Technology for producing fibers from bamboo charcoal micropowder and polylactic acid slices

A technology of bamboo charcoal micropowder and fiber technology, which is applied in the directions of fiber chemical characteristics, melt spinning, rayon manufacturing, etc., can solve the problems of high polymer melt viscosity, affecting the use effect, affecting the spinning quality, etc. The effect of rising moisture regain, cost saving and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

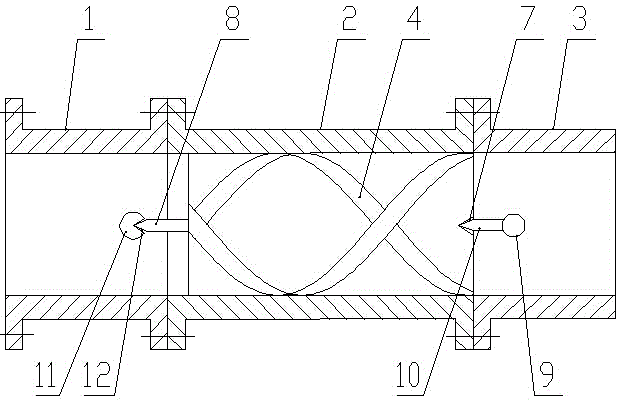

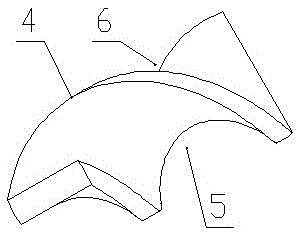

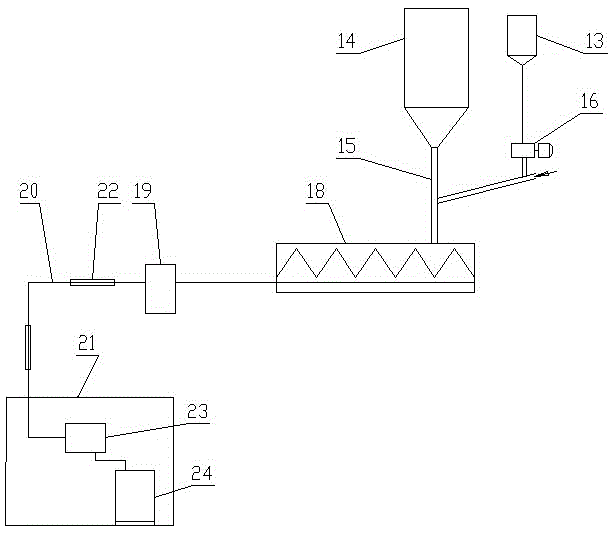

[0024] Such as figure 1 , figure 2 with image 3 Shown, bamboo charcoal micropowder polylactic acid chip production fiber technology of the present invention may further comprise the steps:

[0025] (1) Store the dried bamboo charcoal micropowder in the first silo 13, and store the dry slices of polylactic acid in the second silo 14. The bottom of the second silo 14 passes through the feeding pipe 15 and the spinning screw extruder 18 feed port connections;

[0026] (2), the bamboo charcoal micropowder in the first silo 13 falls into the toner meter 16 by gravity, and the toner meter 16 measures the bamboo charcoal micropowder; the polylactic acid dry slices in the second hopper 14 rely on gravity While falling in the feeding pipe 15, utilize dry compressed air ( figure 1 Shown by the middle arrow) the bamboo charcoal micropowder measured by the toner meter 16 is blown into the feeding pipe 15, and the bamboo charcoal micropowder falls into the spinning screw extruder 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com