Aerodynamic cushioning breathing shoes

An aerodynamic and cushioning technology, applied in footwear, soles, clothing, etc., can solve the problems of elastic airbag sealing and strength, damage to the firmness of shoes, failure of breathing function, etc., to achieve good wear resistance, cushioning The effect of good shock effect and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

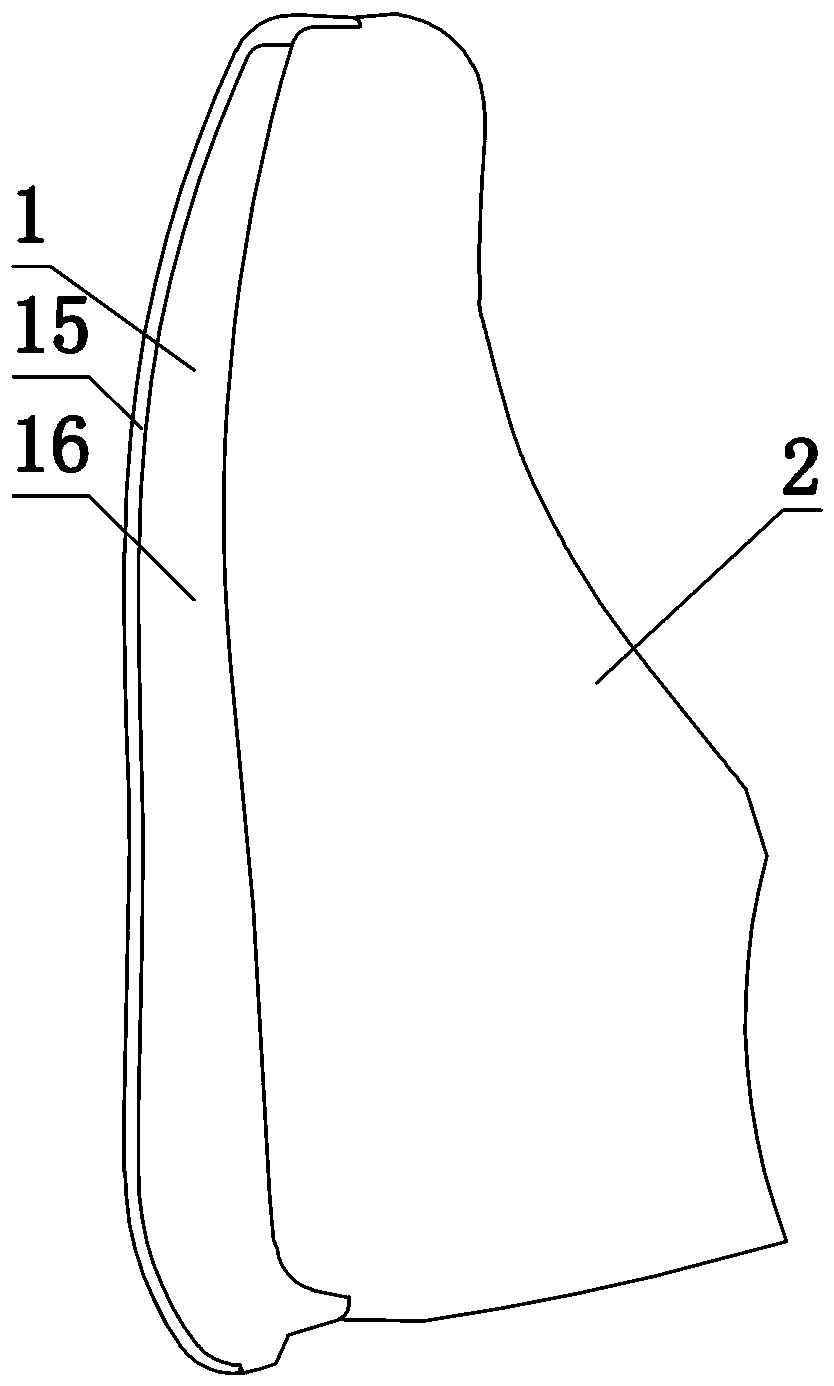

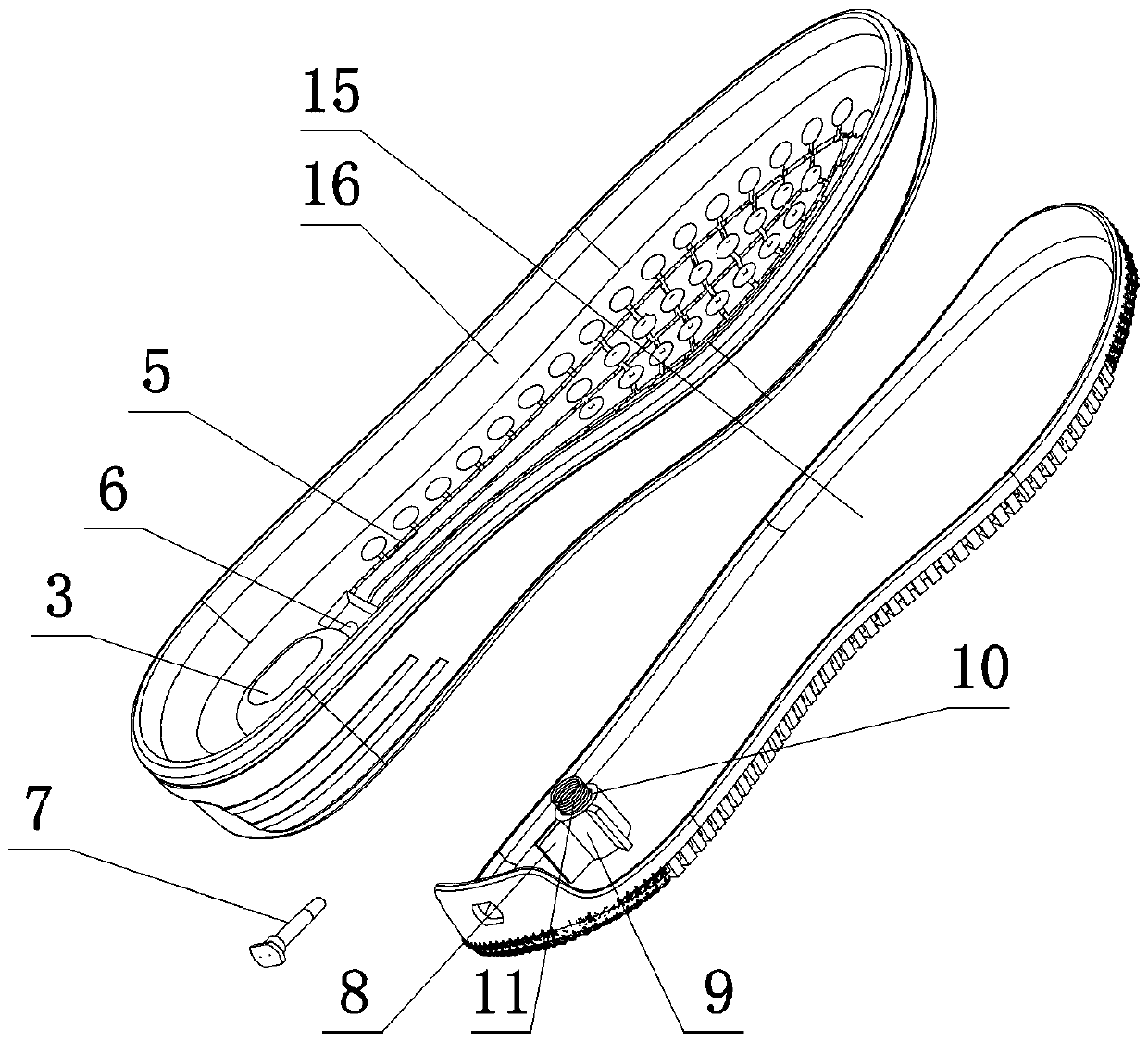

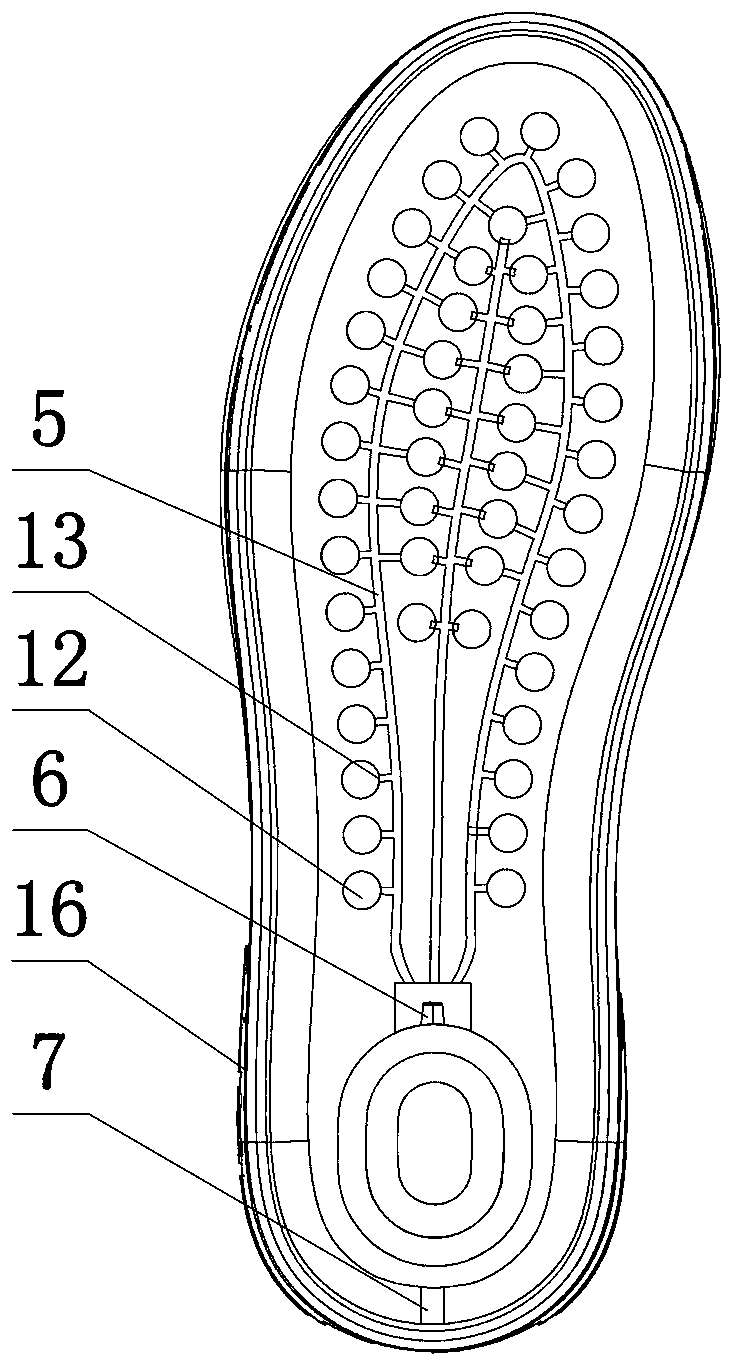

[0016] like Figure 1-4 As shown, an aerodynamic shock-absorbing breathing shoe provided by the present invention includes a sole 1 and a shoe upper 2, the sole 1 includes a bottom surface wear-resistant layer 15 and a shock-absorbing layer 16, and the lower end of the shock-absorbing layer 16 is provided with an opening downward. The cylindrical cavity 21, the rear of the cushioning layer 16 is provided with a breathing air bag 3, the breathing air bag 3 and the cushioning layer 16 are integrally formed, and the opening of the breathing air bag 3 exposes the lower surface of the cushioning layer 16 downward. The bottom surface wear-resistant layer 15 is bonded to the lower end of the shock-absorbing layer 16, and the opening of the cylindrical cavity 21 and the opening of the breathing air bag 3 are sealed. The sole 1 is provided with an air guide 5 at the forefoot and the arch of the foot, and the breathing air bag 3 There is a one-way intake valve 6 and a one-way exhaust va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com