A mold heat treatment process

A mold and process technology, applied in the field of mold heat treatment technology, can solve the problems of mold hardness not meeting the requirements, uneven heating of the mold, inability to contact the lower surface of the mold with hot air, etc., to improve the tempering efficiency, small lattice, The effect of reducing the likelihood of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

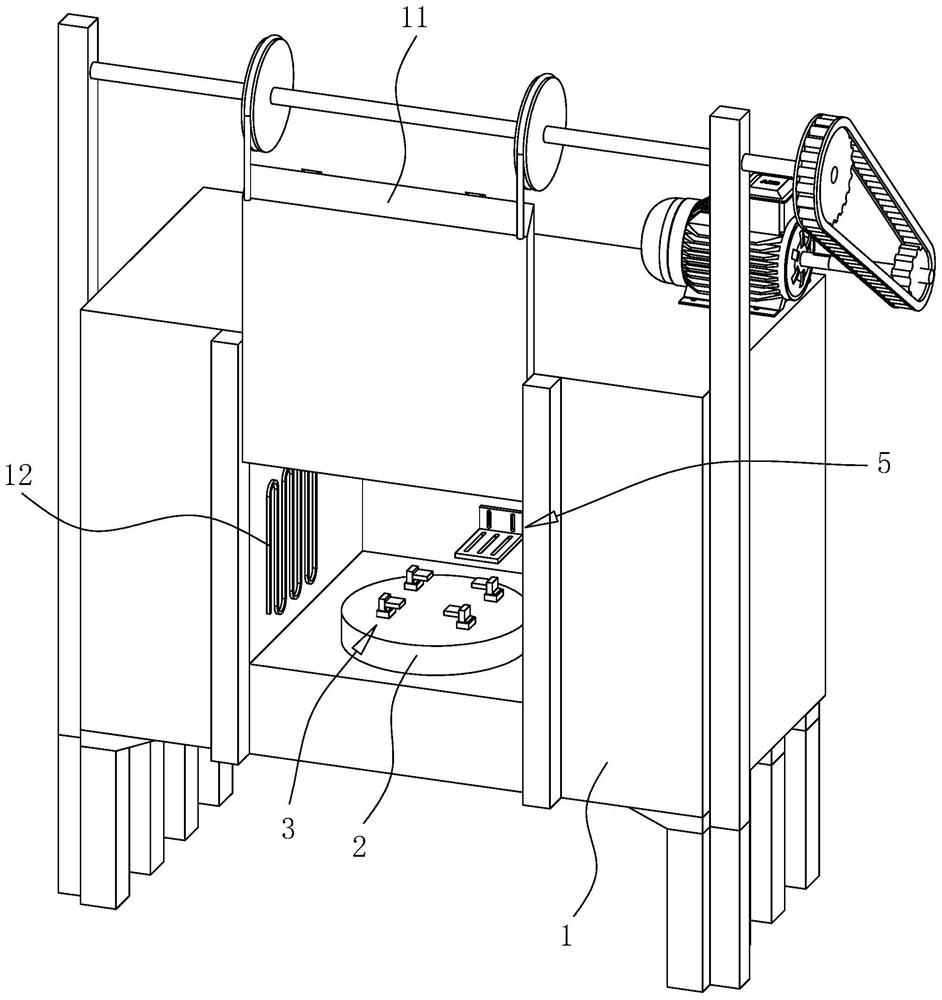

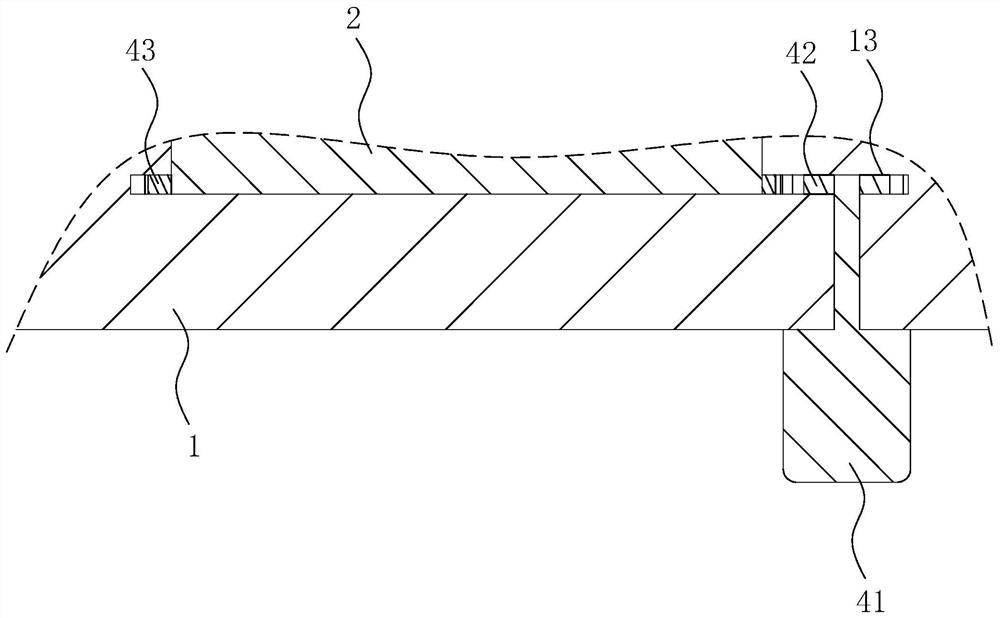

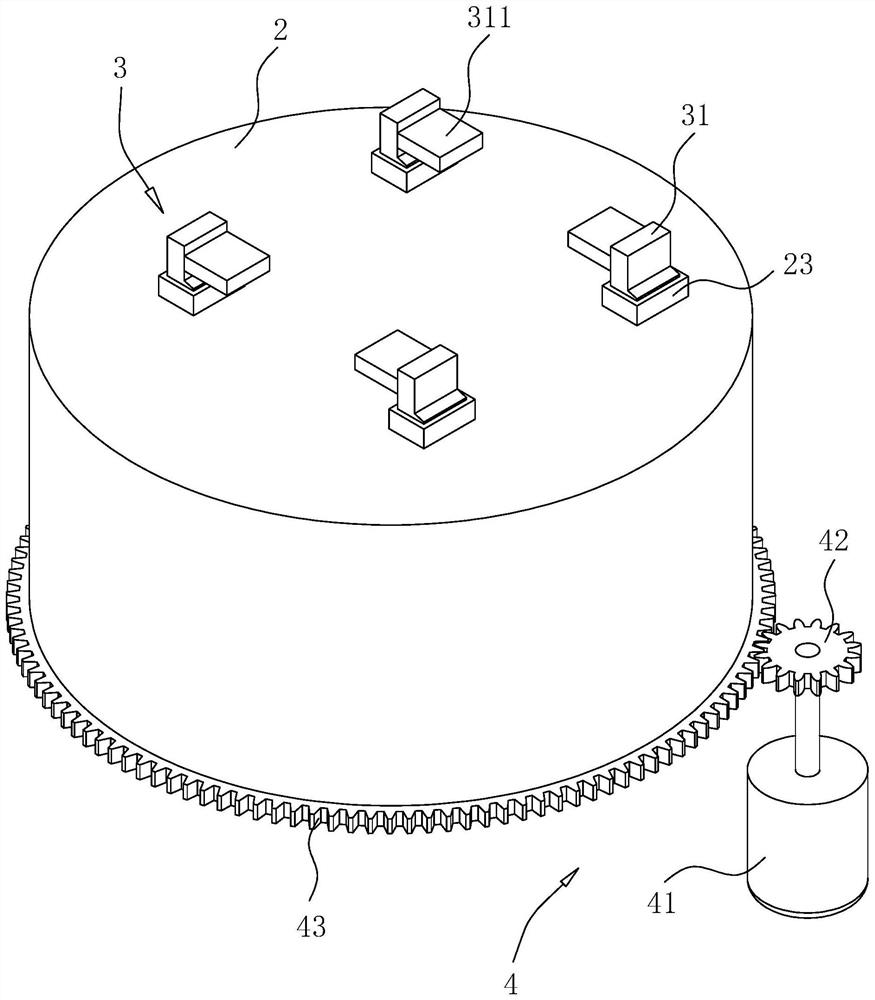

[0043] The following is attached Figure 1-6 The application is described in further detail.

[0044] The embodiment of the present application discloses a mold heat treatment process.

[0045] A mold heat treatment process, comprising the following steps:

[0046] S1. Carry out hole forming and surface grinding on the mold.

[0047] S2. Put the roughly machined mold into a quenching furnace for quenching treatment at 900° C. to 1500° C., and keep it warm for 20 minutes to 40 minutes. Specifically, in this embodiment, keep it warm at 1200° C. for 30 minutes.

[0048] S3. The mold after quenching is water-cooled or oil-cooled. In this embodiment, the mold is put into the quenching oil pool for oil cooling, so that the austenite structure is transformed into a martensite structure, so as to improve the strength, hardness and durability of the mold. Abrasive.

[0049] S4. Reference figure 1 , put the mold into the tempering furnace 1 for tempering treatment at 500°C to 650°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com