Bamboo charcoal polylactic acid particle spinning technology

A spinning process and polylactic acid technology, applied in the field of bamboo charcoal polylactic acid particle spinning process, can solve the problems of high polymer melt viscosity, affecting the use effect, affecting the spinning quality, etc. Cost saving and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

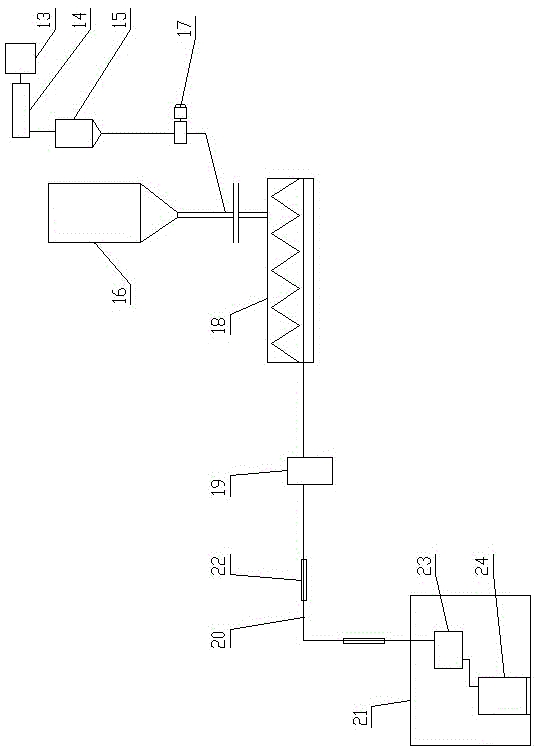

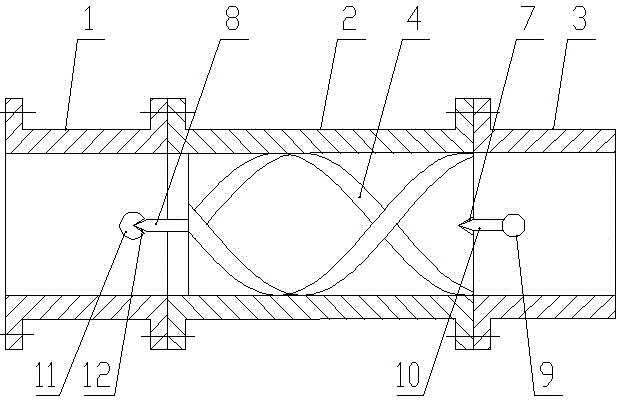

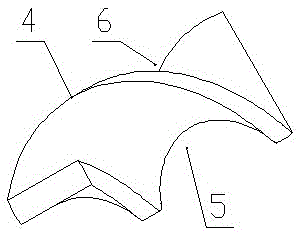

[0025] Such as figure 1 , figure 2 and image 3 Shown, bamboo charcoal polylactic acid particle spinning technique of the present invention, comprises the following steps:

[0026] (1) Use the mixing tank 13 to mix the nano-scale bamboo charcoal powder with fine polylactic acid particles in a certain proportion, and then send the mixture of bamboo charcoal powder and polylactic acid particles to the granulation screw extruder 14 Produced as bamboo charcoal polylactic acid masterbatch;

[0027] (2) Dry the bamboo charcoal polylactic acid masterbatch, and store the dried bamboo charcoal polylactic acid masterbatch in the first silo 15; at the same time, store the polylactic acid dry slices in the second silo 16;

[0028] (3) The bamboo charcoal polylactic acid masterbatch in the first silo 15 is quantitatively measured by the micrometer 17 and sent to the spinning screw extruder 18 together with the polylactic acid dry slices in the second silo 16 ;

[0029] (4), the spinn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com