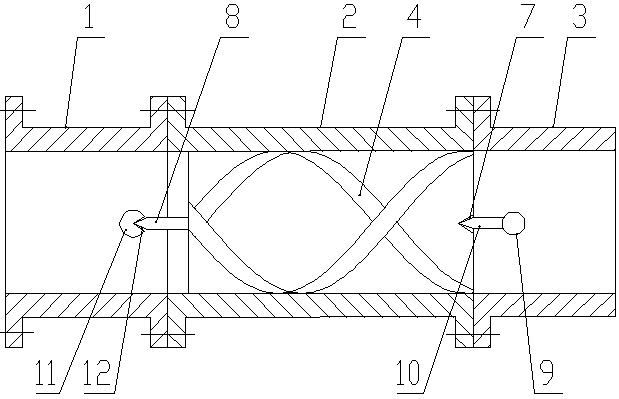

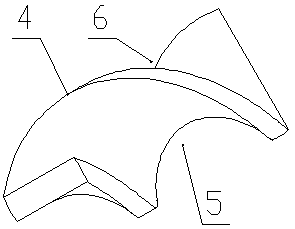

[0024] Such as figure 1 , figure 2 with image 3 Shown, polylactic acid bamboo charcoal slice production technique of the present invention, comprises the following steps:

[0025] (1) Add lactide and bamboo charcoal powder into the mixing tank 13 for stirring operation, wherein the weight of bamboo charcoal powder is 0.5% to 15% of the total weight of lactide and bamboo charcoal powder, stirring for 20 ~40min, until the mixture is uniform;

[0026] (2), open the first valve 14 at the bottom of the stirring tank 13, and drop the mixture of lactide and bamboo charcoal micropowder through the first pipeline 15 into the initial polymerization tank 16 through the first metering pump for preliminary polymerization operation. The temperature of the polymerization operation is 100-150 ° C, the time of the preliminary polymerization operation is 1-2 hours, and the pressure is 0.2 MPa. After the preliminary polymerization operation, the mixture of lactide and bamboo charcoal powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com