Water-soluble color chain extender, copolymerization type colored polyurethane emulsion and colored polyurethane-acrylic ester copolymer emulsion, and preparation methods thereof

A technology of polyurethane emulsion and polyurethane prepolymer, which is applied in the fields of water-soluble color chain extender, copolymerized color polyurethane emulsion and color polyurethane-acrylate copolymer emulsion and its preparation, and can solve the synthesis steps and purification process of color chain extender Complicated, the reaction is difficult to be called green, economical, and limited color types, etc., to achieve the effect of a wide variety of colors, low cost, and complete color spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

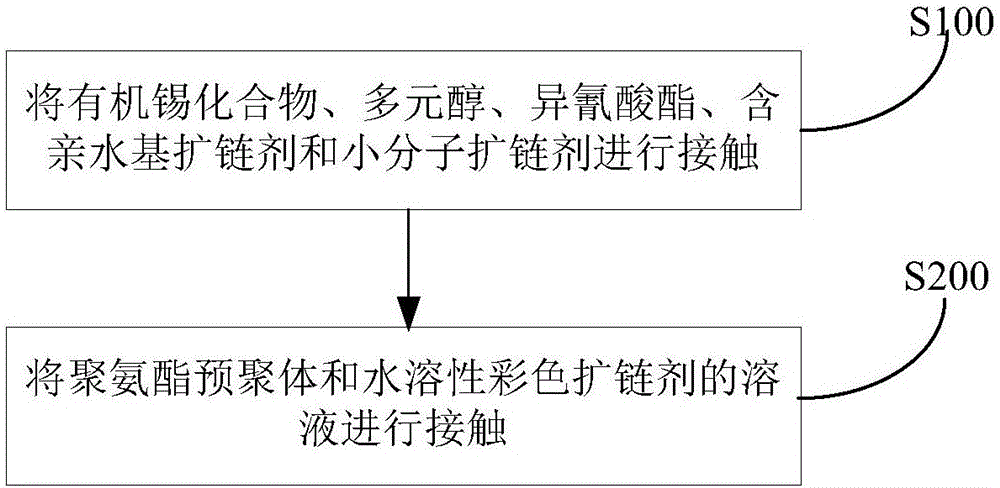

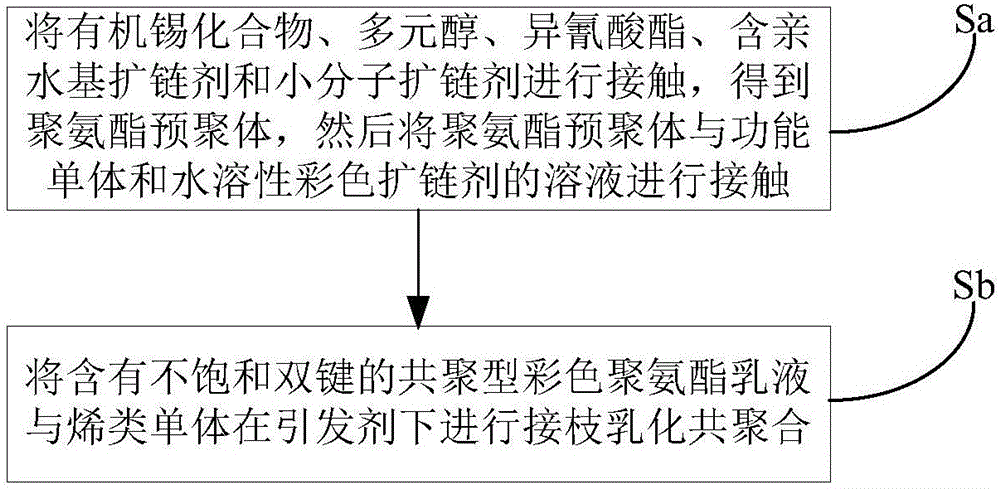

Method used

Image

Examples

Embodiment 1

[0111] Embodiment 1—Water-soluble red chain extender (I)

[0112] 5.62 grams of reactive red 22 (562 grams / mole), 3 grams of ethylenediamine and 40 grams of water were added to a 100 milliliter three-necked flask, stirred and mixed evenly, then heated up to 30°C, reacted for 5 hours and evaporated under reduced pressure at 50°C Remove water, wash with 100 milliliters of absolute ethanol, filter after standing, wash the filter cake three times with absolute ethanol, and vacuum-dry the filter cake to obtain the water-soluble red chain extender (I).

[0113] The above equation for preparing the water-soluble red chain extender is as follows:

[0114]

Embodiment 2

[0115] Embodiment 2—copolymerization type red polyurethane emulsion

[0116] (1) Add 50 grams of polyether polyol N210 and 33 grams of isophorone diisocyanate into a three-necked flask, stir and heat to set 80°C and react for 3 hours;

[0117] (2) Add 0.05 grams of dibutyltin dilaurate, 5.4 grams of dimethylol propionic acid, and 4.8 grams of butanediol into a three-necked flask for chain extension reaction, and continue the reaction at 80°C for 4 hours;

[0118] (3) Cool the above prepolymer to 40°C, add 4 grams of triethylamine and react for 30 minutes, while adding 8 milliliters of acetone to stir and reduce viscosity;

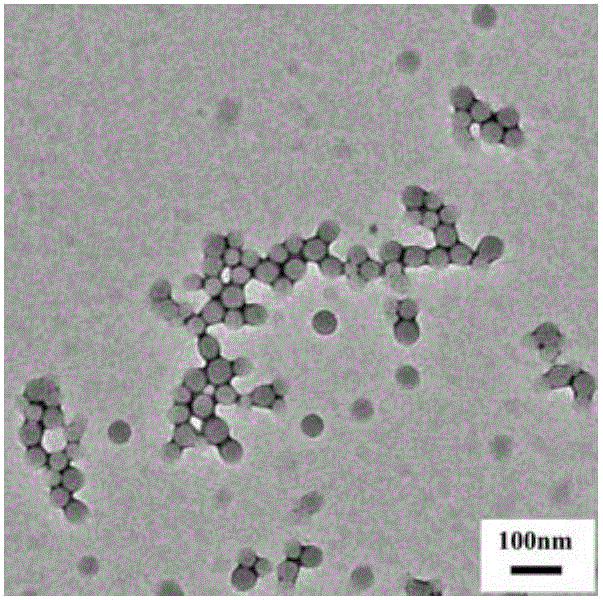

[0119] (4) Dissolve 1.5 grams of water-soluble red chain extender (I) in 180 ml of water, then add it to the polyurethane prepolymer that has been cooled to 25°C, stir vigorously to disperse and extend the chain, and remove it by distillation under reduced pressure Acetone, obtain copolymerization type red polyurethane emulsion, gained copolymerization typ...

Embodiment 3

[0120] Embodiment 3—copolymerization type red polyurethane-acrylate copolymer emulsion

[0121] (1) Add 30 grams of polycarbonate diol (molecular weight: 2000) and 12 grams of 1,6-hexamethylene diisocyanate into a three-necked flask, stir and heat to 80°C and react for 2 hours, then add 0.1 grams of dilaurel Dibutyltin dibutyltin, 2.22 grams of dimethylol butyric acid, 0.9 grams of 1,6-hexanediol, reacted at 80 ° C for 4 hours;

[0122] (2) Cool the prepolymer to 70°C, then add 1.42 g of N,N-bis(2-hydroxyethyl)acrylamide, and continue the reaction for 2 hours;

[0123] (3) Cool the prepolymer to 30°C, add a mixture of 3 g of styrene and 1 g of butyl acrylate, stir to reduce viscosity, then add 1.52 g of triethylamine to form a salt for neutralization, and react for 20 minutes;

[0124] (4) Dissolve 0.2 g of water-soluble red chain extender (I) in 88 ml of water, then add it to the prepolymer that has been cooled to 25°C, and stir for 40 minutes to obtain water-based polyureth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com