Mesoporous phosphate anode material with olivine structure and preparation method and use thereof

An olivine structure and cathode material technology, which is applied in the field of phosphate cathode materials with mesoporous morphology and olivine structure and their preparation, can solve the problems of low mass energy density of electrolyte materials, uneven distribution of material pore size, and carbon-containing materials. In order to overcome the problems of low interface transmission, good electrochemical performance and high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

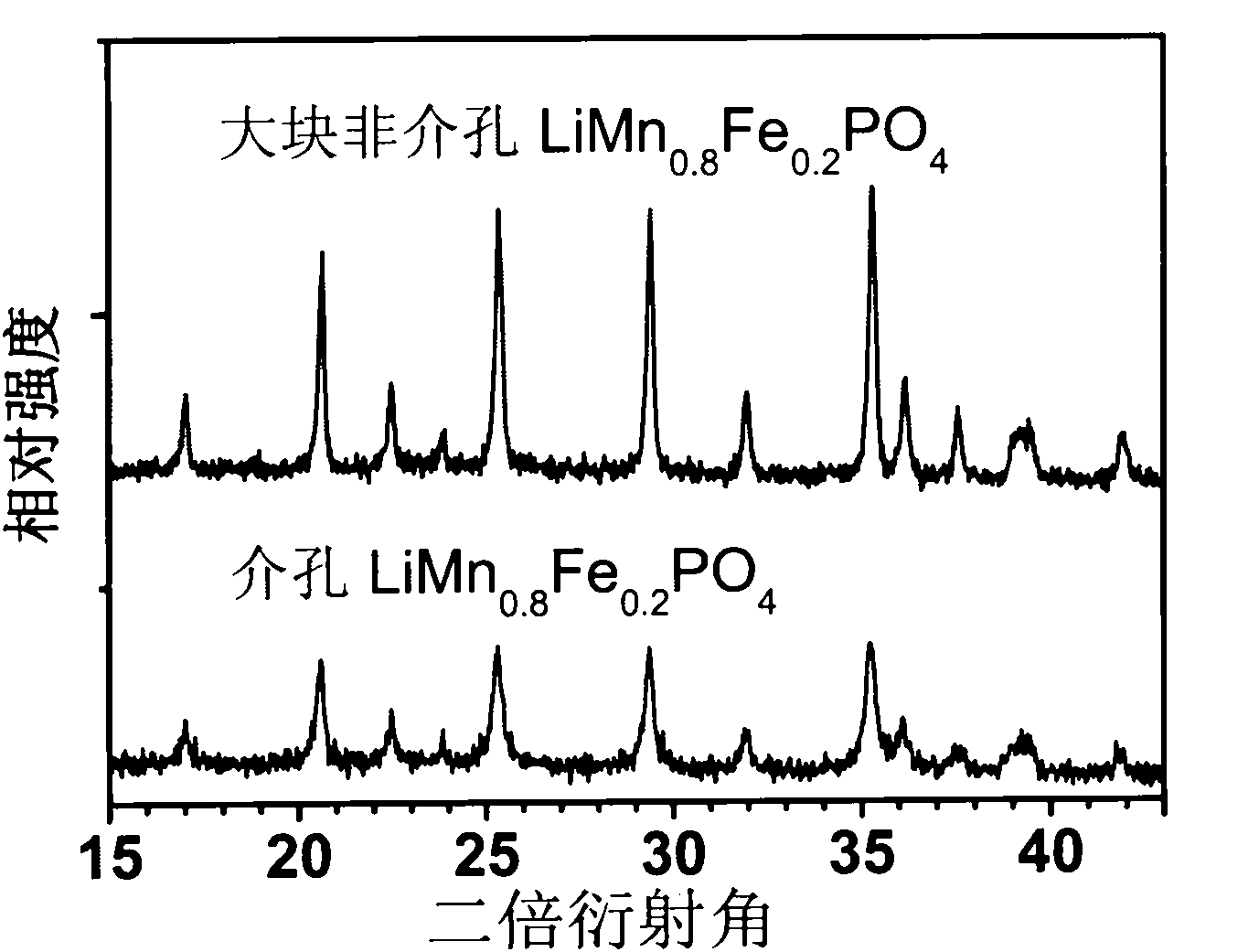

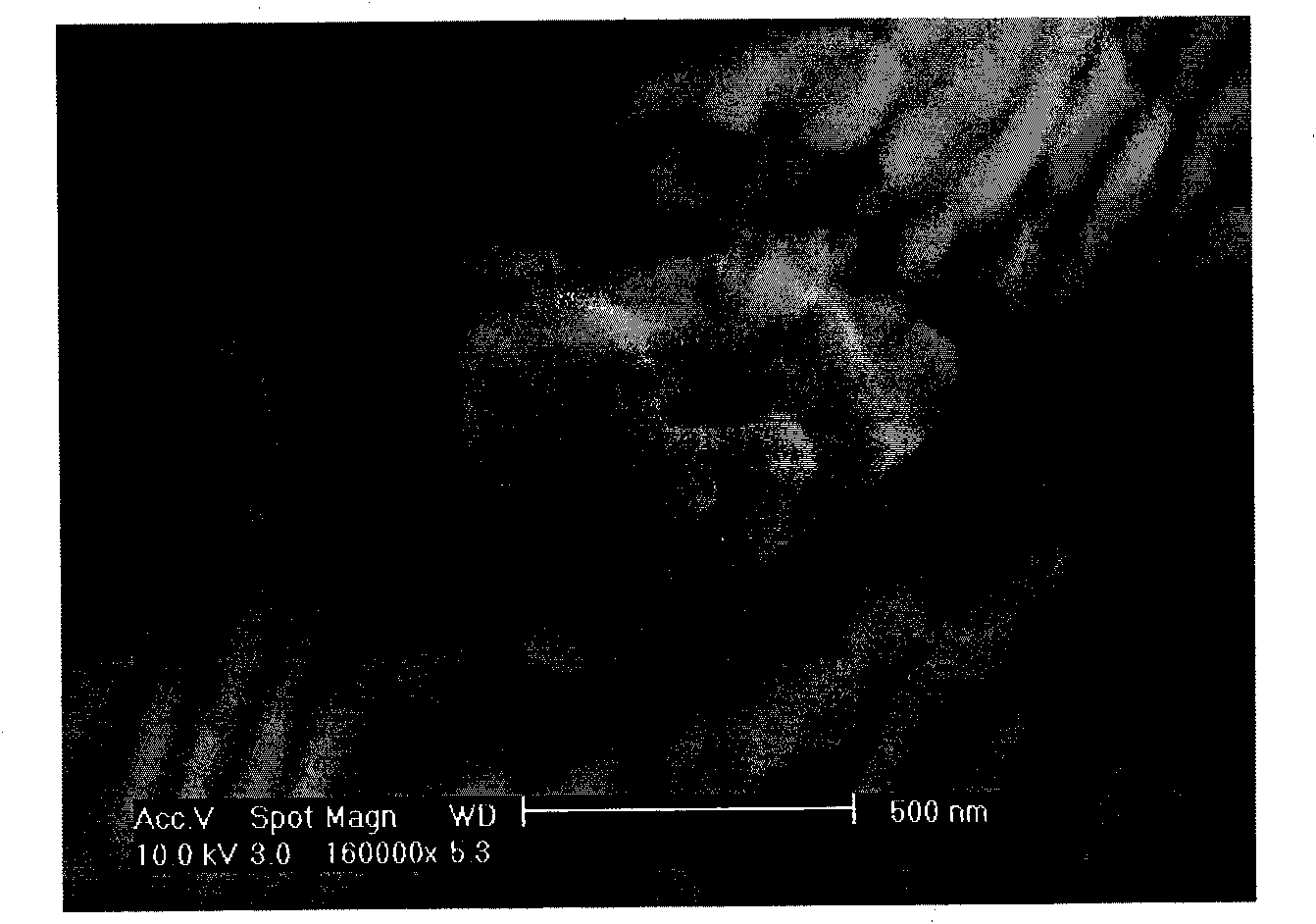

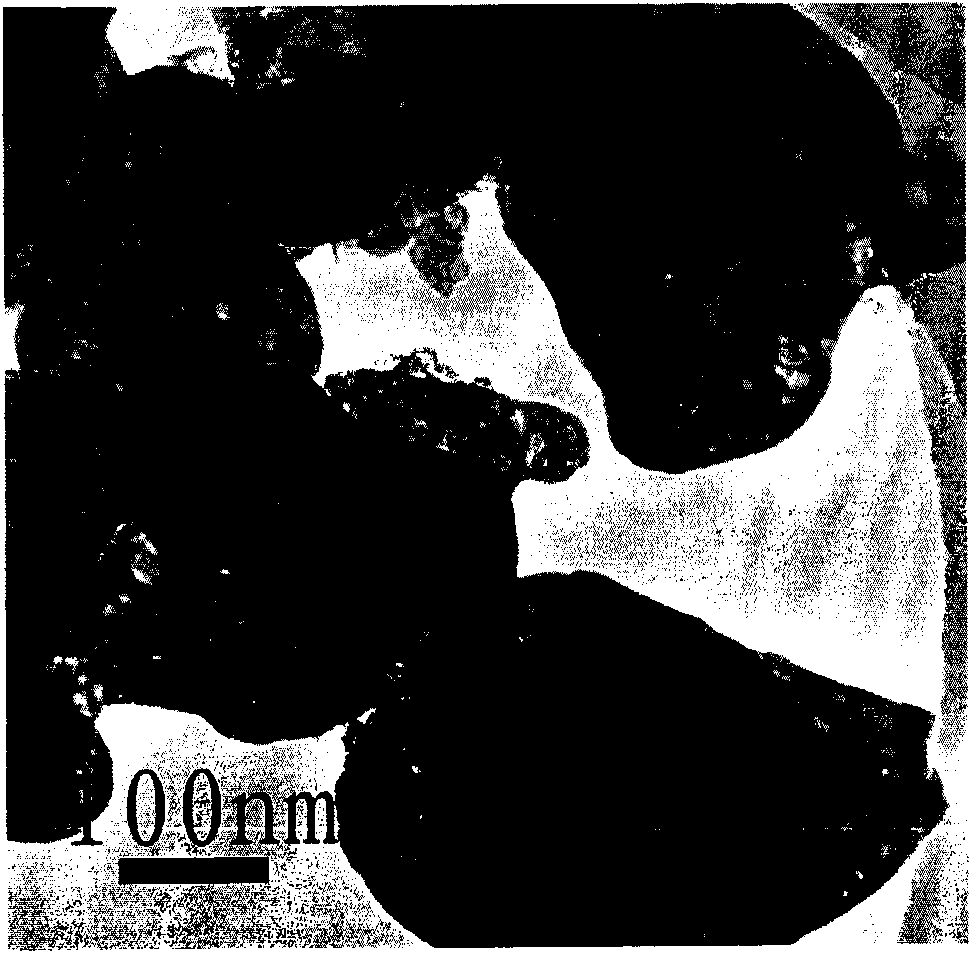

[0036] Example 1: Preparation of mesoporous pure phase LiMn with olivine structure for secondary lithium battery of the present invention 0.8 Fe 0.2 PO 4

[0037] Mesoporous LiMn with olivine structure of the present invention 0.8 Fe 0.2 PO 4 It can be prepared by the following steps. First, weigh Li 2 CO 3 , MnC 2 o 4 2H 2 O, FeC 2 o 4 2H 2 O, NH 4 h 2 PO 4 , C 6 h 8 o 7 (citric acid) and carbon black are put into ethanol solvent together, after mechanical ball milling (ball milling medium particle diameter 1mm-10mm, rotating speed is 2000 rev / min, 5 hours), this mixture is pre-treated under the protection of high-purity Ar gas Sinter (the step of pre-sintering is: take 1 hour to raise the temperature from room temperature to 350 ° C, keep the temperature at 350 ° C for 4 hours, and then use 10 hours to drop to room temperature), after manual grinding and crushing, the mixture is sintered again (sintering step is: take 4 hours The temperature was raised fro...

Embodiment 2

[0038] Example 2: Preparation of mesoporous pure phase LiMnPO with olivine structure for secondary lithium battery of the present invention 4

[0039] Mesoporous LiMnPO with olivine structure of the present invention 4 It can be prepared by the following steps. First, weigh Li according to the molar ratio of 0.5:1:1:0.3:0.3 2 CO 3 , MnC 2 o 4 2H 2 O, NH 4 h 2 PO 4 , C 6 h 8 o 7 (citric acid) and carbon black are put into ethanol solvent together, after mechanical ball milling (ball milling medium particle size 1mm-10mm, rotating speed is 2000 rev / min, 5 hours), this mixture is pre-fired under the protection of high-purity Ar gas (The step of pre-burning is: use 1 hour to raise the temperature from room temperature to 350 ° C, keep the temperature at 350 ° C for 4 hours, and then use 10 hours to drop to room temperature), after manual grinding and pulverization, the mixture is sintered again (the sintering step is: use 4 hours from The room temperature was raised to...

Embodiment 3

[0040] Example 3: Preparation of mesoporous pure phase LiFePO with olivine structure for secondary lithium battery of the present invention 4 .

[0041] Mesoporous LiFePO with olivine structure of the present invention 4 It can be prepared by the following steps. First, weigh Li according to the molar ratio of 0.5:1:1:0.3:0.3 2 CO 3 , FeC 2 o 4 2H 2 O, NH 4 h 2 PO 4 , C 6 h 8 o 7 (citric acid) and carbon black are put into ethanol solvent together, after mechanical ball milling (ball milling medium particle size 1mm-10mm, rotating speed is 2000 rev / min, 5 hours), this mixture is pre-fired under the protection of high-purity Ar gas (The step of pre-burning is: use 1 hour to raise the temperature from room temperature to 350 ° C, keep the temperature at 350 ° C for 4 hours, and then use 10 hours to drop to room temperature), after manual grinding and pulverization, the mixture is sintered again (the sintering step is: use 4 hours from The room temperature was raised ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com