Refining method of aluminum alloy for experiment

An aluminum alloy and experimental technology, which is applied in the field of metallurgical technology, can solve the problems of inability to realize online exhaust, casting rod pores, and many slag inclusions, so as to protect the test environment and the health of the staff, good slag removal effect, and eliminate pores Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

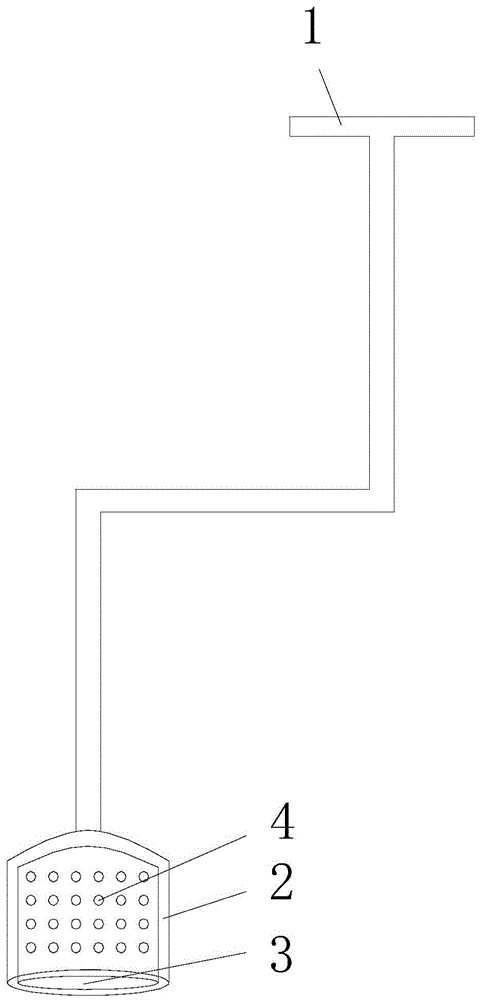

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0015] The aluminum alloy refining method used in the experiment of this embodiment comprises the following steps:

[0016] 1) Preparation of refining agent: Mix hexachloroethane powder and alumina powder at a ratio of 1:1.75 and press it into a cake-shaped refining agent, then wrap the refining agent with aluminum foil for use, and wrap the aluminum foil to prevent the refining agent from deteriorating ;

[0017] 2) Refining: When the aluminum alloy melt reaches a refining temperature of 730°C to 760°C, add a refining agent to the aluminum alloy melt at a rate of 1.5 grams of refining agent per kilogram of Al. The steps for adding the refining agent are as follows:

[0018] a. Put the refining agent into the container with handle 1;

[0019] b. Extend the container from the fume removal hood of the furnace into the molten aluminum in the furnace;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com