Patents

Literature

43results about How to "Not easy to bring in" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

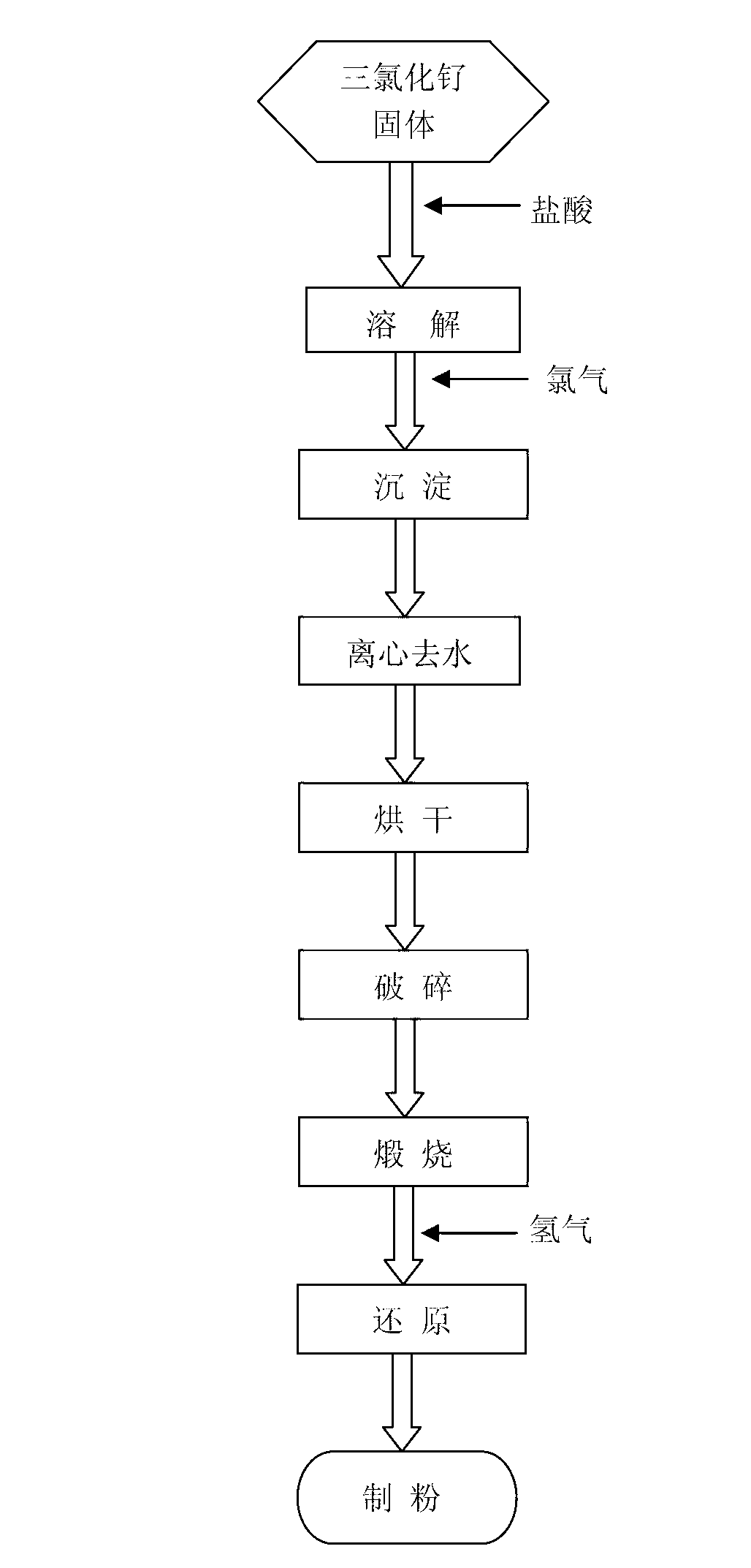

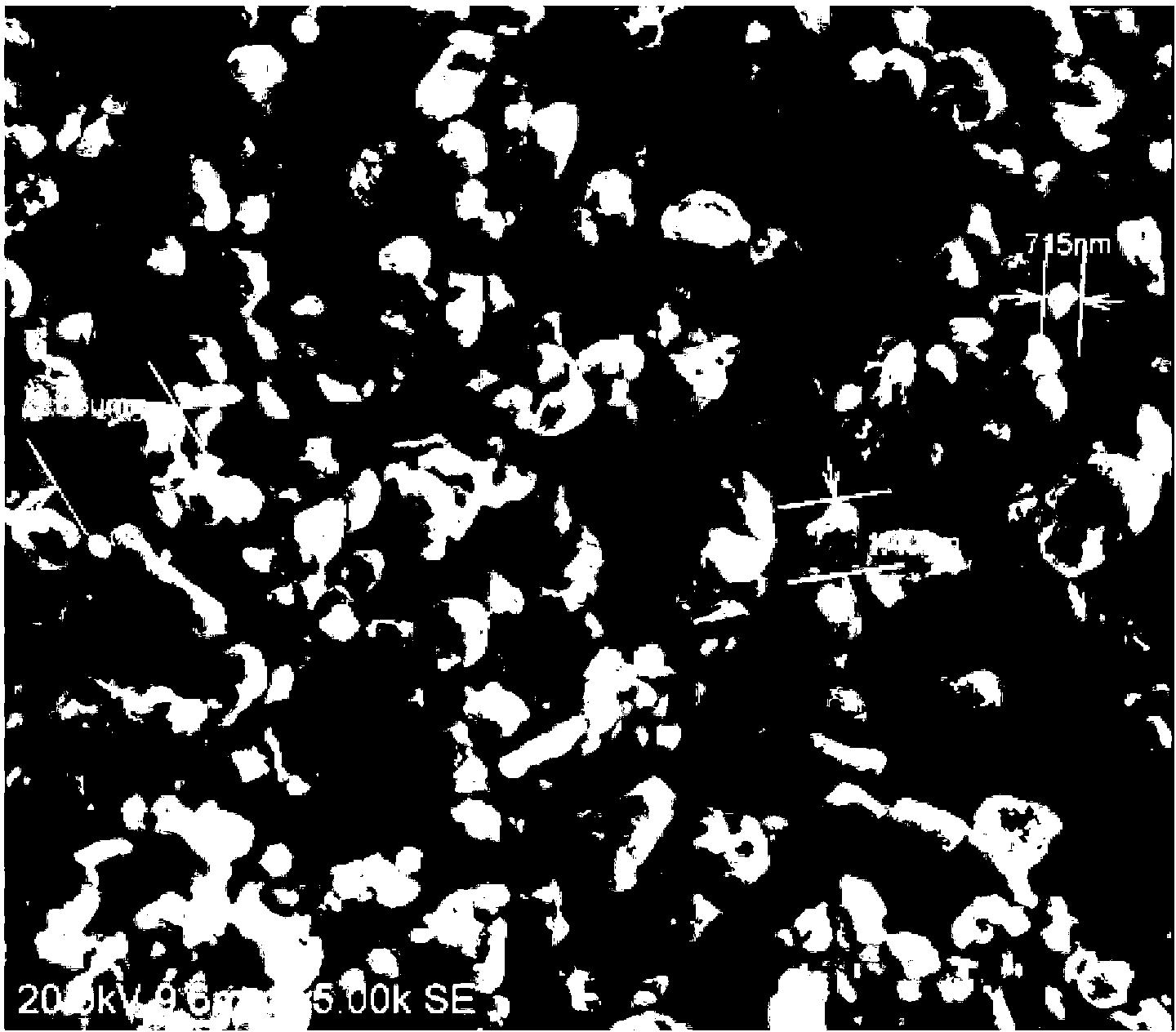

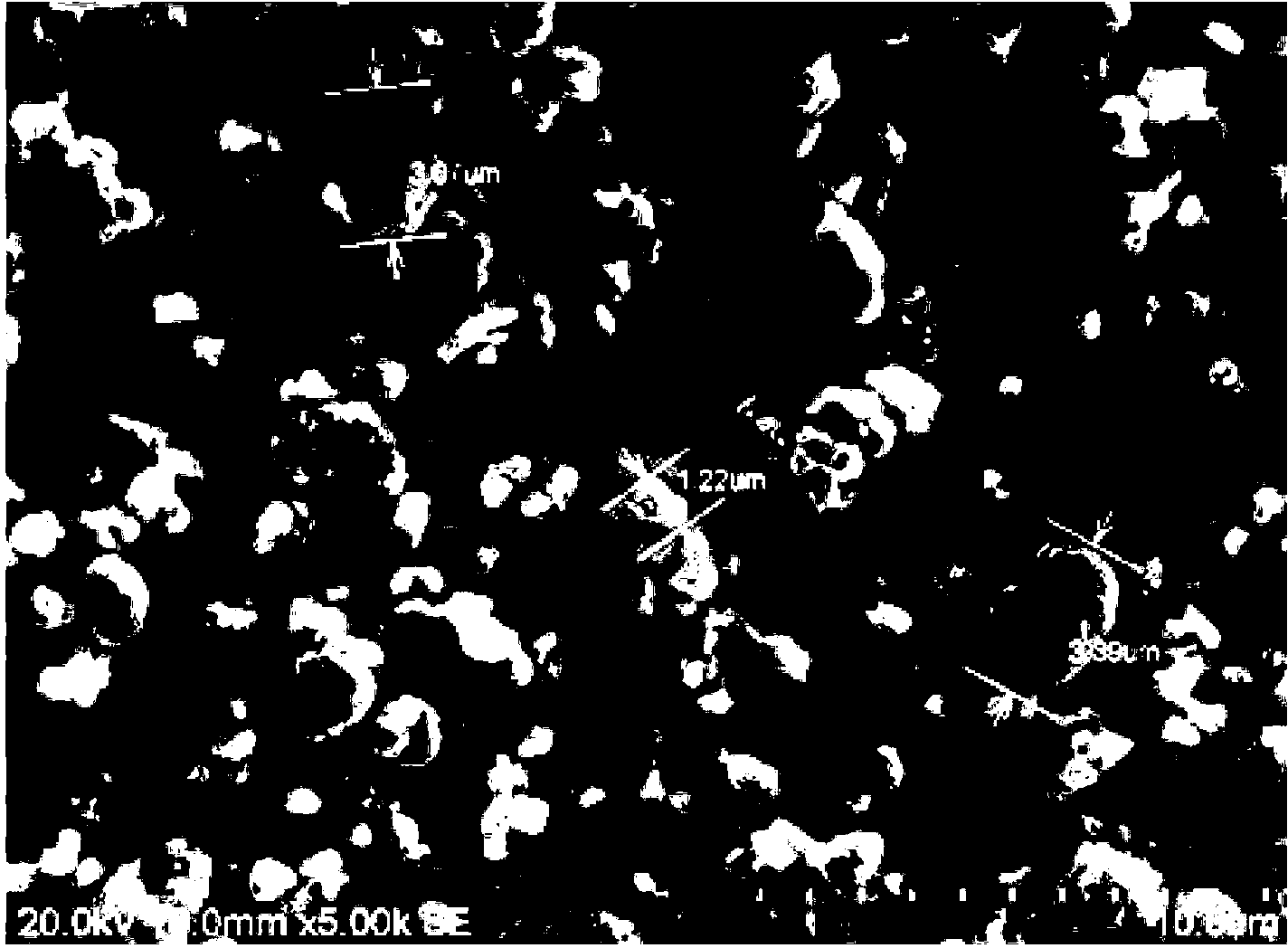

Method for preparing target-used Ru (ruthenium) powder

The invention provides a method for preparing target-used Ru powder and relates to the technical field of precious metal powder production. The method for preparing the target-used Ru powder comprises the steps as follows; 1) solvation, 2) precipitation, 3) centrifugal filtration, 4) drying, 5) crushing, 6) calcination, 7) reduction and 8) powder preparation. According to the method, oxidation reaction is performed by means of chlorine gas to oxidize Ru (III) in a solution into Ru (IV), simultaneously, the concentration of Ru is controlled in a range of 45-55 g / L, the concentration of hydrochloric acid is controlled in a range of 8-12 mol / L, the oxidizing temperature is controlled in a range of 90-100 DEG C, and the mixing speed is 60-90 revolutions / min, so that 99.9% of (NH4)2RuCl6(IV) in the solution can be precipitated, the (NH4)2RuCl6(IV) is separated from impurities, and the purity of the (NH4)2RuCl6(IV) is improved.

Owner:GUIYAN RESOURCE YIMEN

Brewing method for honey wine

InactiveCN106479811ALow alcohol contentSweet and mellow tasteNervous disorderAlcoholic beverage preparationHuman bodyYeast

The invention relates to a brewing method for honey wine. The brewing method for the honey wine comprises the following steps: (1) washing and soaking milled round grain glutinous rice; (2) steaming the milled round grain glutinous rice in a pot; (3) blending distiller's yeast in the steamed milled round grain glutinous rice and placing the milled round grain glutinous rice in a jar; (4) flattening and fermenting; (5) adding honey and fermenting; (6) clarifying and ageing; (7) frying in a pot with a cover to obtain wine; (8) after naturally cooling, extracting fine rice wine on the upper layer, leading the fine rice wine for 1 month to naturally clarify, and removing wine residues on the lower layer to obtain the finished honey wine. The brewing method is simple in process and convenient to operate; the used raw materials are natural ingredients and are harmless to human bodies; the price of the raw materials are low and the raw materials are convenient and easy to obtain; and meanwhile, the obtained honey wine has sweet taste by deep fermentation and perfect combination of the honey and good polished round-grained rice, is suitable for most of consumers, has excellent effects of moistening organs of the body, and has good effect of nourishing the body for most of sub-health people.

Owner:ANHUI NORMAL UNIV

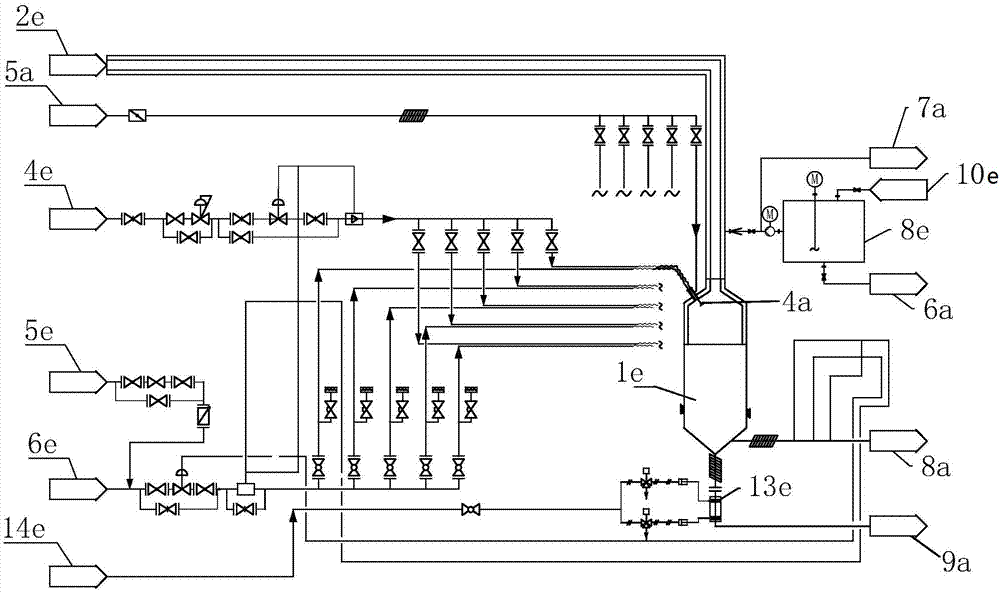

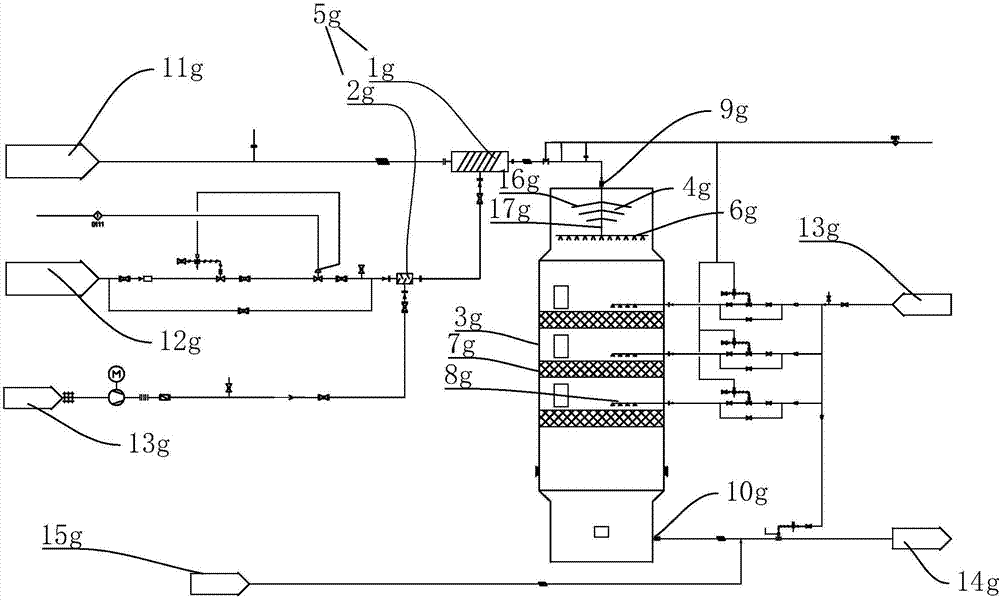

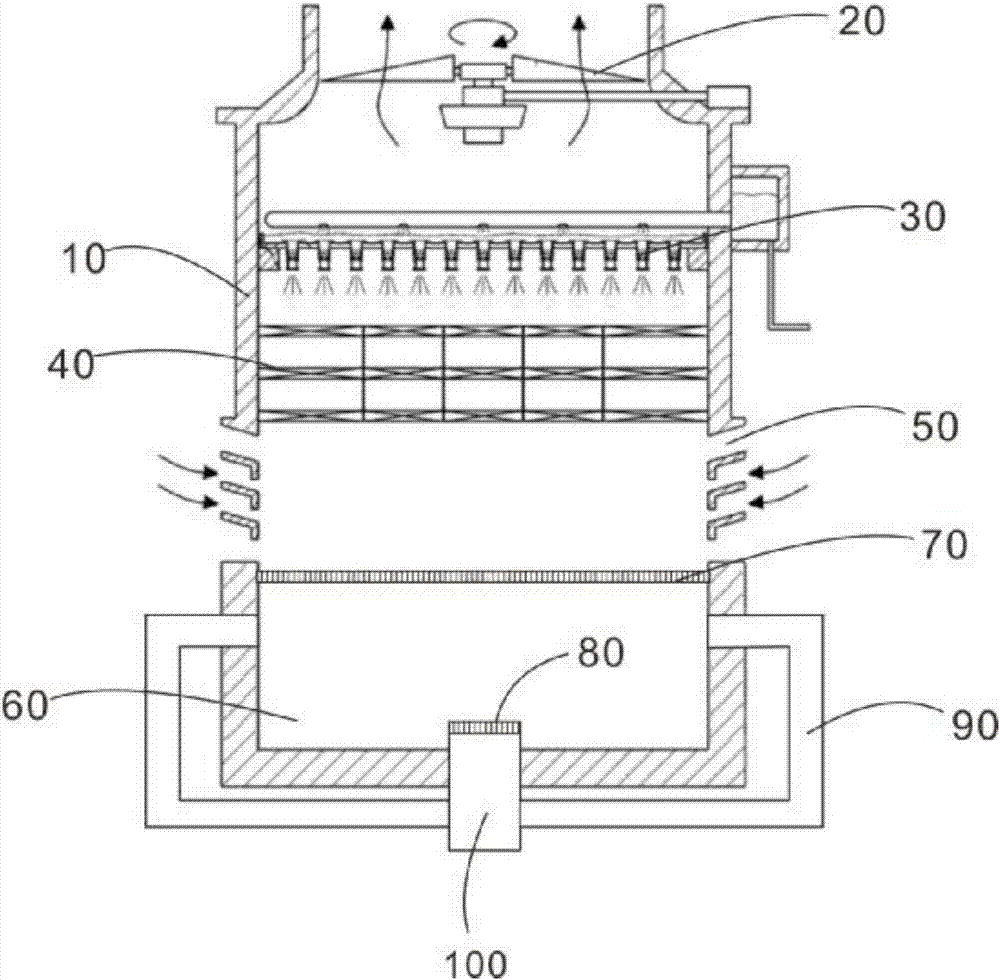

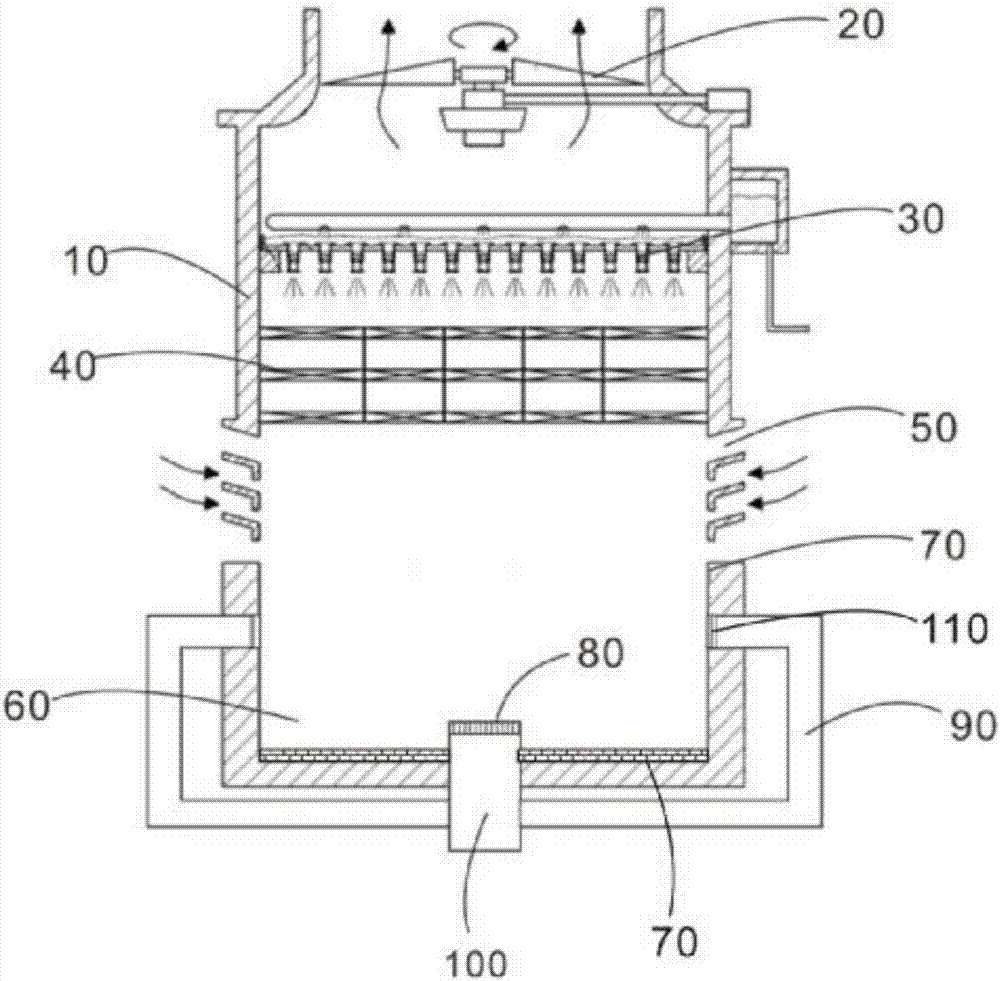

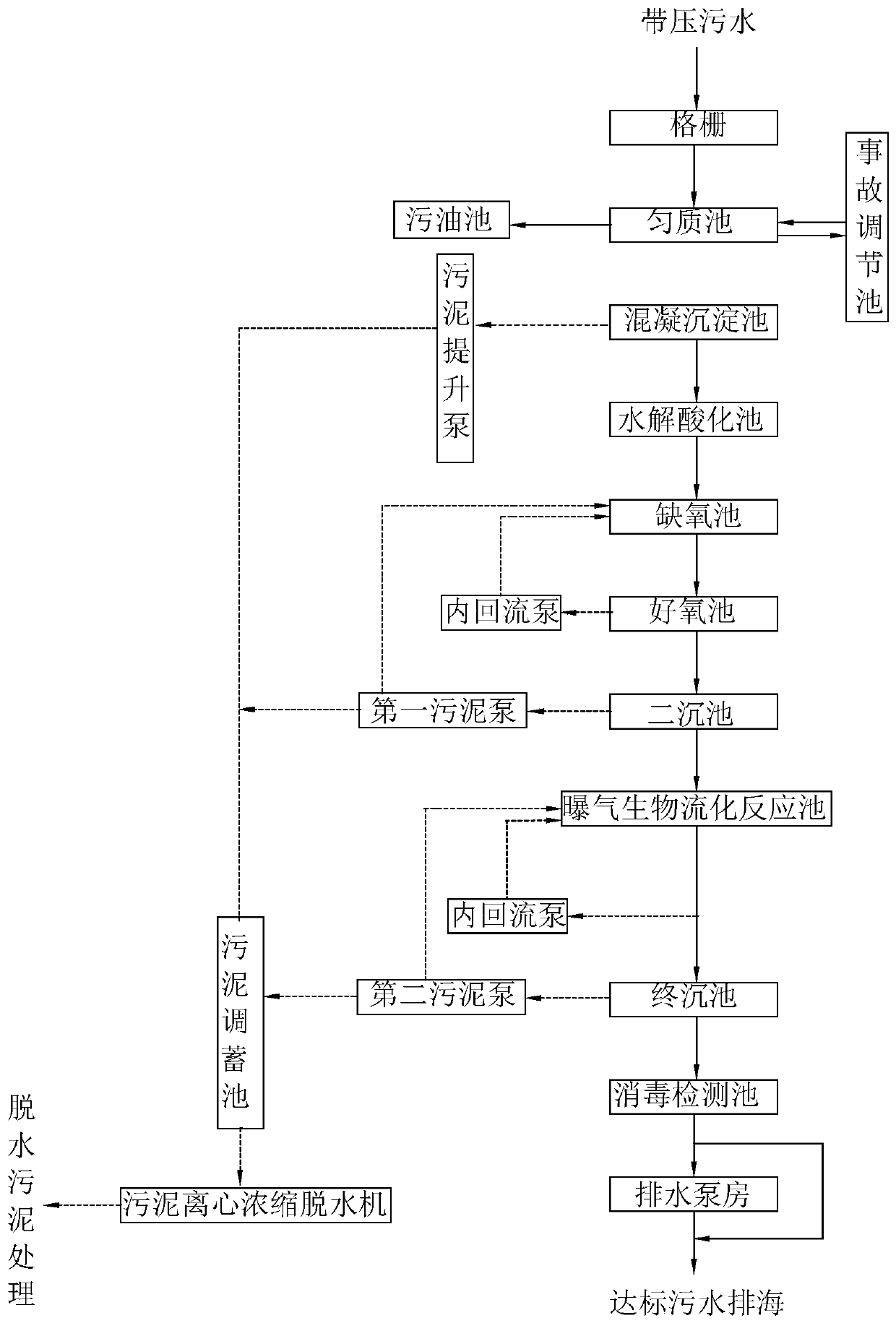

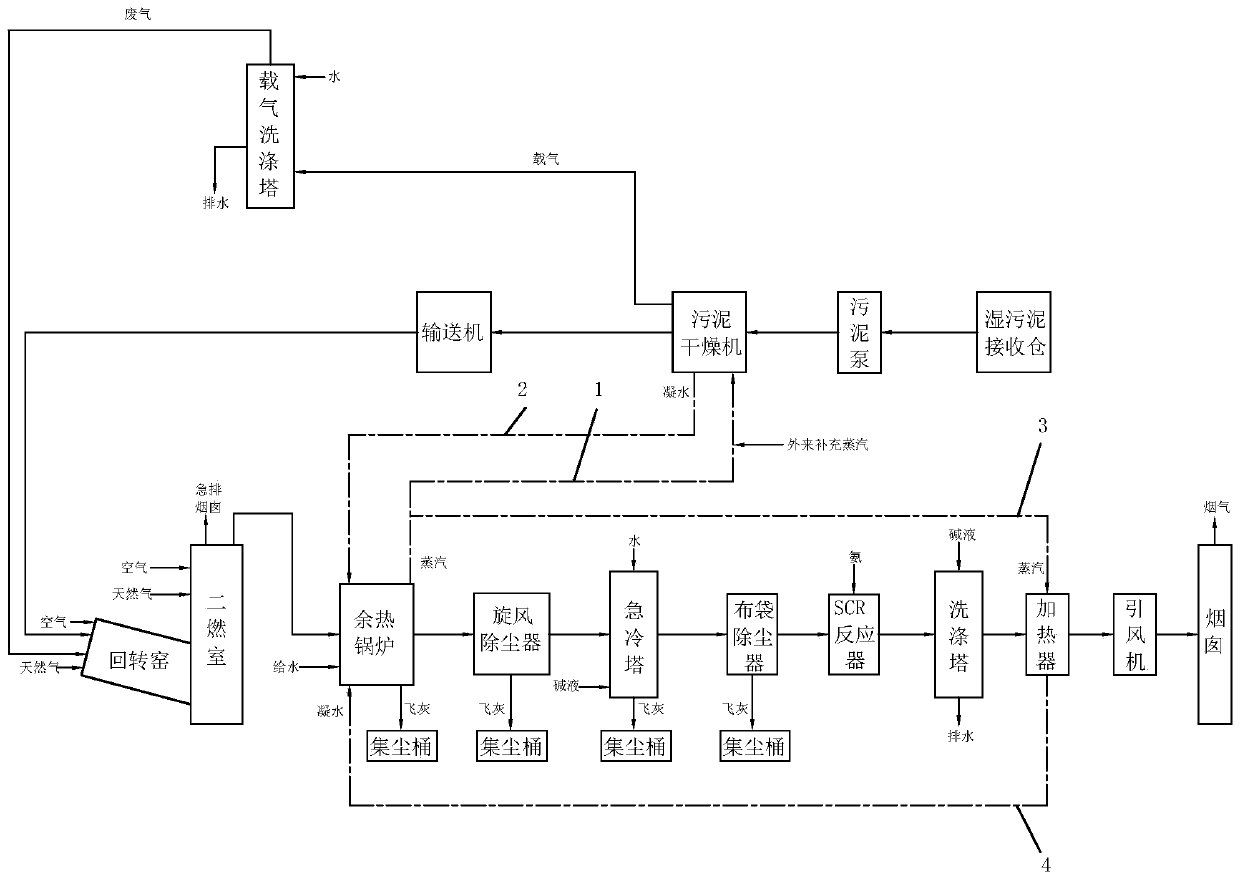

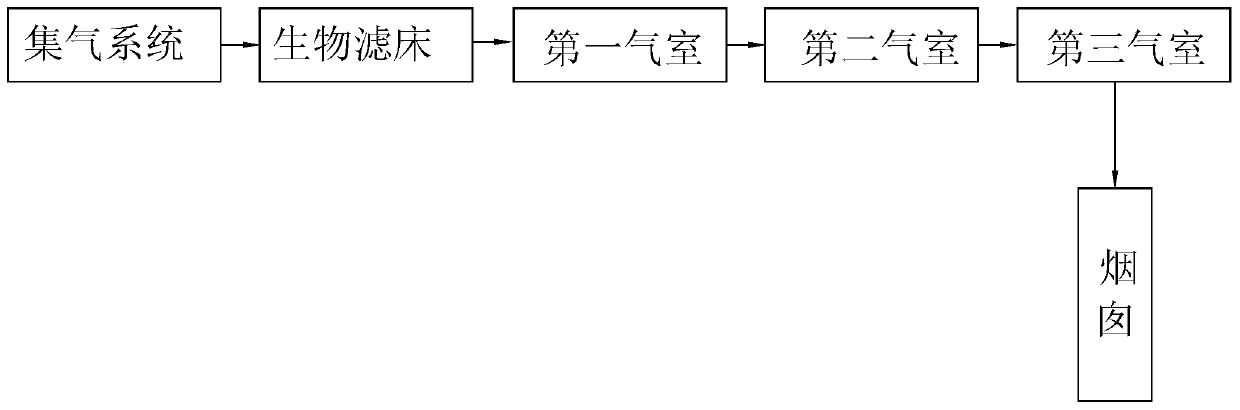

Comprehensive treatment system for chemical emission

ActiveCN107954565AReduce moisture contentReduce dust contentDispersed particle separationTreatment involving filtrationFlue gasPassive treatment system

The invention discloses a comprehensive treatment system for chemical emission. The problems of low treatment efficiency and high treatment cost which are caused by a high-cost treatment system and serious energy waste which are caused by the problem of unreasonable treatment modes in the treatment process of three wastes are solved. Key points of the technical scheme of the comprehensive treatment system comprises a sewage treatment system, a sludge regulating and storing tank, a sludge treatment system and an exhaust gas treatment system, wherein sludge in the sewage treatment system is connected with the sludge regulating and storing tank through at least one sludge pump, and the sludge treatment system includes a drying system, a sludge incineration system, an excess heat utilizing system and a flue gas purifying system which are connected sequentially; the exhaust gas treatment system includes a gas collecting device which is used for collecting exhaust gas which is generated in the sewage treatment system and the sludge treatment system, and a gas collecting system is connected with a biologically deodorizing system and at least one level of gas absorption chamber systems sequentially. Not only can emission requirements of multiple aspects be met, but also the utilization of effective energy can be achieved, so that the treatment process is cleaner, and the efficiency ishigh.

Owner:宁波华清环保技术有限公司

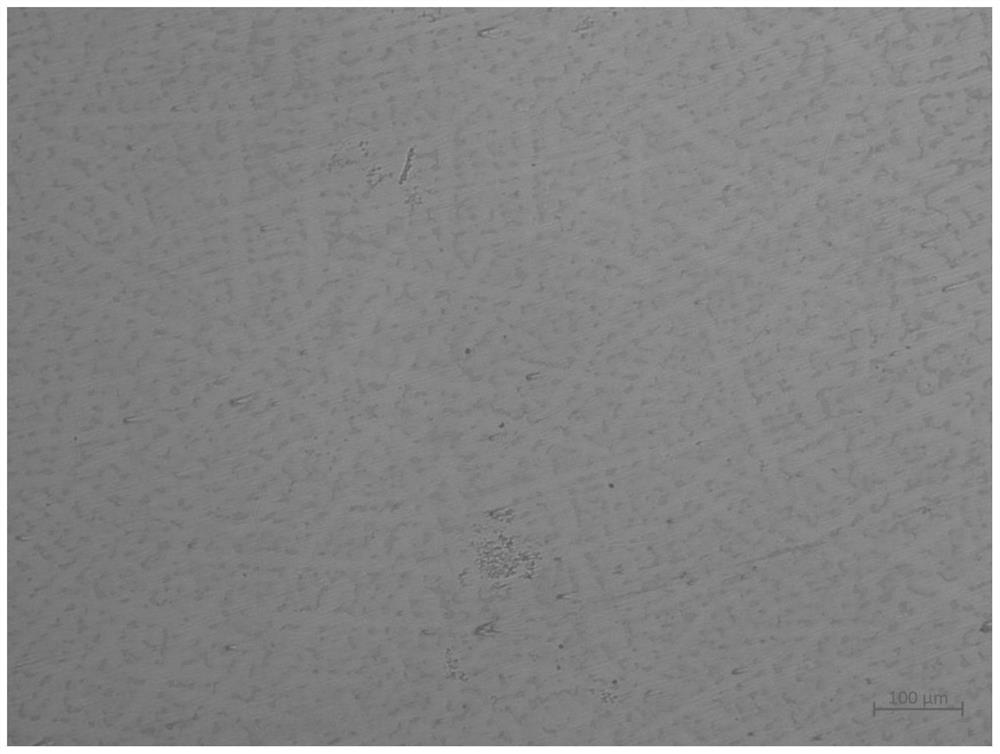

Tungsten-rhenium-molybdenum alloy layer composite anode target material for X-ray tube and preparation method thereof

InactiveCN108977777AHigh activityUniform compositionVacuum evaporation coatingSputtering coatingRheniumCompression molding

The invention discloses a tungsten-rhenium-molybdenum alloy layer composite anode target material for an X-ray tube and a preparation method thereof. The target material comprises a tungsten-rhenium alloy layer and a molybdenum alloy layer. Tungsten-rhenium pre-alloy powder is prepared by a mode of mixing tungsten powder and ammonium rhenate solution and reducing after evaporating. In the tungsten-rhenium pre-alloy powder, a mass percentage of rhenium is 1-5%, and the balance is tungsten. The target material is prepared by using the tungsten powder, ammonium rhenate and molybdenum alloy powderas raw materials, through pre-alloying, compression-molding, sintering in intermediate frequency, shaping in high temperature, and machining successively. Prepared high-activity tungsten-rhenium pre-alloy coated powder in a special matching ratio is more uniform in composition, and higher in activity. The prepared tungsten-rhenium-molybdenum alloy layer composite anode target material is uniformin composition, fine and uniform in grain structure, high in finished product pass percent, less in working procedure, and low in cost.

Owner:ZHUZHOU JIABANG REFRACTORY METAL

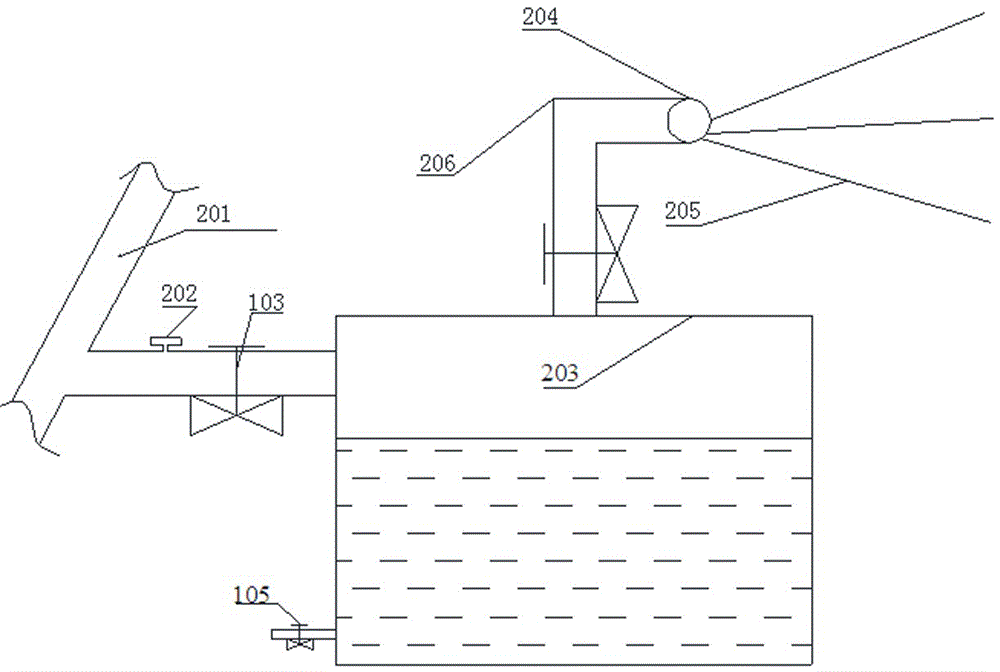

Method for improving stability of permanent gas extraction system of outburst mine

InactiveCN105525941AReduce Waterlogging ProblemsReduce the frequency of wateringDrainageGas removalSystem stabilitySlurry

The invention discloses a method for improving the stability of a permanent gas extraction system of an outburst mine. The method comprises a solution to water accumulation in a pipeline of the permanent gas extraction system, a solution to hole collapse occurring when drilling is carried out on a low-permeability soft coal seam, a solution to blockage of an extraction pipe due to excessive slurry, and a solution to gas leakage and abnormal negative pressure of the pipeline of the extraction system. By means of the method, the probability of water accumulation of the pipeline is reduced, and the extraction effect is improved; moreover, the phenomena of gas emission and hole collapse can be effectively avoided, and the situation that the gas cannot be extracted due to the fact that the extraction pipe is blocked by slightly excessive slurry is avoided; the stability and integrity of the permanent gas extraction system of the outburst mine are improved.

Owner:HUNAN UNIV OF SCI & TECH

Honey-wolfberry-tomato juice and preparation method thereof

The invention relates to the technical field of processing of heath beverages and particularly relates to honey-wolfberry-tomato juice and a preparation method thereof. The honey-wolfberry-tomato juice is prepared from the following components in percentage by weight: 20%-30% of concentrated tomato sauce, 6%-12% of honey, 2%-8% of wolfberry and 55%-72% of water. The preparation method comprises the following steps: (1) cooking soup; (2) filtering; (3) mixing; (4) homogenizing; and (5) carrying out preheating and sterilization. Compared with tomato juice beverages in the prior art, the honey-wolfberry-tomato juice does not contain any food additive, so that the honey-wolfberry-tomato juice is beneficial to the human health and has no any side effect to human bodies. The honey-wolfberry-tomato juice has the advantages that the content and the absorption rate of lycopene are high, the tomato and wolfberry flavors are relatively strong, the nutritive value is high, and the taste is sour, sweet and delicious; furthermore, the human immune capability can be well enhanced, and life cultivation and health preservation effects are achieved.

Owner:DONGGUAN YONGYI FOODS

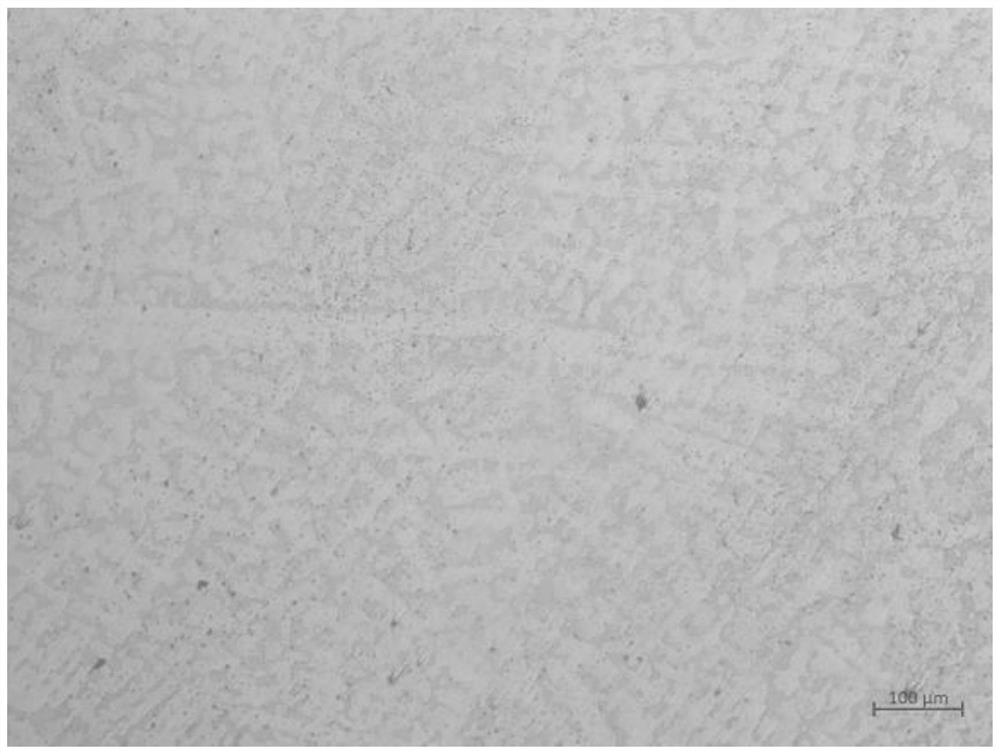

Preparation method for smelting copper-titanium series alloy material by adopting vacuum self-consuming electric arc

The invention discloses a preparation method for smelting a copper-titanium series alloy material by adopting vacuum self-consuming electric arc, and relates to the technical field of copper-titanium alloy preparation. The preparation method comprises the following steps of, S1, raw material proportioning, specifically, the material comprises the following components of, in percentage by mass: 0.5-99.5% of copper powder and 99.5-0.5% of sponge titanium; s2, mixing the raw materials, specifically, weighing the required raw materials according to the proportion, and mixing the raw materials in a mixer; s3, pressing, specifically, putting the mixture into a mold for powder upsetting, and putting the mold subjected to powder upsetting into a cold isostatic press for blank pressing; s4, sintering: putting the pressed green body into a vacuum sintering furnace for sintering; and S5, smelting, specifically, taking the sintered blank as a consumable electrode to be loaded into a vacuum consumable electric arc smelting furnace to be smelted. The alloy material prepared through the method has the advantages of being low in gas content, few in inclusion, uniform in structure and free of copper, titanium enrichment and other microdefects.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

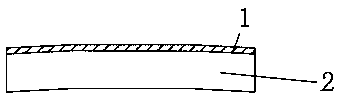

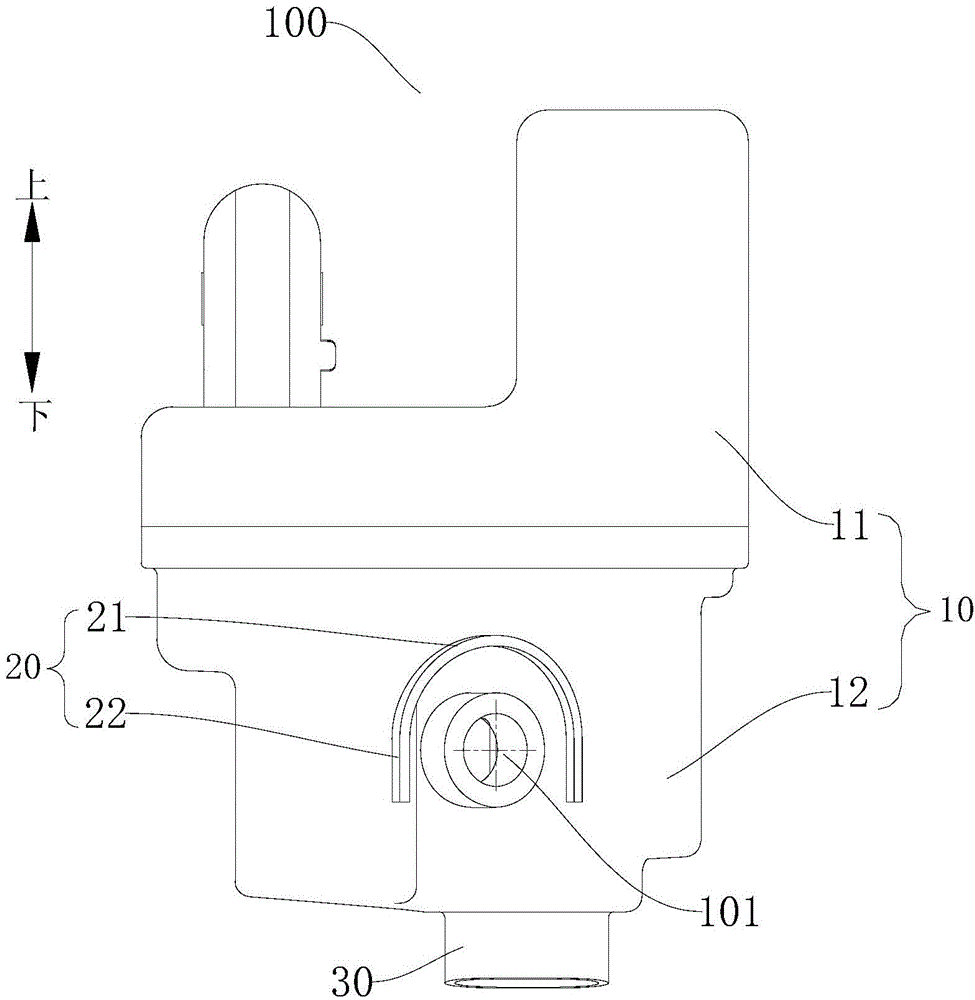

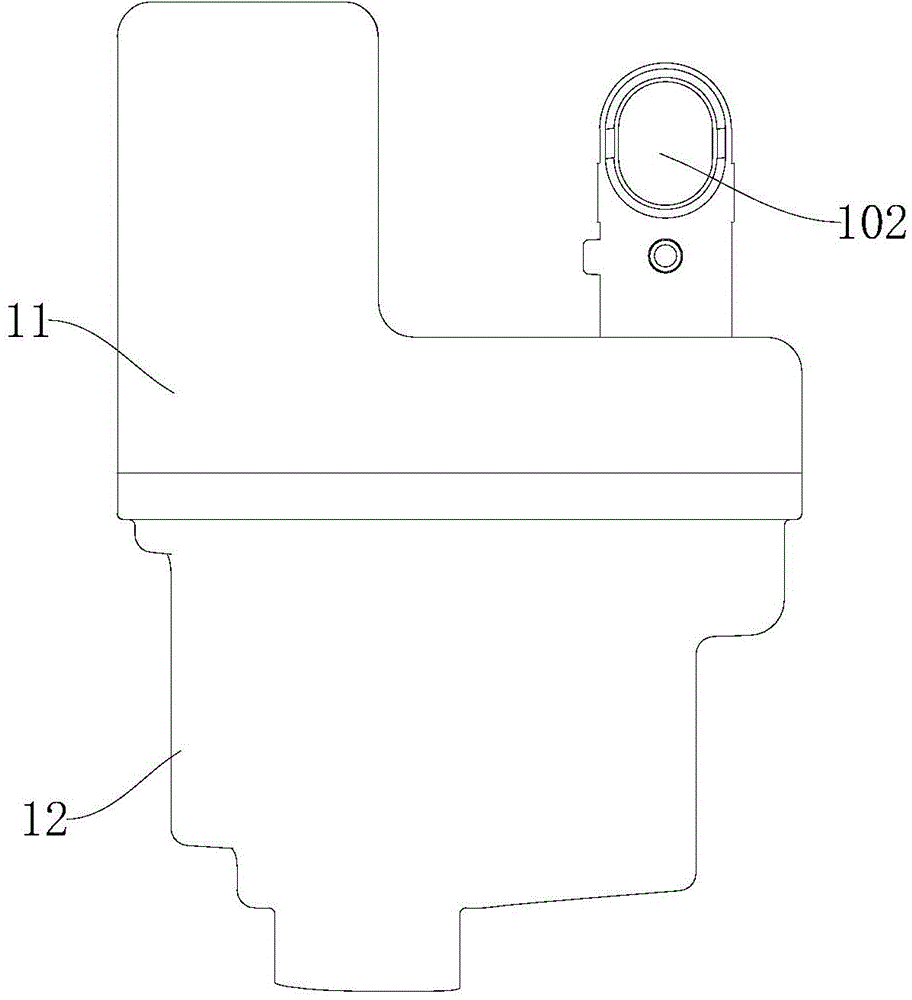

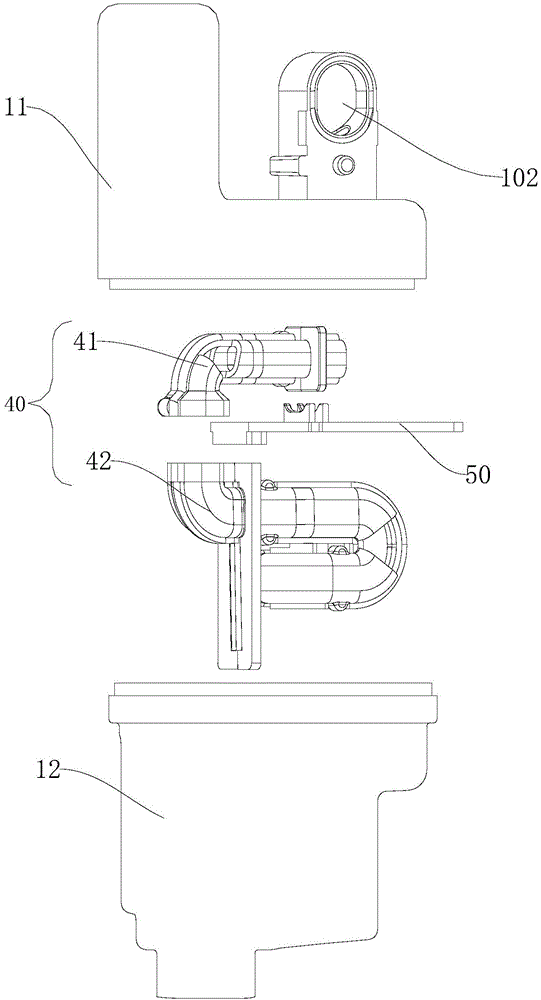

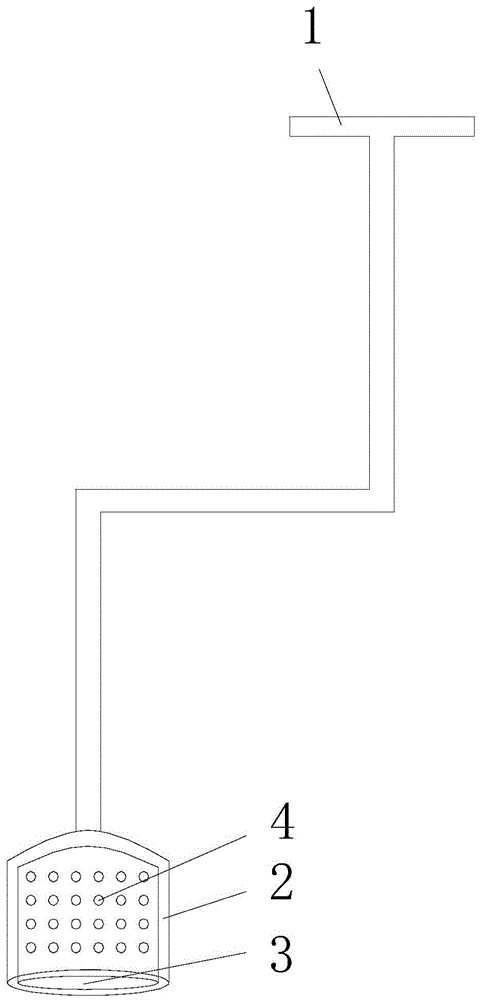

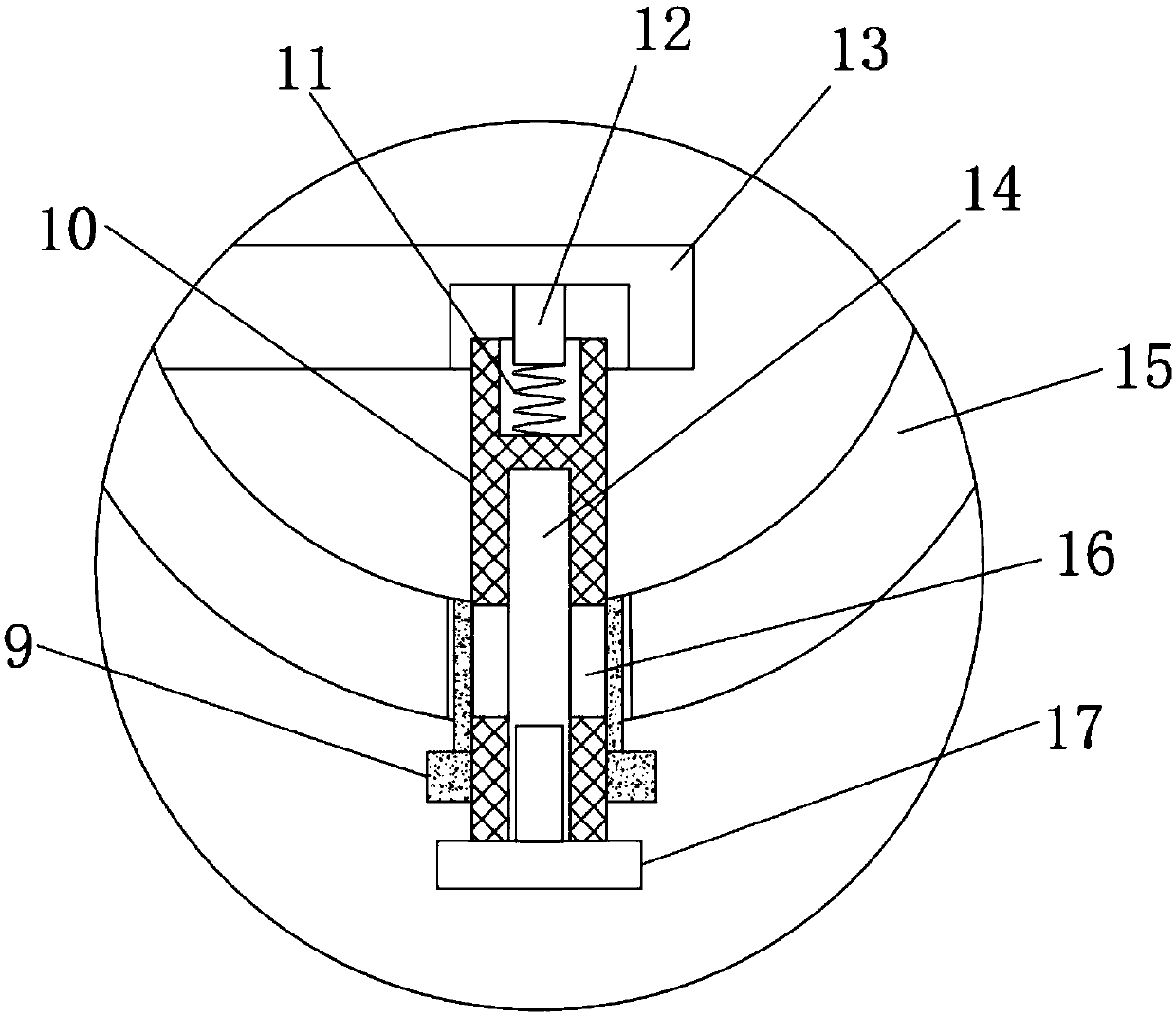

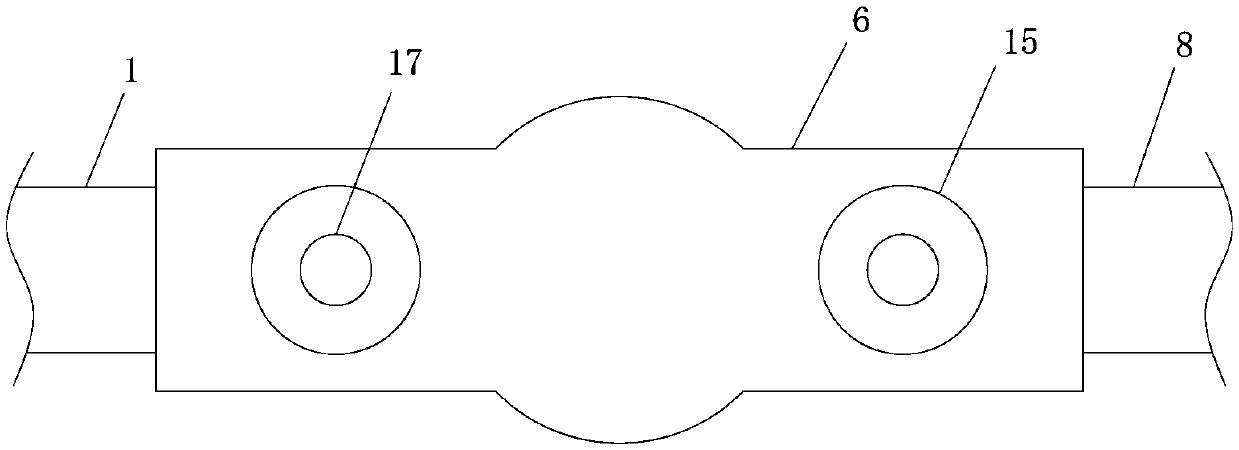

Air suction muffler and compressor provided with same

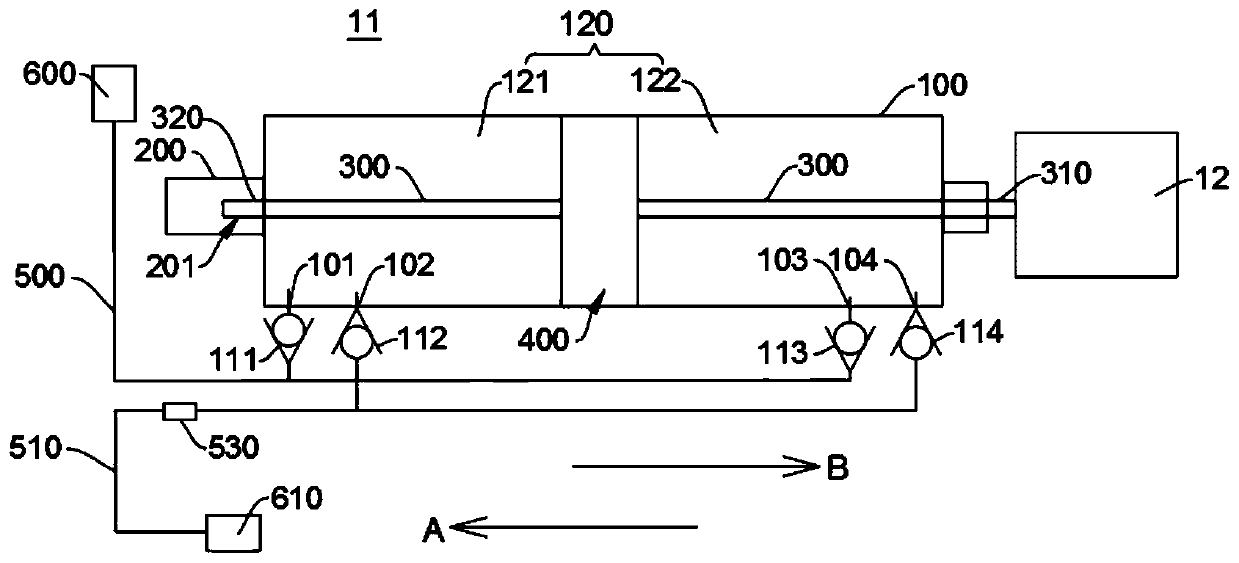

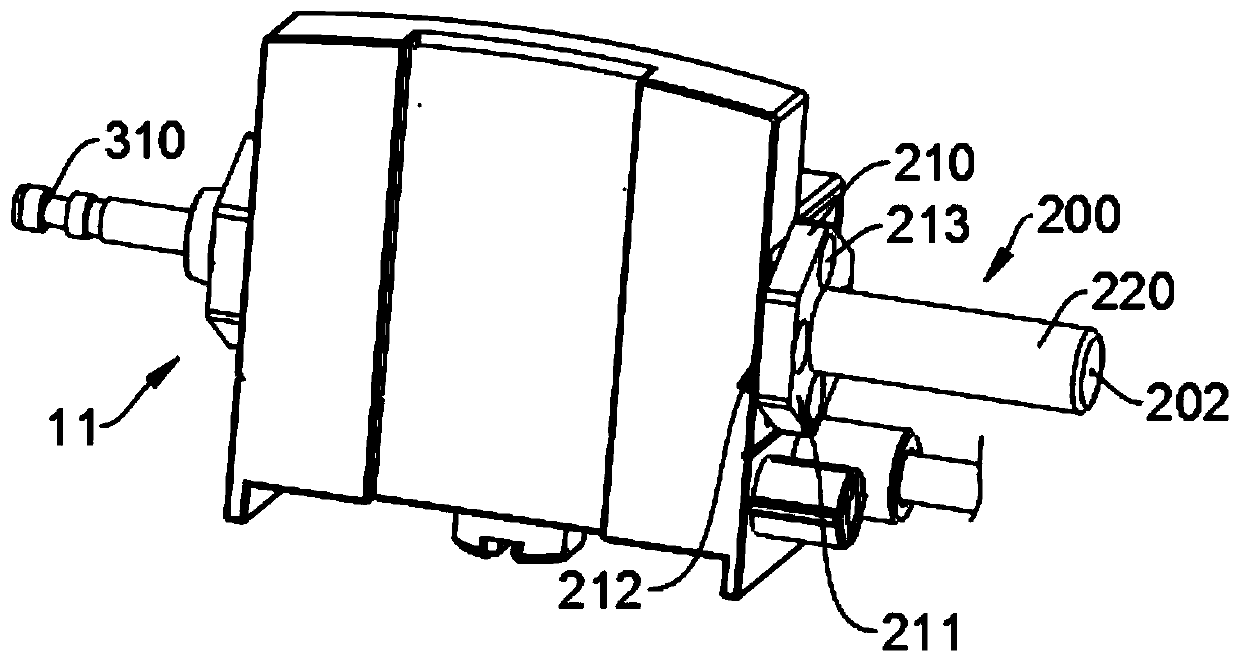

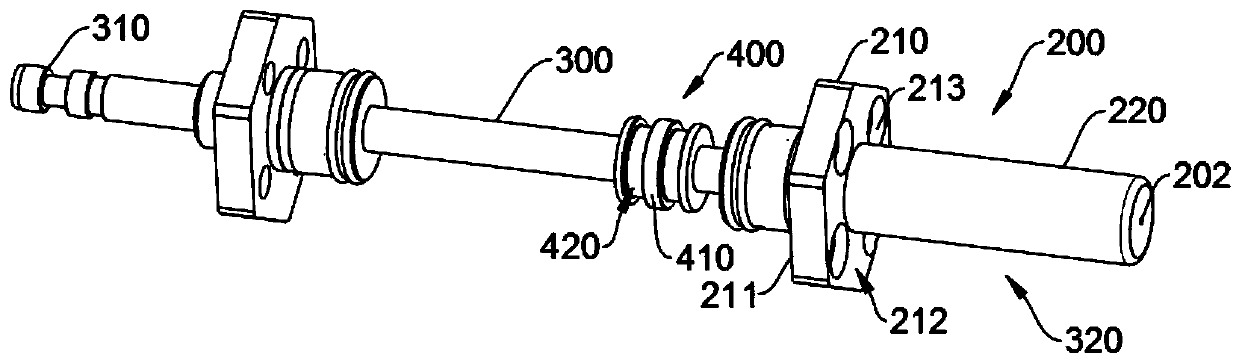

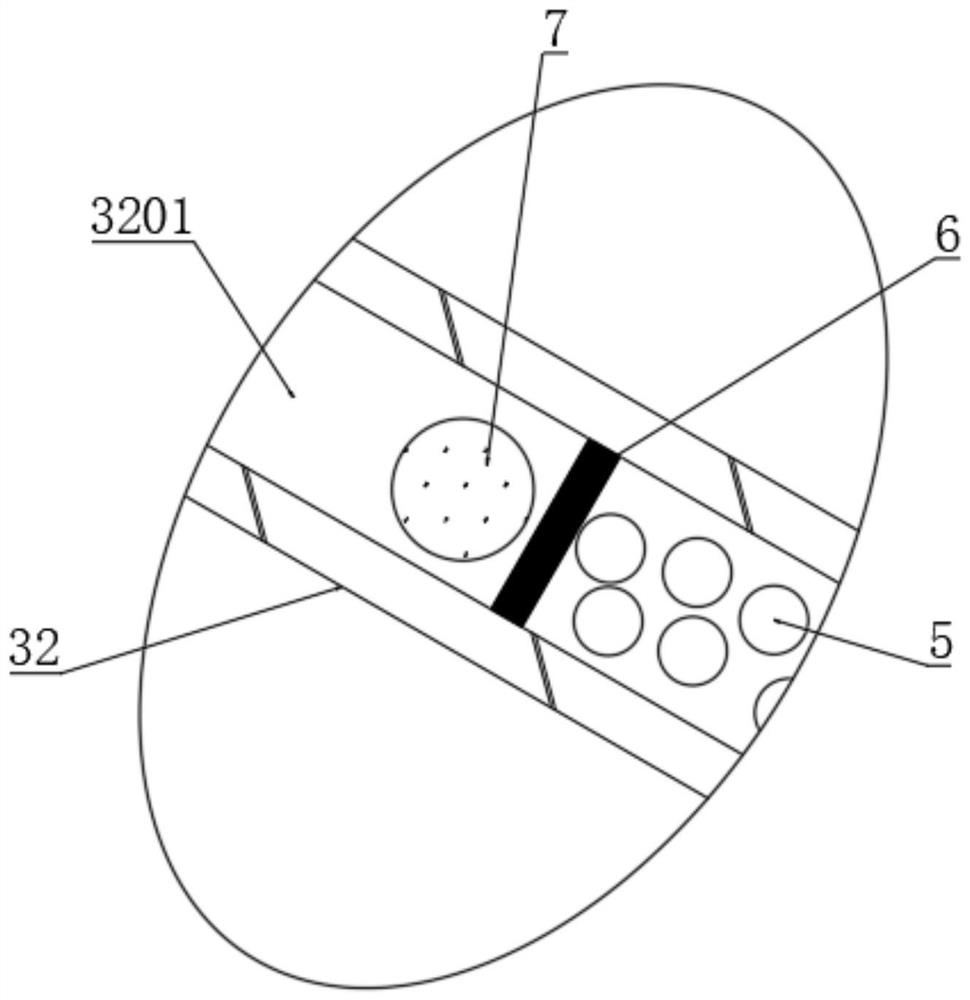

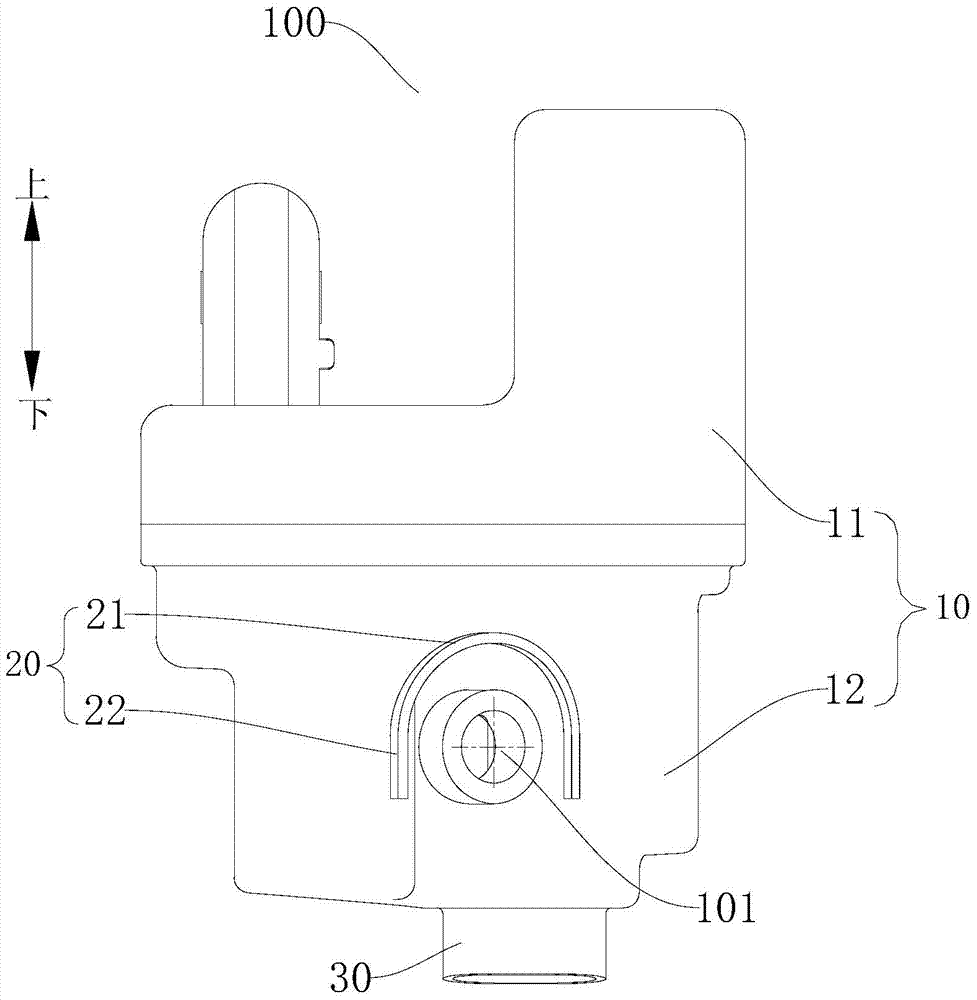

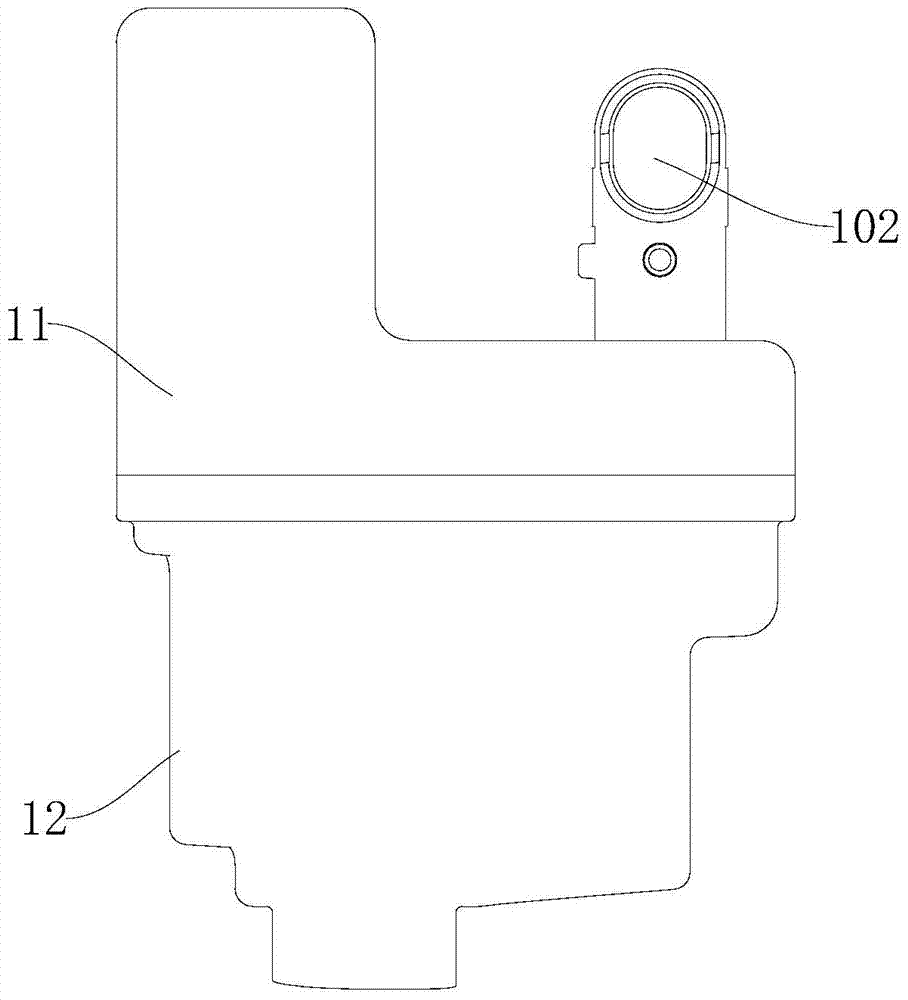

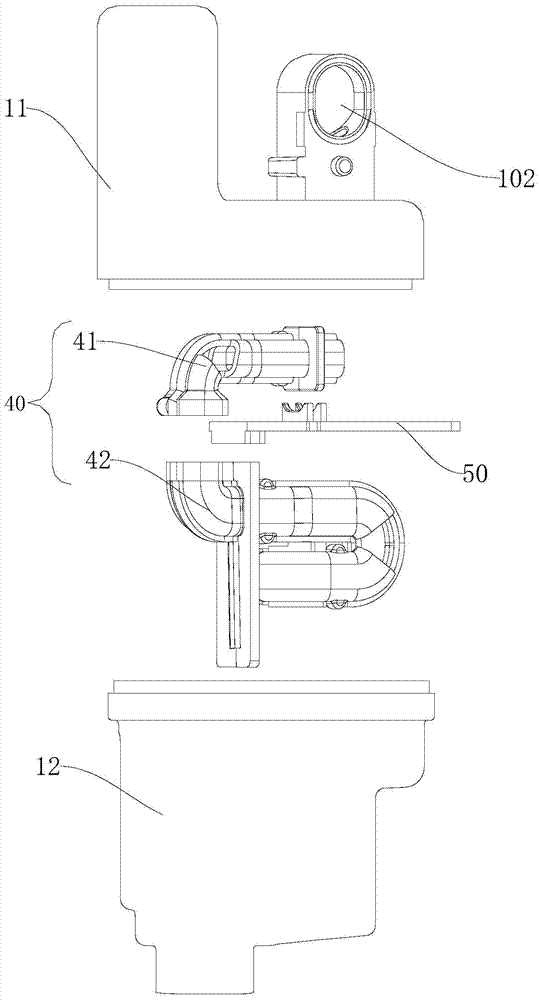

ActiveCN104879288ANot easy to bring inLess quantityPositive displacement pump componentsPositive-displacement liquid enginesRefrigerantRefrigerated temperature

The invention discloses an air suction muffler and a compressor provided with the same. The air suction muffler comprises a casing and an oil baffle element, wherein the casing is provided with an air suction port and an air exhaust port, and an airflow channel communicated with the air suction port and the air exhaust port is formed in the casing; the oil baffle element is arranged on the casing, bulges out of the outer wall surface of the casing and extends outwards, and at least part of the oil baffle element is located right above the air suction port. According to the air suction muffler disclosed by the embodiment, refrigerator oil is not easily carried into the air suction muffler by a refrigerant from the air suction port, so that the quantity of the refrigerator oil flowing into a compression chamber along with the refrigerant is reduced greatly, the oil puff quantity of the compressor is reduced, and the safe reliability is improved.

Owner:ANHUI MEIZHI COMPRESSOR +1

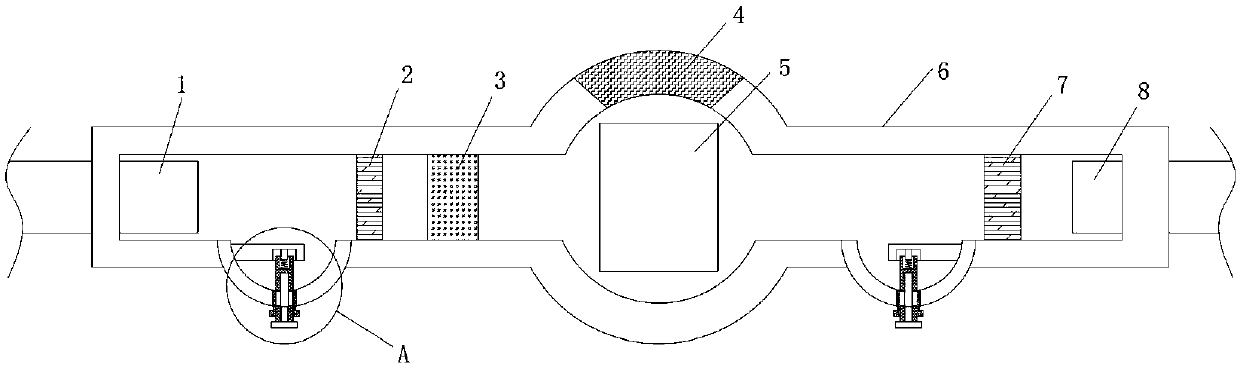

Containing piece, pump head and pressure pump

PendingCN111053958AWith dustproof effectFast stretching frequencyPressure infusionMedicineApparatus instruments

The embodiment of the invention provides a containing piece, a pump head and a pressure pump, and relates to the field of medical instruments. The problems that in an existing infusion pressure pump,dust easily enters a pump body, and a telescopic rod stretches out and draws back to injure people are solved. The containing piece is used for being connected to the exterior of a pump body, the pumpbody is provided with a containing cavity used for containing a piston rod, the containing piece is provided with a sliding channel used for being communicated with the containing cavity, and the sliding channel is used for enabling the free end, stretching out of the pump body, of the piston rod to stretch in. The pump head comprises the pump body and the containing piece. The pressure pump comprises the pump head. The containing piece is connected to the outer portion of the pump body, the sliding channel in the containing piece is communicated with the containing cavity, the free end, stretching out of the containing cavity, of the piston rod stretches into the containing cavity, in the reciprocating movement process of the piston rod, the containing piece has the dustproof effect on the free end of the piston rod, and external dust is prevented from being brought into the pump body in the stretching and retracting process of the free end of the piston rod. And meanwhile, the containing piece further has a protection effect on the free end of the piston rod, and personal injury to people in the telescopic process is avoided.

Owner:MICRO TECH (NANJING) CO LTD

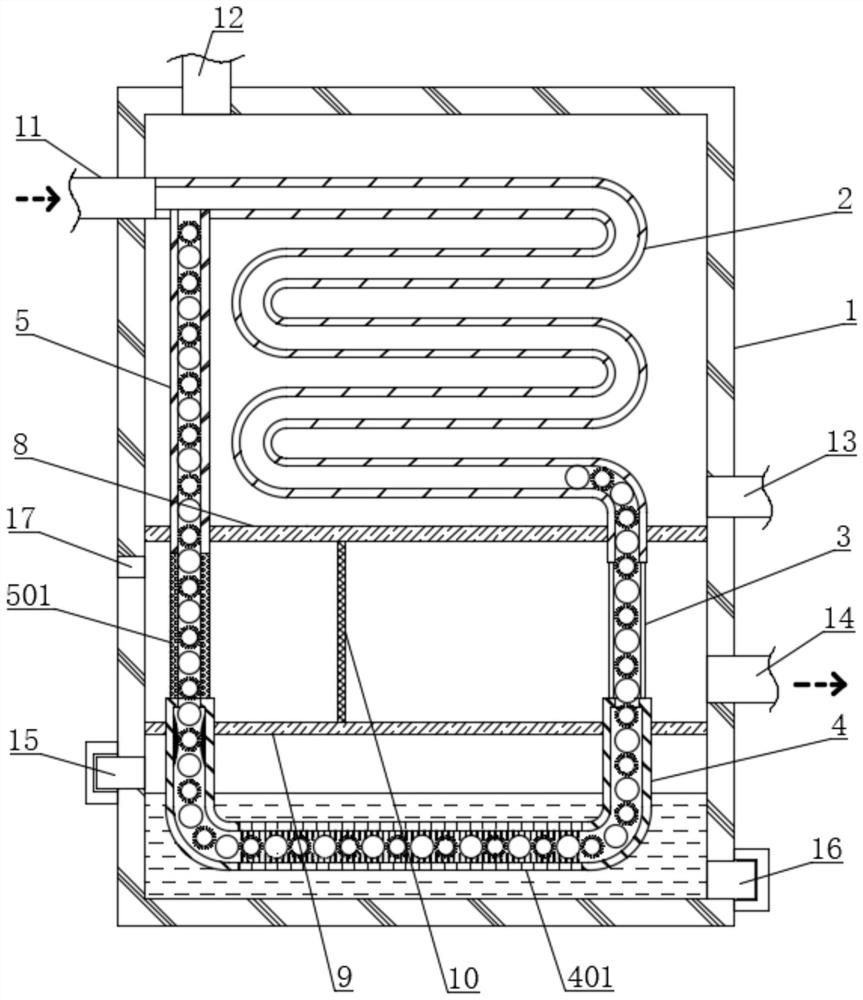

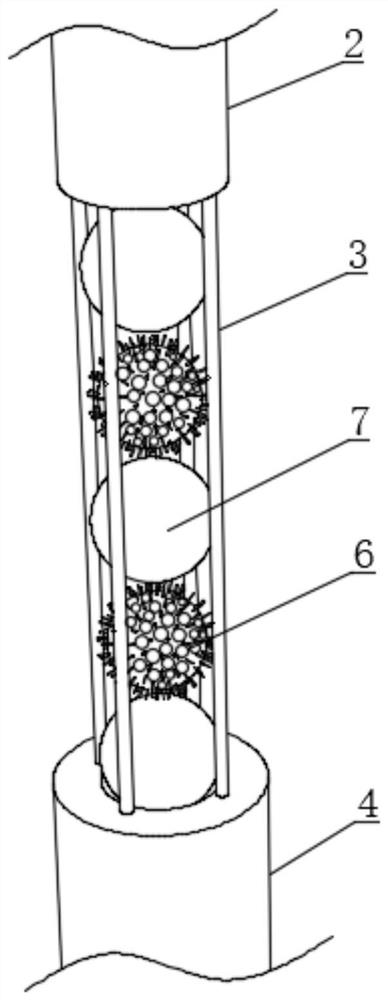

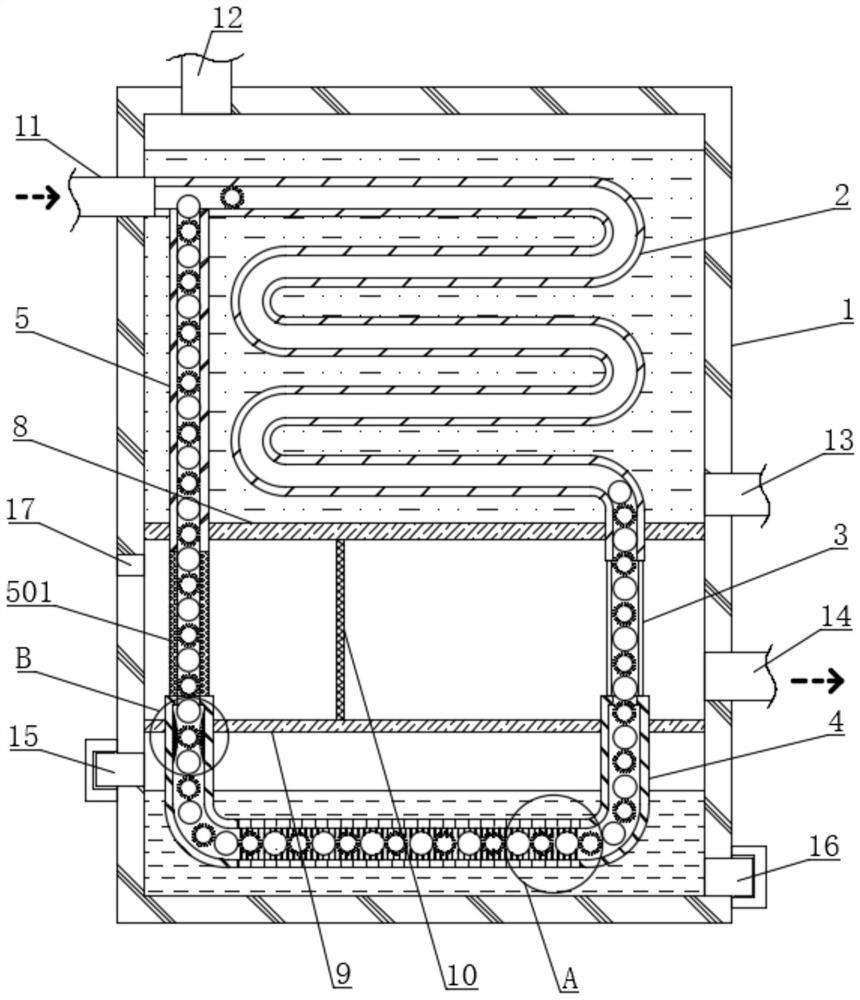

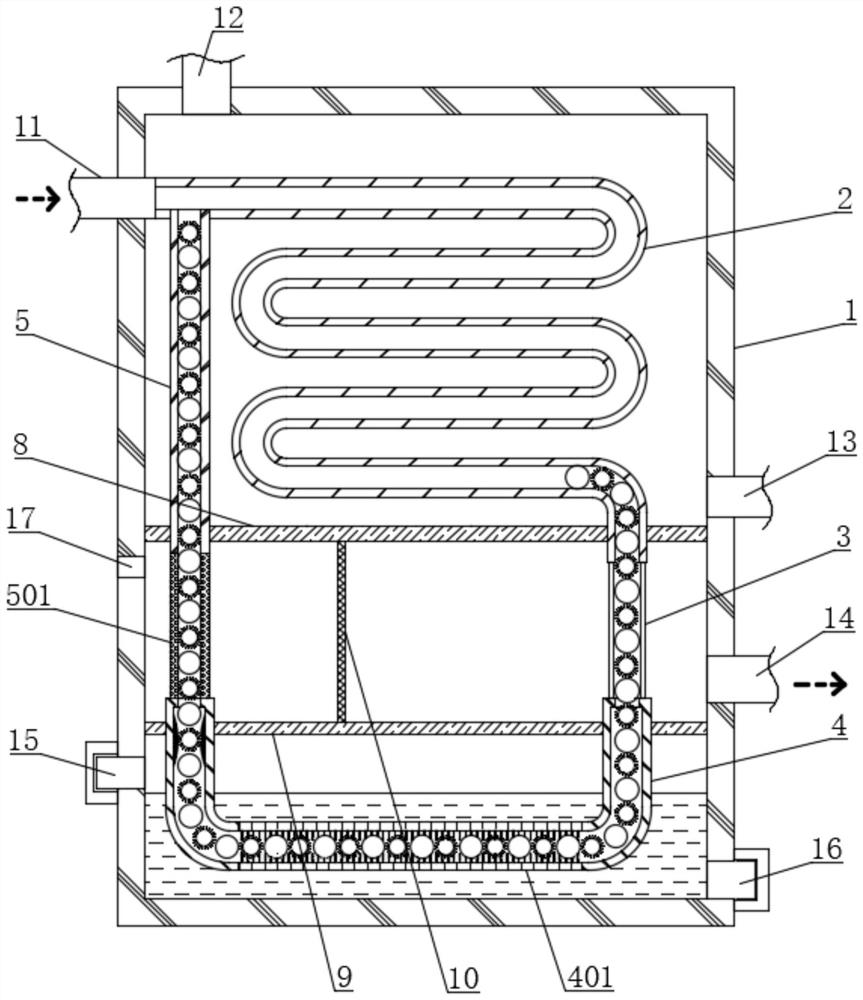

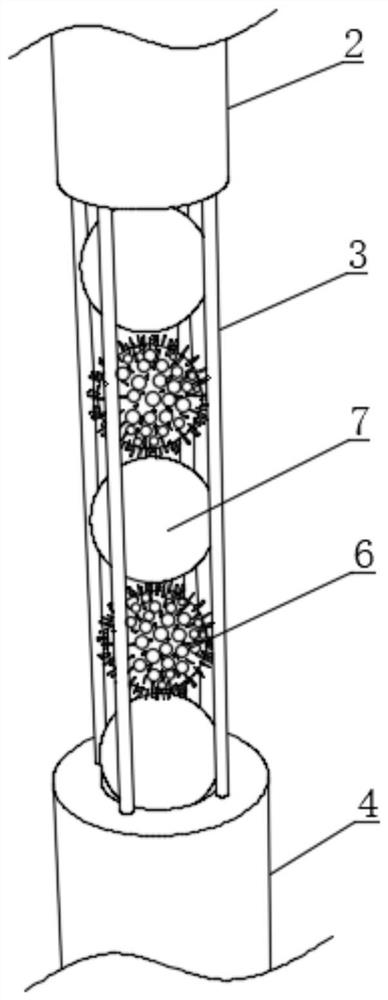

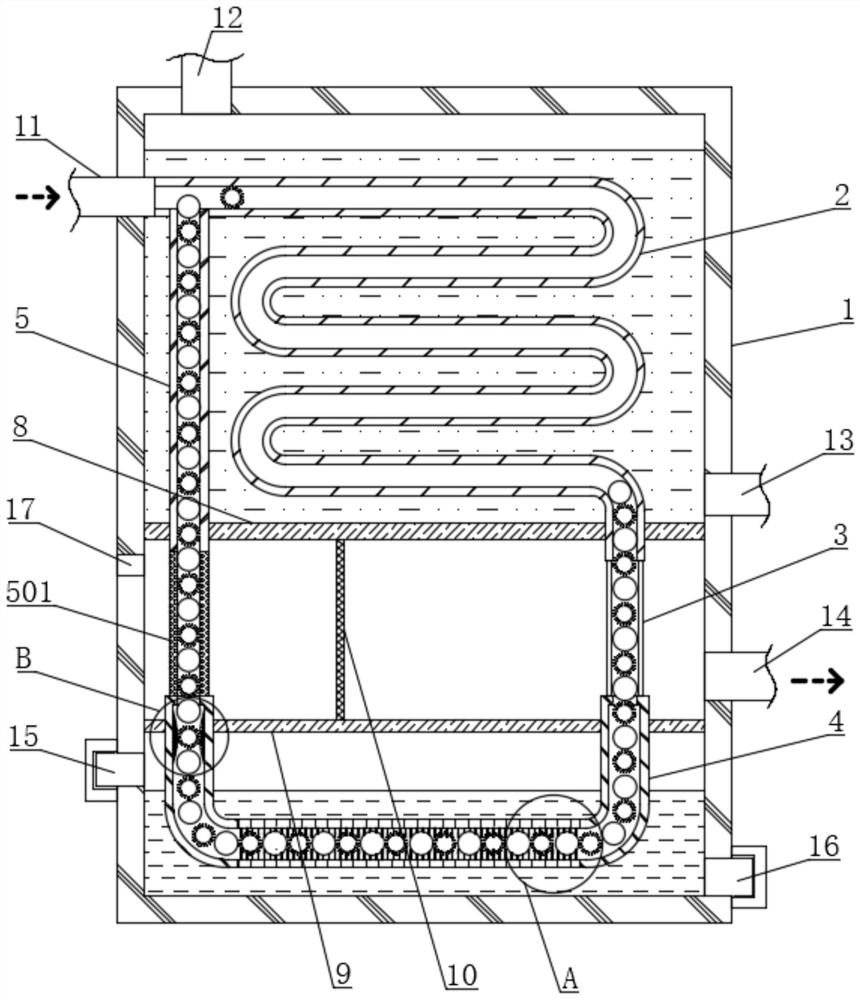

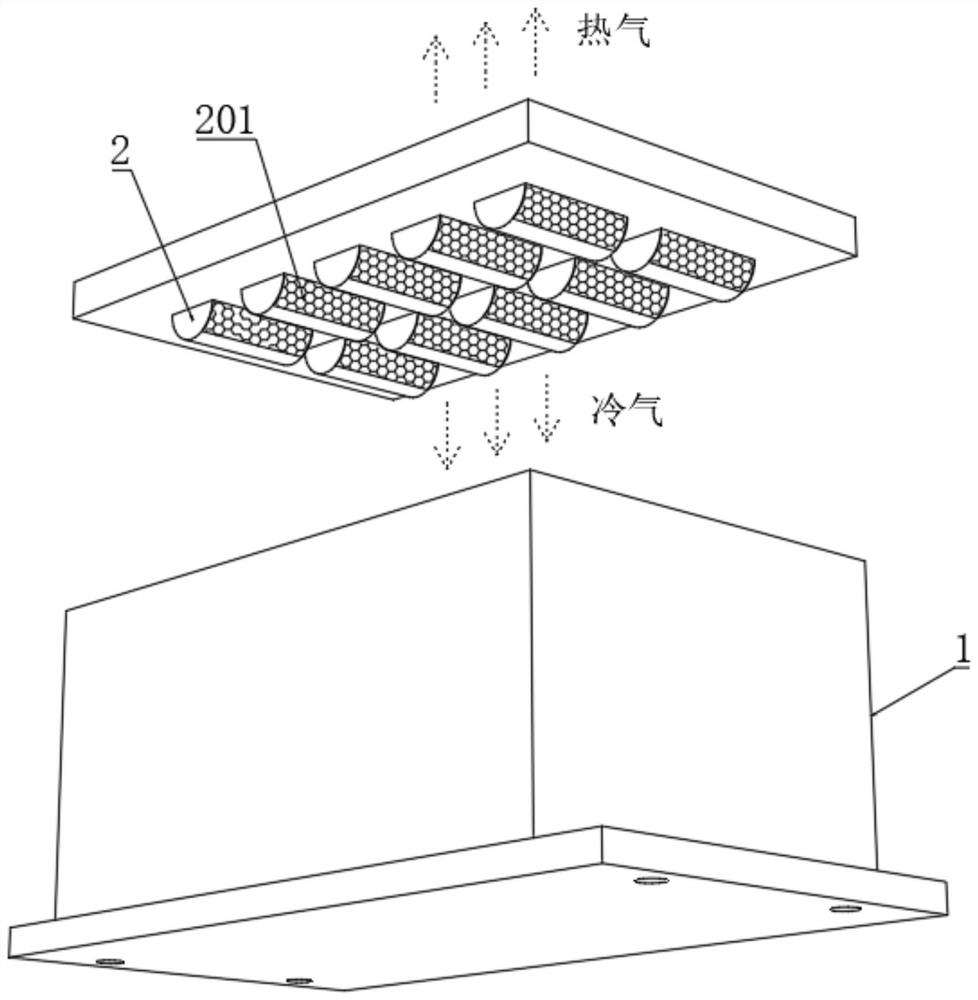

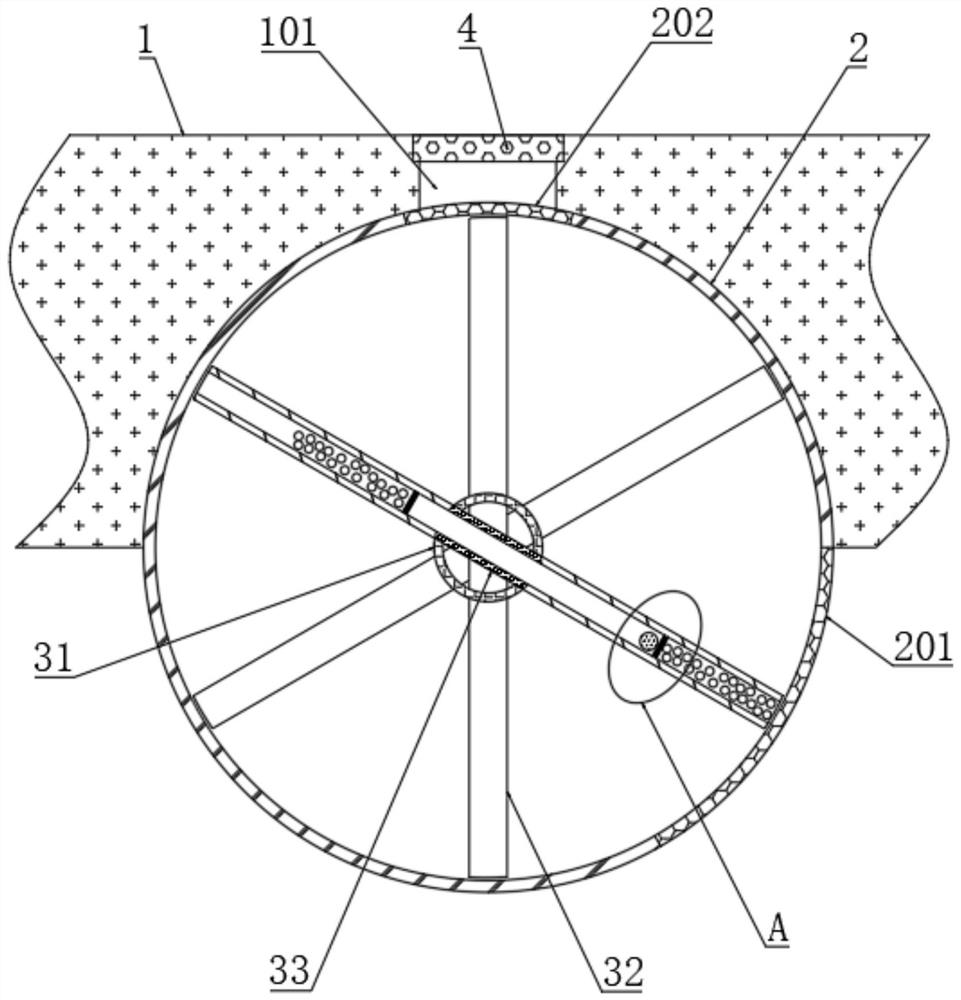

Boiler flue gas waste heat recovery device and recovery method

ActiveCN111765782AGuaranteed cleaning effectClean thoroughlyDrying solid materials without heatStationary tubular conduit assembliesParticulatesThermodynamics

The invention discloses a boiler flue gas waste heat recovery device and a recovery method, and belongs to the technical field of flue gas waste heat recovery. The boiler flue gas waste heat recoverydevice comprises a device shell, a heat exchange pipe is arranged in the device shell, and the upper end of the heat exchange pipe is fixedly connected with a gas inlet pipe. In the process of carrying out waste heat recovery on flue gas, main clearing balls and auxiliary clearing balls are pushed by flue gas flow, so that the main clearing balls and the auxiliary clearing balls cyclically and constantly roll in the heat exchange pipe in turns, the inner wall of the heat exchange pipe is constantly cleaned synchronously in the waste heat recovery process, and flue gas particulate matter attached to the inner wall of the heat exchange pipe is cleared away; and in the process that the main clearing balls and the auxiliary clearing balls complete clearing of one time on the heat exchange pipeand return to the gas inlet end of the heat exchange pipe, the processes of self cleaning, dewatering, drying and the like are sequentially achieved, then the main clearing balls and the auxiliary clearing balls enter the heat exchange pipe again to clean the heat exchange pipe, and therefore the clearing effect to the heat exchange pipe is further guaranteed.

Owner:四川陆亨能源科技有限公司

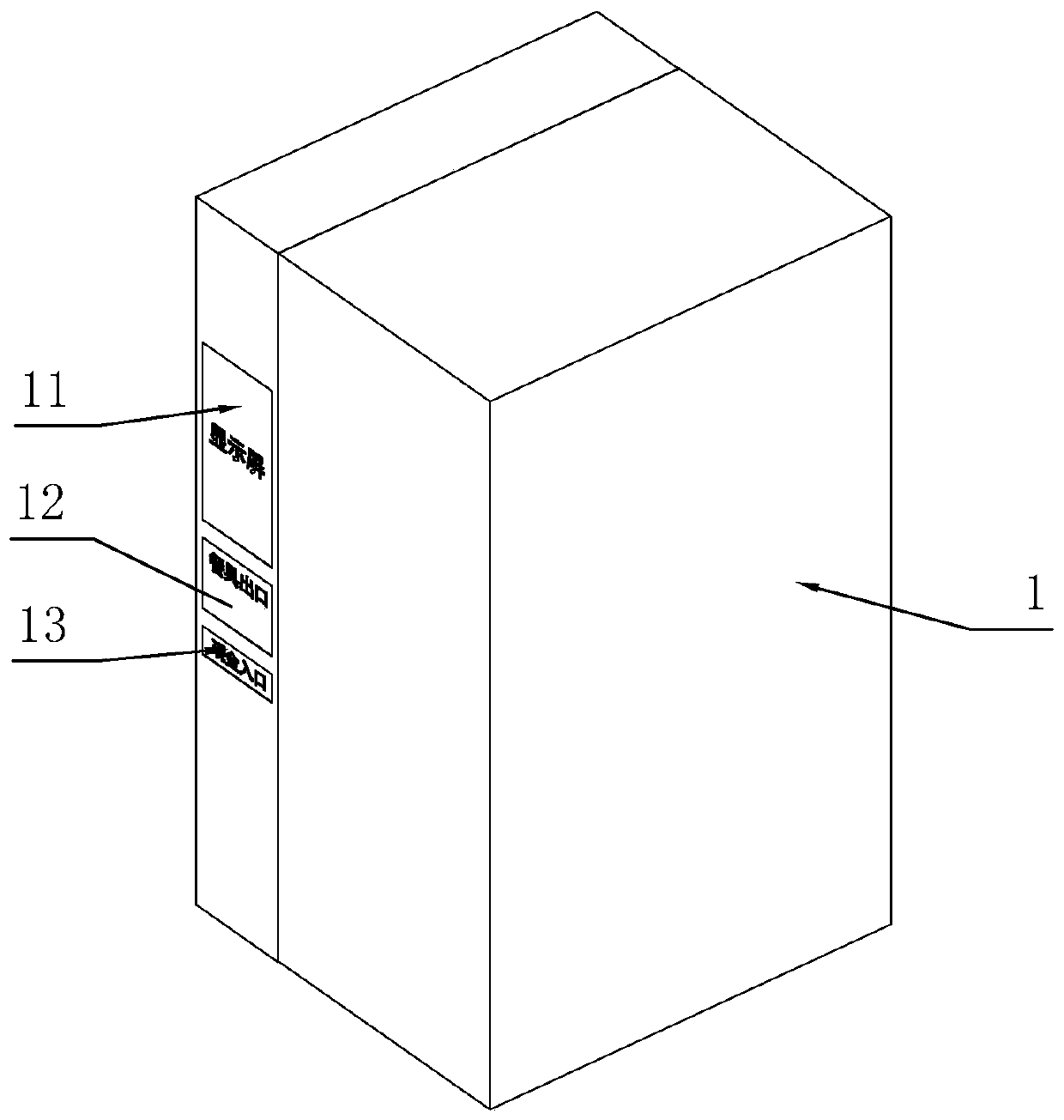

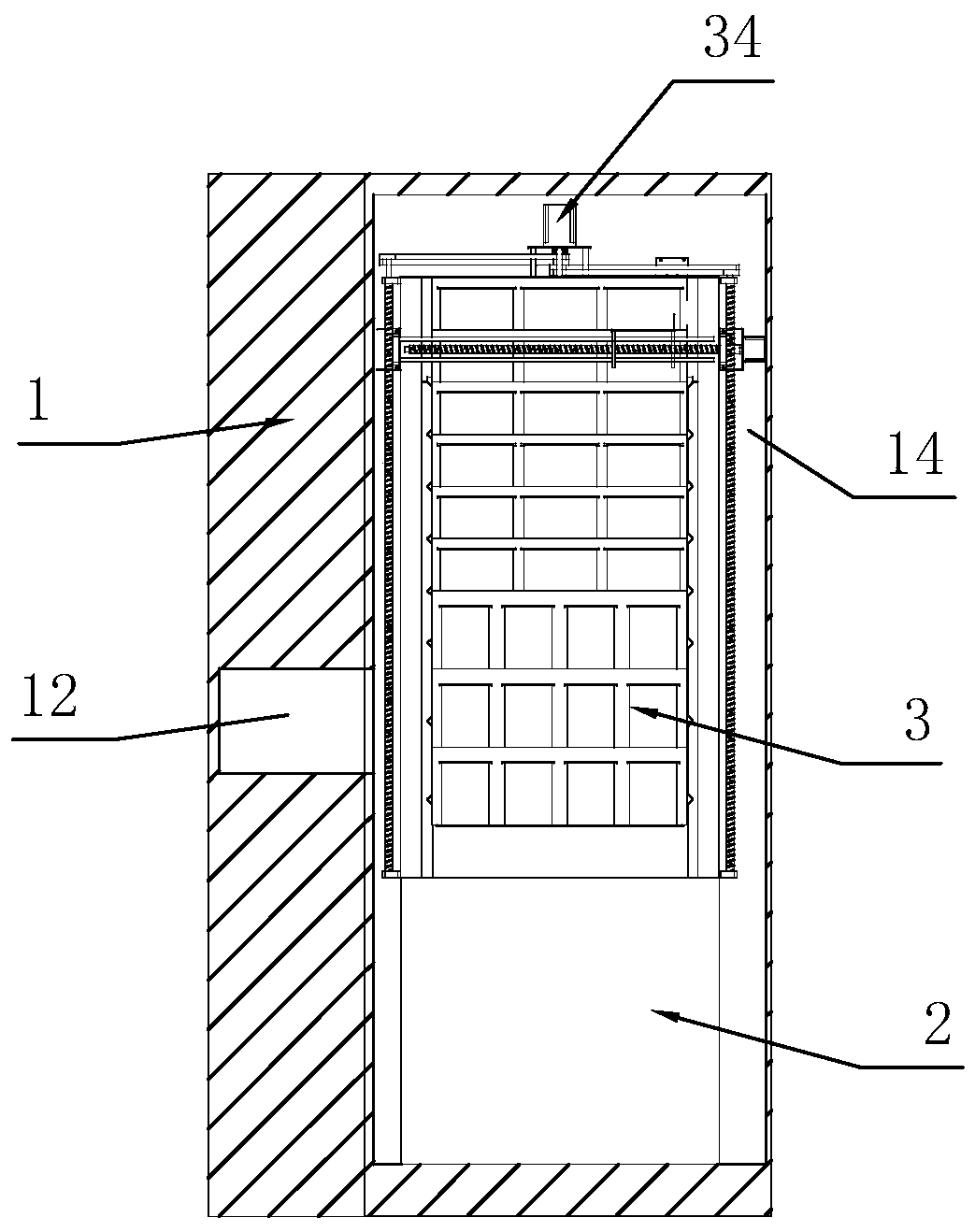

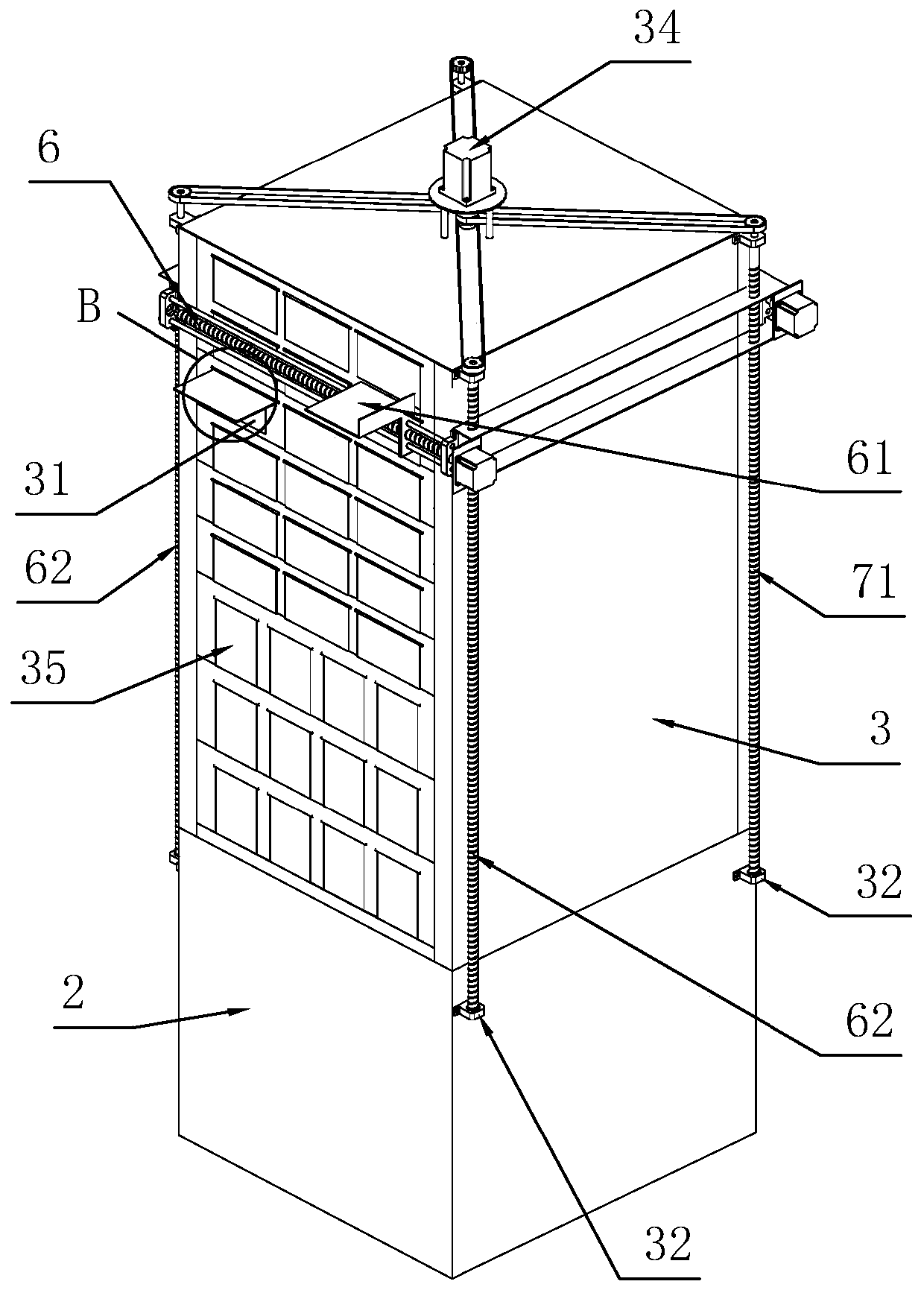

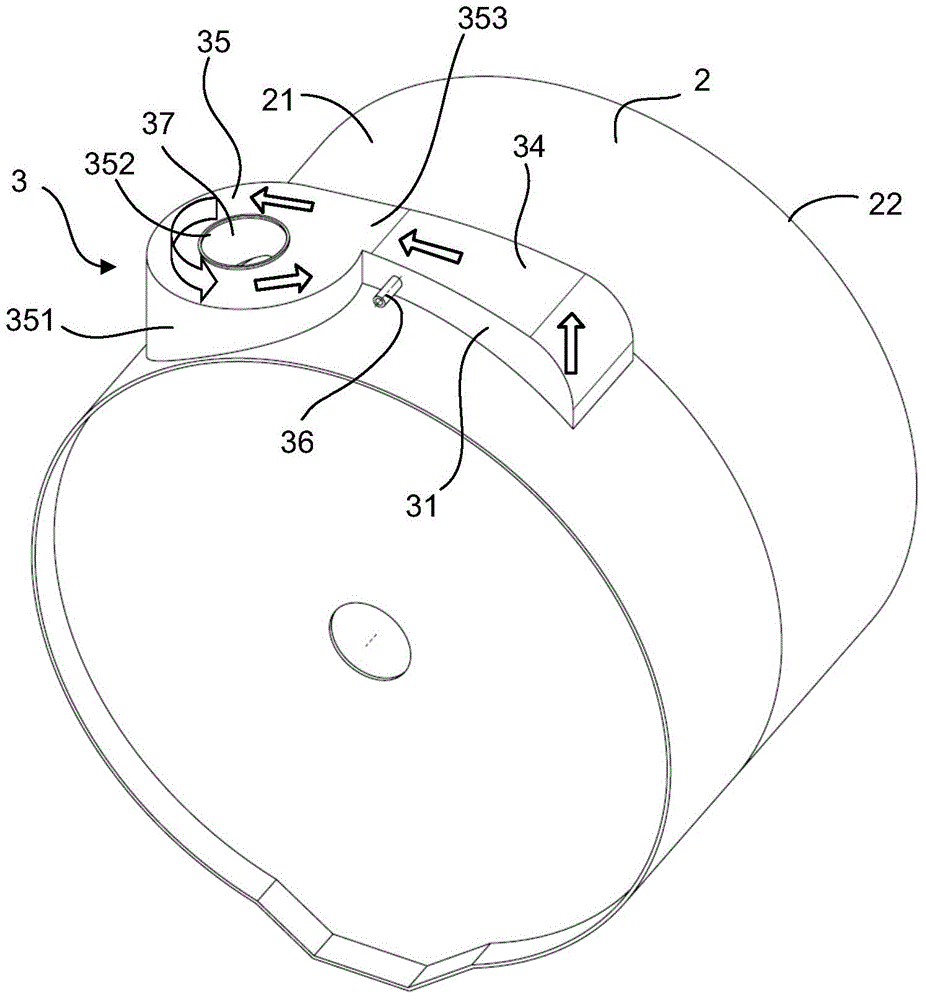

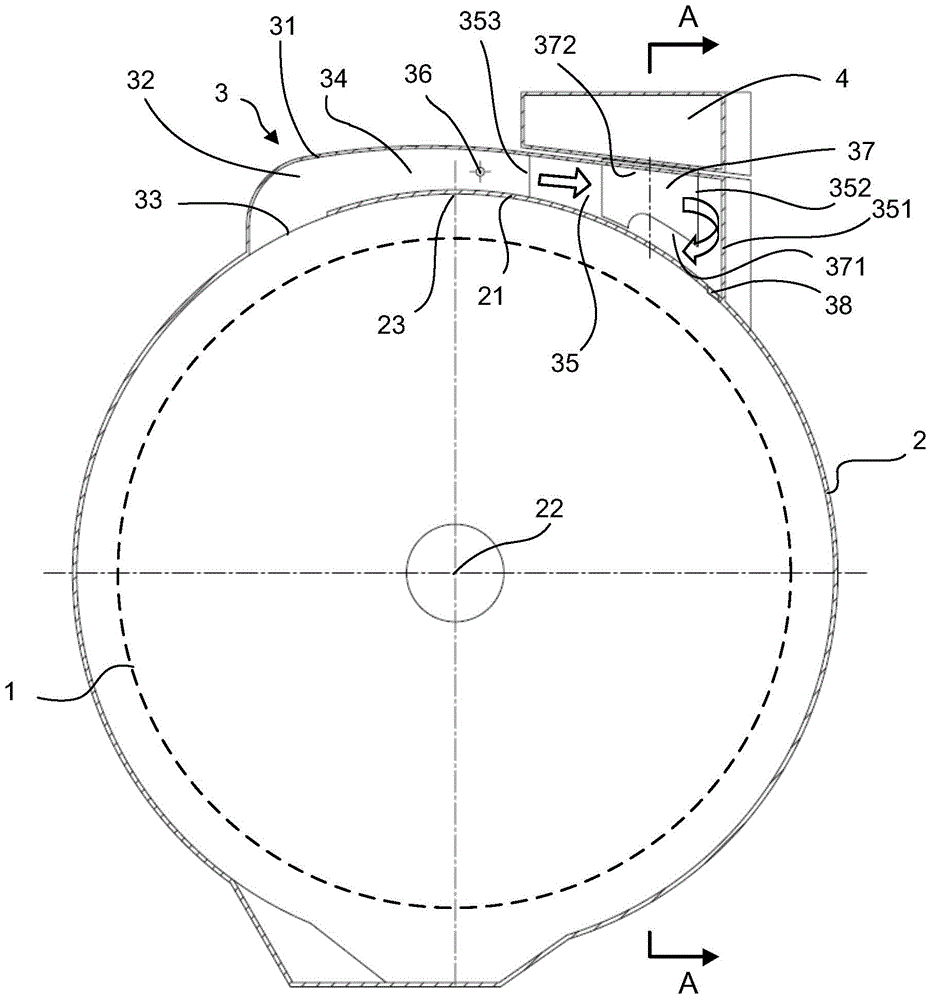

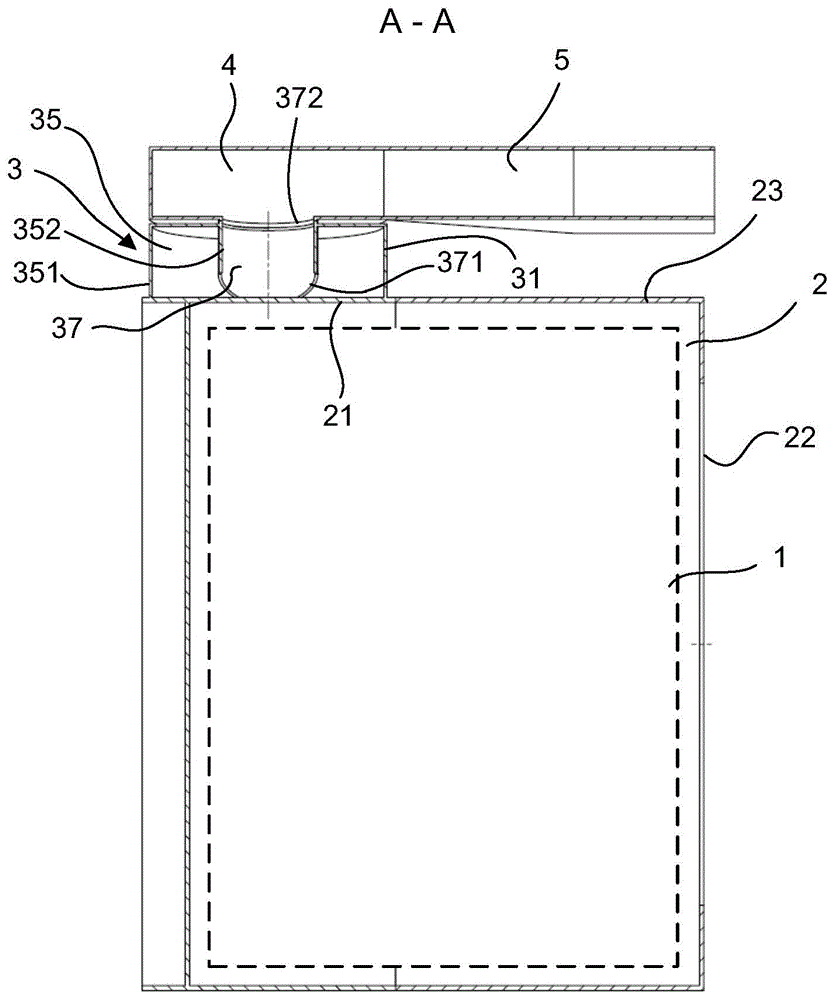

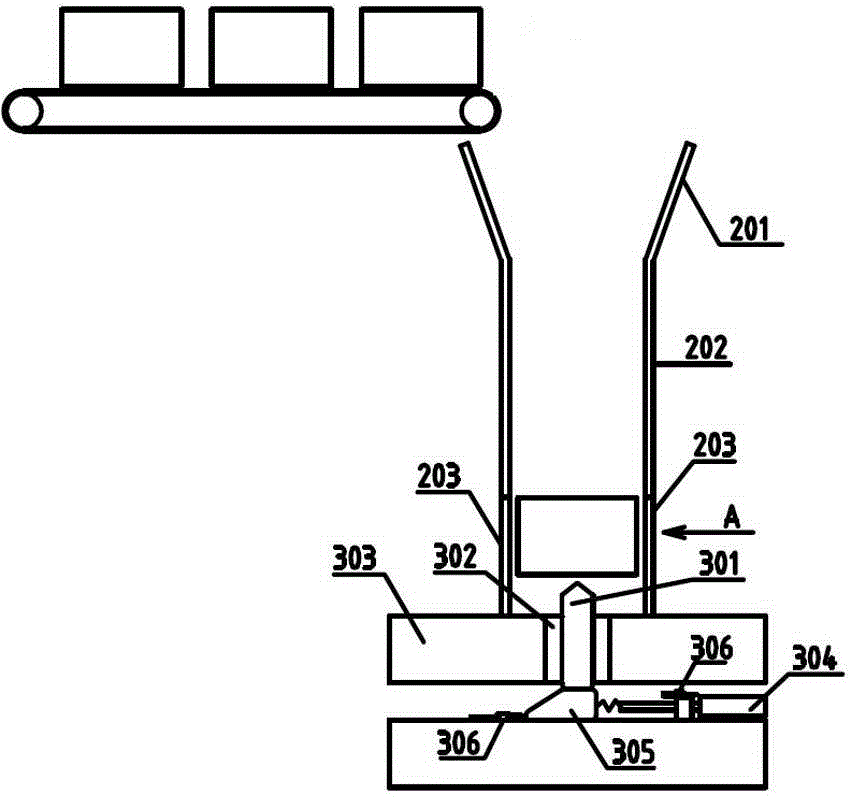

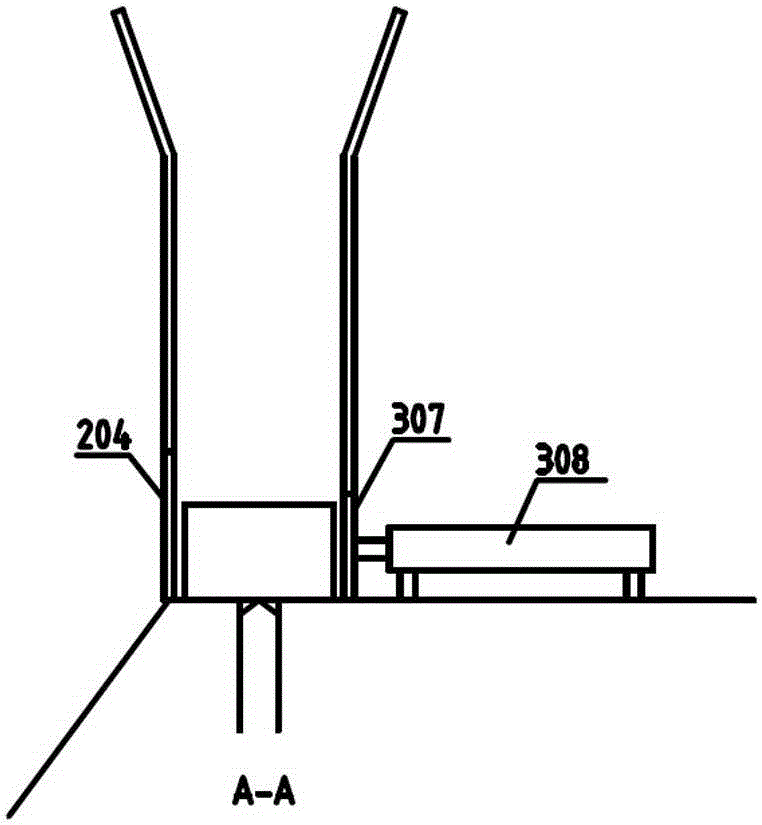

Vending machine having simple structure

PendingCN110211291AReduce the quantity requiredRealize automatic vending functionCoin-freed apparatus detailsApparatus for dispensing discrete articlesCouplingEngineering

The invention relates to a vending machine having a simple structure. The vending machine having the simple structure comprises a machine frame; a storage cavity and a pickup hole are arranged in themachine frame; several supply tracks for placing sold articles are arranged in the storage cavity; a delivery hole is formed on one end of the track direction of the supply track; a delivery mechanismfor transmitting the sold articles towards the delivery hole is arranged at the other end; the delivery mechanism comprises several push parts arranged on the various supply tracks, and a driving motor for driving the delivery part; the number of the driving motor is at least one; a first coupling part is arranged on the output shaft of the driving motor; each delivery part is separately providedwith a second coupling part; the first coupling part and the second coupling part can be in separable connection; and a switching mechanism for moving the first coupling part to any second coupling part is arranged on the machine frame. By adoption of the scheme, delivery for any supply track can be realized by adoption of the single driving motor; and thus, the vending machine having the simplestructure in the invention is low in equipment production cost, convenient to maintenance, and precise, simple and convenient to debug.

Owner:黄诚

Black pepper juice and preparation method thereof

The invention discloses black pepper juice. The black pepper juice comprises the following components in parts by weight of 27.35-55.5 parts of water, 12-19 parts of sugar, 6-10 parts of black peppers, 8-15 parts of a soy sauce, 3-6 parts of table salt, 3-5 parts of tomato paste, 2-4 parts of oyster juice, 2-4 parts of yeast cream, 2-4 parts of garlic, 1-3 parts of vegetable oil, 2-4 parts of modified starch, 0.1-0.4 part of disodium 5'-ribonucleotide, 0.3-1 part of caramel, 0.05-0.2 part of citric acid and 0.05 part of potassium sorbate. The black pepper juice has unique fragrant flavor of the pepper fruits, is moderate in hot and sweet degree, rich in taste, suitable for being used for cooking, mixing and dipping; during blending, modified starch liquid for thickening is added, so that in the cooking process, the modified starch can enable the black pepper juice to be in the moderate viscous state, and the black pepper juice cannot separate out moisture. The black pepper juice is good in stability, and good quality of the black pepper juice disclosed by the invention is guaranteed. After can sealing is performed, sprinkling for sterilization is performed, so that in the package process, microorganisms of bacteria and the like are not liable to carry in, and the quality guarantee period of the black pepper juice is prolonged.

Owner:珠海市宝门食品企业有限公司

Electric clothes dryer

ActiveCN106192325ALong heat exchange strokeCompact spaceWashing machine with receptaclesTextiles and paperCentrifugal forceAir heating

The invention discloses an electric clothes dryer which comprises a bucket for containing clothes, a condenser communicated with the space of the bucket, and a fan for promoting air to flow to the condenser from the bucket. The condenser and the bucket are provided with a common wall, and the condenser is provided with an annular airflow channel. Due to the fact that the condenser and the bucket are combined, the electric clothes dryer is more compact spatially, the annular airflow channel provides a longer heat exchange travel, and condensation efficiency is improved. Condensate water is thrown to the wall of the annular airflow channel under the action of centrifugal force through rotary airflow, and therefore the condensate water cannot be easily taken into the fan or an air heating device by the airflow.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU +1

Refining method of aluminum alloy for experiment

The invention discloses an experimental aluminum alloy refining method. The experimental aluminum alloy refining method comprises the following steps: (1) a refining agent is prepared; and (2) refining: when aluminum alloy molten liquid reaches the refining temperature of 730-760 DEG C, the refining agent is added into the aluminum alloy molten liquid in a manner of adding 1.5 g of the refining agent per kilogram of Al. The refining agent can reach the optimal reaction speed with the aluminum alloy molten liquid, meanwhile, a large quantity of bubbles can be generated in the reaction process of hexachloroethane and the aluminum alloy molten liquid, so that gas in the aluminum alloy molten liquid is gathered and ascends to achieve excellent degassing effect; the bubbles generated by the reaction of the hexachloroethane and aluminum also can absorb and dissolve suspended maters in the aluminum alloy molten liquid, so that impurities in the molten liquid ascend to the liquid surface along with the bubbles to achieve excellent slag removing effect; and when a container slowly rotates, the container is always buried below the liquid surface, so that the gas is effectively prevented from being taken into the aluminum alloy molten liquid in the rotating process so as to eliminate such quality problems as air holes and slag inclusions in aluminum alloy cast bars.

Owner:YINGKOU ZHONGWANG ALUMINUM CO LTD

Novel cooling tower

InactiveCN107144151ANot easy to blockSimple structureCorrosion preventionHeat exchange apparatusWater storage tankEngineering

The invention relates to a new type of cooling tower, which includes a cooling tower body. A cooling fan, a water distributor, a filler and a water storage tank are sequentially arranged in the cooling tower body from top to bottom, and an air inlet and outlet are arranged on the side wall of the cooling tower body. The reservoir is provided with a first filter screen, the first filter screen is installed above the reservoir, the bottom of the reservoir is provided with a drainage pipe, and the top of the drainage pipe is 10-20cm higher than the bottom wall of the reservoir. The top of the drain pipe is provided with a second filter screen, and the side walls of the reservoir are provided with drain outlets, which communicate with the drain pipe through connecting pipes. The invention can effectively filter waste slag and debris, the drain port is not easy to be blocked, has the advantages of simple and reasonable structure, and is convenient for users to use.

Owner:WUXI OCEAN COOLING EQUIP YIZHENG

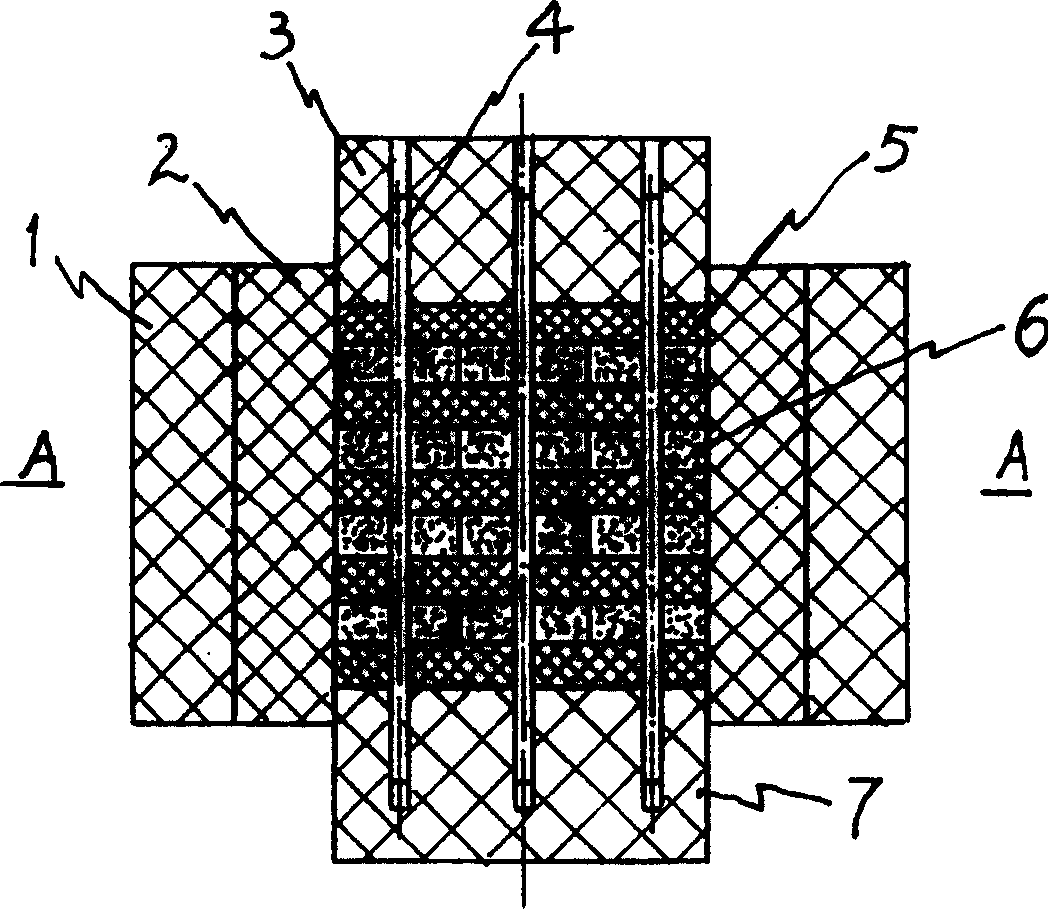

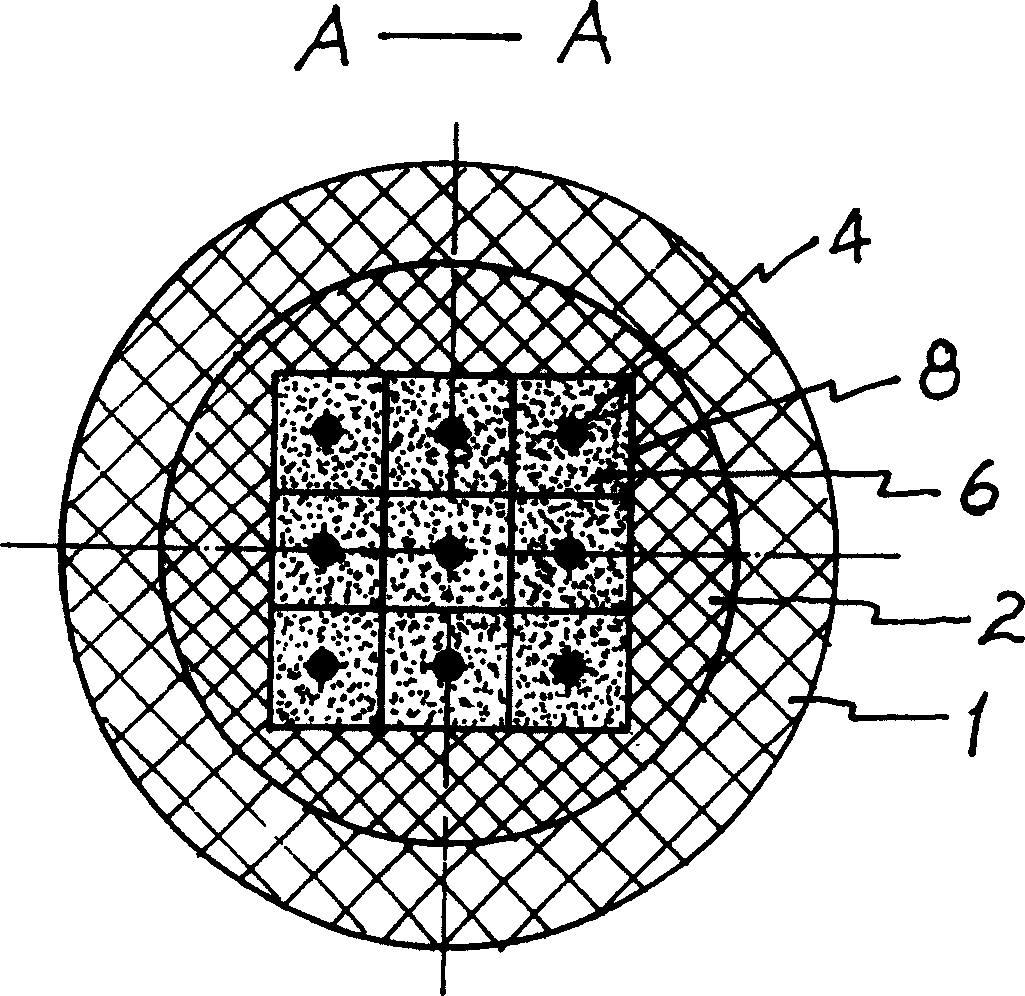

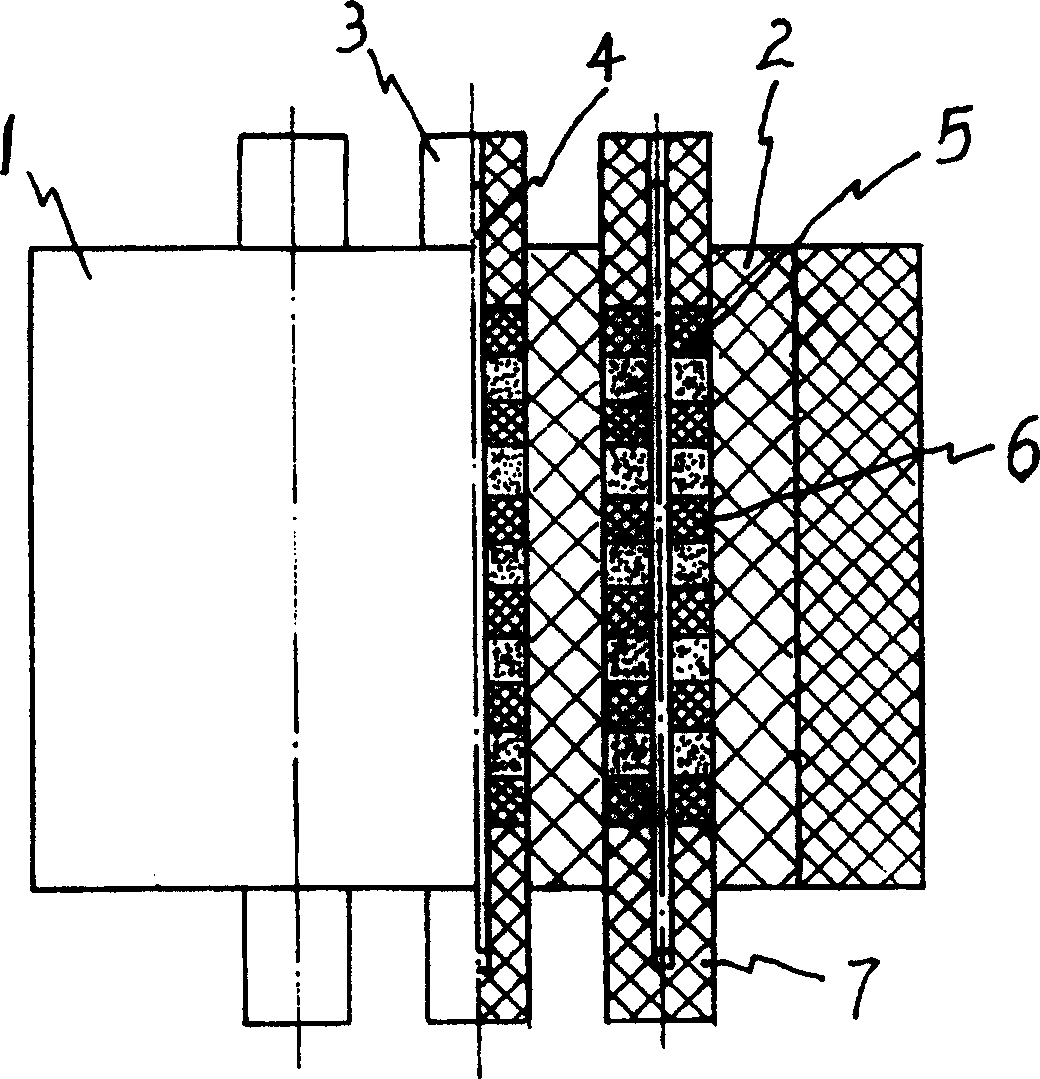

Hot-pressing sintering method and mould for ceramic,hard metal products with holes

Owner:ZIGONG CEMENTED CARBIDE CORP

Simple pollution discharge water meter

InactiveCN111174849AEasy to operateExcellent cleaning effectVolume meteringWater flowEnvironmental engineering

The invention discloses a simple pollution discharge water meter. The water meter comprises a water meter body, a metering device is arranged in the water meter body, two pollution discharge mechanisms are arranged at a bottoms of two ends of the water meter body, a filtering mechanism is arranged on an inner wall of the water meter body, and water conveying devices are arranged at the two ends ofthe water meter body. The water meter is reasonable in structural design, and is very simple, rapid and convenient in pollution discharge operation and capable of filtering most impurities in a waterflow.

Owner:XIAN TRIONES DIGITAL INFORMATION

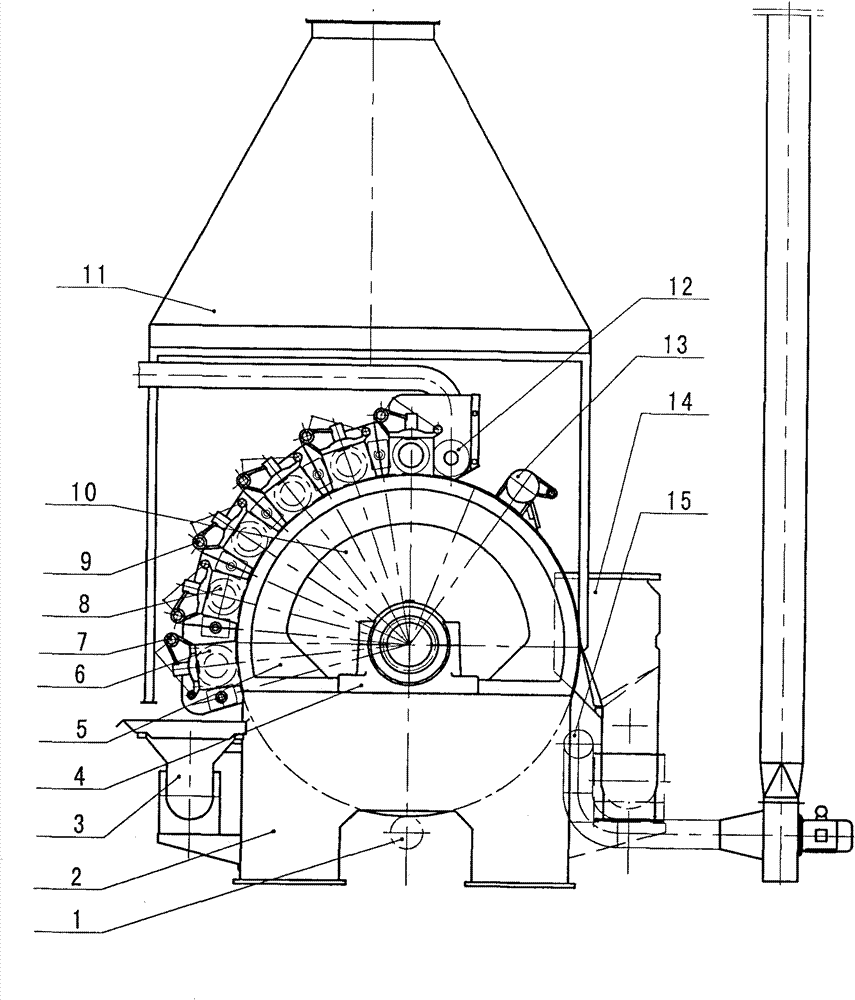

Roller dryer

The invention discloses a roller dryer. The roller dryer comprises power devices, main racks, waste collecting devices, main bearing seats, semicircular supports, small waste rollers, small waste scrappers, small material distributing rollers, small material distributing scrappers, main rollers, upper dehumidifying hoods, material distributing spiral devices, scrapper devices, breaking and conveying devices and lower dehumidifying devices; the main bearing seats at two ends of the main roller are arranged on the main racks of the dryer; a semicircular support is arranged on each of the two main racks; and the small material distributing rollers, the small waste rollers, the scrapper devices and the material distributing spiral devices are arranged on the semicircular supports. By adopting the roller dryer, the integrity of cell granulates can be remained to the maximum extent during the processing process of whole potato powder, so that the products have flavor and taste close to those of original potato; and impurities such as stems and black spots in material processing can be removed, and thus the quality of the whole powder can be ensured.

Owner:东台市食品机械厂有限公司

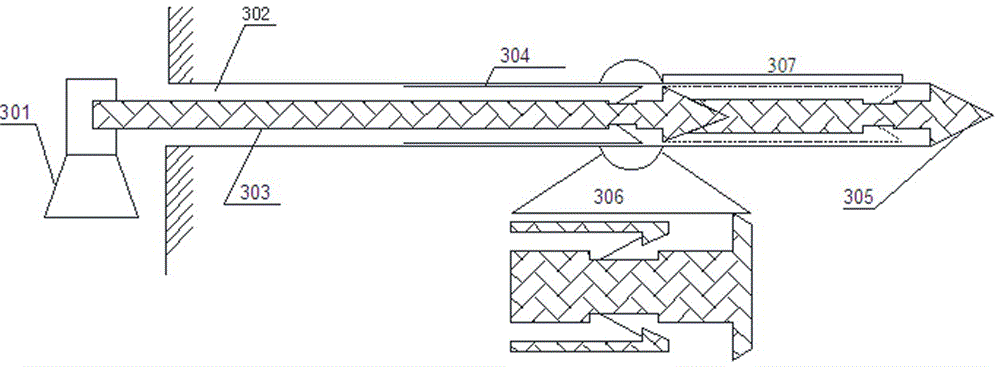

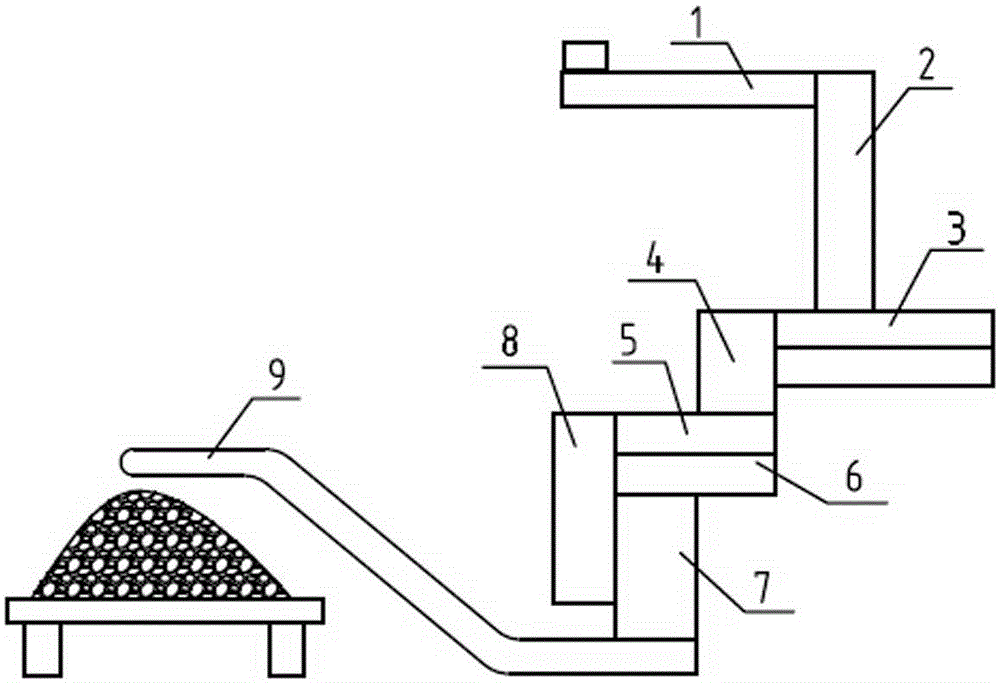

Metallic silicon crushing system

InactiveCN105149074ARound and beautiful grain shapeImprove uniformityGrain treatmentsFailure rateEngineering

The invention relates to a metallic silicon crushing system which comprises a feeding system, a dropping pipeline, a crushing system, a screening system, a primary crushing system, a secondary crushing system, a particle producing system, a dust removing system and a discharging system, wherein the feeding system is connected with the upper end of the dropping pipeline; the lower end of the dropping pipeline is connected with the crushing system; the screening system is arranged below the crushing system; the primary crushing system is arranged below the screening system, and is connected with the secondary crushing system; the secondary crushing system is connected with the particle producing system; the discharging system is arranged below the particle producing system; the dust removing system is connected with the primary crushing system, the secondary crushing system and the particle producing system. The metallic silicon crushing system is simple and practical in overall structure, low in yield, high in production efficiency, lower in energy consumption, low in cost, low in failure rate and long in service life; the produced discharged small silicon particles are round and aesthetic in particle shape, good in uniformity, free of violent struck crushing, small in powder amount, low in possibility of impurity introduction, and free of dust pollution problems.

Owner:怒江宏盛锦盟硅业有限公司

Closed type cooling tower

InactiveCN107202500AImprove adsorption capacityAvoid easy cloggingTrickle coolersWater storageWater discharge

The invention relates to a closed cooling tower, comprising a cooling tower body, a cooling fan, a water distributor, a filler and a water reservoir are arranged in the cooling tower body in sequence from top to bottom, and the side wall of the cooling tower body is provided with an air inlet and outlet , the bottom of the reservoir is provided with a magnetic plate and a drainage pipe, the magnetic plate is close to and covers the bottom wall of the reservoir, the top of the drainage pipe is 15-25cm higher than the bottom wall of the reservoir, and the Both sides of the side wall are provided with drainage ports, which are communicated with the drainage pipes through connecting pipes. The invention can effectively absorb metal slag, the drainage port is not easy to be blocked, and has the advantages of simple and reasonable structure, convenient use by users, and the like.

Owner:WUXI OCEAN COOLING EQUIP YIZHENG

Scorpion medicinal tablet production process

The invention discloses a scorpion medicinal tablet production process which comprises the following steps: selecting materials, washing, cooking, washing, centrifuging, drying, packaging and inspecting; during the processes of washing, cooking, washing centrifuging and drying, corresponding working areas are cleaned before the processes are carried out; after each step, the sites are cleaned again; during the cooking process, boiled salt water is used for cooking, and 100 parts by weight of wet scorpions are required to be cooked by using 20-25 parts by weight of edible salt; during the drying process, the whole scorpions are dried for 90 to 120 minutes by a hot air circulating drying oven, and a drying tray on a drying frame is exchanged up and down every 10 minutes. The whole technical scheme standardizes the steps of scorpion production, so that the produced scorpions are stable in efficacy, high in quality of efficacy and relatively short in processing cycle, thereby facilitating industrialization and standardized production.

Owner:河南尚华堂药业股份有限公司

Boiler flue gas waste heat recovery device and recovery method

ActiveCN111765782BGuaranteed cleaning effectClean thoroughlyDrying solid materials without heatStationary tubular conduit assembliesFlue gasProcess engineering

The invention discloses a boiler flue gas waste heat recovery device and a recovery method, which belong to the technical field of flue gas waste heat recovery. A boiler flue gas waste heat recovery device includes a device shell, and a heat exchange tube is arranged inside the device shell. The upper end of the air inlet pipe is fixedly connected with the air intake pipe. In the process of waste heat recovery of the flue gas, the present invention pushes the main cleaning ball and the auxiliary cleaning ball through the flue gas flow, so that the main cleaning ball and the auxiliary cleaning ball circulate continuously in the heat exchange tube. Rolling, in the process of waste heat recovery, the inner wall of the heat exchange tube is continuously and continuously cleaned, and the flue gas particles attached to the inner wall of the heat exchange tube are cleaned, and when the main cleaning ball and the auxiliary cleaning ball complete a cleaning of the heat exchange tube, In the process of returning to the inlet end of the heat exchange tube, the processes of self-cleaning, dehydration and drying are also realized in sequence, and then enter the heat exchange tube again to clean the heat exchange tube, thereby further ensuring the cleaning effect of the heat exchange tube .

Owner:四川陆亨能源科技有限公司

A comprehensive treatment system for chemical emissions

ActiveCN107954565BReduce moisture contentReduce dust contentDispersed particle separationTreatment involving filtrationFlue gasExhaust fumes

The invention discloses a comprehensive treatment system for chemical emission. The problems of low treatment efficiency and high treatment cost which are caused by a high-cost treatment system and serious energy waste which are caused by the problem of unreasonable treatment modes in the treatment process of three wastes are solved. Key points of the technical scheme of the comprehensive treatment system comprises a sewage treatment system, a sludge regulating and storing tank, a sludge treatment system and an exhaust gas treatment system, wherein sludge in the sewage treatment system is connected with the sludge regulating and storing tank through at least one sludge pump, and the sludge treatment system includes a drying system, a sludge incineration system, an excess heat utilizing system and a flue gas purifying system which are connected sequentially; the exhaust gas treatment system includes a gas collecting device which is used for collecting exhaust gas which is generated in the sewage treatment system and the sludge treatment system, and a gas collecting system is connected with a biologically deodorizing system and at least one level of gas absorption chamber systems sequentially. Not only can emission requirements of multiple aspects be met, but also the utilization of effective energy can be achieved, so that the treatment process is cleaner, and the efficiency ishigh.

Owner:宁波华清环保技术有限公司

A kind of tomato sauce and preparation method thereof

The invention relates to the technical field of seasoning processing, specifically to tomato ketchup and its preparation method. The tomato ketchup comprises the following components: by weight, 40-50 of concentrated ketchup, 4-5% of white sugar, 2-4% of acetylated distarch adipate, 0.3-0.6% of salt, 0.05-0.18% of edible acetic acid, 0.05-0.2% of vitamin C, 0.05-0.12% of cochineal, 0.03-0.08% of potassium sorbate, and 40-50% of water. The preparation method of the tomato ketchup comprises the following steps: Step 1, preparing a dissolved solution; Step 2, heating and adding a self-made thickening liquid; Step 3, carrying out gelatinization; Step 4, stirring materials; Step 5, boiling; and Step 6, cooling and adding auxiliary materials. The tomato ketchup has advantages of rich tomato flavor, soft mouthfeel, high nutritive value, anti-cancer efficacy, good stability, excellent quality and long shelf life.

Owner:DONGGUAN YONGYI FOODS

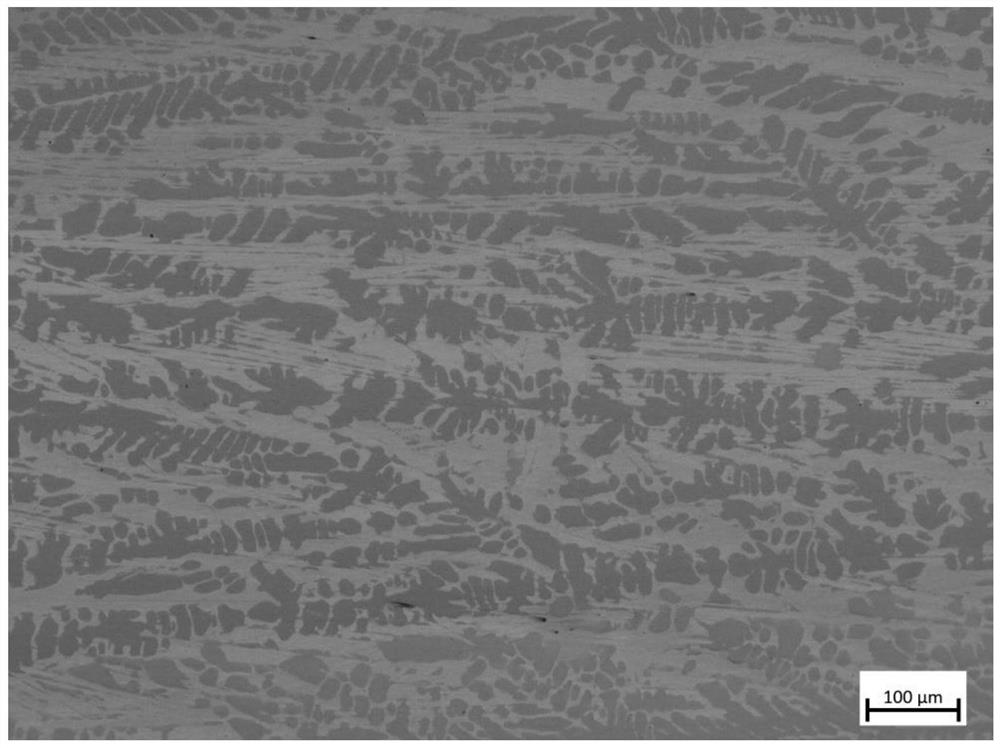

Magnesium alloy material for building formwork and preparation method

The invention belongs to the field of building formworks, and particularly relates to a magnesium alloy material for a building formwork and a preparation method. The magnesium alloy material comprises the following raw materials in percentage by mass: 0.25-0.6% of Ca, 0.25-0.5% of Y, 0.35-0.8% of Sn, 0.1-0.5% of Sr and the balance of AZ41. The preparation method comprises the following step: S1, melting, specifically, carrying out heating melting on magnesium alloy in a clean crucible to prepare magnesium liquid. According to the magnesium alloy material, the condition that a refiner is added in the refining process is improved, the refining effect of the refiner is improved, slag is sufficiently dredged in the two refining processes, the magnesium liquid is cleaner, flux slag at the bottom of the crucible is reduced, the cast product is cleaner, a flux mixture is not easily brought in, the corrosion resistance of the product is improved, and the preparation method is simple in process, reliable, economical and easy to apply and popularize.

Owner:陕西绥德臻梦镁合金材料有限公司

Manufacturing method of mixing blades used for mixing polyurethane resin

Belonging to manufacturing technologies of polyurethane floats, the invention relates to a manufacturing method of mixing blades used for mixing polyurethane resin. The method is characterized by employing a polytetrafluoroethene plate to make mixing blades and comprising the following steps of: first drawing the profiles of mixing blades on a polytetrafluoroethene plate, then scissoring the profiles of the mixing blades manually with a pair of scissors, and finally drilling out a central installing hole of the mixing blades. The method of the invention can manufacture a plurality of mixing blades so as to raise mixing uniformity, and bubbles are difficult to be brought in during mixing, so that resin residues on the blades can be easy to remove.

Owner:XINXIANG AVIATION IND GROUP RUBBER PLASTICPROD

A self-ventilating heat-dissipating type automobile regulator

ActiveCN113438861BExtended service lifeRealize the process of cooling and heatingCasings/cabinets/drawers detailsModifications for power electronicsThermal dilatationEngineering

Owner:徐州利明汽车电器有限公司

Suction muffler and compressor having same

ActiveCN104879288BReduce oil outputNot easy to bring inPositive displacement pump componentsPositive-displacement liquid enginesEngineeringRefrigeration

The invention discloses a suction muffler and a compressor with the same. The suction muffler comprises: a housing, the housing has a suction port and an air outlet, and a The gas port and the airflow channel of the air outlet; the oil retainer, the oil retainer is arranged on the housing, the oil retainer protrudes from the outer wall of the housing and extends outward, and at least a part is located on the directly above the suction port. According to the suction muffler of the embodiment of the present invention, it is difficult for the refrigerant to bring the refrigerating machine oil into the suction muffler from the suction port, so that the amount of refrigerating machine oil flowing into the compression cavity with the refrigerant is greatly reduced, and the discharge of the compressor The oil quantity is reduced, and the safety and reliability are improved.

Owner:ANHUI MEIZHI COMPRESSOR +1

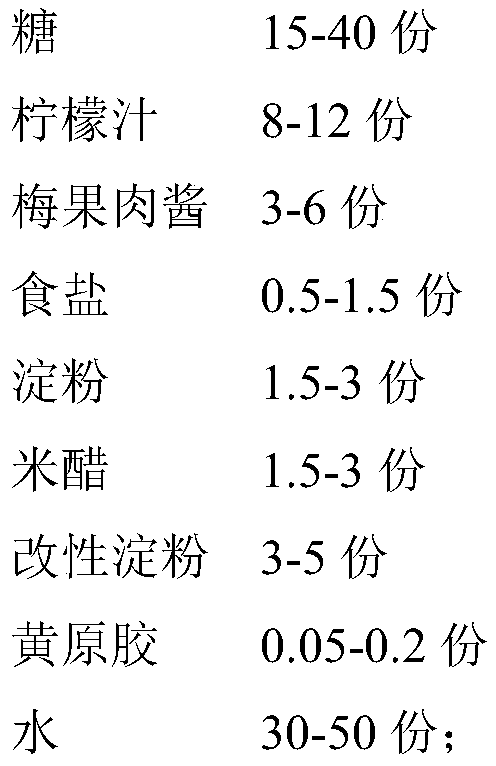

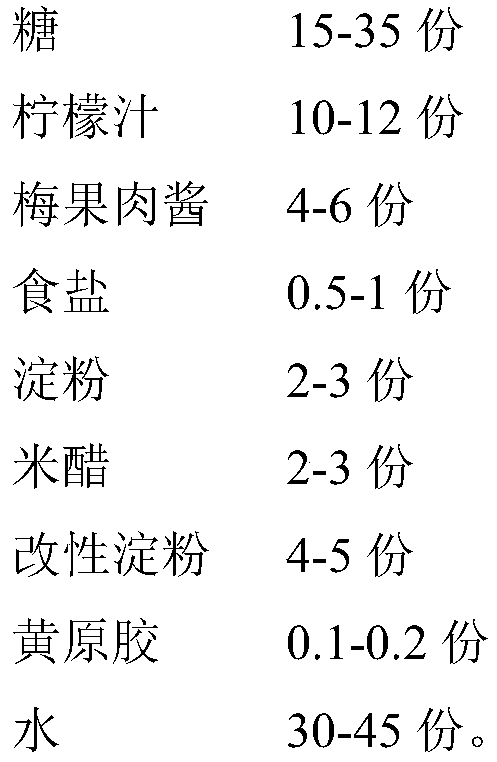

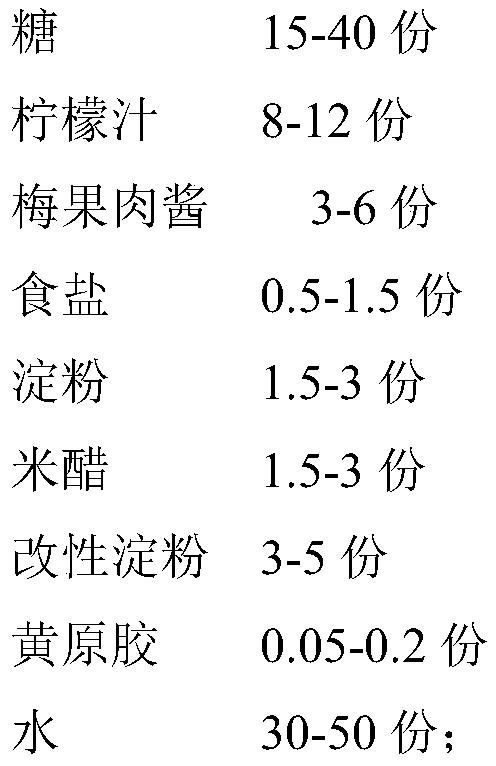

Fragrant lemon juice and preparation method thereof

PendingCN110037277AUnique lemonUnique plum flavorFood ingredient as thickening agentFood thermal treatmentFlavorLemon juice

The invention discloses fragrant lemon juice. The fragrant lemon juice comprises the following components in parts by weight of 15-40 parts of sugar, 8-12 parts of lemon juice, 3-6 parts of plum fleshjam, 0.5-1.5 parts of table salt, 1.5-3 parts of starch, 1.5-3 parts of rice vinegar, 3-5 parts of modified starch, 0.05-0.2 part of xanthan gum and 30-50 parts of water, wherein the modified starchis hydroxypropyl distarch phosphate. The invention further provides a preparation method of the fragrant lemon juice, wherein the preparation method comprises the steps of preparing the lemon juice, preparing the plum fresh jam, preparing starch liquid, preparing thickening liquid, performing blending and cooking, performing sterilizing, and performing packing. The fragrant lemon juice has uniquedelicately fragrant flavor of lemons and plums, and is moderate in stickiness, moderate in sour and sweet degrees, delicious, and suitable for cooking blending materials and toppings; and the fragrantlemon juice maintains moderate viscous state, and within the quality guarantee period, the fragrant lemon juice is free from layering, good in stability, and long in quality guarantee period.

Owner:珠海市宝门食品企业有限公司

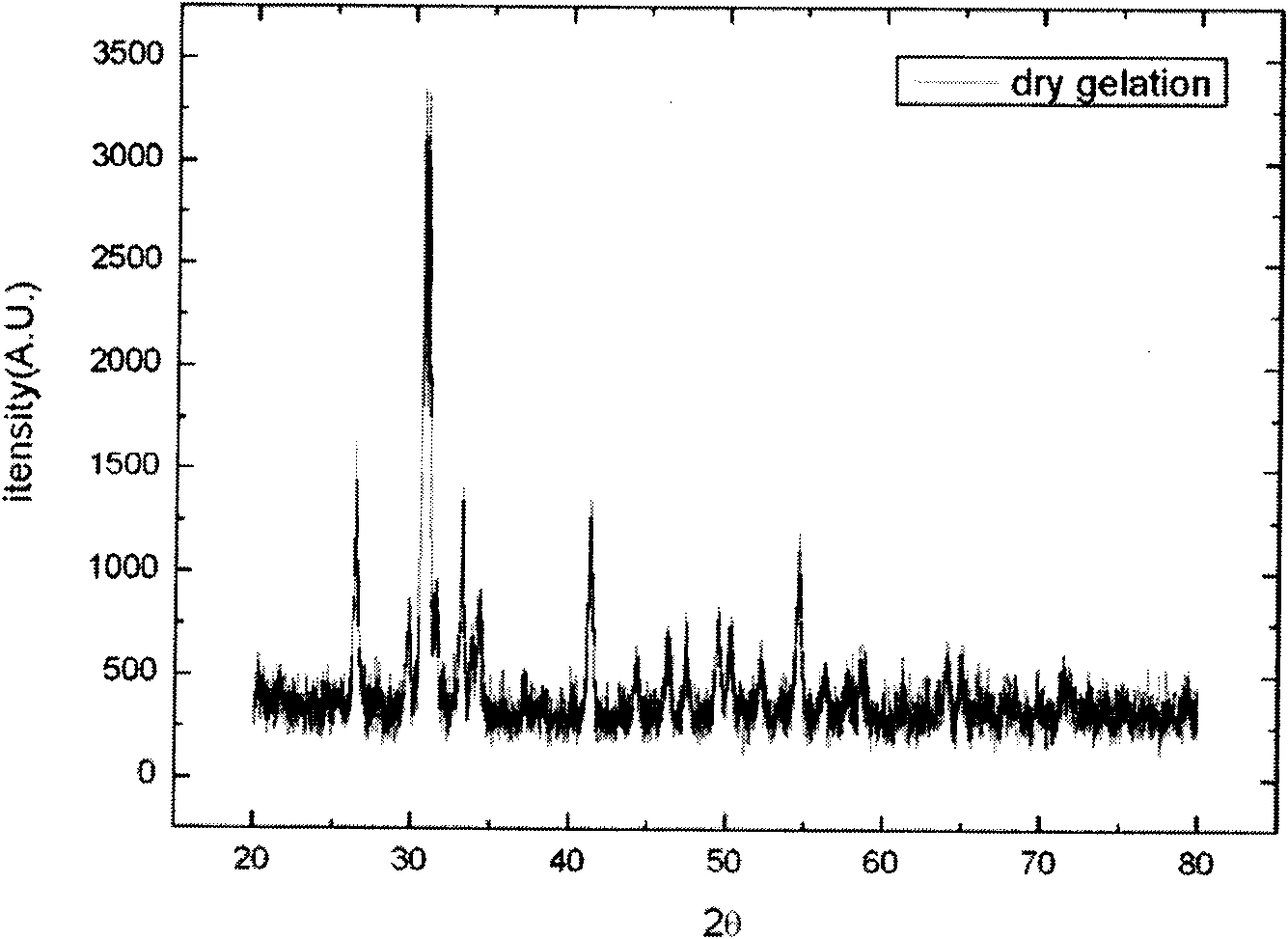

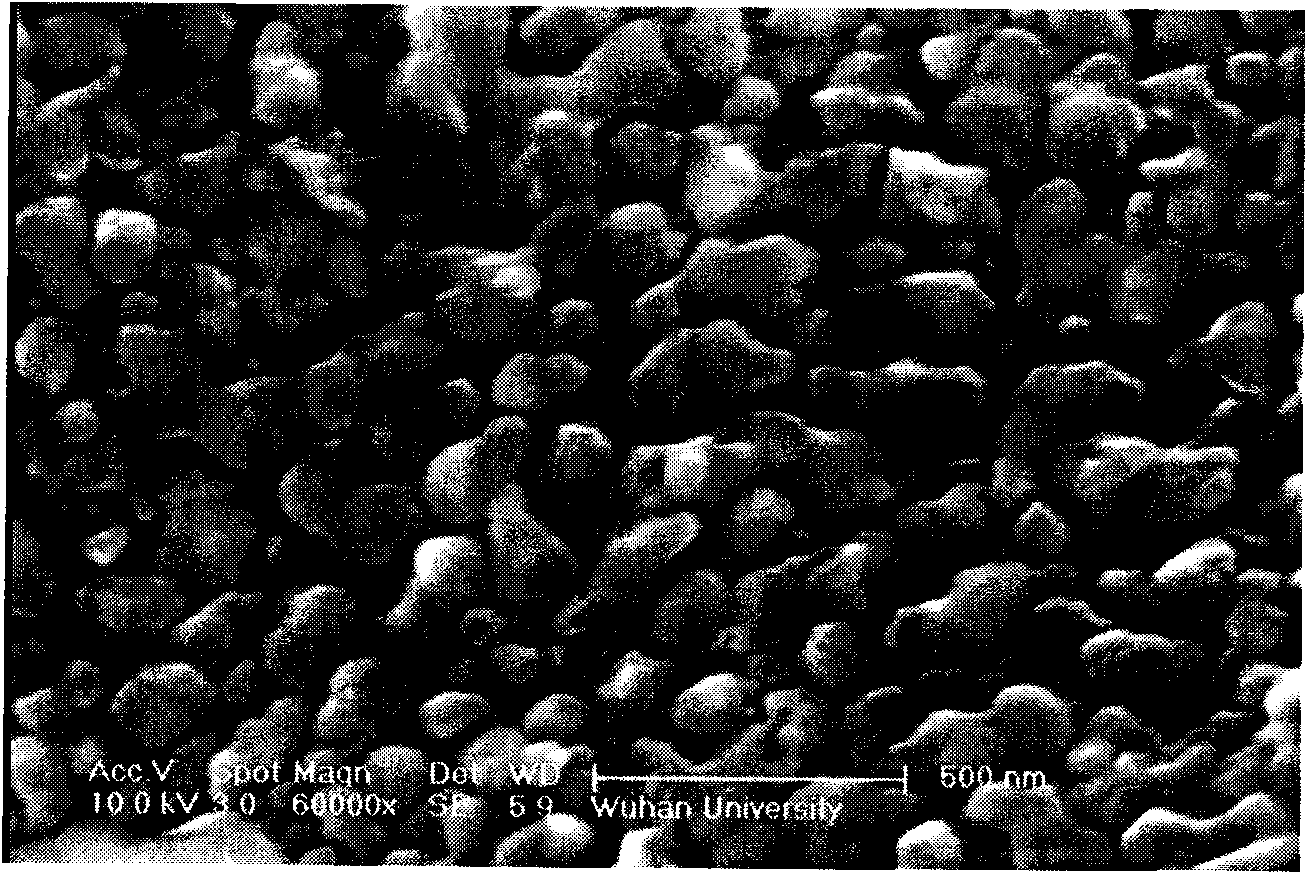

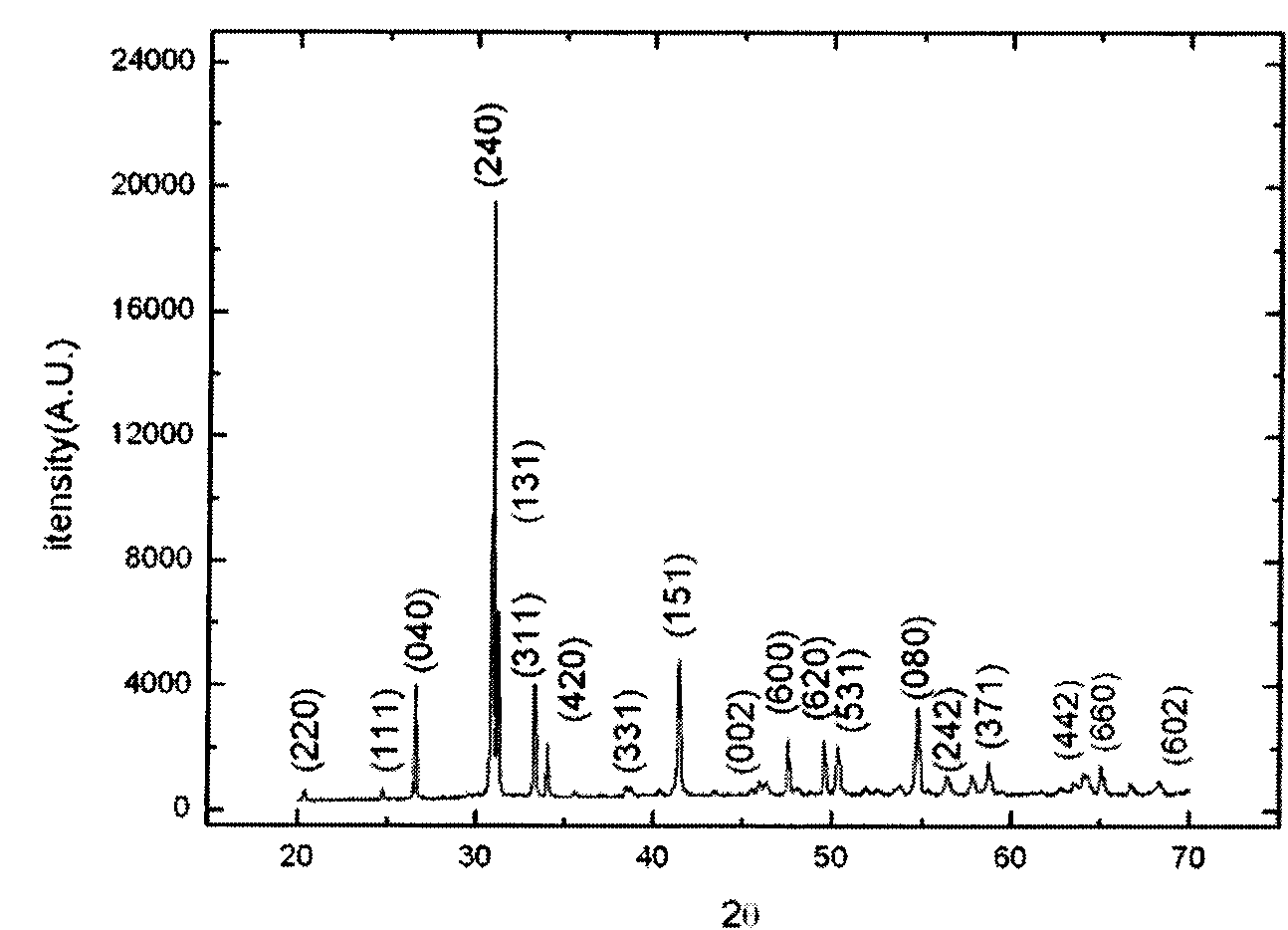

Method for preparing spin ladder compound

The invention relates to a method for preparing a spin ladder compound Sr14Cu24O41, which comprises the following steps of: taking 0.014 mol of Sr(NO3)2 and 0.024 mol of Cu(NO3)2*3H2O in a ratio of Sr to Cu of 14:24, and dissolving in double distilled water; weighing citric acid in a molar ratio of metal to citric acid of 3:1, adding the citric acid into the solution, and adding 8 to 12ml of glycol; stirring the solution for 1 hour until the solution forms blue sol; the heating and evaporating the blue sol, grinding the obtained substance, and firing the ground substance in a jade crucible at 850 DEG C for 10 hours; pressing the fired substance into a circular sheet with the diameter of 15mm and the thickness of 5mm; and finally, putting the circular sheet in the environment of 940 DEG C for 12 hours. The reaction temperature and heat preservation time required by the method are greatly reduced, and energy consumption and manpower resource are greatly reduced on the premise of maintaining the quality of the prepared sample.

Owner:汪丽莉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com