Method for preparing 3A type zeolite molecular sieve

A technology of zeolite molecular sieve and molecular sieve, applied in the direction of A-type crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problems of long production cycle and high calcination temperature, and achieve high production efficiency, low calcination temperature and environmental pollution small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for preparing 3A type zeolite molecular sieve, it comprises the steps:

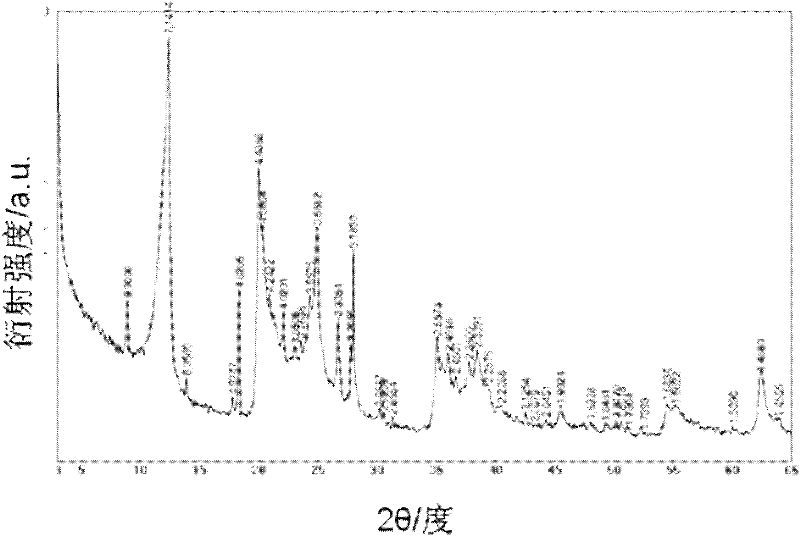

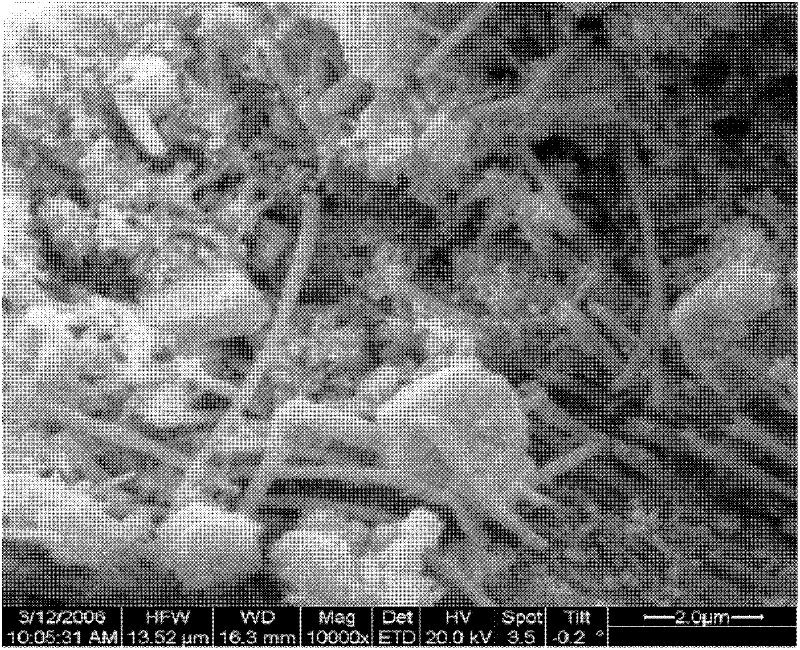

[0042] 1), the calcining of kaolin: be raw material (see figure 1 , figure 2 ), calcined at 550°C for 4 hours to obtain metakaolin. The soft kaolin in Lincang, Yunnan is the soft kaolin obtained from Lincang, Yunnan, and the Al 2 o 3 The mass percentage content is 37.7%, Fe 2 o 3 The mass percentage content is 0.19%, TiO 2 The mass percent content of is 0.13%, whiteness=86, average particle diameter=10 microns.

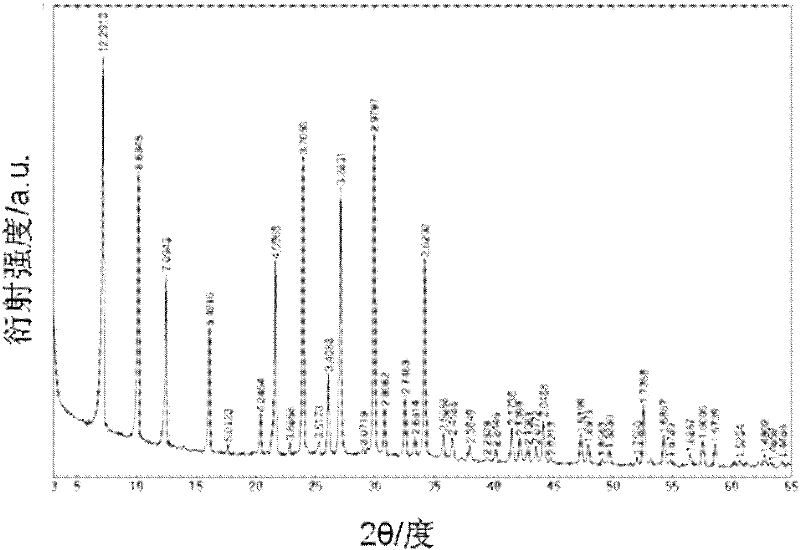

[0043] 2), Preparation of 4A molecular sieve: Weigh 20g of metakaolin, measure 100ml of 4mol / L NaOH aqueous solution, mix evenly, stir vigorously in a water bath at 80°C for 5h (greater than 600 rpm), and then heat up to 100°C at a medium speed Stir for 4 hours (300-600 rpm) to obtain a mixture; filter the mixture, wash the filter cake with distilled water and filter again, and dry the filter cake at 100°C for 2 hours to obtain 4A molecular sieve. The X-ray powder crystal...

Embodiment 2

[0047] A method for preparing 3A type zeolite molecular sieve, it comprises the steps:

[0048] 1) Calcination of kaolin: take soft kaolin from Lincang, Yunnan as raw material, and calcinate at 700° C. for 3 hours to obtain metakaolin. The soft kaolin in Lincang, Yunnan is the soft kaolin obtained from Lincang, Yunnan, and the Al 2 o 3 The mass percentage content is 37.7%, Fe 2 o 3 The mass percentage content is 0.19%, TiO 2 The mass percent content of is 0.13%, whiteness=86, average particle diameter=10 microns.

[0049] 2), Preparation of 4A molecular sieve: Weigh 15g of metakaolin, measure 100ml of 2mol / L NaOH aqueous solution, mix evenly, stir vigorously in a water bath at 70°C for 3h (greater than 600 rpm), and then heat up to 90°C at a medium speed Stir for 6 hours (300-600 rpm) to obtain a mixture; filter the mixture, wash the filter cake with distilled water and filter again, and dry the filter cake at 90°C for 4 hours to obtain 4A molecular sieve.

[0050] 3), t...

Embodiment 3

[0053] A method for preparing 3A type zeolite molecular sieve, it comprises the steps:

[0054] 1) Calcination of kaolin: take soft kaolin from Lincang, Yunnan as raw material, and calcinate at 650° C. for 3 hours to obtain metakaolin. The soft kaolin in Lincang, Yunnan is the soft kaolin obtained from Lincang, Yunnan, and the Al 2 o 3 The mass percentage content is 37.7%, Fe 2 o 3 The mass percentage content is 0.19%, TiO 2 The mass percent content of is 0.13%, whiteness=86, average particle diameter=10 microns.

[0055] 2), Preparation of 4A molecular sieve: Weigh 25g of metakaolin, measure 100ml of 3mol / L NaOH aqueous solution, mix evenly, stir vigorously in a water bath at 75°C for 4h (greater than 600 rpm), and then heat up to 95°C at a medium speed Stir for 4 hours (300-600 rpm) to obtain a mixture; filter the mixture, wash the filter cake with distilled water and filter again, and dry the filter cake at 90° C. for 4 hours to obtain 4A molecular sieve.

[0056] 3) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com