Method for extracting aluminum hydrate or alumina from coal gangue and method for producing cement from fag end

A technology of aluminum hydroxide and alumina, which is applied in alumina/hydroxide preparation, cement production and other directions, can solve the problems of high energy consumption and uneconomical, high calcination temperature and high process energy consumption, and achieve the effect of reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

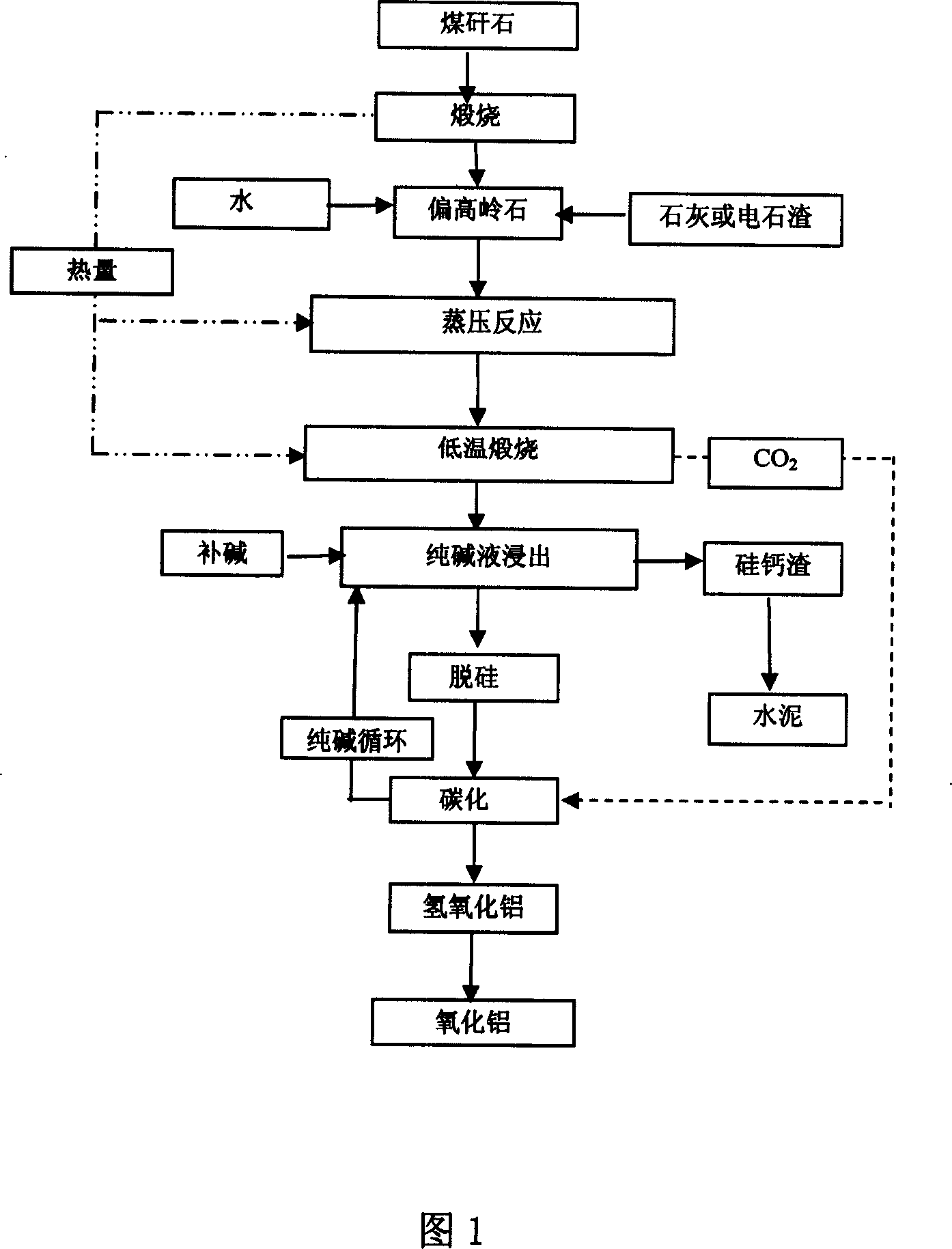

[0023] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0024] Firstly, after the coal gangue with an alumina content greater than 30% (weight percent) is pulverized and calcined into metakaolin, it is ball milled and mixed with calcined calcium oxide or carbide slag at a ratio of 1: (1-3). The ratio is 1: (0.1-1) and the ratio is 1: (0.1-1) and water is added to form it and then sent to the autoclave for autoclaving reaction. The autoclave reaction can be steam heating or self-autoclaving. The pressure is 0.14-6.4MPa. The autoclaving time is 0.5-12 hours, the heat energy in the autoclaving process is obtained by calcining coal gangue, and the product obtained after autoclaving is autoclaved material.

[0025] Secondly, the autoclaved material is calcined, the calcining temperature is 800-1000° C., and the calcining time is 0.5-12 hours. Calcination equipment can be tunnel kiln for ceramic production process, rotary kiln...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com