Direct spinning system for mixed melt of bamboo charcoal and polylactic acid

A technology of melt direct spinning and polylactic acid, which is applied in the directions of melt spinning, spinning solution defoaming, filament forming treatment, etc. Silk quality and other issues, to achieve the effect of rising moisture regain, cost saving and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

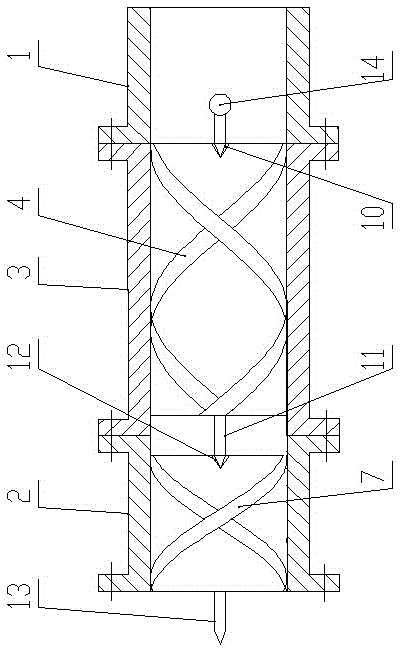

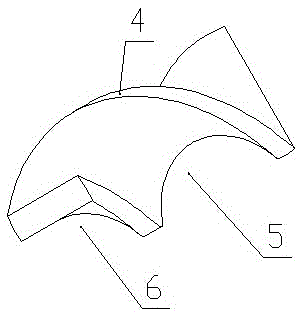

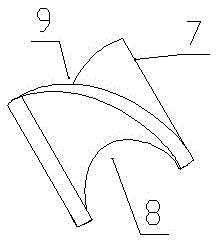

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the direct spinning system of bamboo charcoal polylactic acid mixed melt of the present invention comprises polymerization frame 16 and spinning housing 17, and polymerization frame 16 is provided with stirring tank 19, primary polymerization tank 20 and final polymerization successively from top to bottom. Tank 21, the bottom of the stirring tank 19 is connected to the top of the initial polymerization tank 20 through the first feed pipe 22, the first feed pipe 22 is provided with a first automatic control valve 23 and a first metering pump 24, and the bottom of the initial polymerization tank 20 passes through The second feed pipe 25 is connected with the top of the final polymerization tank 21, the second feed pipe 25 is provided with a second automatic control valve 26 and a second metering pump 27, the bottom of the final polymerization tank 21 is connected with a third feed pipe 28, Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com