Elastic polyester fiber with low melting point and preparation method of elastic polyester fiber

An elastic polyester, low melting point technology, applied in the field of polyester fiber, can solve the problem of fiber sticking phenomenon and high aldehyde content, achieve the effect of low cost, improve fiber softness, and avoid sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

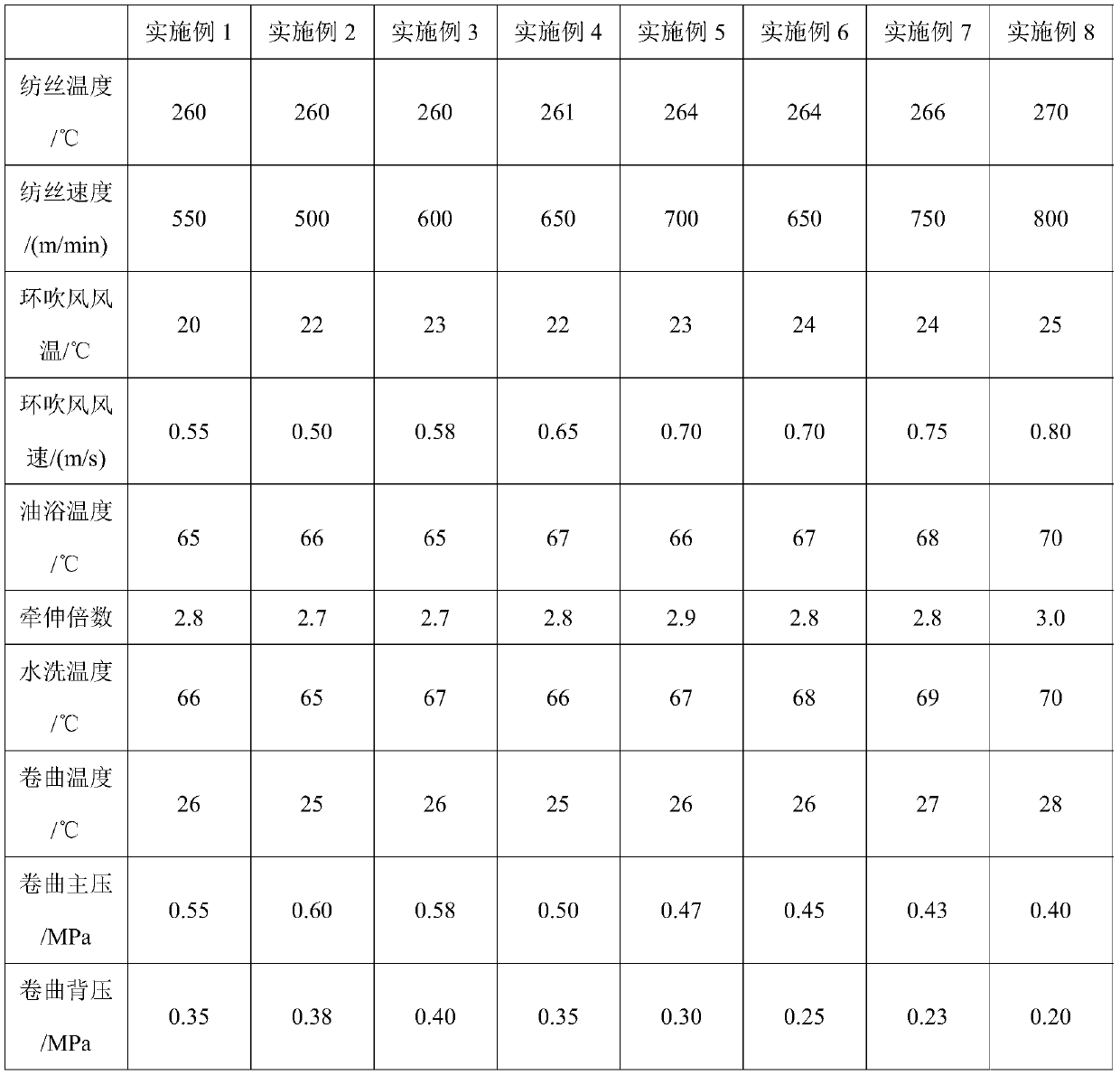

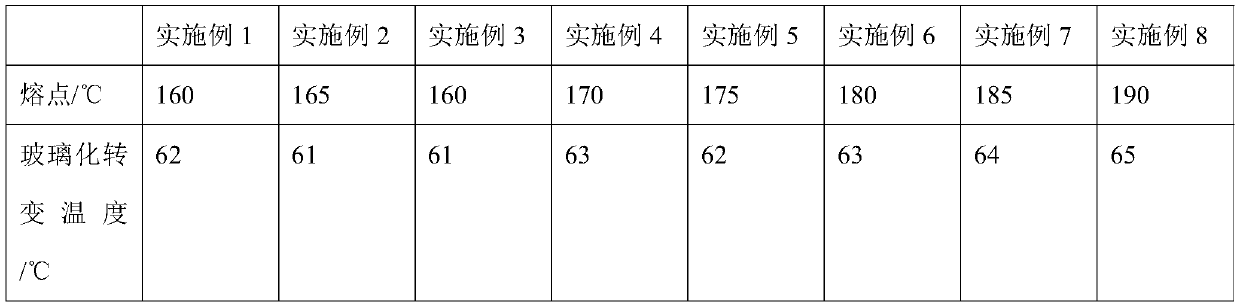

Embodiment 1

[0051] A kind of low melting point elastic polyester fiber, its preparation process is basically as follows:

[0052] (1) esterification reaction;

[0053] Phthalic acid (terephthalic acid and isophthalic acid), ethylene glycol, polytetrahydrofuran with a number average molecular weight of 1500, calcium isophthalate sulfonate and polybutylene adipate with a number average molecular weight of 500 After the ester is made into a slurry, it is reacted at a temperature of 180 ° C and a nitrogen atmosphere until the water distillate reaches 90% of the theoretical value; among them, terephthalic acid, isophthalic acid, ethylene glycol and isophthalic acid sulfonic acid The molar ratio of calcium acid is 1:0.4:1.5:0.01, and the mass addition of polytetrahydrofuran is 20% of the mass addition of phthalic acid (that is, the sum of the mass additions of terephthalic acid and isophthalic acid). The mass add-on of butylene adipate is 3% of the mass add-on of phthalic acid;

[0054] (2) p...

Embodiment 2

[0066] A kind of low melting point elastic polyester fiber, its preparation process is basically as follows:

[0067] (1) esterification reaction;

[0068] Phthalic acid (terephthalic acid and isophthalic acid), ethylene glycol, polytetrahydrofuran with a number average molecular weight of 1600, zinc isophthalate sulfonate, and polytrimethylene adipate with a number average molecular weight of 600 were formulated. After the slurry is formed, the reaction is carried out at a temperature of 200 ° C and a nitrogen atmosphere until the water distillate reaches 92% of the theoretical value; among them, terephthalic acid, isophthalic acid, ethylene glycol and isophthalic acid zinc sulfonate The molar ratio is 1:0.5:1.7:0.01, the mass add-on of polytetrahydrofuran is 23% of the mass add-on of phthalic acid, and the mass add-on of polytrimethylene adipate is 3.5% of the mass add-on of phthalic acid;

[0069] (2) polycondensation reaction;

[0070] In the system of step (1), add n-bu...

Embodiment 3

[0075] A kind of low melting point elastic polyester fiber, its preparation process is basically as follows:

[0076] (1) esterification reaction;

[0077] After mixing phthalic acid (terephthalic acid and isophthalic acid), ethylene glycol, polytetrahydrofuran with a number average molecular weight of 1650, magnesium isophthalate sulfonate and 1,5-pentanediol into a slurry, The reaction was carried out at a temperature of 198 ° C and a nitrogen atmosphere until the water distillate reached 95% of the theoretical value; wherein, the molar ratio of terephthalic acid, isophthalic acid, ethylene glycol and magnesium isophthalate sulfonate was 1 : 0.6:1.8:0.03, the mass addition of polytetrahydrofuran is 25% of the mass addition of phthalic acid, and the mass addition of 1,5-pentanediol is 25% of the mass addition of phthalic acid;

[0078] (2) polycondensation reaction;

[0079] In the system of step (1), add n-butyl titanate and trimethyl phosphite, and react for 30min under t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com