Bismuth oxide/bismuth tetraoxide heterojunction photocatalyst, preparation method and use thereof

A photocatalyst and heterojunction technology, applied in the field of photocatalysis, can solve the problems of easy recombination of photogenerated electrons and holes, high production cost, and increased synthesis cost, so as to achieve high visible photocatalytic activity, save synthesis cost, shorten The effect of the synthesis cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Grind 2.80 g of bismuth salt and 1.12 g of alkali, and mix them into a paste;

[0044] (2) Put the mixture into a muffle furnace for calcination, the calcination time is 4 h, the calcination temperature is 300 ℃, and the heating rate is 5 ℃ / min;

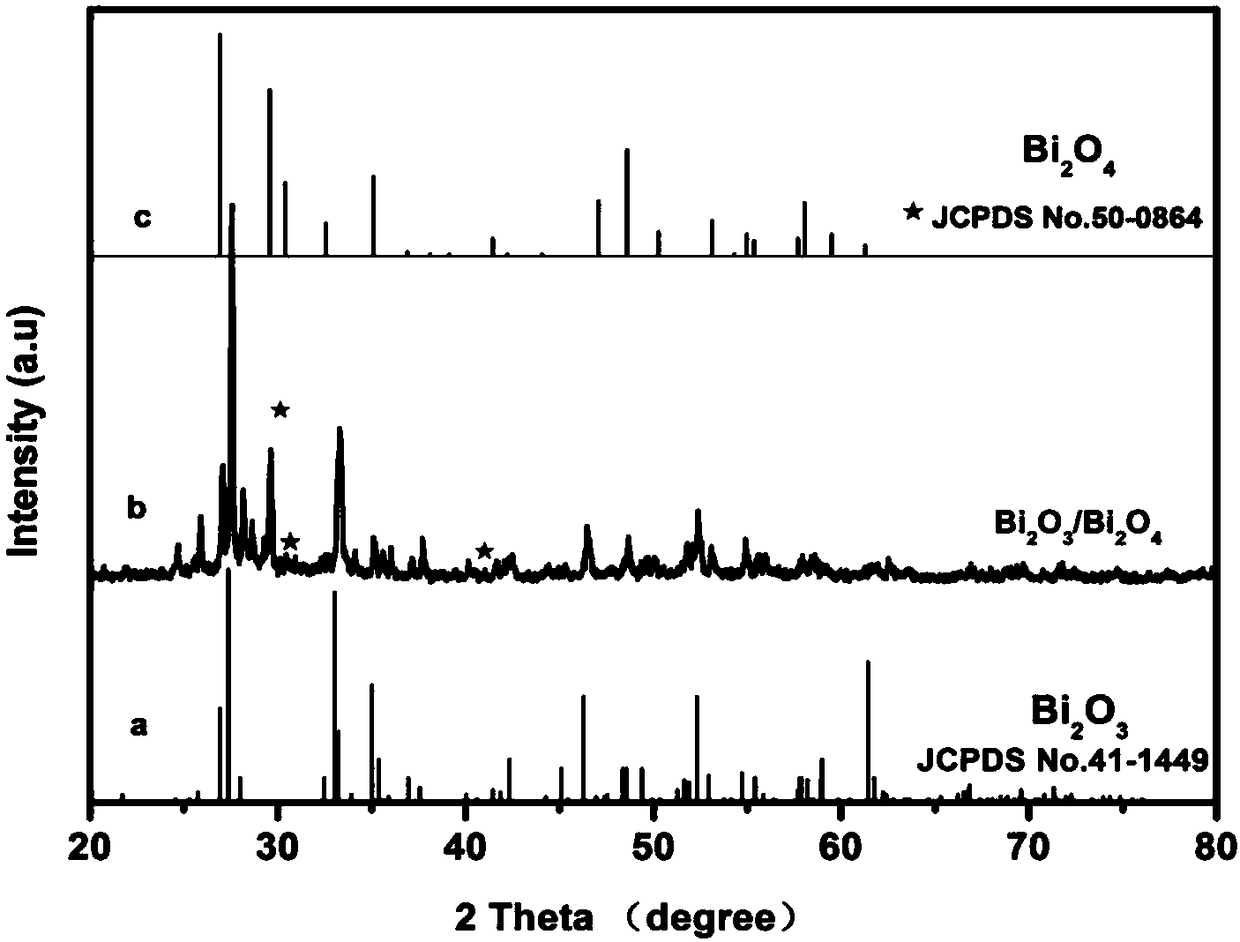

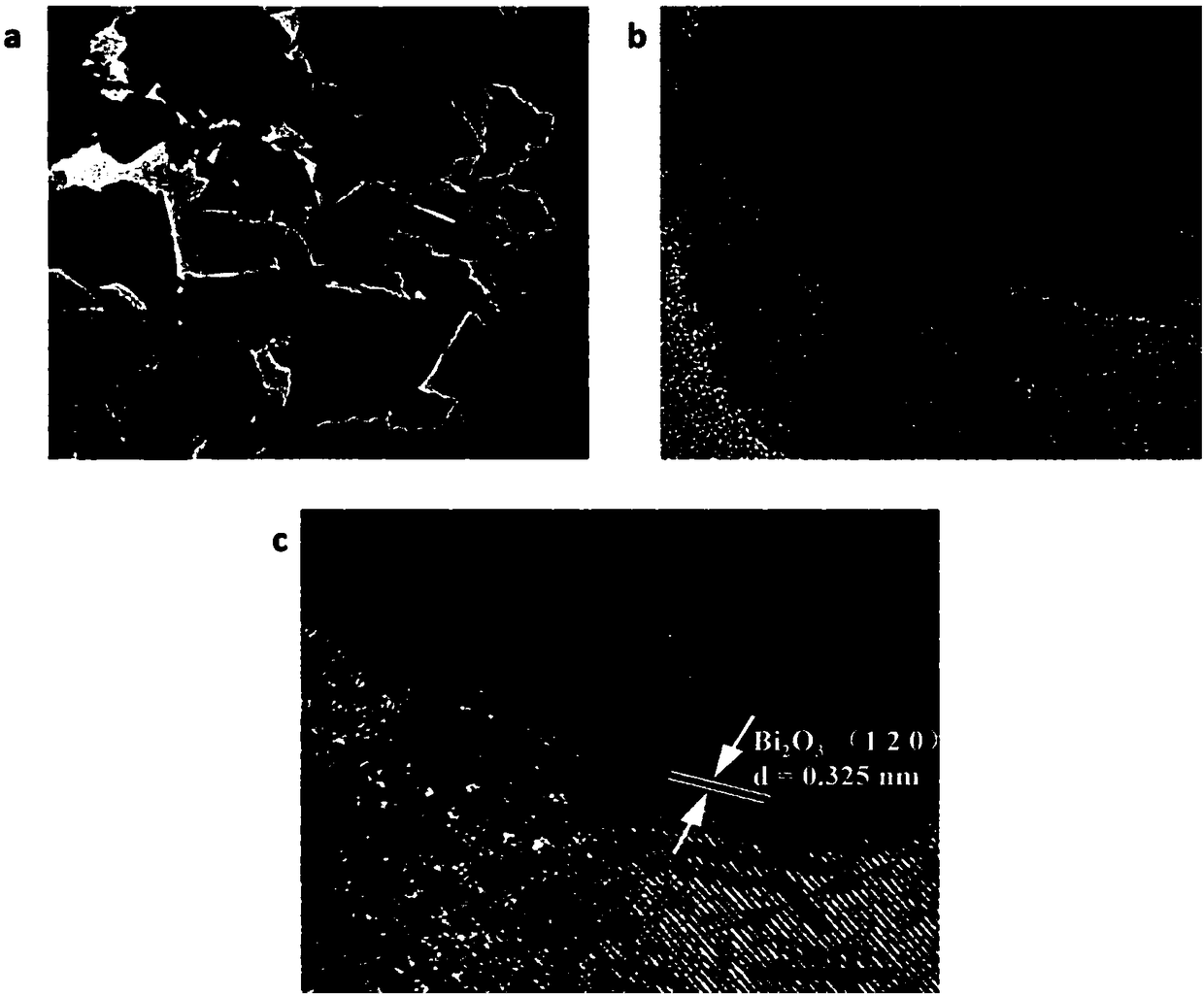

[0045] (3) Wash the calcined material repeatedly with deionized water, and dry it in an oven at 60 °C to obtain a khaki powder, which is Bi 2 o 3 / Bi 2 o 4 catalyst;

[0046] 5 mg Bi 2 o 3 / Bi 2 o 4 The photocatalyst was added to the EE2 solution with a concentration of 3 mg / L, and after dark reaction for 30 min, the photocatalytic degradation was carried out under the irradiation of visible light (500 W xenon lamp + 420 nm filter). The degradation rate of EE2 can reach 93.5% after 12 min of light exposure.

Embodiment 2

[0048] (1) Grind 2.80 g of bismuth salt and 1.12 g of alkali, and mix them into a paste;

[0049] The mixture was calcined in a muffle furnace, the calcination time was 2 h, the calcination temperature was 250 °C, and the heating rate was 10 °C / min;

[0050] (2) Wash the calcined material repeatedly with deionized water, and dry it in an oven at 60 °C to obtain a khaki powder, which is Bi 2 o 3 / Bi 2 o 4 catalyst;

[0051] 5 mg Bi 2 o 3 / Bi 2 o 4 The photocatalyst was added to the BPA solution with a concentration of 10 mg / L, and after dark reaction for 30 min, the photocatalytic degradation was carried out under the irradiation of visible light (500 W xenon lamp + 420 nm filter). The degradation rate of BPA can reach 80% after being illuminated for 12 minutes.

Embodiment 3

[0053] (1) Grind 2.80 g of bismuth salt and 0.62 g of alkali, and mix them into a paste;

[0054] (2) Put the mixture into a muffle furnace for calcination, the calcination time is 2 h, the calcination temperature is 250 ℃, and the heating rate is 5 ℃ / min;

[0055] (3) Wash the calcined material repeatedly with deionized water, and dry it in an oven at 60 °C to obtain a reddish-brown powder, which is Bi 2 o 3 / Bi 2 o 4 catalyst;

[0056] 5 mg Bi 2 o 3 / Bi 2 o 4 The photocatalyst was added to the EE2 solution with a concentration of 3 mg / L, and after dark reaction for 30 min, the photocatalytic degradation was carried out under the irradiation of visible light (500 W xenon lamp + 420 nm filter). The degradation rate of EE2 can reach 68% after 12 min of light exposure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com