Biological aerated filter packing and preparation method thereof

A biological aerated filter and aggregate technology, applied in the direction of sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc. Solve problems such as uranium formation, and achieve the effect of low price, low calcination temperature and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

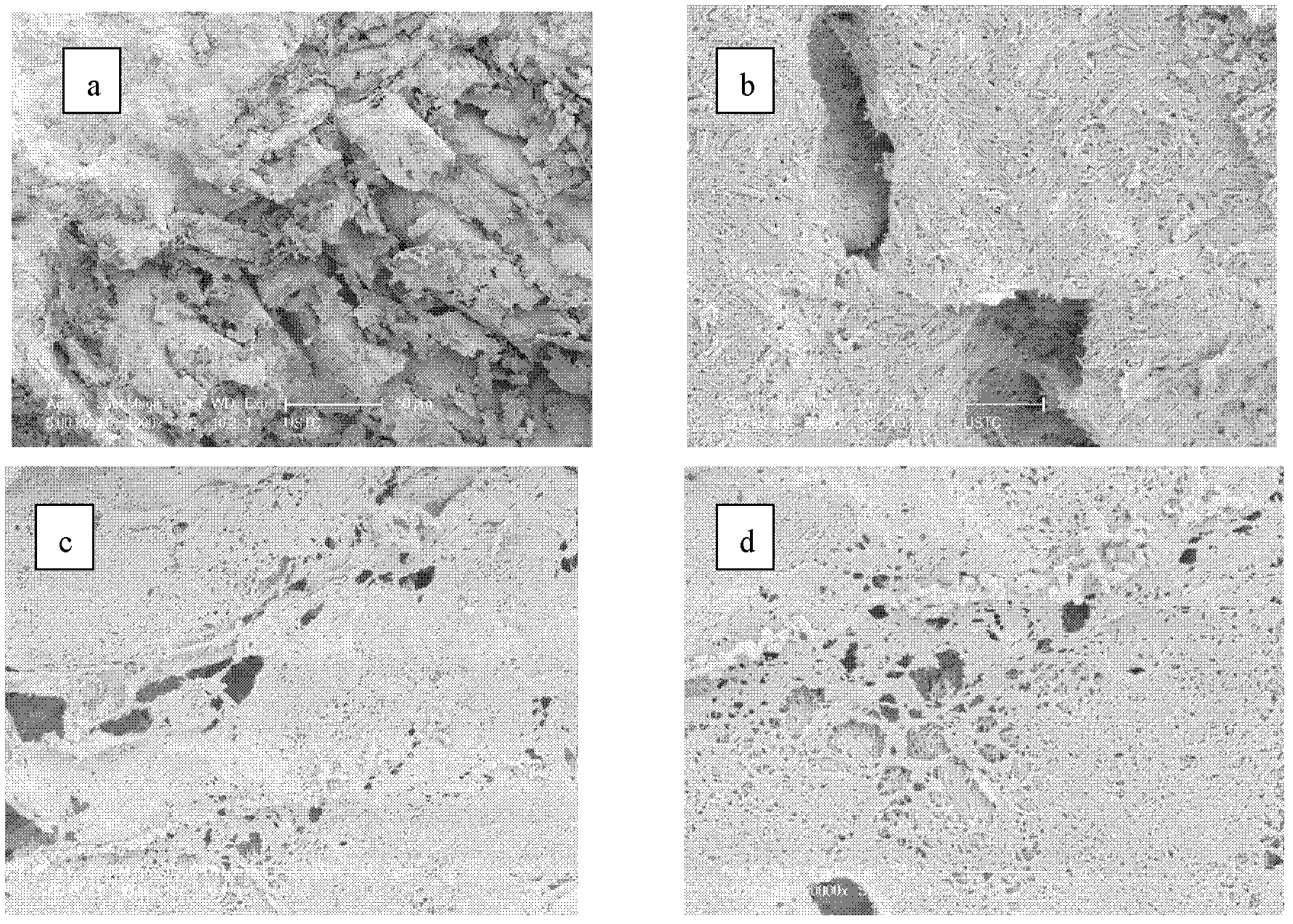

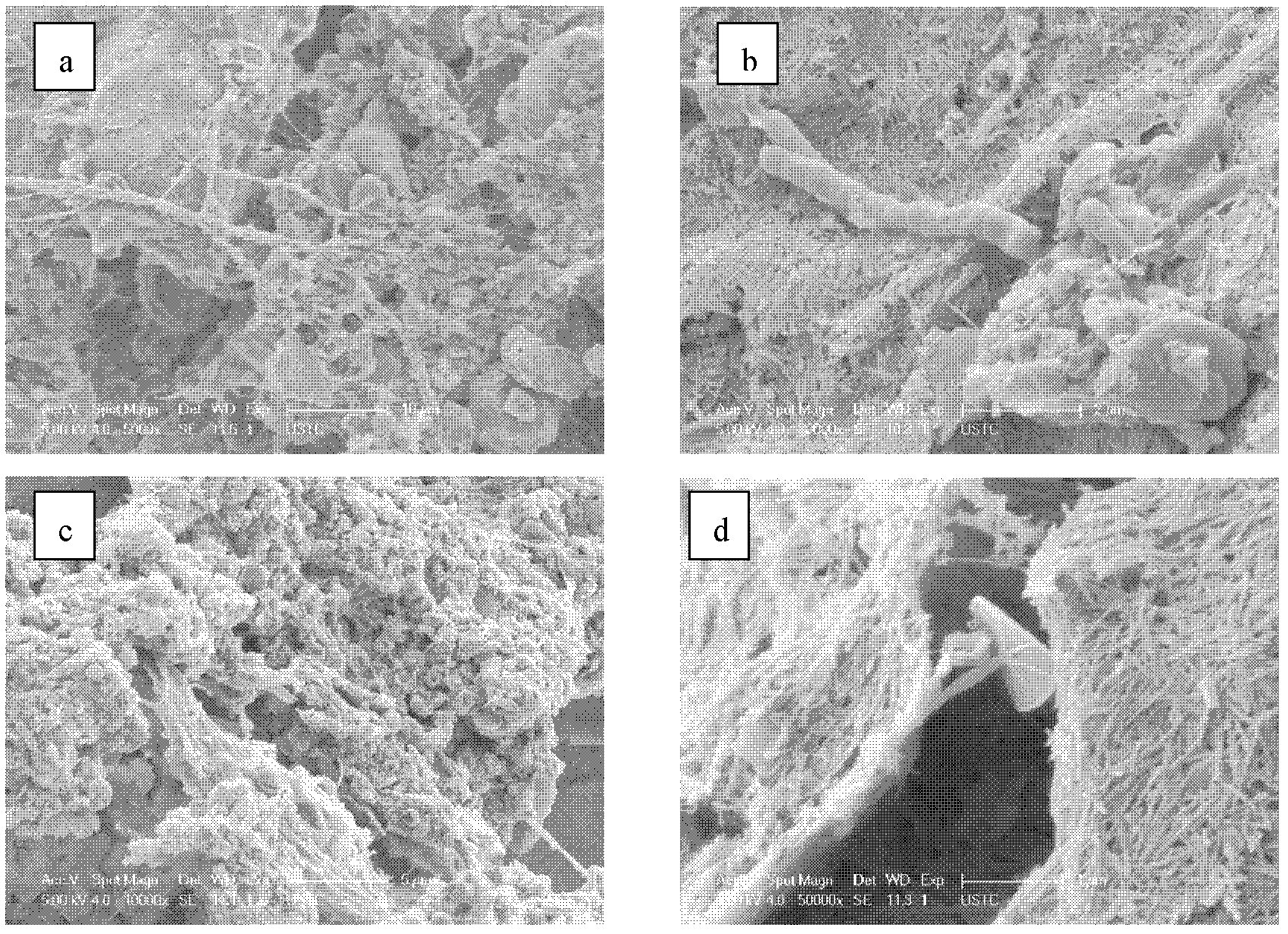

Image

Examples

Embodiment 1

[0024] The raw materials of the biological aerated filter filler in this embodiment are constituted by mass percentage as follows:

[0025] Attapulgite clay 78%, straw 12%, goethite 10% (iron content 30%);

[0026] The aggregate is one or a mixture of attapulgite clay, kaolin, montmorillonite and diatomite;

[0027] The iron oxide is an iron oxide substance containing iron in a mass percentage of not less than 30%;

[0028] The pore forming agent is one or more of sawdust, straw and leaves.

[0029] The preparation method of the biological aerated filter filler of the present embodiment is as follows:

[0030] Pass attapulgite clay, straw and goethite respectively through a 200-mesh sieve and mix to obtain a mixture;

[0031] Add water with 30% of the mass of the mixture to the mixture, then granulate and shape, control the particle size to 5-6mm, dry naturally, and calcinate at 800°C for 2 hours in the air to obtain the biological aerated filter filler.

[0032] The biolo...

Embodiment 2

[0037] The raw materials of the biological aerated filter filler in this embodiment are constituted by mass percentage as follows:

[0038] Kaolin 80%, leaves 10%, hematite 10% (iron content 35%).

[0039] The preparation method of the biological aerated filter filler of the present embodiment is as follows:

[0040] Pass kaolin, leaves and hematite respectively through a 200-mesh sieve and mix to obtain a mixture;

[0041] Add water with 40% of the weight of the mixture to the mixture, and then granulate it, control the particle size to 5-7mm, dry it naturally, and then calcinate in the air at 500°C for 2 hours to obtain the biological aerated filter filler.

[0042] The biological aerated filter filler prepared in this example is used as the carrier of microorganisms in the biological aerated filter:

[0043]The inoculum sludge used in the test was taken from the sludge in the oxidation ditch of the urban sewage treatment plant. Firstly, the filler filter material of the b...

Embodiment 3

[0047] The raw materials of the biological aerated filter filler in this embodiment are constituted by mass percentage as follows:

[0048] 75% montmorillonite, 15% sawdust, 10% magnetite (30% iron content).

[0049] The preparation method of the biological aerated filter filler of the present embodiment is as follows:

[0050] Pass montmorillonite, sawdust and magnetite respectively through a 200-mesh sieve and mix to obtain a mixture;

[0051] Add water with 50% of the mass of the mixture to the mixture, then granulate and shape, control the particle size to 5-7mm, dry naturally, and calcinate at 700°C for 3 hours in the air to obtain the biological aerated filter filler.

[0052] The biological aerated filter filler prepared in this example is used as the carrier of microorganisms in the biological aerated filter:

[0053] The inoculum sludge used in the test was taken from the sludge in the oxidation ditch of the urban sewage treatment plant. Firstly, the filler filter m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com