Preparation method of magnetorheological elastomer with high heat resistance and tensile properties

A magnetorheological elastomer, high heat-resistant technology, applied in the direction of magnetic objects, magnetic materials, circuits, etc., can solve the problem of affecting the mechanical strength and stability of magnetorheological elastomers, molecular chain non-polarity, and low magnetorheological effect and other issues, to achieve the effect of enhancing the pre-structure effect, improving compatibility, weather resistance and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

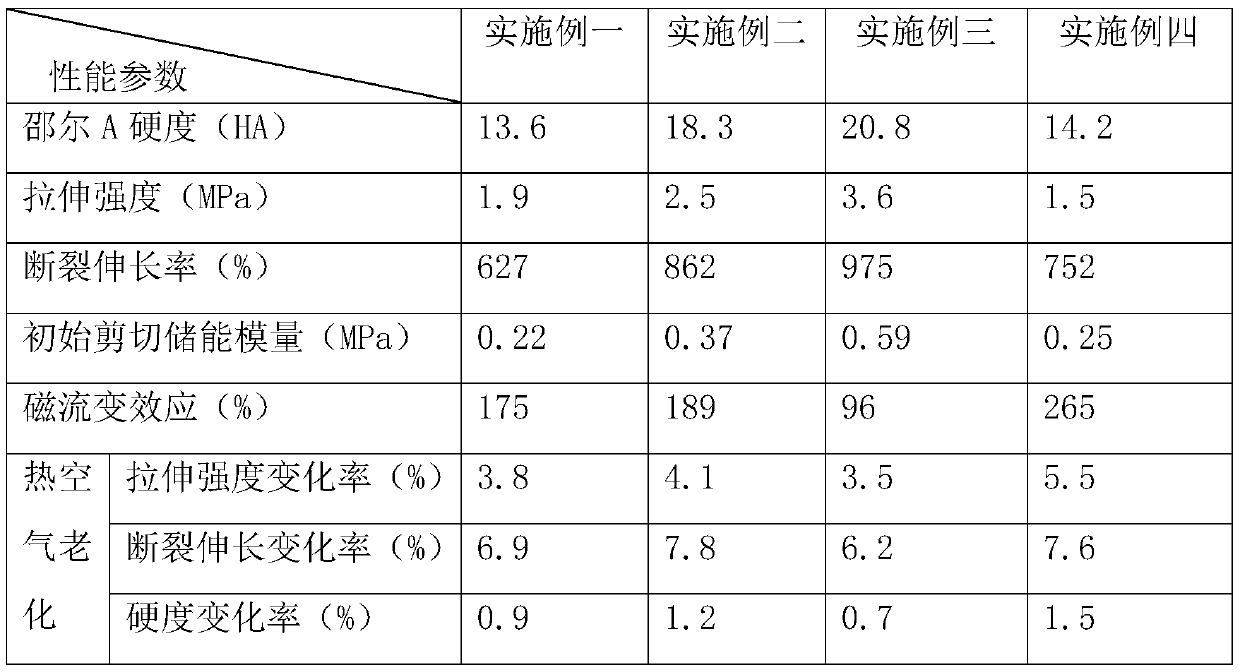

Examples

Embodiment 1

[0029] The mass fractions of each raw material component in the magnetorheological elastomer provided in this example are: EPDM rubber 5%, methyl vinyl silicone rubber 25%, modified carbonyl iron powder 60%, plasticizer 6% %, 1% silane coupling agent, 1% reinforcing particles, 1% anti-aging agent, 1% vulcanizing agent;

[0030] Wherein, the silane coupling agent is KH550 (γ-aminopropyltriethoxysilane), which can be replaced by KH560 (γ-(2,3-glycidyloxy)propyltrimethoxysilane) or KH570 (γ-methacryloxypropyltrimethoxysilane);

[0031] The plasticizer is paraffin oil, the reinforcing particles are a mixture of white carbon black and zinc oxide, the anti-aging agent is 2-mercaptobenzimidazole, and the vulcanizing agent is 2,5-dimethyl - Mixture of 2,5-bis(tert-butylperoxy)hexane and dicumyl peroxide.

[0032] In the present embodiment, the preparation method of the modified carbonyl iron powder comprises the following steps:

[0033] (1) Mix ethyl orthosilicate and absolute eth...

Embodiment 2

[0039]The mass fractions of the raw material components in the magnetorheological elastomer provided in this example are: 10% EPDM rubber, 20% methyl vinyl silicone rubber, 60% modified carbonyl iron powder, 60% plasticizer %, 1% silane coupling agent, 0.7% reinforcing particles, 0.3% anti-aging agent, 2% vulcanizing agent;

[0040] Wherein, the silane coupling agent is KH560 (γ-(2,3-glycidoxy)propyltrimethoxysilane), which can be replaced by KH550 (γ-aminopropyltriethoxysilane) or KH570 (γ-methacryloxypropyltrimethoxysilane);

[0041] The plasticizer is paraffin oil, the reinforcing particles are a mixture of white carbon black and zinc oxide, the anti-aging agent is 2-mercaptobenzimidazole, and the vulcanizing agent is 2,5-dimethyl - Mixture of 2,5-bis(tert-butylperoxy)hexane and dicumyl peroxide.

[0042] In the present embodiment, the preparation method of the modified carbonyl iron powder comprises the following steps:

[0043] (1) Mix ethyl orthosilicate and absolute ...

Embodiment 3

[0049] The mass fractions of the raw material components in the magnetorheological elastomer provided in this example are: EPDM rubber 15%, methyl vinyl silicone rubber 15%, modified carbonyl iron powder 60%, plasticizer 6% %, 1% silane coupling agent, 0.7% reinforcing particles, 0.3% anti-aging agent, 2% vulcanizing agent;

[0050] Wherein, the silane coupling agent is KH570 (γ-methacryloxypropyltrimethoxysilane), which can be replaced by KH550 (γ-aminopropyltriethoxysilane) or KH560 (γ-( 2,3-Glycidoxy)propyltrimethoxysilane);

[0051] The plasticizer is paraffin oil, the reinforcing particles are a mixture of zinc oxide and white carbon black, the anti-aging agent is 2-mercaptobenzimidazole, and the vulcanizing agent is 2,5-dimethyl - Mixture of 2,5-bis(tert-butylperoxy)hexane and dicumyl peroxide.

[0052] In the present embodiment, the preparation method of the modified carbonyl iron powder comprises the following steps:

[0053] (1) Mix ethyl orthosilicate and absolute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com