Method for producing rutile type white titanium pigment by using crystal seed method of double action

A technology of rutile-type titanium dioxide and double-effect seed crystals, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of high calcination temperature, low output, long time, etc. nuclear easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

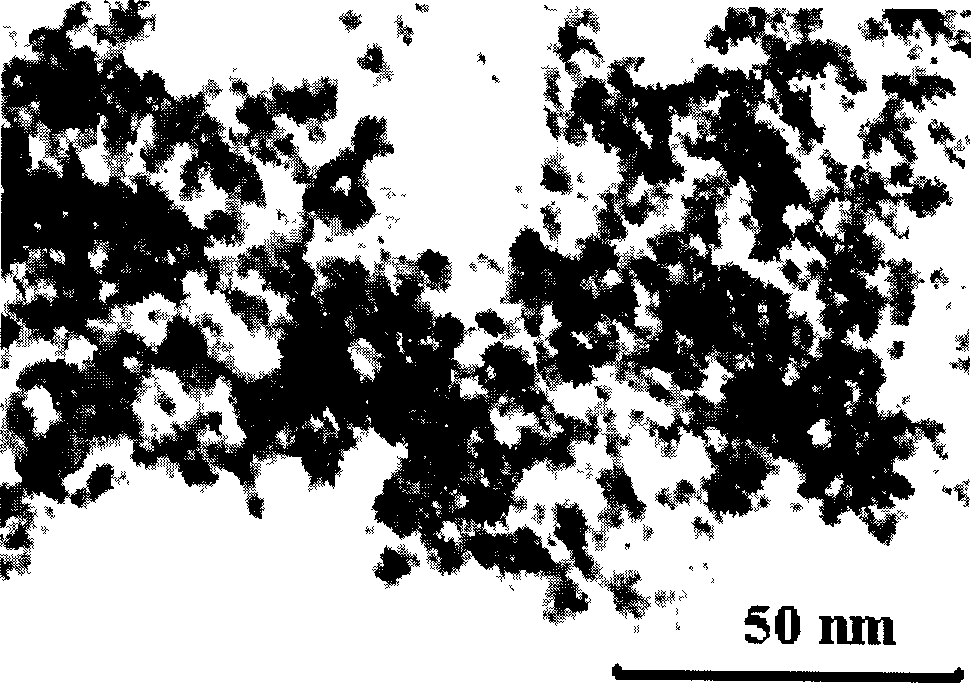

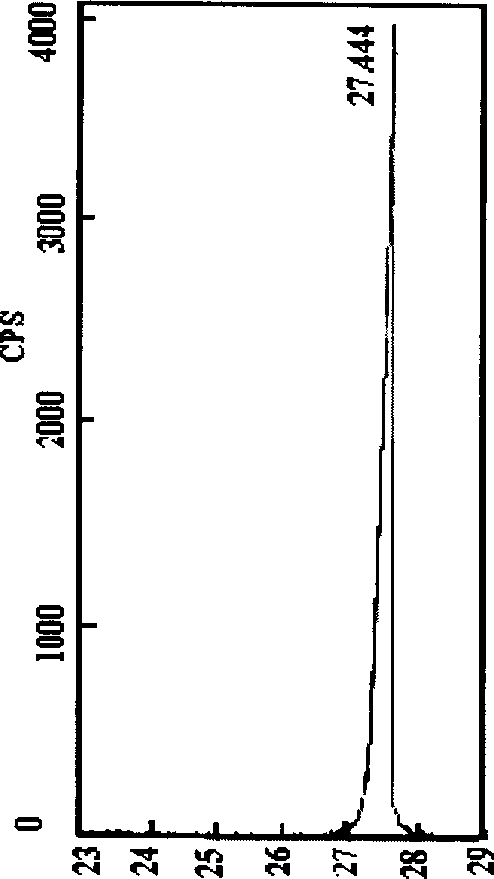

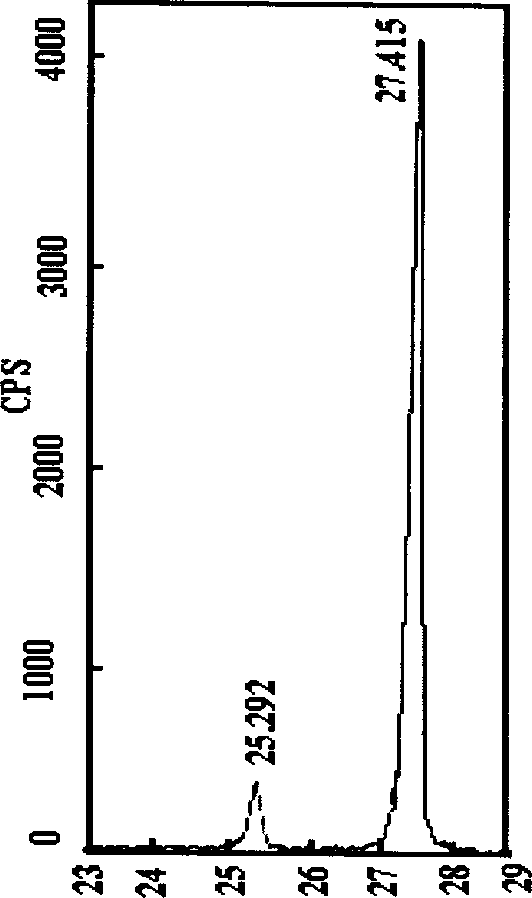

Image

Examples

Embodiment 1

[0020] TiOCl 2 Solution (concentration: containing TiO 2 0.160g / ml) 60 parts, under stirring, with 120 parts of NH 4 Add OH (concentration 5N) solution into the reactor, adjust the pH value to less than 1.5, and keep it warm for 20 minutes; add 200 parts of SnCl 2 2H 2 O solution (concentration is 0.153g / ml), adjust the pH value to 2.5, add H 2 o 2 to guarantee Sn 2+ becomes Sn 4+ , keep warm for half an hour, then let it stand still for 4 hours, suck off the supernatant to obtain a suspension of seed crystals.

[0021] Take 1500ml of the titanium solution used in the production of sharp titanium dioxide, add the above-prepared seed crystal suspension at 70°C, boil at 110°C for 3 hours, wash with water, and control the Fe 2+ , Fe 3+ The content of which is less than 0.003%, is suction filtered and dried to obtain metatitanic acid powder.

[0022] Salt treatment introduces impurity ions: metatitanic acid dry powder: KNO 3 : ZnCl 2 :H 2 The ratio of O=100:0.34:0.6:10...

Embodiment 2

[0025] TiOCl 2 Solution (concentration: containing TiO 2 0.160g / ml) 60 parts, under stirring, with 120 parts of NH 4 Add OH (concentration 5N) solution into the reactor, adjust the pH value to less than 1.5, and keep it warm for 20 minutes; take SnCl 2 2H 2 Add 150 parts of O solution (0.153g / ml concentration), adjust the pH value to 2.5, add H 2 o 2 to guarantee Sn 2+ becomes Sn 4+ . After adding, keep warm for half an hour, then let it stand still for 4 hours, absorb the supernatant liquid, and obtain a suspension of seed crystals.

[0026] Take 1500ml of the titanium solution used in the production of sharp titanium dioxide, add the above-prepared seed crystal suspension at 80°C, boil at 110°C for 3 hours, wash with water, and control the Fe 2+ , Fe 3+ The content of which is less than 0.003%, is suction filtered and dried to obtain metatitanic acid powder.

[0027] Salt treatment introduces impurity ions: metatitanic acid dry powder: KNO 3 : ZnCl 2 :H 2 The ra...

Embodiment 3

[0030] TiOCl 2 Solution (concentration: containing TiO 2 0.160g / ml) 60 parts, under stirring, with 120 parts of NH 4 Add OH (concentration 5N) solution into the reactor, adjust the pH value to less than 1.5, and keep it warm for 20 minutes; take SnCl 2 2H 2 Add 150 parts of O solution (concentration: 0.153g / ml), and use NH 4 OH to adjust the pH value to 2.5, add H 2 o 2 to guarantee Sn 2+ becomes Sn 4+ . After adding, keep warm for half an hour, then let it stand still for 4 hours, absorb the supernatant liquid, and obtain a suspension of seed crystals.

[0031] Take 1500ml of the titanium liquid used in the production of sharp titanium dioxide, add the above-prepared seed crystal suspension at 80°C, boil at 110°C for 3 hours, wash with water, and control the Fe 2+ , Fe 3+ The content of which is less than 0.003%, is suction filtered and dried to obtain metatitanic acid powder.

[0032]Calcination: heat preservation at 500°C for 40 minutes, heat preservation at 870°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com