One-bath one-step dyeing method for polyester/cotton blended fabric

A dyeing method and cotton blending technology, applied in the field of textile printing and dyeing, can solve the problems of insufficient chromatogram and limited variety of dyes, and achieve the effects of short technological process, low cost and wide source.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

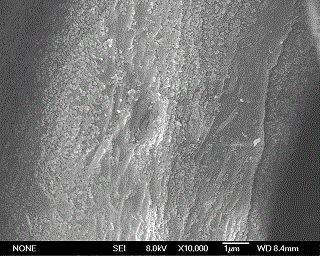

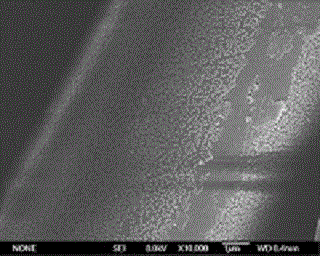

Image

Examples

Embodiment 1

[0013] Polystyrene-ethyl acrylate-p-vinylbenzyl trimethacrylate prepared by double-dipping and double-rolling 0.10g / L soap-free emulsion polymerization of polyester / cotton blended fabric (T / C, 65 / 35) at 30°C Hydroxyl ammonium chloride dispersion, the liquid carrying rate is 40%, the pH of the dispersion is 6-7, dried, washed and dried; the treated fabric is dyed by padding with 0.10g / L acid red A dye solution, dried , baked at 120°C for 30 seconds, then washed with water to remove floating color, and dried.

Embodiment 2

[0015] Pad the polyester / cotton blended fabric (T / C, 50 / 50) with 0.10g / L, 0.20g / L, 0.50g / L, 0.75g / L, 1.00g / L, 1.50 g / L polystyrene-butyl acrylate-p-vinylbenzyltrimethylammonium chloride dispersion, with a liquid retention rate of 60%, dried, then washed with water and dried. The treated fabrics were respectively padded with 0.50g / L acid orange II dye solution, the liquid retention rate was 30%, dried, baked at 140°C for 120 seconds, then washed with water to remove floating color, and dried.

Embodiment 3

[0017] Prepare a polystyrene-ethyl acrylate-p-vinylbenzyltrimethylammonium chloride dispersion with a pH of 6-7 and a concentration of 5g / L, and use this dispersion to pad the polyester / cotton blended fabric (T / C , 70 / 30), the liquid-carrying rate was 60%, dried, washed and dried; the treated fabric was padded with 1g / L acid blue R solution, the liquid-carrying rate was 40%, and baked at 140°C for 90 Seconds, then wash to remove floating color and dry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com