Construction method for water-permeable and water-retaining water-permeable pavement structure

A technology of permeable pavement and construction method, applied in the direction of roads, roads, road repair, etc., can solve the problems that permeable pavement structure is difficult to achieve permeable effect, natural precipitation cannot naturally penetrate into the ground, and pavement structure is impermeable, etc., and achieves high water permeability. Features High water retention performance, avoiding energy problems, and the effect of large porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

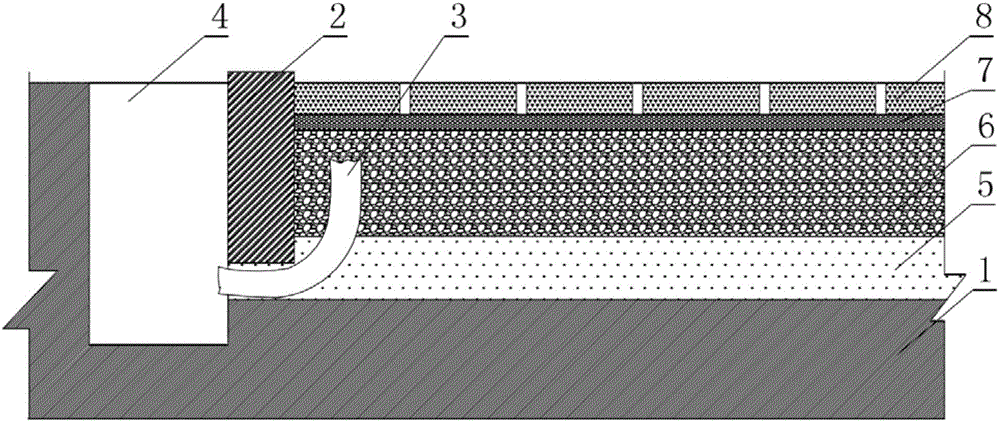

[0040] A construction method of a water-permeable and water-retaining permeable pavement structure, comprising the following steps:

[0041] Subgrade excavation: According to the design requirements, excavate the subgrade, clean up the earthwork, and reach the design elevation; check the longitudinal slope, transverse slope and sideline; repair the subgrade, level and roll it compactly, and the compaction coefficient can reach more than 95%;

[0042] Cushion laying: Lay 60mm thick regenerated sand on the excavated subgrade; it is required that the accumulated sieve allowance of regenerated sand passing through the 5.0mm sieve hole should not exceed 5%, the content of fine powder should be less than 5%, and the content of mud block should be less than 2 %, the moisture content should be less than 3%, and compacted, the compaction coefficient should be above 95%;

[0043] Base laying: Lay graded recycled coarse aggregate with a particle size of 5-63mm on the top of the cushion a...

Embodiment 2

[0051] A construction method of a water-permeable and water-retaining permeable pavement structure, comprising the following steps:

[0052] Subgrade excavation: according to the design requirements, excavate the subgrade, clear the earthwork, and reach the design elevation; check the longitudinal slope, transverse slope and sideline; repair the subgrade, level and compact the compaction coefficient to over 95%, and pay attention to underground burial the pipeline;

[0053] Cushion laying: Lay the lime-soil mixture as a cushion on the excavated roadbed. The mass ratio of lime to soil in the lime-soil is 0.12:1. After laying, it is leveled and compacted. 120mm;

[0054] Laying of waterproof layer: Lay a waterproof layer on the cushion layer. The waterproof layer is laid with non-permeable geotextile or geomembrane, so that the water that penetrates from the surface layer to the base layer will flow through the slope designed on the base layer on the surface of the impermeable ...

Embodiment 3

[0063] A construction method of a water-permeable and water-retaining permeable pavement structure, comprising the following steps:

[0064] Subgrade excavation: according to the design requirements, excavate the subgrade, clear the earthwork, and reach the design elevation; check the longitudinal slope, transverse slope and sideline; repair the subgrade, level and compact the compaction coefficient to over 95%, and pay attention to underground burial the pipeline;

[0065] Cushion laying: Lay the lime-soil mixture as a cushion on the excavated roadbed. The mass ratio of lime to soil in the lime-soil is 0.12:1. After laying, it is leveled and compacted. 150mm;

[0066] Laying of the waterproof layer: Lay the waterproof layer on the cushion layer. The waterproof layer is laid with cement mortar with a thickness of 30mm. The mass ratio of the cement or cementitious material in the cement mortar to the sand is 1:3; Troweling, let the water infiltrated by the surface layer flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com