Composite flame retardant sizing agent for regenerated cellulose fiber

A technology of compounding flame retardant and regenerated cellulose, applied in the field of textile fibers, can solve the problems of flame retardant regenerated cellulose fiber breaking strength, reduced modulus, loss of mechanical strength of flame retardant regenerated cellulose fiber, poor elastic recovery performance, etc. , to achieve the effect of excellent performance, good ecological safety and compatibility, and flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

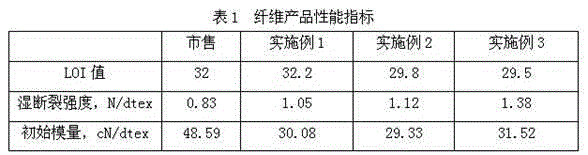

Embodiment 1

[0023] Add 100g of the reinforcing agent hydroxymethyl cellulose, 600g of the flame retardant hexaphenoxycyclotriphosphazene and 100g of the emulsifier APG (0810) into 2200g of industrial soft water, and stir at a constant speed for 2 hours at 40°C to make a flame retardant A composite flame retardant slurry with an additive content of 20wt%.

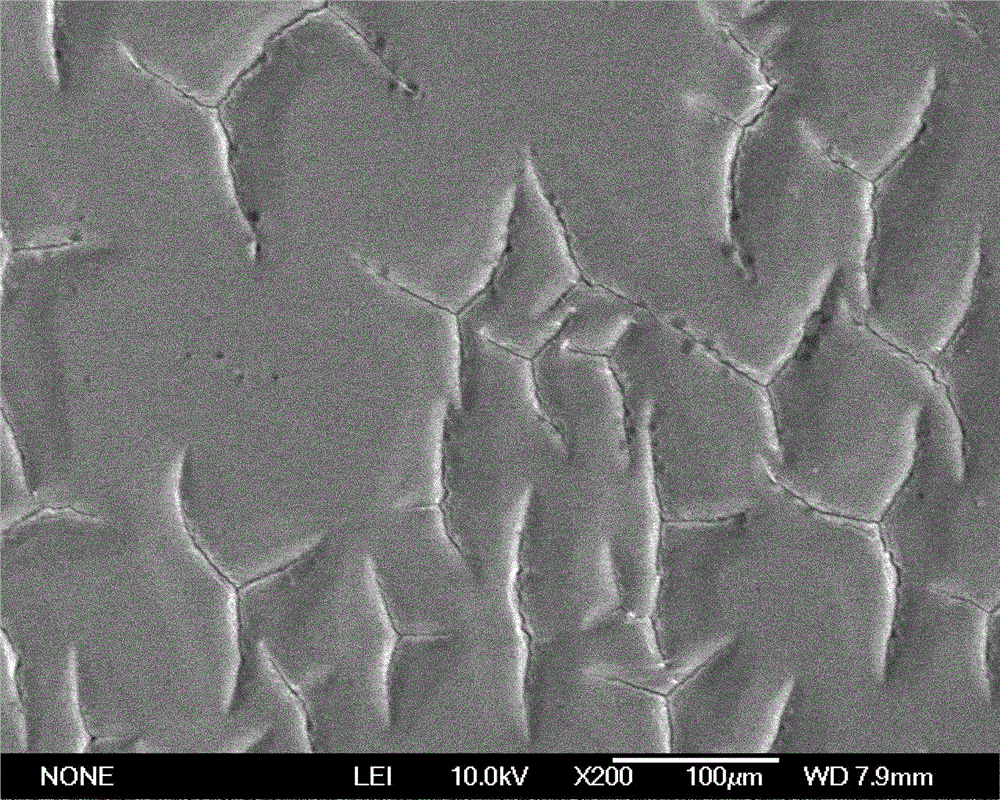

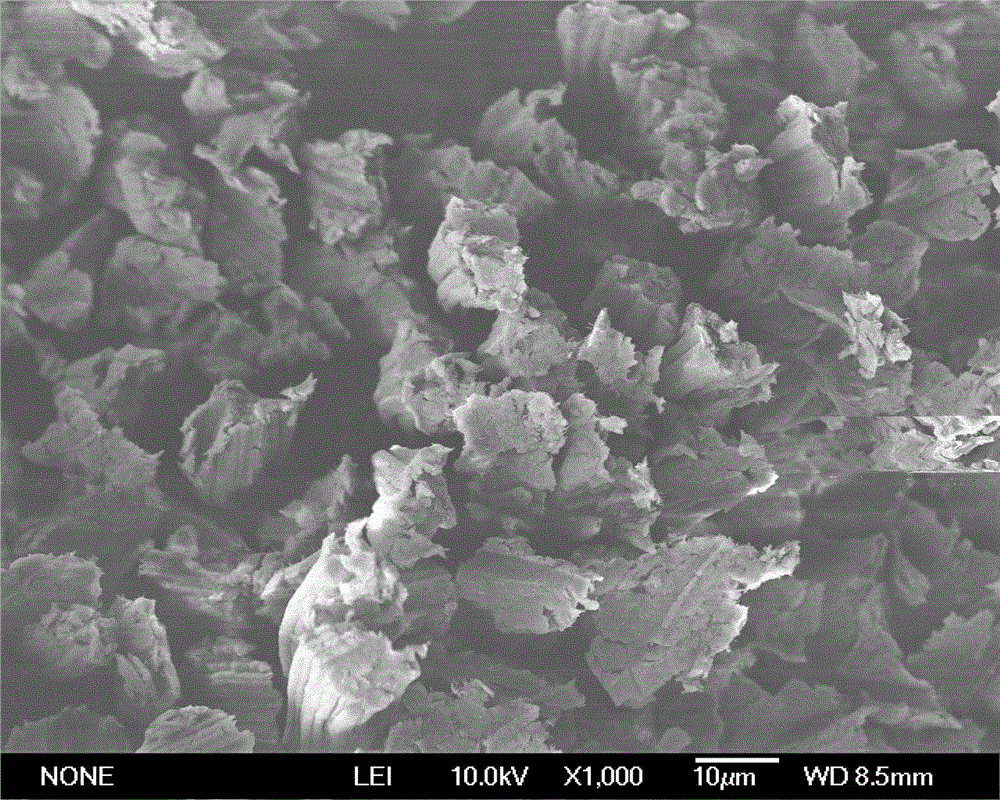

[0024] figure 1 It is the SEM picture (10kv, 200 times) of the above composite flame retardant slurry. Depend on figure 1 It can be seen that a large number of triangular protrusions appear in the flame retardant slurry after the gold spraying treatment, which is caused by the encapsulation of the flame retardant by the reinforcing agent under the action of the emulsifier.

[0025] In the regenerated cellulose fiber spinning solution with a methyl cellulose content of 10%, add the above-mentioned composite flame retardant slurry equivalent to 10% of the spinning solution weight, stir and mix evenly, and vacuumize and defoam for 180min...

Embodiment 2

[0028] Add 200g of the enhancer hydroxyethyl methylcellulose, 500g of the flame retardant hexaaminocyclotriphosphazene and 100g of the emulsifier APG (0814) into 4200g of industrial soft water in sequence, and stir at a constant speed for 2 hours at 40°C to prepare A flame retardant slurry with a flame retardant content of 10 wt%.

[0029] In the regenerated cellulose fiber spinning solution with a methyl cellulose content of 10%, add the above-mentioned composite flame retardant slurry equivalent to 10% of the spinning solution weight, stir and mix evenly, and vacuumize and defoam for 180min, pass through the wet High-strength flame-retardant regenerated cellulose fiber is made by spinning by spinning method, and desulfurization treatment is carried out with 15% sodium carbonate aqueous solution at 40 °C. The desulfurized high-strength flame-retardant regenerated cellulose fiber was washed twice with deionized water, and then passed into the finishing solution at 35 °C contai...

Embodiment 3

[0031] Add 200g of the enhancer hydroxyethyl methylcellulose, 700g of the flame retardant octachlorocyclotetraphosphazene and 100g of the emulsifier APG (1216) into 3670g of industrial soft water in sequence, and stir at a constant speed for 1 hour at 60°C to prepare A flame retardant slurry with a flame retardant content of 15 wt%.

[0032]In the regenerated cellulose fiber spinning solution with a methyl cellulose content of 10%, add the above-mentioned composite flame retardant slurry equivalent to 10% of the spinning solution weight, stir and mix evenly, and vacuumize and defoam for 180min, pass through the wet High-strength flame-retardant regenerated cellulose fiber is made by spinning by spinning method, and desulfurization treatment is carried out with 15% sodium carbonate aqueous solution at 40 °C. The desulfurized high-strength flame-retardant regenerated cellulose fiber was washed twice with deionized water, and then passed into the finishing solution at 35°C contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com