A lamp powder that produces medium wave ultraviolet rays and its preparation methods and applications

An ultraviolet and lamp powder technology, applied in chemical instruments and methods, lighting and heating equipment, components of lighting devices, etc., can solve the problem of large light decay of fluorescent powder, shortened life of wave ultraviolet rays, and great hidden dangers to the environment and people. and other problems, to achieve the effect of high brightness, long service life and variable service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] This embodiment relates to a preparation method of lamp powder that produces medium-wave ultraviolet rays. The preparation method is based on strontium carbonate (SrCO 3 ), strontium chloride (SrCl 2 ), magnesium oxide (MgO), boric acid (H 3 BO 3 ), aluminum oxide (Al 2 O3), lead oxide (PbO) and rare earth metal oxides are mixed and fired at a high temperature in solid phase to obtain the lamp powder for producing medium-wave ultraviolet rays.

[0062] The rare earth metal oxides include one of actinide oxides and lanthanide oxides.

[0063] The lanthanide oxides include lanthanum oxide (La 2 o 3 ), gadolinium oxide (Gd 2 o 3 ) and samarium oxide (Sm 2 o 3 ).

[0064] The concrete steps of described preparation method preparation are:

[0065] Step 1, raw material processing: raw material strontium carbonate (SrCO 3 ), strontium chloride (SrCl 2 ), magnesium oxide (MgO), boric acid (H 3 BO 3 ), aluminum oxide (Al 2 o 3 ), any one of lead oxide (PbO) and...

Embodiment 2

[0075] The preparation method of the present embodiment is basically the same as that of Example 1, except that:

[0076] The raw materials to be weighed are: 4.2g (0.03mol) of strontium carbonate, 1.7g (0.01mol) of strontium chloride, 0.4g (0.01mol) of magnesium oxide, 12.4g (0.2mol) of boric acid, and 0.515g of aluminum oxide (0.005mol), lead oxide 0.335g (0.002mol) and lanthanum oxide 0.40g (0.001mol).

[0077] The chemical formula of the prepared lamp powder producing medium-wave ultraviolet rays is: (B 2 o 3 ) 2 ·(Al 2 o 3 ) 0.1 (Mg,Sr)O 0.87 Cl 0.4 :0.04Pb 2+ 0.02La 3+ .

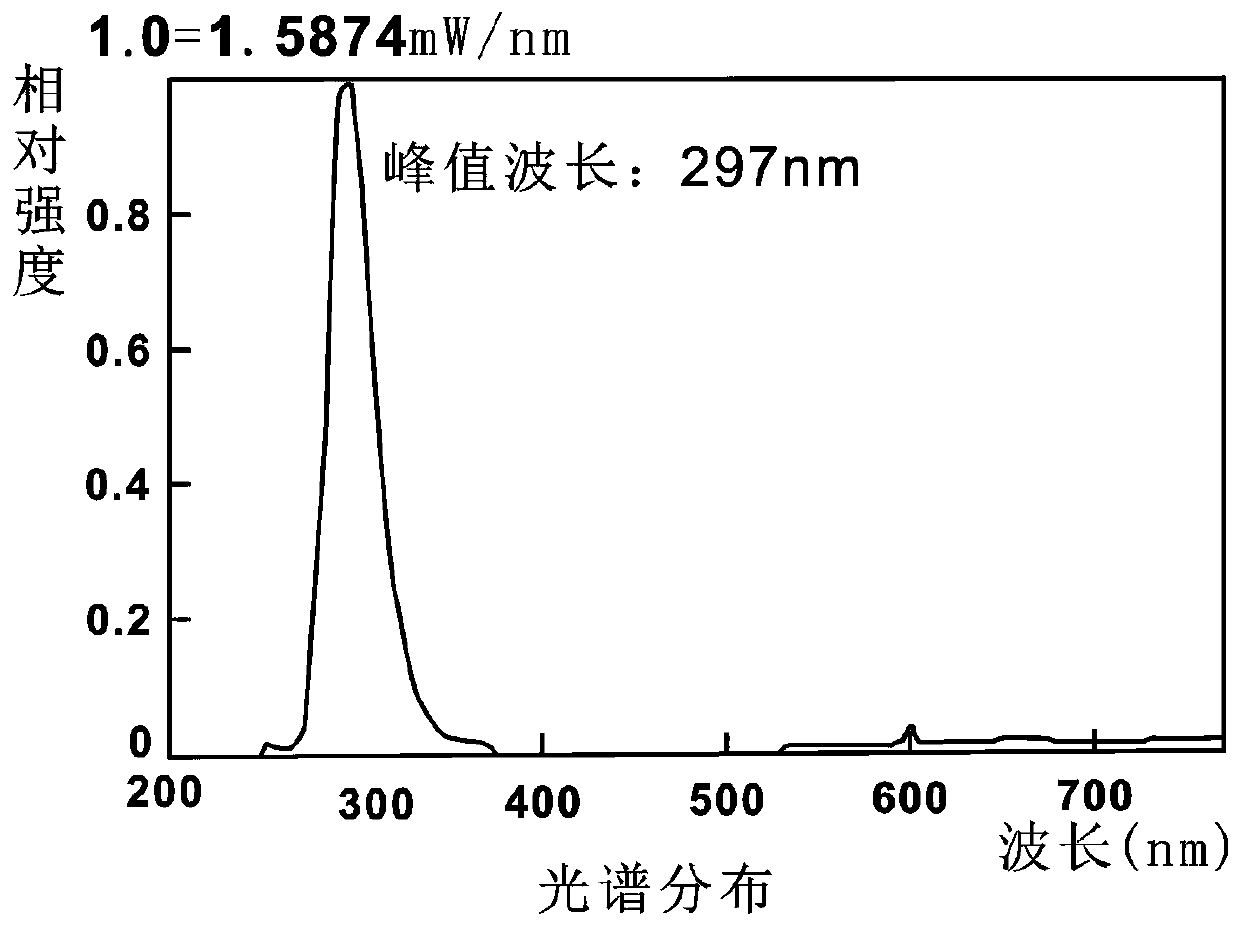

[0078] The spectrum of the prepared lamp powder measured by an ultraviolet analyzer is a band spectrum, the peak value is λ=297nm, and the measured relative intensity is stronger than that of phosphate activated by calcium zinc thallium and gadolinium.

Embodiment 3

[0080] The preparation method of the present embodiment is basically the same as that of Example 1, except that:

[0081] The raw materials to be weighed are: 8.86g (0.06mol) of strontium carbonate, 3.2g (0.02mol) of strontium chloride, 0.8g (0.02mol) of magnesium oxide, 24.8g (0.4mol) of boric acid, and 1.03g of aluminum oxide (0.01mol), lead oxide 0.67g (0.003mol) and lanthanum oxide 0.81g (0.005mol).

[0082] The chemical formula of the prepared lamp powder producing medium-wave ultraviolet rays is: (B 2 o 3 ) 2 ·(Al 2 o 3 ) 0.1 (Mg,Sr)O 0.905 Cl 0.2 :0.03Pb 2+ 0.05La 3+ .

[0083] The spectrum of the prepared lamp powder measured by an ultraviolet analyzer is a band spectrum, the peak value is λ=297nm, and the measured relative intensity is stronger than that of phosphate activated by calcium zinc thallium and gadolinium.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com