Method for preparing carbon nano tubes on surfaces of silicon carbide particles through in-situ synthesis

A technology of silicon carbide particles and carbon nanotubes, applied in silicon carbide, nanotechnology for materials and surface science, chemical instruments and methods, etc., can solve the problem of uneven size and distribution of metal particles, and poor final performance of composite materials. , can not catalytic performance and other problems, to reduce the calcination and reduction temperature, the process is simple and feasible, and the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

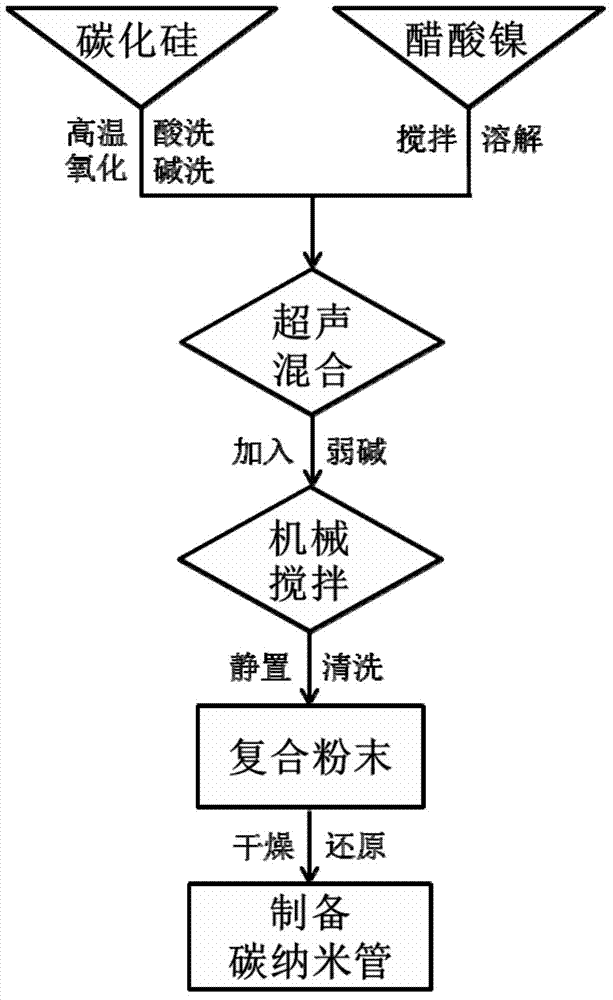

Method used

Image

Examples

Embodiment 1

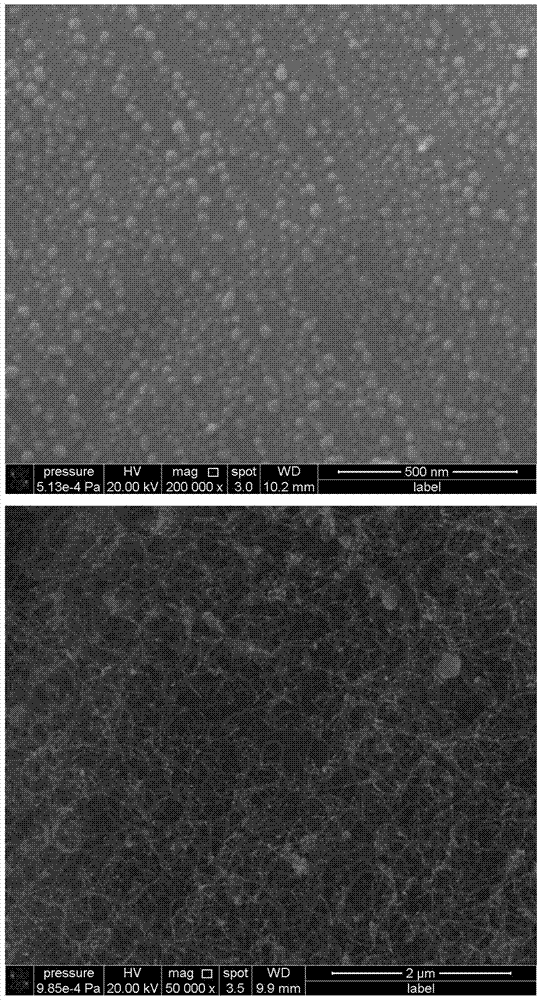

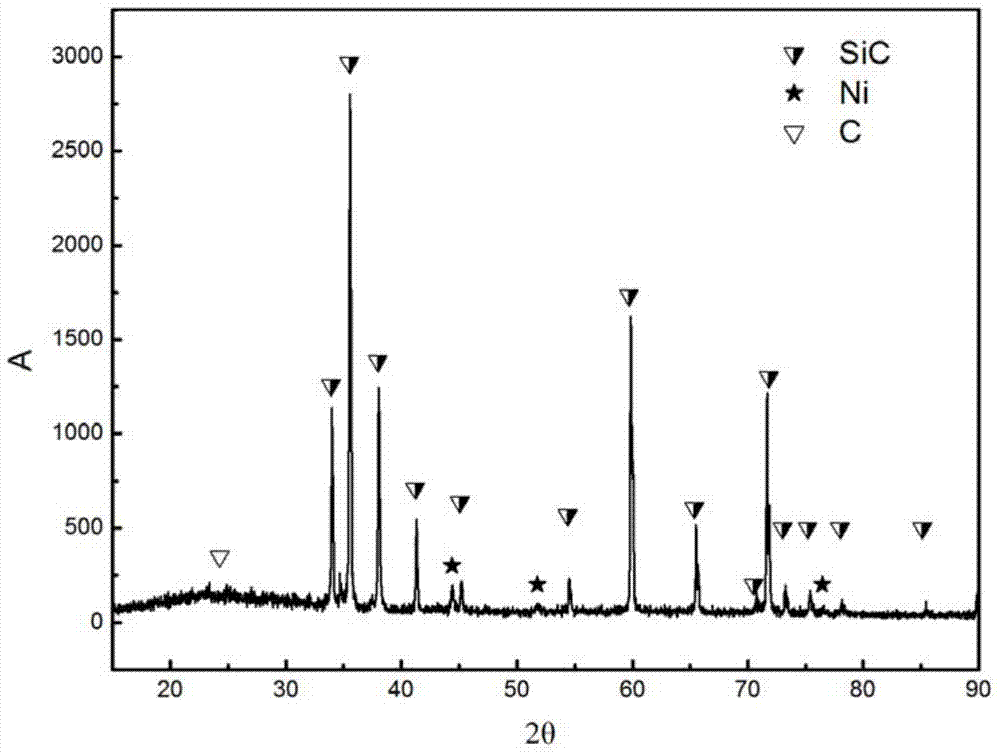

[0032] Put nickel acetate tetrahydrate into a 150ml beaker, add 80ml deionized water, stir until clarified, add the surface-treated silicon carbide into the beaker at a molar ratio of 20:1 to nickel acetate tetrahydrate, and put it into an ultrasonic instrument Ultrasonic cleaning for 0.5 hours, take it out, put it on a magnetic stirrer, add 0.5mol / L NH while stirring 3 ·H 2 O aqueous solution, until the pH value is 7, continue magnetic stirring for 1 hour, let stand at room temperature for 48 hours, then rinse with deionized water, filter with suction; take out the powder in the funnel, put it in a drying oven at 100 °C, Dry for 10 hours, then put it into a box-type resistance furnace at 450°C, and calcinate for 2 hours in an air atmosphere. Nanoscale catalyst oxide particles are prepared on the surface of the catalyst.

[0033] Take 500 mg of processed powder, put it into a quartz boat, place it in a quartz tube furnace, raise the temperature to 500°C under an argon protec...

Embodiment 2

[0035]Put nickel acetate tetrahydrate into a 150ml beaker, add 50ml deionized water, stir until clarified, then add the surface-treated silicon carbide into the beaker at a molar ratio of 10:1 to nickel acetate tetrahydrate, and put it into the ultrasonic Ultrasonic cleaning in the instrument for 0.5 hours, take it out, put it on a magnetic stirrer, add 0.5mol / L NH3·H2O aqueous solution 8 while stirring, continue stirring for 1 hour, let it stand at room temperature for 48 hours, and then use Rinse with deionized water until the pH is neutral, and filter with suction; take out the powder in the funnel, put it in a drying oven at 150°C, dry for 10 hours, then put it in a box-type resistance furnace at 500°C, and calcinate 2 pieces in an air atmosphere Hour.

[0036] Take 500 mg of the treated powder, put it into a quartz boat, place it in a quartz tube furnace, raise the temperature to 550°C under an argon protective atmosphere of 500ml / min, turn off the argon, and introduce 30...

Embodiment 3

[0038] Put nickel acetate tetrahydrate into a 150ml beaker, add 50ml deionized water, stir until clarified, then add the surface-treated silicon carbide into the beaker at a molar ratio of 20:1 to nickel acetate tetrahydrate, and put it into the ultrasonic Ultrasonic cleaning in the instrument for 0.5 hours, take it out, put it on a magnetic stirrer, add 0.5mol / L ammonia solution while stirring until the pH value is 9, continue to stir for 1 hour, and let it stand at room temperature for 24 hours , and then rinsed with deionized water, suction filtered; the powder in the funnel was taken out, put into a drying oven at 120°C, dried for 10 hours, then put into a box-type resistance furnace at 500°C, and calcined for 2 hours in an air atmosphere.

[0039] Take 500 mg of processed powder, put it into a quartz boat, place it in a quartz tube furnace, raise the temperature to 500°C under an argon protective atmosphere of 500ml / min, turn off the argon, and pass in 300ml / min of hydroge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com