Method for preparing target-used Ru (ruthenium) powder

The technology of ruthenium powder and ruthenium trichloride is applied in the production field of ruthenium powder for target materials, and can solve the problems of unreachable ruthenium powder for target and low tap density of powder, and achieve the effect of improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

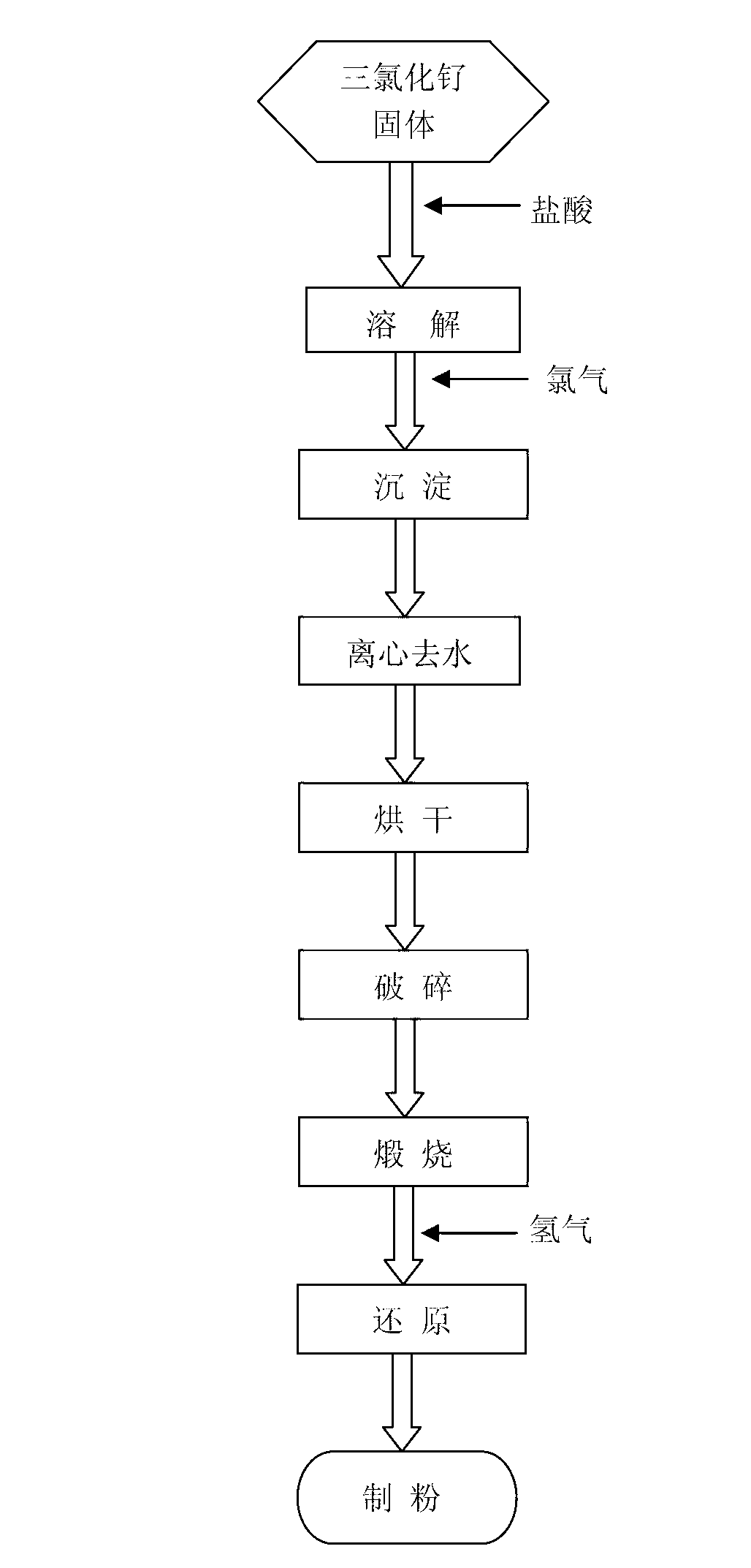

[0026] like figure 1 Shown, get solid ruthenium trichloride 1000 grams, contain ruthenium 370 grams, operate as follows:

[0027] 1. Dissolving: Solid ruthenium trichloride is dissolved with 7.4 liters of 8mol / L hydrochloric acid, so that the concentration of ruthenium is 50 grams / liter, and a saturated solution of ammonium chloride is added to the ruthenium-containing solution to generate (NH 4 ) 3 RuCl 6 (Ⅲ), the amount of ammonium chloride added is 1.3 times of the theoretical amount.

[0028] ②Precipitation: Heating the solution at a temperature of 90°C, passing in 1 liter / min of chlorine gas for oxidation and stirring to obtain (NH 4 ) 2 RuCl 6 (Ⅳ) Precipitation, the stirring speed is 80 rpm, and the chlorine gas oxidation time is 2 hours, until the ammonium chlororuthenate (Ⅳ) precipitates completely, and the ammonium chlororuthenate (Ⅳ) precipitate is obtained by filtration, and the mother liquor is analyzed to contain 0.7 grams of ruthenium , The precipitation ra...

Embodiment 2

[0036] like figure 1 Shown, get solid ruthenium trichloride 3000 grams, contain ruthenium 1110 grams, operate as follows:

[0037] ① Dissolution: Dissolve the solid ruthenium trichloride with 24.66 liters of 10mol / L hydrochloric acid, so that the concentration of ruthenium is 45 grams / liter, and add saturated ammonium chloride solution to the ruthenium-containing solution to generate (NH 4 ) 3 RuCl 6 (Ⅲ), the amount of ammonium chloride added is 1.3 times of the theoretical amount.

[0038] ②Precipitation: Heating the solution at a temperature of 95°C, passing in 0.8 liter / min of chlorine gas for oxidation and stirring to obtain (NH 4 ) 2 RuCl 6 (Ⅳ) Precipitation, the stirring speed is 70 rpm, and the chlorine gas oxidation time is 2.5 hours, until the ammonium chlororuthenate (Ⅳ) precipitates completely, and the ammonium chlororuthenate (Ⅳ) precipitate is obtained by filtration, and the precipitated mother liquor is analyzed to contain ruthenium 5.12 grams, the precipit...

Embodiment 3

[0046] like figure 1 Shown, get solid ruthenium trichloride 6000 grams, contain ruthenium 2220 grams, operate as follows:

[0047] ① Dissolution: Dissolve the solid ruthenium trichloride with 40.36 liters of 8mol / L hydrochloric acid to make the concentration of ruthenium 55 grams / liter, add saturated ammonium chloride solution to the ruthenium-containing solution to generate (NH 4 ) 3 RuCl 6 (Ⅲ), the amount of ammonium chloride added is 1.4 times of the theoretical amount.

[0048] ②Precipitation: Heating the solution at a temperature of 98°C, passing in 0.9 liters / min of chlorine gas for oxidation and stirring to obtain (NH 4 ) 2 RuCl 6 (Ⅳ) Precipitation, the stirring speed is 90 rpm, and the chlorine gas oxidation time is 3 hours, until the ammonium chlororuthenate (Ⅳ) precipitates completely, and the ammonium chlororuthenate (Ⅳ) precipitate is obtained by filtration, and the mother liquor contains 2.12 grams of ruthenium , The precipitation rate of ruthenium was 99.9%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com