Method for dyeing modified polyester

A technology for modifying polyester and dyeing methods, applied in dyeing methods, textiles and papermaking, etc., can solve the problems of harsh operating conditions, unfavorable promotion and use, inability to achieve dyeing, etc. The effect of improving the elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

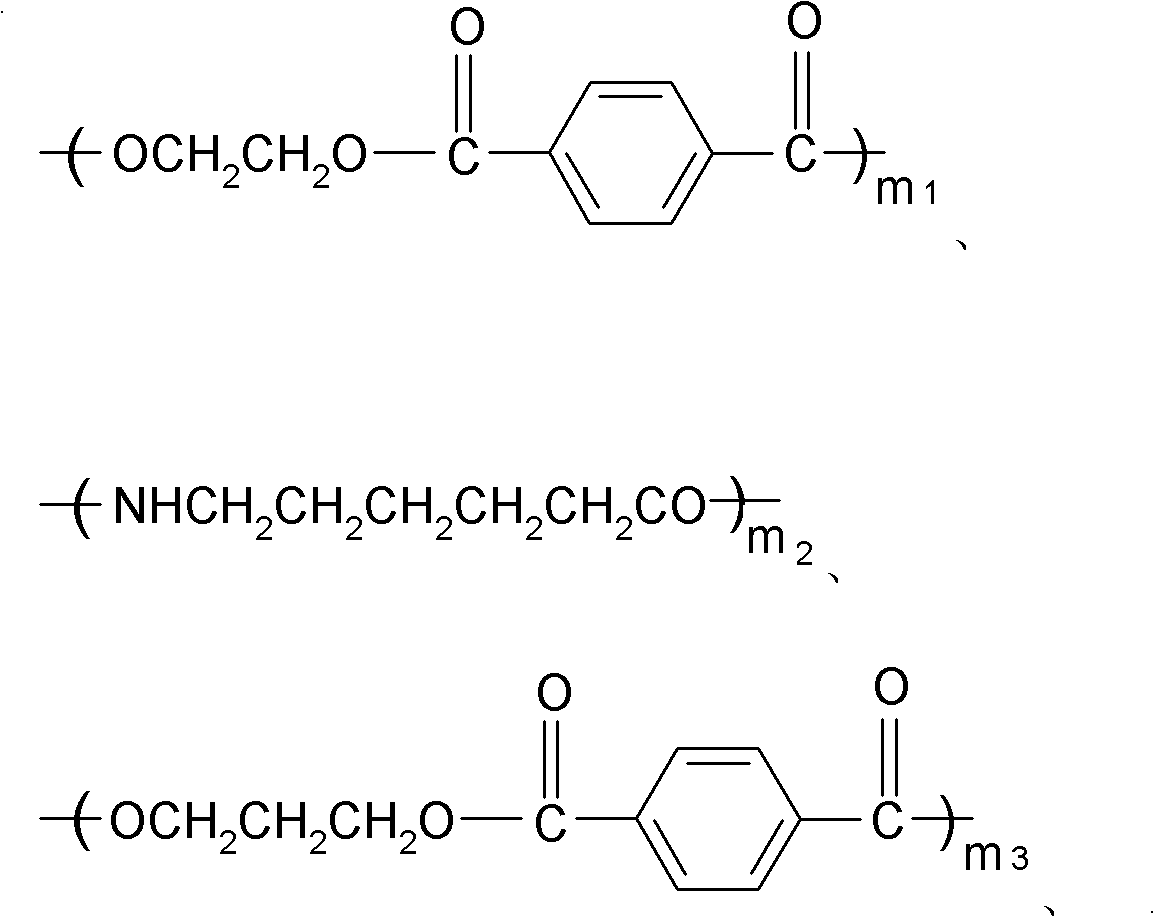

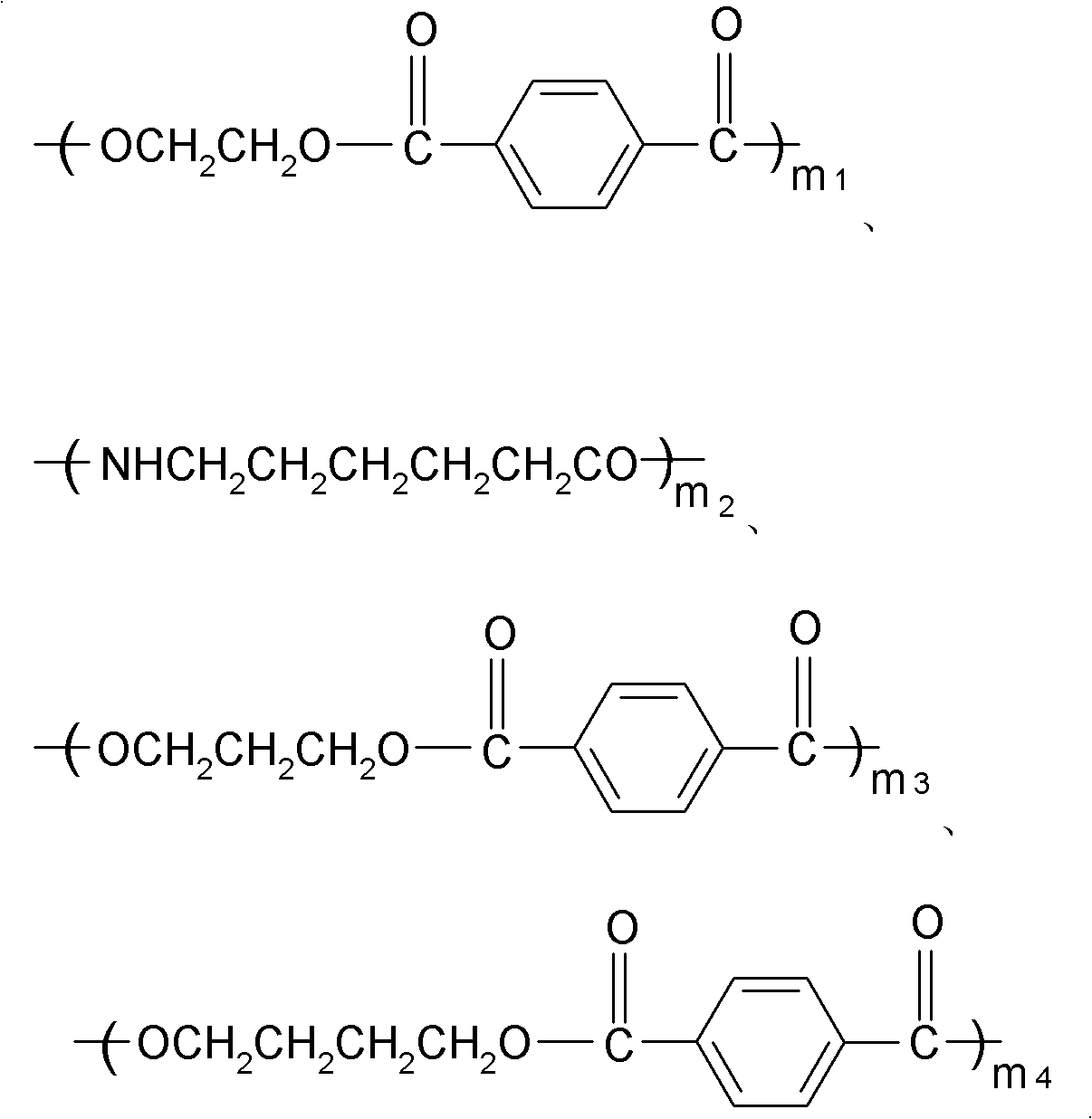

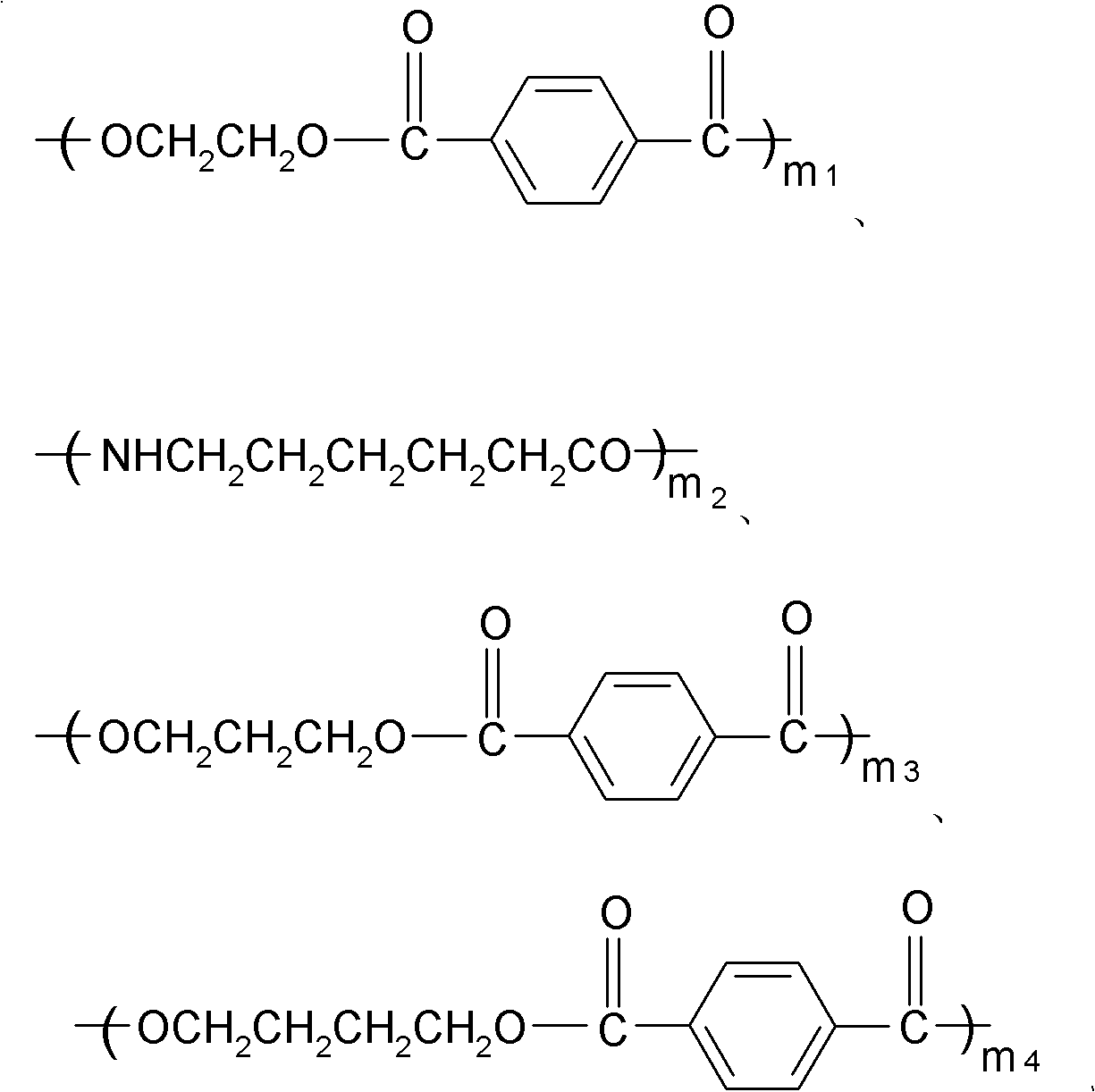

Method used

Image

Examples

Embodiment 1

[0072] The preparation of embodiment 1 modified polyester

[0073] 1) transesterification reaction

[0074] Add 800g of dimethyl terephthalate and 521g of ethylene glycol, 15g of diol and 25g of butanediol into the reaction kettle, then add 0.12g of tetrabutyl titanate as a catalyst to carry out transesterification reaction at 220°C, the reaction time For 40 minutes, when the fraction reaches 98% of the theoretical amount, the transesterification reaction is terminated to obtain the transesterification reaction product;

[0075] 2) Copolymerization reaction

[0076] Add 0.25g of tetrabutyl titanate polycondensation catalyst to the transesterification reaction product obtained in step 1), then raise the temperature to 230°C, add 63.4g of nylon 6 polymer with a relative viscosity of 1.5 for copolymerization reaction, when the temperature reaches 240°C , pump a high vacuum, keep the vacuum at 30Pa, continue to heat up to 255°C, and react for 5 hours. When the intrinsic viscosit...

Embodiment 2

[0077] The preparation of embodiment 2 modified polyester

[0078] 1) transesterification reaction

[0079] Add 600g of dimethyl terephthalate, 400g of ethylene glycol and 21g of propylene glycol into the reactor, then add 0.13g of tetrabutyl titanate as a catalyst to carry out transesterification reaction at 160°C, the reaction time is 90 minutes, and the fraction When reaching 98% of theoretical amount, end transesterification reaction, obtain transesterification reaction product;

[0080] 2) Copolymerization reaction

[0081] Add 0.26g of tetrabutyl titanate polycondensation catalyst to the transesterification reaction product obtained in step 1), then raise the temperature to 230°C, add 66.1g of nylon 6 polymer with a relative viscosity of 2.2 for copolymerization reaction, when the temperature reaches 250°C , pump a high vacuum, keep the vacuum at 100Pa, continue to heat up to 260°C, and react for 6 hours. When the intrinsic viscosity reaches 0.90dL / g, the material is d...

Embodiment 3

[0082] The preparation of embodiment 3 modified polyester

[0083] 1) transesterification reaction

[0084] Add 970g of dimethyl terephthalate, 682g of ethylene glycol and 19g of propylene glycol into the reaction kettle, then add 0.50g of tetrabutyl titanate as a catalyst to carry out transesterification reaction at 170°C, the reaction time is 60 minutes, and the fraction When reaching 98% of theoretical amount, end transesterification reaction, obtain transesterification reaction product;

[0085] 2) Copolymerization reaction

[0086] Add 0.34g of tetrabutyl titanate polycondensation catalyst to the transesterification product obtained in step 1), then raise the temperature to 230°C, add 168.3g of nylon 6 polymer with a relative viscosity of 1.7 for copolymerization, when the temperature reaches 248°C , pump high vacuum, keep the vacuum degree at 60Pa, continue to heat up to 256°C, and react for 6.5 hours. When the intrinsic viscosity reaches 0.88dL / g, the material is disc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com