Preparation method of antibacterial anti-flaming protein viscose fiber

A technology of viscose fiber and protein glue, which is applied in the field of textile fibers, can solve the problems of poor wearing performance of flame-retardant viscose fiber and easy deterioration of protein viscose fiber, and achieve improved mechanical properties and wearing performance, good fastness, and distribution uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

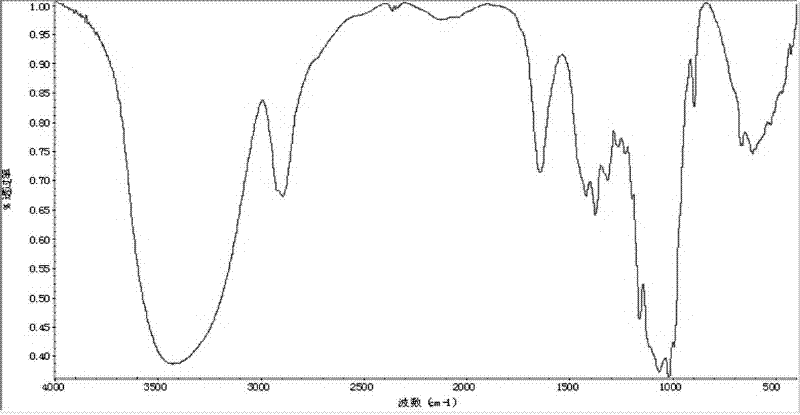

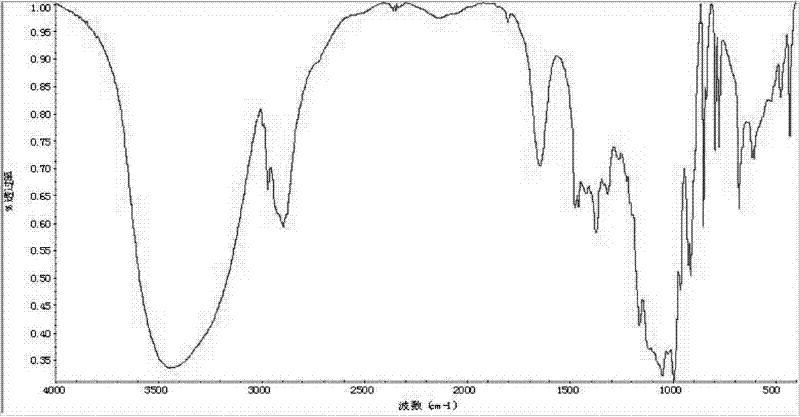

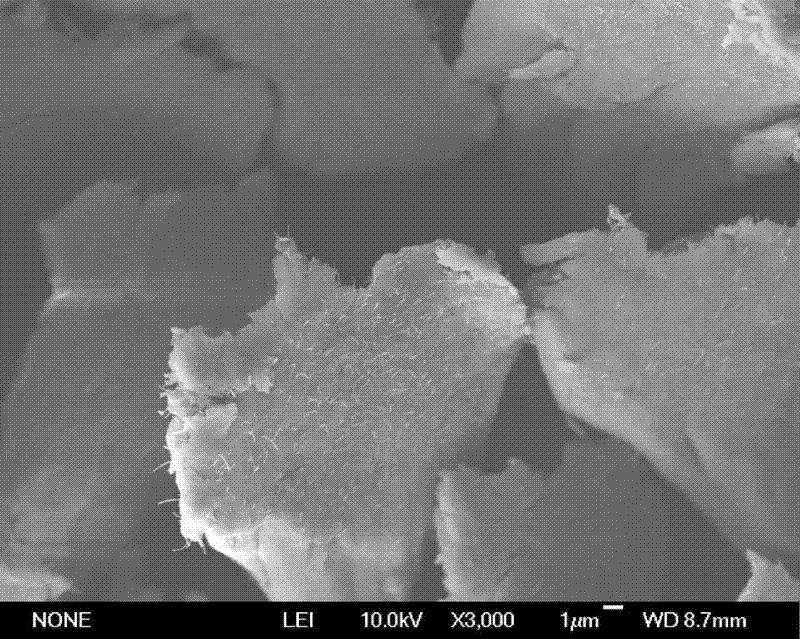

Method used

Image

Examples

Embodiment 1

[0036]Preparation of flame retardant slurry: use hexaphenoxycyclotriphosphazene as flame retardant, alkyl polyglycoside as emulsifier, mix according to the mass ratio of emulsifier:flame retardant=1:6, add industrial soft water, Wet process for 4.5 hours to make a flame retardant slurry with a flame retardant content of 17.5%.

[0037] Preparation of protein glue: put 23 parts by weight of washed and dried wool scraps into 77 parts by weight of 1mol / L sodium hydroxide solution, stir and dissolve for 20 minutes at 65°C, and place for 3.5 hours to obtain crude wool keratin solution, after filtration and dialysis, a protein glue solution with a protein content of 21% was obtained.

[0038] Preparation of chitosan solution: Add chitosan, citric acid and sodium hypophosphite to 3% acetic acid solution, heat to 75°C, stir well to dissolve, add penetrant JFC, stir for 40 minutes, and filter to obtain shell Polysan solution, the obtained chitosan solution contains 4% chitosan, 3% cit...

Embodiment 2

[0047] Preparation of flame retardant slurry: use hexaphenoxycyclotriphosphazene as flame retardant, alkyl polyglycoside as emulsifier, mix according to the mass ratio of emulsifier:flame retardant=1:5, add industrial soft water, Wet process for 5 hours to make a flame retardant slurry with a flame retardant content of 20%.

[0048] Preparation of protein glue: put 20 parts by weight of washed and dried wool scraps into 80 parts by weight of 1mol / L sodium hydroxide solution, stir and dissolve for 20 minutes at 80°C, and place for 4 hours to obtain crude wool keratin solution, after filtration and dialysis, a protein glue solution with a protein content of 18% was obtained.

[0049] Preparation of chitosan solution: Add chitosan, citric acid and sodium hypophosphite to 3% acetic acid solution, heat to 90°C, stir well to dissolve, add penetrant JFC, stir for 30 minutes, and filter to obtain shell Polysan solution, the obtained chitosan solution contains 4.5% chitosan, 3.8% citr...

Embodiment 3

[0057] Preparation of flame retardant slurry: use hexaphenoxycyclotriphosphazene as flame retardant, alkyl polyglycoside as emulsifier, mix according to the mass ratio of emulsifier:flame retardant=1:8, add industrial soft water, Wet process for 3.5 hours to make a flame retardant slurry with a flame retardant content of 12.5%.

[0058] Preparation of protein glue: put 16 parts by weight of washed and dried wool scraps into 84 parts by weight of 1mol / L sodium hydroxide solution, stir and dissolve for 25 minutes at 70°C, and place for 3 hours to obtain crude wool keratin solution, after filtration and dialysis, a protein glue solution with a protein content of 15% was obtained.

[0059] Preparation of chitosan solution: add chitosan, citric acid and sodium hypophosphite to 3% acetic acid solution, heat to 80°C, stir well to dissolve, add penetrant JFC, stir for 45 minutes, and filter to obtain shell Polysan solution, the obtained chitosan solution contains 5% chitosan, 4% citr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com