High-efficiency phase change energy storage microcapsule with thermochromic function, and preparation method thereof

A phase-change energy storage, thermochromic technology, applied in microcapsule preparation, microsphere preparation, color-changing fluorescent materials, etc., can solve the problems of poor heat storage capacity, limited content, no heat storage performance, etc. Value, easy control, high yield of microcapsules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

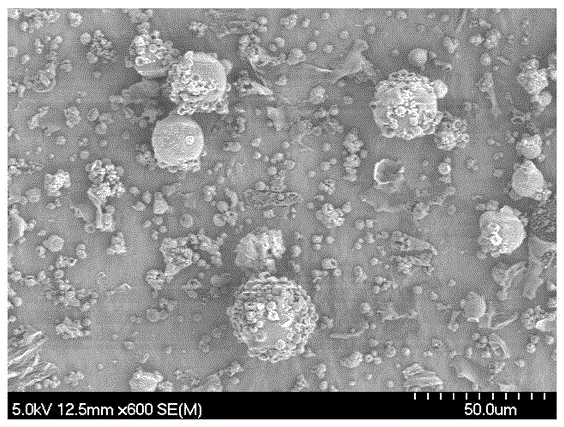

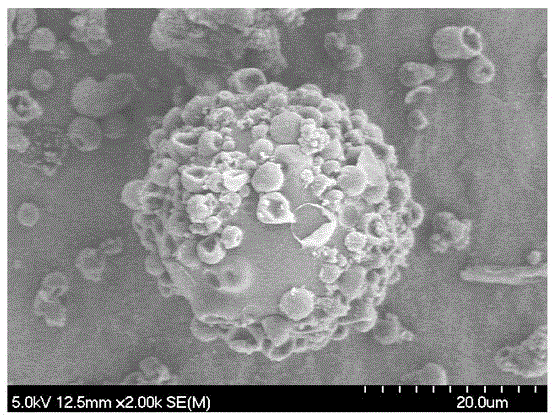

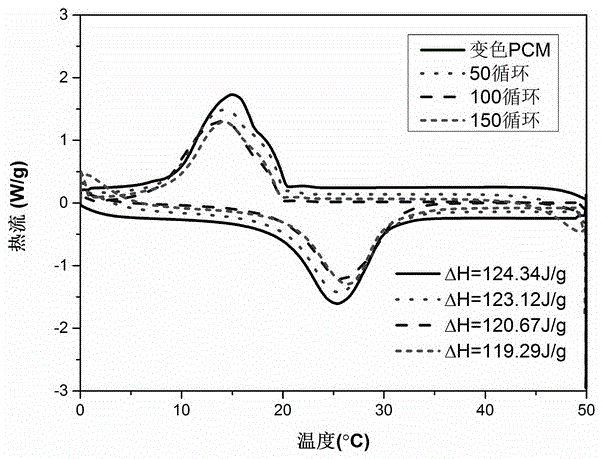

Image

Examples

Embodiment 1

[0034]1) Weigh 2g of rose red thermochromic powder with a discoloration temperature of 20°C and add it to 100ml of alcohol-water (volume ratio 9:1) solution, ultrasonically disperse for 10min, then adjust the pH value to 5.5 with acetic acid, and stir magnetically for 40min. Raise the temperature to 50°C, slowly add 5g of γ-methacryloxypropyltrimethoxysilane (KH570) dropwise, react for 1.5h under stirring at 700rpm, finally filter, wash and dry to obtain surface-modified thermochromic powder .

[0035] 2) Heat 8g of n-octadecane to melt, then add 0.3g of the modified thermochromic powder obtained in step 1) and 7g of methyl methacrylate, stir and mix, and ultrasonically disperse for 15 minutes to form an oil phase.

[0036] 3) Stir and mix 100g of deionized water and 7g of styrene-maleic anhydride copolymer to form a water phase.

[0037] 4) Add the oil phase formed in step 2) to the water phase formed in step 3) at 40°C,

[0038] Emulsify for 15 minutes under stirring at 10...

Embodiment 2

[0043] 1) Weigh 1g of rose red thermochromic powder with a color change temperature of 30°C and add it to 100ml of alcohol-water (volume ratio 7:1) solution, ultrasonically disperse for 15min, then adjust the pH value to 7 with acetic acid, and stir magnetically for 30min. Raise the temperature to 40°C, slowly add 3g of γ-(2,3-glycidoxy)propyltrimethoxysilane (KH560) dropwise, react for 1h under stirring at 800rpm, finally filter, wash and dry to obtain surface modification Thermochromic powder.

[0044] 2) Heat 10g of n-octadecane to melt, then add 0.5g of the modified thermochromic powder obtained in step 1) and 8g of methyl methacrylate, stir and mix, and ultrasonically disperse for 10 minutes to form an oil phase.

[0045] 3) Stir and mix 100 g of deionized water, 3 g of styrene-maleic anhydride copolymer, and 2.5 g of sodium dodecylbenzene sulfate to form a water phase.

[0046] 4) Add the oil phase formed in step 2) to the water phase formed in step 3) at 40°C, and emul...

Embodiment 3

[0050] 1) Weigh 1g of blue thermochromic powder with a discoloration temperature of 30°C and add it to 100ml of alcohol-water (volume ratio 9:1) solution, ultrasonically disperse for 10min, then adjust the pH value to 7 with acetic acid, and stir magnetically for 30min. Increase the temperature to 60°C, slowly add 3g of isopropoxy distearate acyloxyaluminate (DL-411-A), react for 1h under stirring at 600rpm, finally filter, wash and dry to obtain surface modification Thermochromic powder.

[0051] 2) Heat 8g of n-butyl stearate to melt, then add 1g of the modified thermochromic powder obtained in step 1) and 10g of methyl methacrylate, stir and mix, and ultrasonically disperse for 10 minutes to form an oil phase.

[0052] 3) Stir and mix 100g of deionized water and 7g of styrene-maleic anhydride copolymer to form a water phase.

[0053] 4) Add the oil phase formed in step 2) to the water phase formed in step 3) at 40°C, and emulsify for 15 minutes under stirring at 1000 rpm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com