Low-temperature softening treatment method for jute fibers

A treatment method and hemp fiber technology, applied in the field of natural polymer chemistry, can solve the problems of loss of crispness and roughness, fiber damage, and easy generation of ammonia gas, etc., and achieve the effects of improved dyeing performance, reduced fiber stiffness, and reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

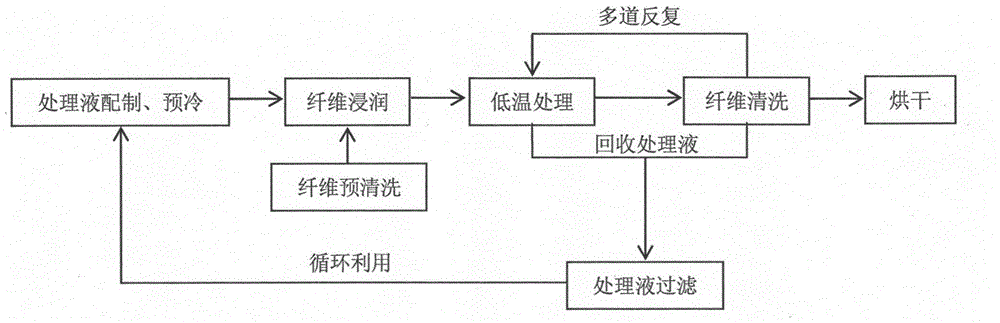

[0021] A kind of hemp fiber low-temperature softening treatment method, concrete steps are: as figure 1 As shown, the ramie fiber is pre-washed with water to remove surface impurities, and then softened and dried to obtain the softened ramie fiber; the softened treatment includes mixing ramie with a bath ratio of 1:24 The fiber is soaked in the softening treatment liquid, and the softening treatment liquid is made up of sodium hydroxide, urea and water, the concentration of sodium hydroxide is 7wt%, the concentration of urea is 12wt%, precooling to 4 ℃, at low temperature The ramie fiber was processed under the condition of -10°C and 30min, and the temperature was raised to 25°C. The fiber was first cleaned with a softening treatment solution, then washed with water, and dried at 50°C to obtain a cotton-feeling flexible ramie fiber. The above-mentioned softening treatment liquid is filtered and recycled.

Embodiment 2

[0023] A kind of hemp fiber low-temperature softening treatment method, concrete steps are: as figure 1 As shown, the flax fiber is pre-cleaned with water to remove surface impurities, and then softened in three steps, and then dried to obtain the softened flax fiber; each softening process includes making the flax fiber Soaked in the softening treatment solution, the softening treatment solution is composed of sodium hydroxide, thiourea and water, the concentration of sodium hydroxide is 5.5wt%, the concentration of thiourea is 13.5wt%, pre-cooled to -15 ℃, in a low temperature state, the treatment temperature is -80 ℃, the treatment time is 1h, take it out, raise the temperature to 30 ℃, wash with water, and dry at 50 ℃ to obtain cotton-like flexible flax fibers, and the tingling feeling of flax fibers has been significantly reduced improve. The softening treatment liquid is filtered and recycled.

Embodiment 3

[0025] A kind of hemp fiber low-temperature softening treatment method, concrete steps are: as figure 1 As shown, the ramie fiber was pre-cleaned with water to remove surface impurities, and five softening treatments were performed, followed by drying to obtain the softened ramie fiber; each softening treatment included mixing the ramie fiber with a bath ratio of 1:24 Soaked in the softening treatment solution, the softening treatment solution is composed of sodium hydroxide, urea and water, the concentration of sodium hydroxide is 11wt%, the concentration of urea is 8wt%, pre-cooled to -15 ° C, at low temperature The processing temperature is -80°C, the processing time is 10min, take it out, heat up to 30°C, wash with water, and dry at 50°C to obtain cotton-like flexible ramie fibers, the fiber crystallinity decreases, the initial modulus decreases, and the hand feel Significant improvement. The softening treatment liquid is filtered and recycled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com