Manufacturing method of mixing blades used for mixing polyurethane resin

A technology of polyurethane resin and stirring fan blades, which is applied in the direction of mixer accessories, chemical instruments and methods, dissolution, etc., can solve the problems of affecting the uniformity of stirring, easy to bring air bubbles, easy to break the fan blades, etc., to achieve easy removal and improve The effect of uniformity and the number of fan blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

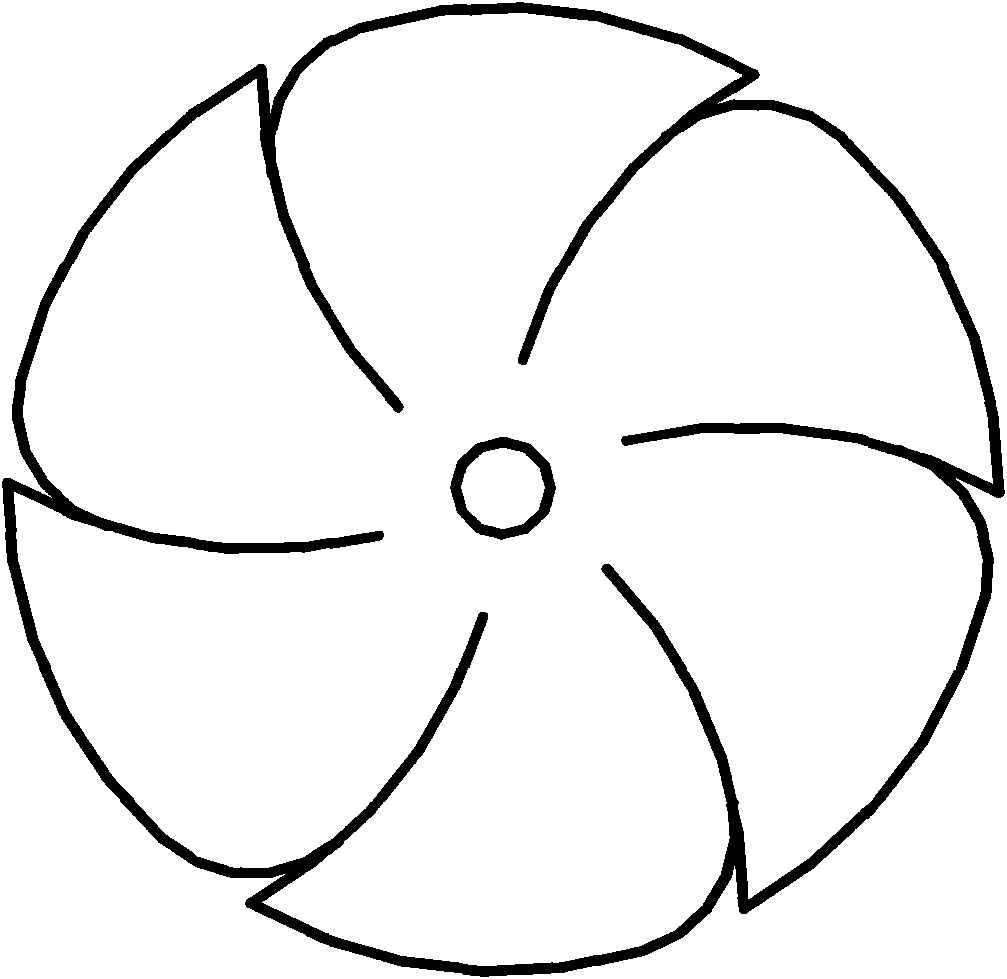

[0010] Embodiment 1, making 4-leaf stirring fan blades. The thickness of the polytetrafluoroethylene sheet is 0.8mm. The production steps are: first draw the outline of the stirring fan blade on the polytetrafluoroethylene sheet, then use scissors to manually cut out the outline of the four-blade stirring fan blade, and finally drill The central installation hole of the stirring fan blade is inserted, which naturally forms the deflection angle of the fan blade.

Embodiment 2

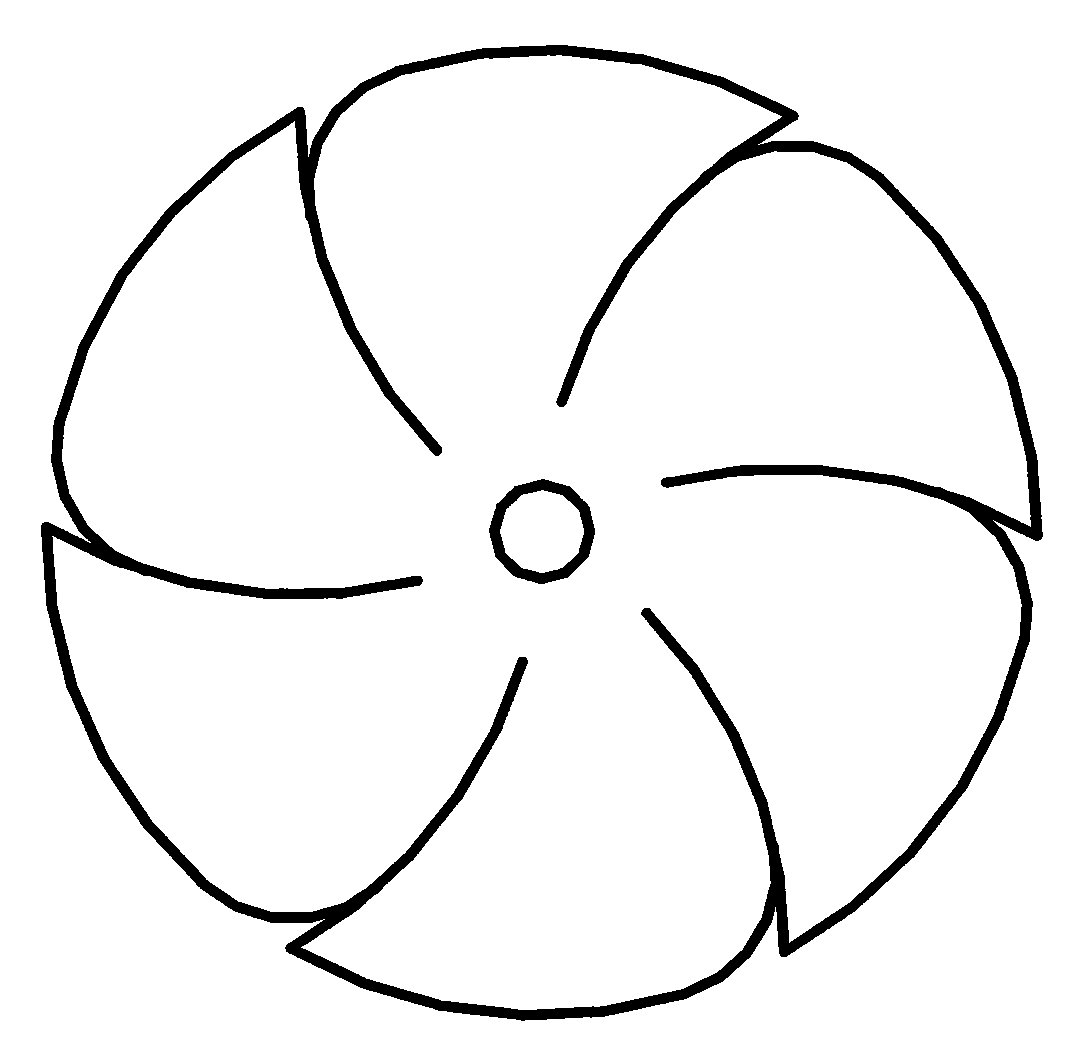

[0011] Embodiment 2, making 6-blade stirring fan blades. The thickness of the polytetrafluoroethylene sheet is 1mm. The production steps are: first draw the outline of the stirring fan blade on the polytetrafluoroethylene sheet, then use scissors to manually cut out the outline of the 6-blade stirring fan blade, and finally drill out The center mounting hole of the stirring fan blade naturally forms the deflection angle of the fan blade.

Embodiment 3

[0012] Embodiment 3, making 8-blade stirring fan blades. The thickness of the polytetrafluoroethylene sheet is 1.2mm. The production steps are: first draw the outline of the stirring fan blade on the polytetrafluoroethylene sheet, then use scissors to manually cut out the outline of the 8-blade stirring fan blade, and finally drill Insert the central mounting hole of the stirring fan blade, and manually adjust the deflection angle of the fan blade.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com