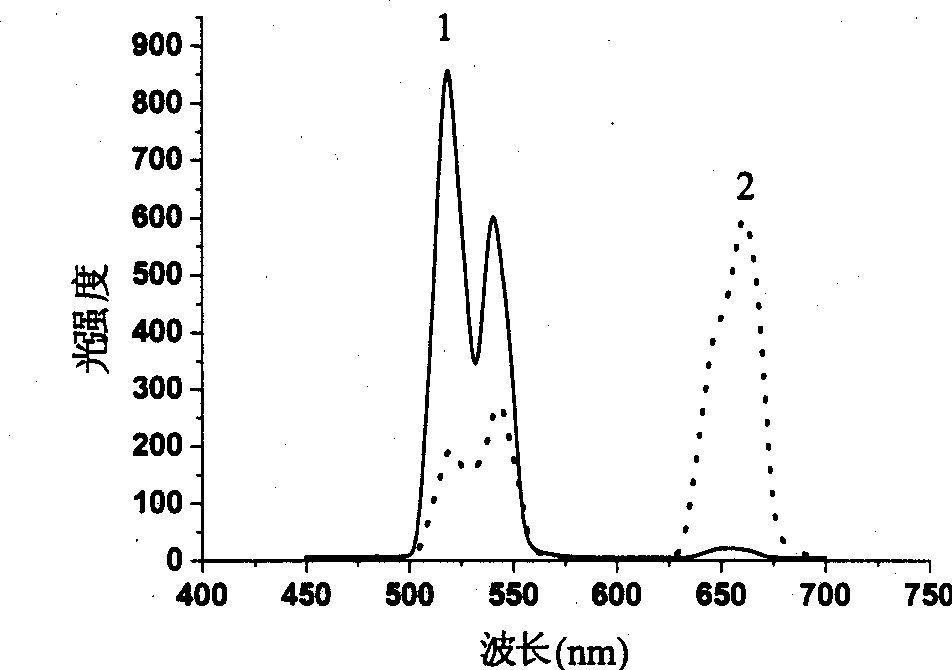

Up converting fluorescent material with nanometer level molybdate substrate and its prepn

A fluorescent material and nano-level technology, applied in the field of nano fluorescent materials, can solve the problems of difficulty in preparing materials, no preparation, etc., and achieve the effects of cheap raw materials, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Weigh 1.1760g lanthanum oxide (La 2 o 3 ), 0.3692g ytterbium oxide (Yb 2 0 3 ), 0.0537g erbium oxide (Er 2 o 3 ), placed in a 100ml beaker, add 2ml concentrated nitric acid (HNO 3 ) is heated and dissolved, and the molar ratio of rare earth ions is La 3+ :Yb 3+ :Er 3+ =77:20:3, evaporate to dryness, remove the remaining HNO 3 ;

[0025] (2) Add 30ml of deionized water to dissolve the above product, and transfer it to a 100ml three-necked bottle;

[0026] (3) under rapid stirring, the sodium molybdate solution is dripped into the above-mentioned three-neck flask to generate a milky precipitate;

[0027] (4) Centrifuge the precipitate and wash it with water three times to make a hydrogel;

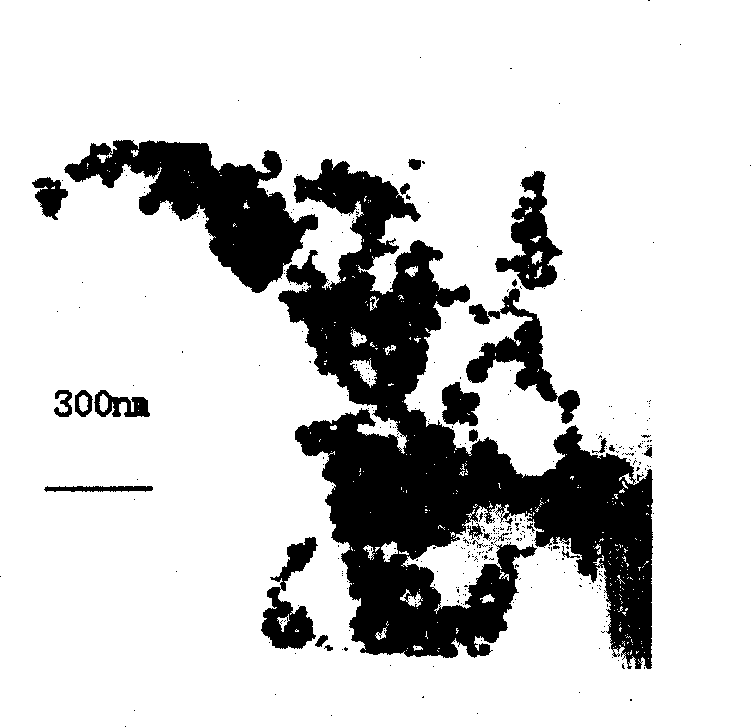

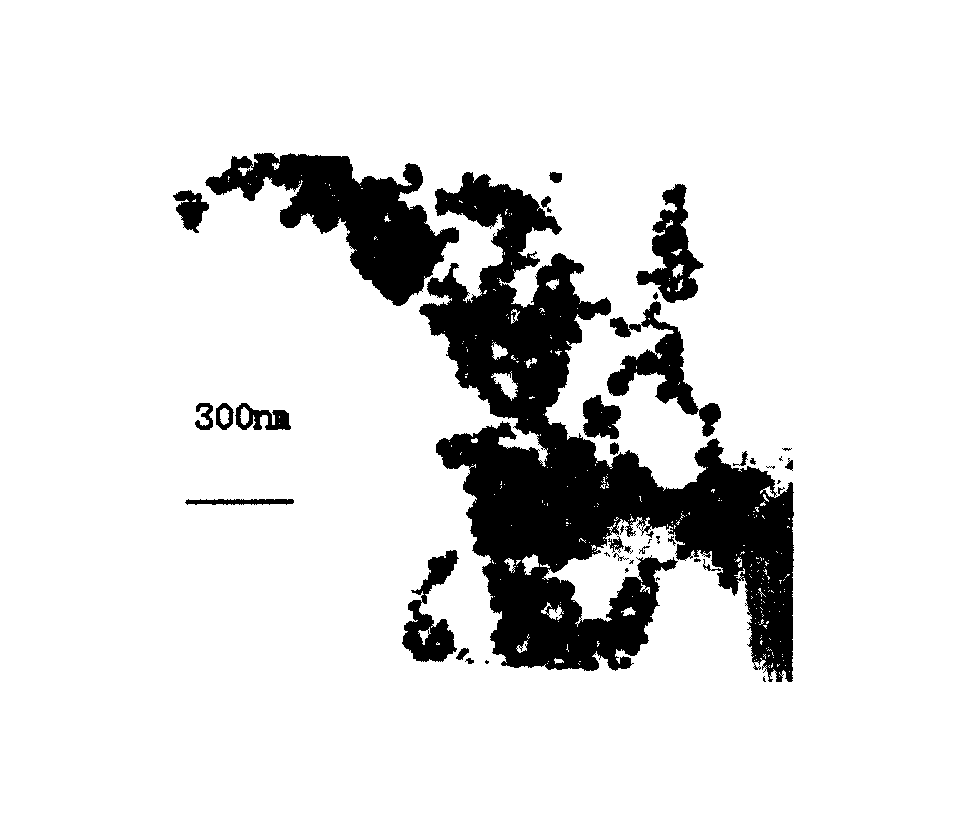

[0028] (5) Putting the hydrogel as a precursor into a high-temperature furnace and calcining at 800° C. for 5 hours to obtain a nanoscale up-conversion fluorescent material with an average particle size of 50 nm.

Embodiment 2

[0030] (1) Weigh 1.1760g lanthanum oxide (La 2 o 3 ), 0.3692g ytterbium oxide (Yb 2 o 3 ), 0.0537g erbium oxide (Er 2 o 3 ), placed in a 100ml beaker, add 2ml of concentrated hydrochloric acid (HCl) and heat to dissolve. At this time, the molar ratio of rare earth ions is La 3+ :Yb 3+ :Er 3+ =77:20:3, evaporate to dryness, remove remaining hydrochloric acid;

[0031] (2) Add 30ml of deionized water to dissolve the above product, and transfer it to a 100ml three-necked bottle;

[0032] (3) under rapid stirring, the potassium molybdate solution is dripped in the above-mentioned three-necked flask to generate a milky precipitate;

[0033] (4) Centrifuge the precipitate and wash it with water three times to make a hydrogel;

[0034] (5) Add ethanol to soak in the prepared hydrogel to make alcohol gel;

[0035] (6) Put the prepared alcohol gel into a high-temperature furnace and calcinate at 400° C. for 10 hours to obtain a nanoscale up-conversion fluorescent material wit...

Embodiment 3

[0037] (1) Measure lanthanum chloride, ytterbium chloride, and erbium chloride to be mixed with 25ml solution, so that the molar ratio of rare earth ions is La 3+ :Yb 3+ :Er 3+ =70.29:1, the total concentration of rare earth ions is 0.04mol / L, placed in a three-necked flask;

[0038] (2) Add 5ml of 0.2mol / L ethylenediaminetetraacetic acid (EDTA) solution to fully complex EDTA with rare earth ions;

[0039] (3) under rapid stirring, the sodium molybdate solution is rapidly injected into the above-mentioned three-necked bottle to generate a milky precipitate;

[0040] (4) adding ethanol to cooking in the prepared hydrogel to make alcohol gel;

[0041] (5) Put the produced alcohol gel as a precursor into a high-temperature furnace, and calcinate at 1100° C. for 1 hour to obtain a nanoscale up-conversion fluorescent material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com