Preparation method of magnetorheological elastomer with high heat resistance and good tensile property

A magnetorheological elastomer, high heat resistance technology, applied in the direction of magnetic objects, magnetic materials, circuits, etc., can solve the problems affecting the mechanical strength and stability of magnetorheological elastomer, non-polar molecular chain, low magnetorheological effect and other problems, to achieve the effect of enhancing the pre-structural effect, improving the compatibility, and outstanding weather resistance and heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

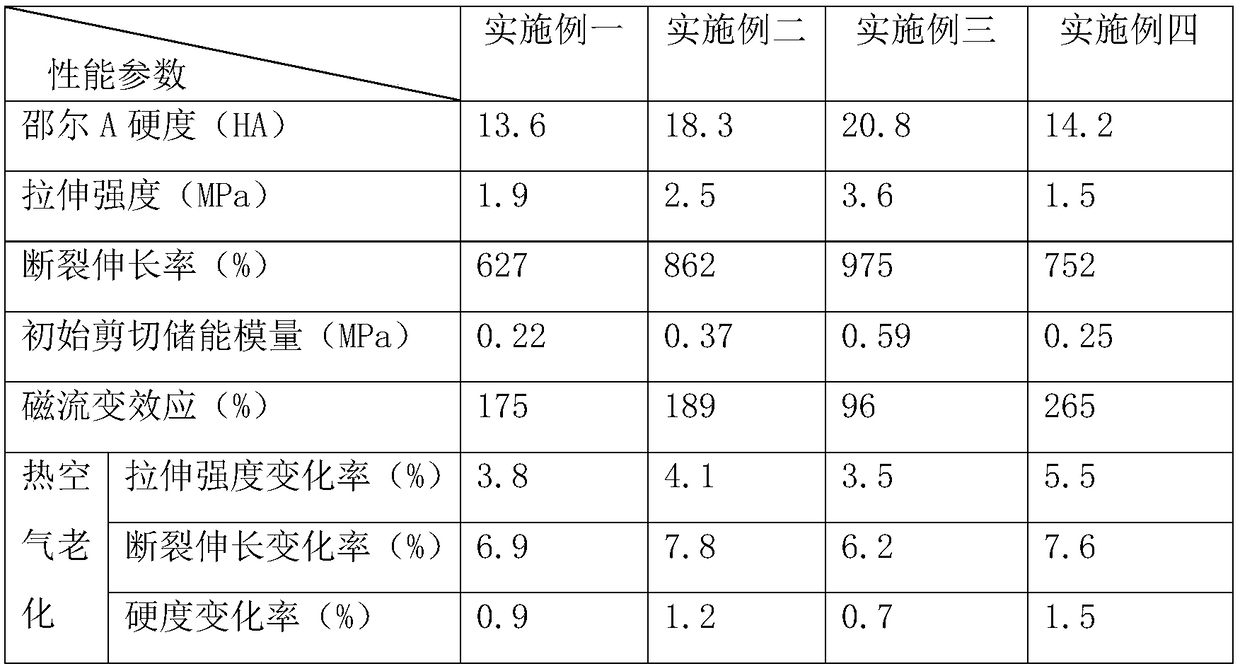

Examples

Embodiment 1

[0029] The mass fractions of each raw material component in the magnetorheological elastomer provided in this example are: EPDM rubber 5%, methyl vinyl silicone rubber 25%, modified carbonyl iron powder 60%, plasticizer 6% %, 1% silane coupling agent, 1% reinforcing particles, 1% anti-aging agent, 1% vulcanizing agent;

[0030] Wherein, the silane coupling agent is KH550 (γ-aminopropyltriethoxysilane), which can be replaced by KH560 (γ-(2,3-glycidyloxy)propyltrimethoxysilane) or KH570 (γ-methacryloxypropyltrimethoxysilane);

[0031] The plasticizer is paraffin oil, the reinforcing particles are a mixture of white carbon black and zinc oxide, the anti-aging agent is 2-mercaptobenzimidazole, and the vulcanizing agent is 2,5-dimethyl - Mixture of 2,5-bis(tert-butylperoxy)hexane and dicumyl peroxide.

[0032] In the present embodiment, the preparation method of the modified carbonyl iron powder comprises the following steps:

[0033] (1) Mix ethyl orthosilicate and absolute eth...

Embodiment 2

[0039]The mass fractions of the raw material components in the magnetorheological elastomer provided in this example are: 10% EPDM rubber, 20% methyl vinyl silicone rubber, 60% modified carbonyl iron powder, 60% plasticizer %, 1% silane coupling agent, 0.7% reinforcing particles, 0.3% anti-aging agent, 2% vulcanizing agent;

[0040] Wherein, the silane coupling agent is KH560 (γ-(2,3-glycidoxy)propyltrimethoxysilane), which can be replaced by KH550 (γ-aminopropyltriethoxysilane) or KH570 (γ-methacryloxypropyltrimethoxysilane);

[0041] The plasticizer is paraffin oil, the reinforcing particles are a mixture of white carbon black and zinc oxide, the anti-aging agent is 2-mercaptobenzimidazole, and the vulcanizing agent is 2,5-dimethyl - Mixture of 2,5-bis(tert-butylperoxy)hexane and dicumyl peroxide.

[0042] In the present embodiment, the preparation method of the modified carbonyl iron powder comprises the following steps:

[0043] (1) Mix ethyl orthosilicate and absolute ...

Embodiment 3

[0049] The mass fractions of the raw material components in the magnetorheological elastomer provided in this example are: EPDM rubber 15%, methyl vinyl silicone rubber 15%, modified carbonyl iron powder 60%, plasticizer 6% %, 1% silane coupling agent, 0.7% reinforcing particles, 0.3% anti-aging agent, 2% vulcanizing agent;

[0050] Wherein, the silane coupling agent is KH570 (γ-methacryloxypropyltrimethoxysilane), which can be replaced by KH550 (γ-aminopropyltriethoxysilane) or KH560 (γ-( 2,3-Glycidoxy)propyltrimethoxysilane);

[0051] The plasticizer is paraffin oil, the reinforcing particles are a mixture of zinc oxide and white carbon black, the anti-aging agent is 2-mercaptobenzimidazole, and the vulcanizing agent is 2,5-dimethyl - Mixture of 2,5-bis(tert-butylperoxy)hexane and dicumyl peroxide.

[0052] In the present embodiment, the preparation method of the modified carbonyl iron powder comprises the following steps:

[0053] (1) Mix ethyl orthosilicate and absolute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com