Integrated regenerative fuel cell structure

A fuel cell, integrated technology, applied in the field of integrated proton exchange membrane renewable fuel cell structure, can solve the problems of complicated URFC cell structure design, unstable cell performance, cumbersome assembly process, etc., and achieves novel design and increased size The effect of simple reaction interface and assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

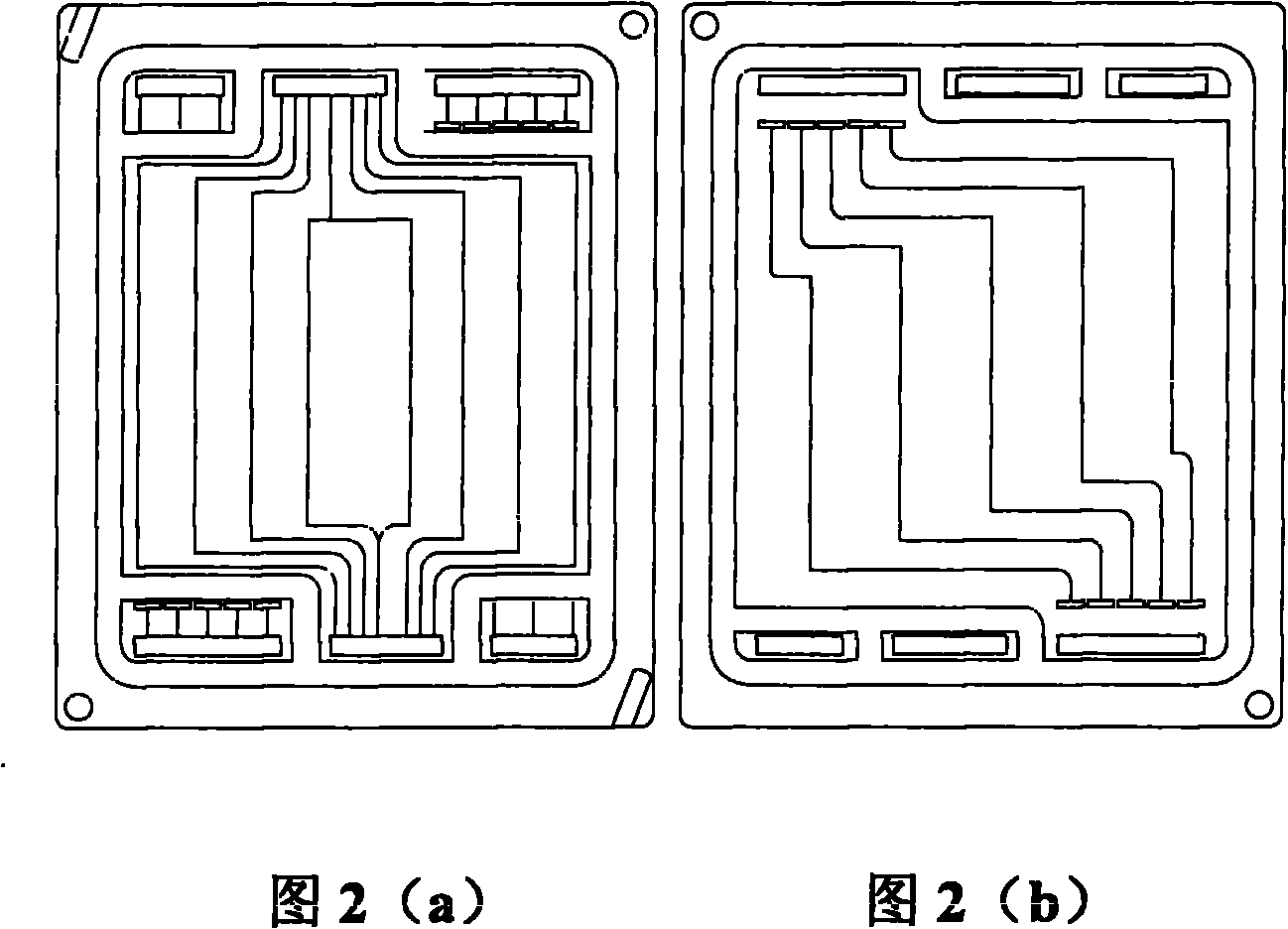

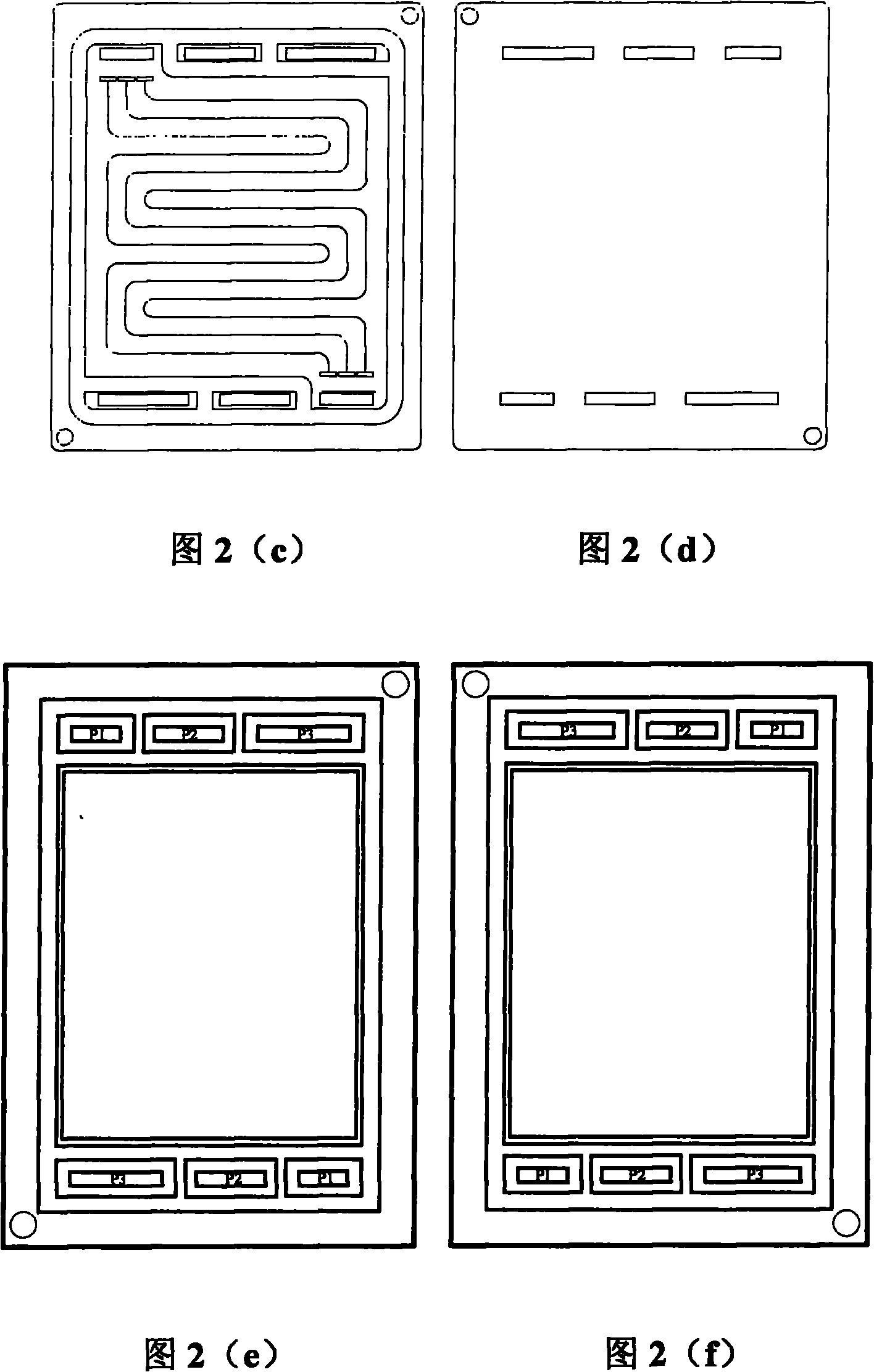

[0035]Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0036] Such as figure 1 As shown, in the assembly structure of the integrated regenerative fuel cell provided by the preferred embodiment of the present invention, the anode insulation buffer plate A2, the anode conductive plate A3, the front special plate A4, the anode flow field assembly (water / oxygen double-sided flow field plate A5, plane limit metal ring A6, plane thin porous metal plate A7), double-effect membrane electrode assembly M1, cathode flow field assembly (plane thin porous metal plate B7, plane limit metal ring B6, hydrogen single-sided flow field plate B5 ), the rear special water plate B4, the cathode conductive plate B3 and the cathode insulating buffer plate B2 are sequentially stacked to form a battery stack;

[0037] Front-end plate A1 and rear-end plate B1 are respectively installed at both ends of the battery stack; the outer ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com