Electromagnetic wave absorbing material with periodic structure, and preparation method thereof

An electromagnetic absorption and periodic structure technology, applied in chemical instruments and methods, electrical components, magnetic field/electric field shielding, etc., can solve the problems of limited absorption bandwidth, high volume density, narrow absorption bandwidth, etc., and improve the absorption bandwidth , low volume density, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Kind of like Figure 4 ~ Figure 6 The electromagnetic absorbing material with a periodic structure shown in the present invention includes a magnetic absorbing material grid 2 and a dielectric block 1 made of dielectric material. The magnetic absorbing material grid 2 has a through hole and the dielectric block 1 It is embedded in the through holes of the magnetic absorbing material grid 2 according to a certain period. In this embodiment, the embedding according to a certain period specifically means that the embedding is arranged in a matrix to form a rectangular array of dielectric blocks.

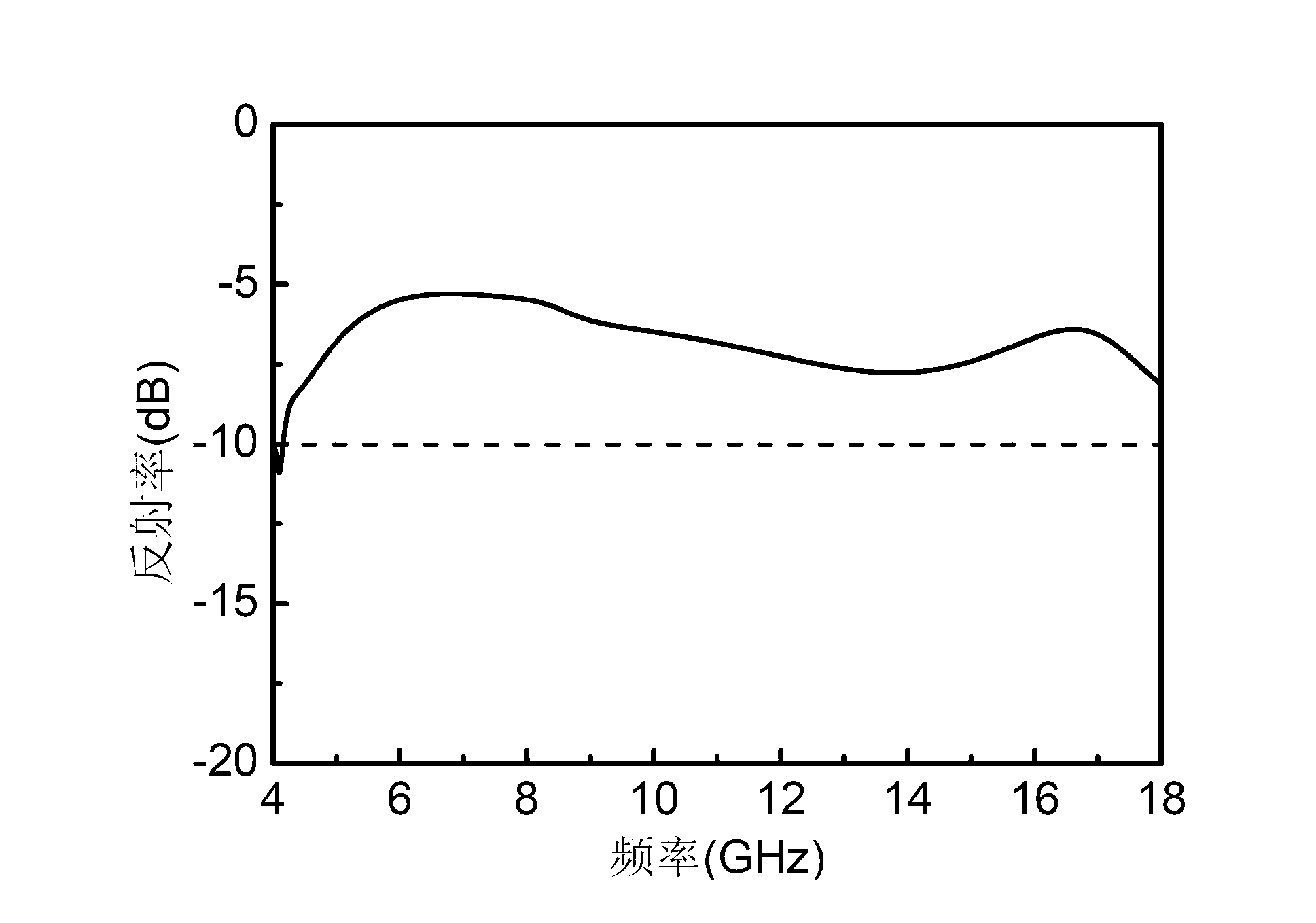

[0030] In this embodiment, the dielectric block 1 is cylindrical, with a bottom diameter of 10 mm, and the distance between the centers of two adjacent dielectric blocks 1 is 12.5 mm. The dielectric block 1 is made of epoxy resin material, and its relative dielectric constant is about 3, and the dielectric loss is negligible. The thickness of the entire electromagnetic absorbing ma...

Embodiment 2

[0037] Kind of like Figure 4 ~ Figure 5 The electromagnetic absorbing material with a periodic structure shown in the present invention includes a magnetic absorbing material grid 2 and a dielectric block 1 made of dielectric material. The magnetic absorbing material grid 2 has a through hole and the dielectric block 1 It is embedded in the through holes of the magnetic absorbing material grid 2 according to a certain period. In this embodiment, the embedding according to a certain period specifically means that the embedding is arranged in a matrix to form a rectangular array of dielectric blocks.

[0038] In this embodiment, the dielectric block 1 is cylindrical, with a bottom diameter of 8 mm, and the distance between the centers of two adjacent dielectric blocks 1 is 12.5 mm. The dielectric block 1 is made of epoxy resin material, and its relative dielectric constant is about 3, and the dielectric loss is negligible. The thickness of the entire electromagnetic absorbing mat...

Embodiment 3

[0042] Kind of like Figure 4 ~ Figure 5 The electromagnetic absorbing material with a periodic structure shown in the present invention includes a magnetic absorbing material grid 2 and a dielectric block 1 made of dielectric material. The magnetic absorbing material grid 2 has a through hole and the dielectric block 1 It is embedded in the through holes of the magnetic absorbing material grid 2 according to a certain period. In this embodiment, the embedding according to a certain period specifically means that the embedding is arranged in a matrix to form a rectangular array of dielectric blocks.

[0043] In this embodiment, the dielectric block 1 is cylindrical, with a bottom diameter of 11.5 mm, and the distance between the centers of two adjacent dielectric blocks 1 is 12.5 mm. The dielectric block 1 is made of epoxy resin material, and its relative dielectric constant is about 3, and the dielectric loss is negligible. The thickness of the entire electromagnetic absorbing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com