Application of ultrasonic technology to hemp fiber dyeing

A technology of ultrasonic wave and hemp fiber, which is applied in the application field of ultrasonic technology in textile dyeing, can solve the problems of shortening the dyeing time, and the utilization needs to be developed and researched, so as to achieve the effect of improving the dyeing rate, bright color and good fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

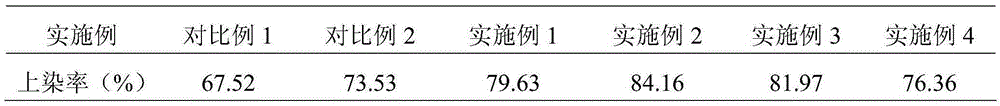

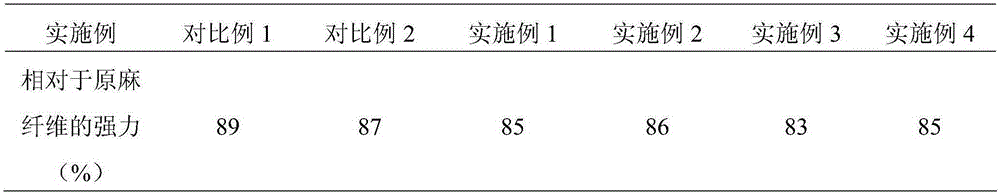

[0024] Embodiment 1: ultrasonic process

[0025] Soak the hemp fiber in 10wt% sodium hydroxide solution for 1 hour at room temperature. After taking it out, wash it with water and dry it for later use.

[0026] Weigh 0.02g of Reactive Brilliant Blue KN-R and dissolve it in 50mL of water, soak the pre-treated hemp fiber in the dye solution at 50°C, add 2g of sodium chloride, treat it under ultrasonic conditions for 30min, and then 90 ℃, add 1g of sodium carbonate, and fix the color at this temperature for 10 minutes. After dyeing, take out the hemp fiber, wash with soap, water, and dry.

Embodiment 2

[0027] Embodiment 2: ultrasonic process

[0028] Soak the hemp fiber in 10wt% sodium hydroxide solution for 1 hour at room temperature. After taking it out, wash it with water and dry it for later use.

[0029] Weigh 0.02g of Reactive Brilliant Blue KN-R and dissolve it in 50mL of water, soak the pre-treated hemp fiber in the dye solution at 50°C, add 2g of sodium chloride, treat it under ultrasonic conditions for 30min, and then 90 ℃, add 1g of sodium carbonate, and fix the color at this temperature for 30 minutes. After dyeing, take out the hemp fiber, wash with soap, water, and dry.

Embodiment 3

[0030] Embodiment 3: ultrasonic process

[0031] Soak the hemp fiber in 10wt% sodium hydroxide solution for 1 hour at room temperature. After taking it out, wash it with water and dry it for later use.

[0032] Weigh 0.02g of Reactive Brilliant Blue KN-R and dissolve it in 50mL of water, soak the pre-treated hemp fiber in the dye solution at 60°C, add 2g of sodium chloride, treat it under ultrasonic conditions for 30min, and then 90 ℃, add 1g of sodium carbonate, and fix the color at this temperature for 30 minutes. After dyeing, take out the hemp fiber, wash with soap, water, and dry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com