Preparation method for ultra-low-pressure high-flux reverse osmosis membrane

A reverse osmosis membrane, high-flux technology, applied in semi-permeable membrane separation, chemical instruments and methods, osmosis/dialysis water/sewage treatment, etc., can solve the limited improvement of reverse osmosis membrane water flux, loose desalination layer performance Instability, unstable flux and other problems, to achieve the effect of improving water flux, increasing the reaction interface, and increasing the reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Immerse the polysulfone-coated non-woven fabric base film in an aqueous solution containing 2% m-phenylenediamine (MPD) for 40s, and remove the excess water phase after taking it out;

[0024] Soak the wet film in an oil phase solvent containing 0.15% TMC for 30 seconds. After removing the excess residual liquid, a polyamide dry film is obtained. As a preference, the oil phase solvent of the present invention is ISOPARG in the isoparaffin oil phase solvent;

[0025] The prepared polyamide dry membrane was placed in an oven to dry for 3 minutes, and then immersed in pure water for washing for 5 minutes after being taken out, and a high flux reverse osmosis membrane was prepared.

[0026] Tested by a flat-panel tester, the flux of this wet membrane is 22.53LMH, the salt rejection rate is 98.6%, and the unit of water flux is L / m / h (LMH).

Embodiment 2

[0028] Immerse the polysulfone-coated non-woven fabric base film in an aqueous solution containing 2% m-phenylenediamine (MPD) for 40s, and remove the excess water phase after taking it out;

[0029] Soak the wet film in ISOPARG containing 0.15% trimesoyl chloride (TMC) and 0.05% phthalate (lipid) oil phase solution ISOPARG for 30s. After removing excess residual liquid, a dry polyamide is obtained. membrane;

[0030] The prepared polyamide dry membrane was placed in an oven to dry for 3 minutes, and then immersed in pure water for washing for 5 minutes after being taken out, and a high flux reverse osmosis membrane was prepared.

[0031] Tested by a flat tester, the water flux of this wet membrane is 27.81LMH, and the salt rejection rate is 97.9%.

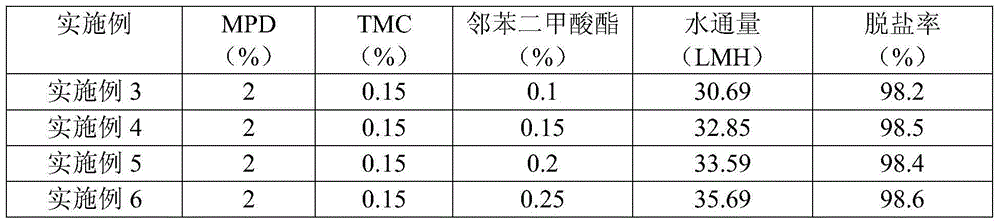

Embodiment 3-6

[0033] The parameter control of each step is the same as in Examples 1 and 2. The components, proportions, and test results of Examples 3-6 are shown in Table 1:

[0034] Table 1 Components, proportions and test results of Examples 3-6

[0035]

[0036] It can be seen that adding a small amount of phthalates to the oil phase solution can significantly increase the flux of the membrane, but the salt rejection rate does not decrease. With the increase of the concentration, the performance of the membrane is slightly improved, so The phthalate concentration is 0.25%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com