Ball-shaped red-enhanced phosphor used in white light LED, and preparation method thereof

A phosphor and spherical technology is applied in the field of spherical, reddening phosphors for white light LEDs and their preparation, which can solve the problems of reduced luminous performance and service life, changes in surface properties of phosphors, irregular morphology, etc., and achieves crystallinity. And the effect of good coating performance, good reproducibility and short holding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

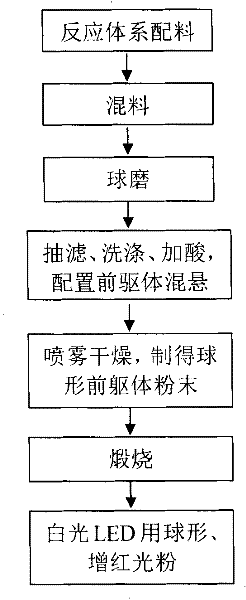

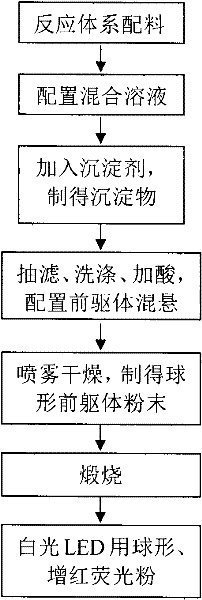

Method used

Image

Examples

Embodiment 1

[0026] According to the structure Y 2.65 Gd 0.2 Sr 0.05 Ce 0.1 Al 5 o 12 Weigh Y(NO 3 ) 3 ·6H 2 O(A.R.)2.65mol, Gd(NO 3 ) 3 ·6H 2 O(A.R.)0.2mol, Sr(NO 3 ) 2 0.05mol, Ce(NO 3 ) 3 ·6H 2 O(A.R.)0.1mol, Al(NO 3 ) 3 9H 2 O (A.R.) 5mol, then weigh respectively the surfactant polyethylene glycol-6000 of 0.1wt% of the total mass of the above medicines; 4 HCO 3 (The ratio of the reactant and the ligand is 1: 4) fully mixed, then ball milled, adding lubricant acetone during ball milling, the amount of acetone added is limited to be kept dispersed by the ball milling system until the reactant reacts completely with the ligand; Filtrate, wash, add dilute nitric acid solution, configure precursor suspension, make the solid content reach 3wt%; set spray dryer parameter sample flow rate 1L / h, inlet temperature 220 ℃, air flow rate 30L / min, mix precursor The suspension was spray-dried to obtain the precursor powder; the precursor powder was pre-sintered at 900°C for 2 hour...

Embodiment 2

[0028] According to the structure Y 2.7 La 0.1 Sr 0.1 Ce 0.1 Al 4.95 Cu 0.05 o 12 Weigh Y(NO 3 ) 3 ·6H 2 O(A.R.)2.7mol, La(NO 3 ) 3 ·6H 2 O(A.R.)0.1mol, Sr(NO 3 ) 2 0.1mol, Ce(NO 3 ) 3 ·6H 2 O(A.R.)0.1mol, Al(NO 3 ) 3 9H 2 O(A.R.)4.95mol and CuSO 4 ·5H 2 O 0.05mol, then respectively take by weighing the surfactant polyvinyl alcohol of above drug gross mass 0.2wt%; With the raw material salt that weighs, surfactant and appropriate part (NH 4 ) 2 CO 3 (The ratio of the reactant and the ligand is 1: 3) fully mixed, and then ball milled, adding lubricant ethanol during ball milling, the amount of ethanol added is limited to be kept dispersed by the ball milling system until the reactant reacts completely with the ligand; Filtrate, wash, add dilute hydrochloric acid solution, configure the precursor suspension, so that the solid content reaches 1wt%; set the spray dryer parameter injection flow rate 1.5L / h, inlet temperature 200 ° C, air flow rate 50L / min, th...

Embodiment 3

[0030] According to the structure Y 2.7 SM 0.1 Ba 0.1 Ce 0.1 Al 4.95 Zn 0.05 o 12 Weigh Y(NO 3 ) 3 ·6H 2 O(A.R.)2.7mol, Sm(NO 3 ) 3 ·6H 2 O(A.R.)0.1mol, Ba(NO 3 ) 2 0.1mol, Ce(NO 3 ) 3 ·6H 2 O(A.R.)0.1mol, Al(NO 3 ) 3 9H 2 O(A.R.)4.95mol and ZnSO 4 ·7H 2 O 0.05mol, then respectively take by weighing the surfactant polyvinyl alcohol of above drug total mass 1wt%; Raw material salt, tensio-active agent and appropriate part (NH 4 ) 2 CO 3 (The ratio of the reactant and the ligand is 1: 6) fully mixed, then ball milled, adding lubricant acetone during ball milling, the amount of acetone added is limited to be kept dispersed by the ball milling system until the reactant and the ligand react completely; Filtrate, wash, add dilute hydrochloric acid solution, prepare the precursor suspension, make the solid content reach 1wt%; set the spray dryer parameter sample flow rate 0.8L / h, inlet temperature 200 ℃, air flow rate 60L / min, the precursor The suspension was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com