Alpha/beta-bismuth oxide phase heterojunction photocatalyst as well as preparation method and application thereof

A photocatalyst and bismuth source technology, applied in the field of photocatalysis, can solve the problems of low photocatalytic activity, complex synthesis method and high energy consumption, and achieve the effects of overcoming low photocatalytic activity, cheap and easily available raw materials, and simplifying the reaction system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) Dissolve 4 mmol of bismuth nitrate in 70 mL of ethylene glycol, and stir magnetically for 30 min at room temperature;

[0049] (2) Add 0.5mL aniline to the above solution and continue to stir for 10min;

[0050] (3) Transfer the above mixed solution to a 100mL reaction kettle, put it in an oven at 180°C for 12h, and obtain a brown solid;

[0051] (4) The solid was separated by centrifugation, washed three times with deionized water and absolute ethanol respectively, and dried in an oven at 60°C;

[0052] (5) Take out the dried solid and grind it with an agate mortar to obtain a dry bismuth-based precursor powder;

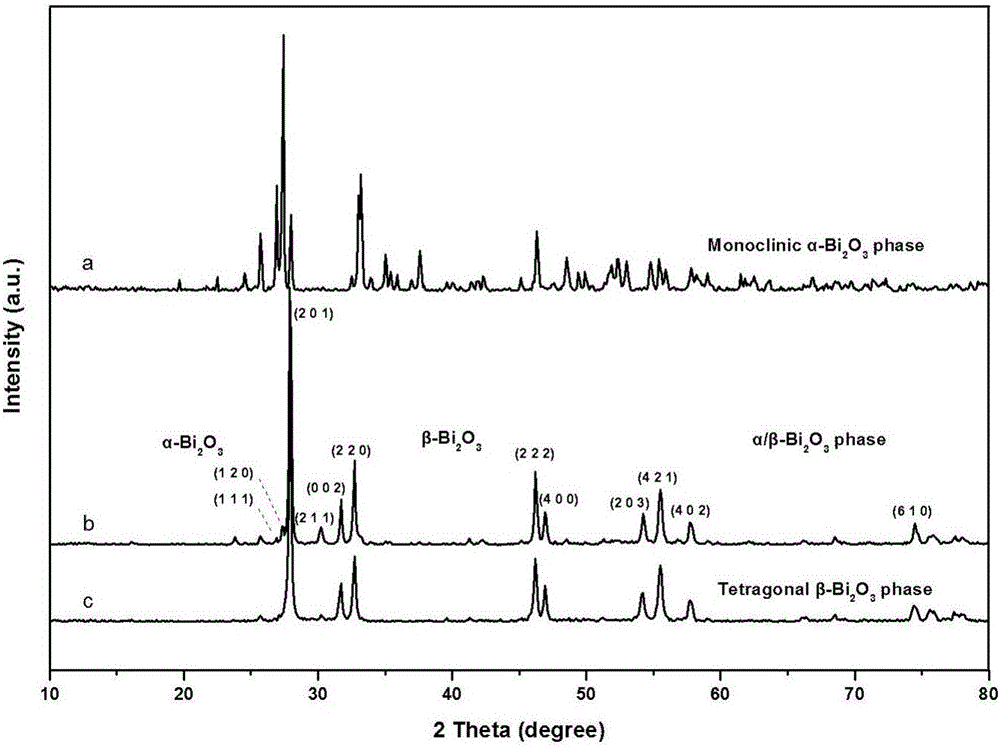

[0053] (6) Put the precursor powder into a muffle furnace and calcinate at 300°C for 1.0h to obtain a yellow-green powder, which is α / β-Bi 2 o 3 catalyst of light.

[0054] 5mgα / β-Bi 2 o 3The photocatalyst was added to the EE2 solution with a concentration of 3 mg / L, and after 30 minutes of dark reaction, photocatalytic degradation was carried out u...

Embodiment 2

[0056] (1) Dissolve 2 mmol of basic bismuth nitrate in 70 mL of glycerol, and stir magnetically at room temperature for 30 min;

[0057] (2) Add 0.5mL aniline to the above solution and continue to stir for 10min;

[0058] (3) Transfer the above mixed solution into a 100mL reaction kettle, put it in an oven at 180°C for 12h, and obtain a light brown solid;

[0059] (4) The solid was separated by centrifugation, washed three times with deionized water and absolute ethanol respectively, and dried in an oven at 60°C;

[0060] (5) Take out the dried solid and grind it with an agate mortar to obtain a dry bismuth-based precursor powder;

[0061] (6) Put the precursor powder into a muffle furnace and calcinate at 300°C for 1.0h to obtain a yellow-green powder, which is α / β-Bi 2 o 3 catalyst of light.

[0062] 5mg α / β-Bi 2 o 3 The photocatalyst was added to the E2 solution with a concentration of 3 mg / L, and after dark reaction for 30 minutes, the photocatalytic degradation was ...

Embodiment 3

[0064] (1) Dissolve 4mmol sodium bismuthate in 70mL benzyl alcohol, and stir magnetically for 30min at room temperature;

[0065] (2) Add 1.5mL of aniline to the above solution and continue to stir for 10min;

[0066] (3) Transfer the above mixed solution to a 100mL reaction kettle, put it in an oven at 180°C for 12h, and obtain a black solid;

[0067] (4) The solid was separated by centrifugation, washed three times with deionized water and absolute ethanol respectively, and dried in an oven at 60°C;

[0068] (5) Take out the dried solid and grind it with an agate mortar to obtain a dry bismuth-based precursor powder;

[0069] (6) Put the precursor powder into a muffle furnace and calcinate at 300°C for 1.0h to obtain a yellow powder, which is α / β-Bi 2 o 3 catalyst of light.

[0070] 5mg α / β-Bi 2 o 3 The photocatalyst was added to the EE2 solution with a concentration of 3 mg / L, and after 30 minutes of dark reaction, photocatalytic degradation was carried out under the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com