Acetate fiber monoazo dye mixture, as well as preparation method and applications thereof

A dye mixture and acetate fiber technology, applied in the field of dyes, can solve the problem of expensive imported dyes, and achieve the effects of wide range of uses, high color giving power and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

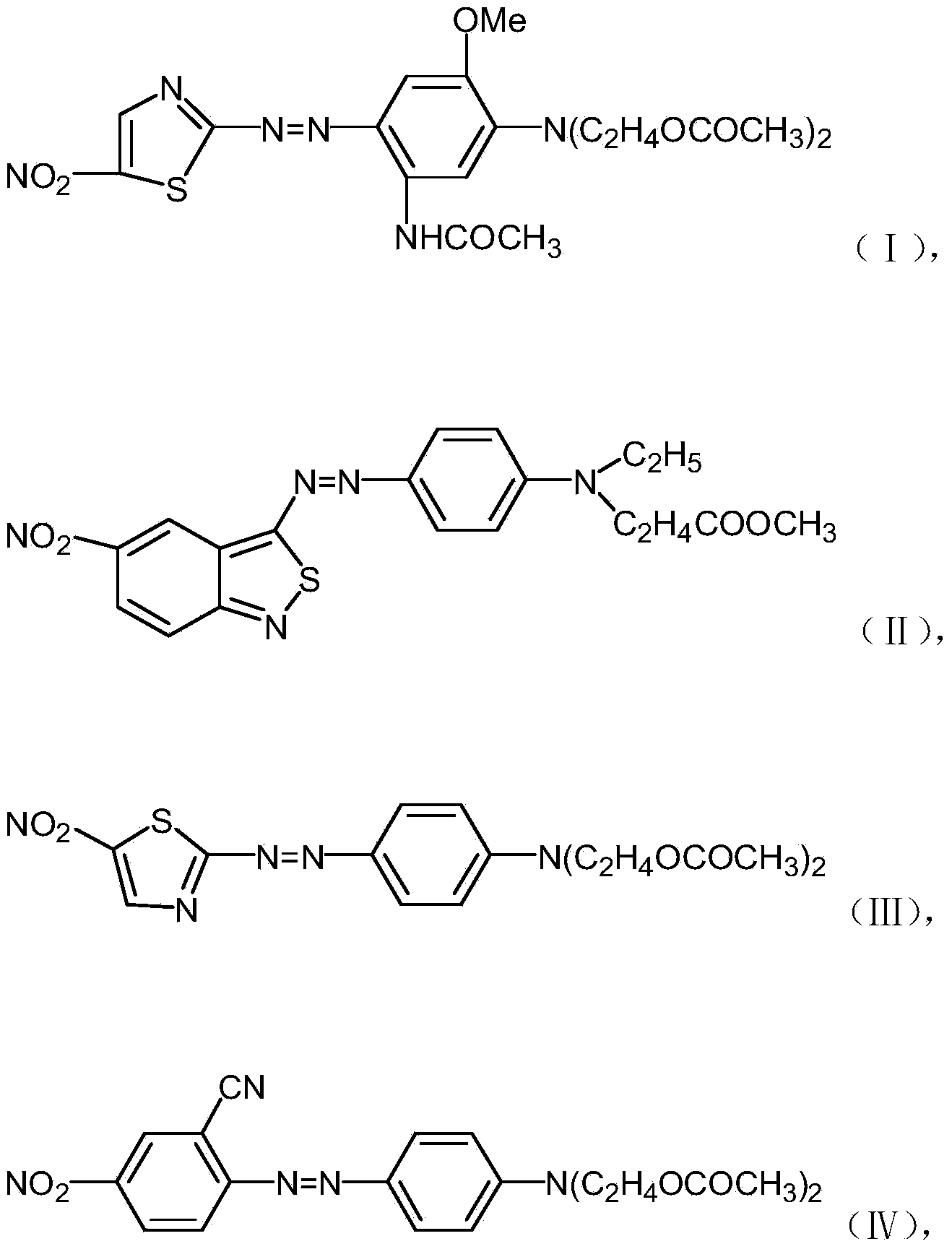

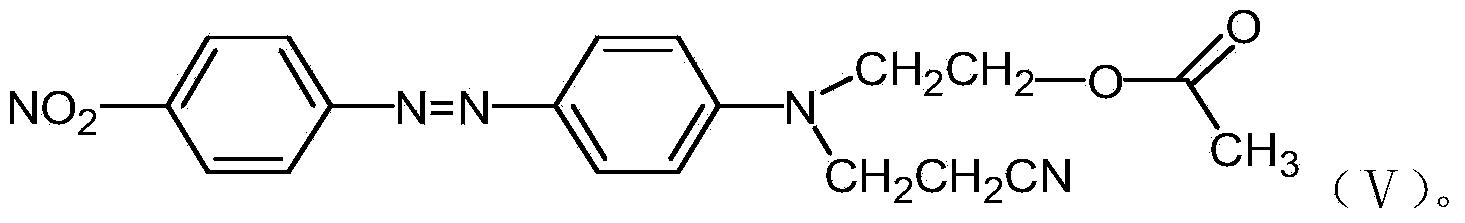

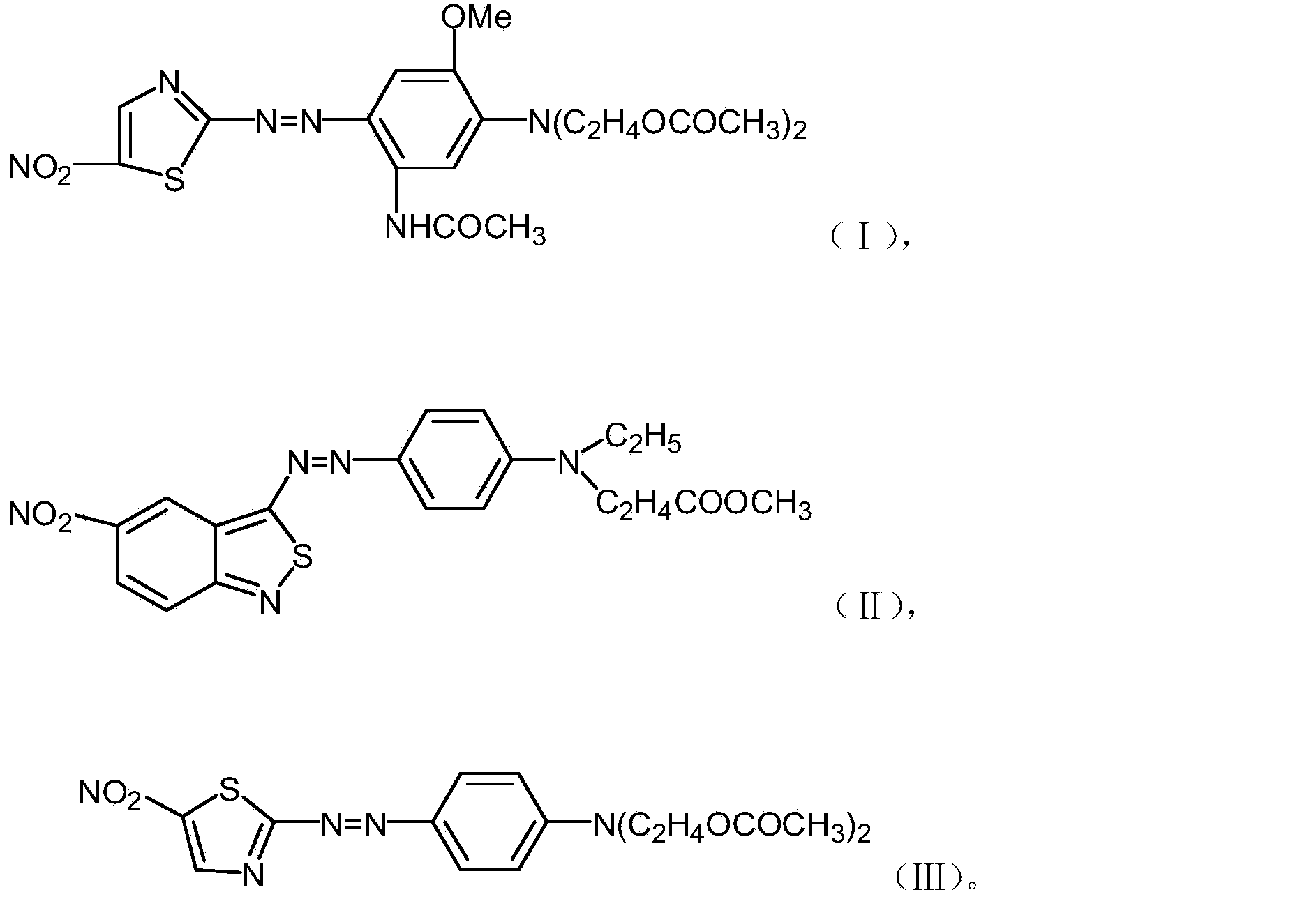

[0022] Based on the total mass of the monoazo dye mixture of acetate fiber, 10% of the compound A shown in the formula (I), 10% of the compound B shown in the formula (II), and 40% of the compound B shown in the formula (III) Shown compound C, the proportioning ratio of the remaining dispersant takes each component, wherein the dispersant is formed by mixing sodium methylnaphthalene sulfonate formaldehyde condensate and sodium lignin sulfonate in a mass ratio of 3:7, and then Mix the above-mentioned components evenly, add water to grind, and spray-dry the slurry obtained by grinding. The spray-drying process conditions are: inlet temperature 120°C, outlet temperature 50°C, after drying, acetate with a particle size of 0.1um is obtained. Mixture of fiber monoazo dyes.

[0023]

Embodiment 2

[0025] The difference between this embodiment and Example 1 is that each component is weighed according to the proportion of 20% compound A, 20% compound B, 30% compound C, and the remaining dispersant; Sodium naphthalene sulfonate formaldehyde condensate and sodium lignosulfonate are mixed at a mass ratio of 10:21; the spray drying process conditions are: inlet temperature 125°C, outlet temperature 55°C, and the particle size after drying is 0.5um The acetate fiber monoazo dye mixture, the rest is exactly the same.

Embodiment 3

[0027] The difference between this embodiment and Example 1 is that each component is weighed according to the proportion of 40% compound A, 5% compound B, 50% compound C, and the remaining dispersant; Sodium naphthalene sulfonate formaldehyde condensate and sodium lignosulfonate are mixed at a mass ratio of 2:3; the spray drying process conditions are: inlet temperature 130°C, outlet temperature 60°C, after drying, the particle size is 1um Acetate monoazo dye mixture, the rest is identical.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com