Magnesium-calcium-based hydride powder for wide-temperature zone hydrolysis hydrogen generation and preparation method for magnesium-calcium-based hydride powder

A magnesium-calcium-based hydride and based hydride technology, which is applied in the production of alkali metal/alkaline earth metal/beryllium/magnesium hydride and hydrogen, can solve the problems of poor hydrolysis performance, uncontrollable process and safety of hydride composite materials. Low-level problems, to achieve the effect of increasing the actual hydrogen production, increasing the hydrogen production rate, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

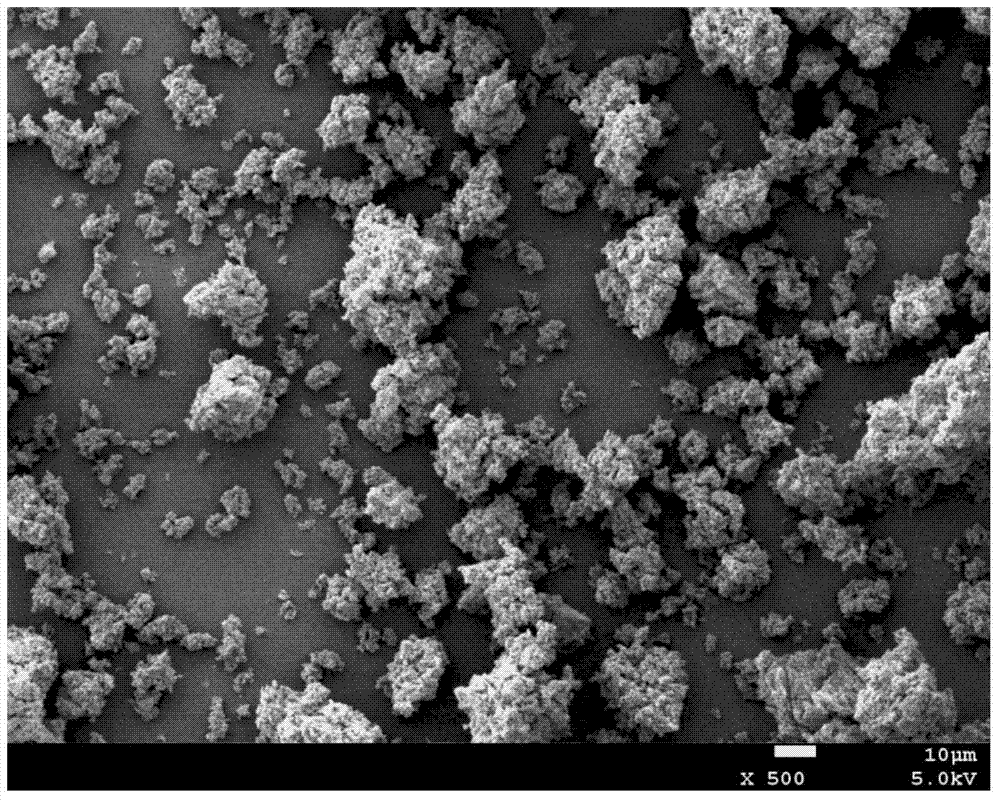

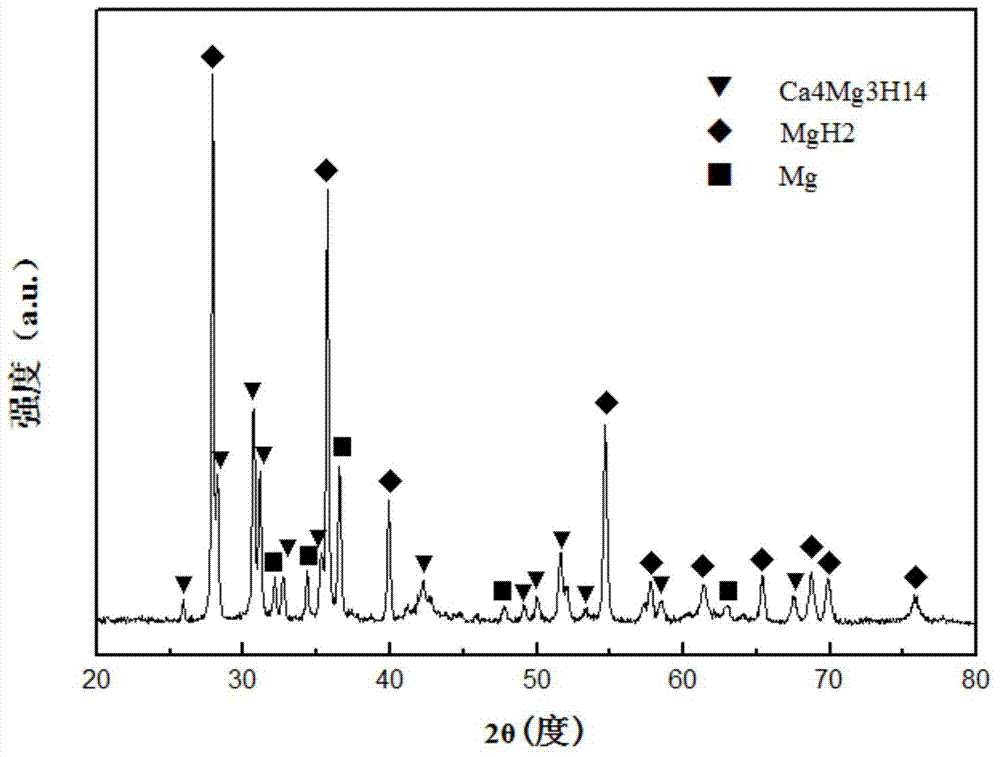

[0034] The magnesium-calcium alloy containing 35wt% calcium and 65wt% magnesium is crushed to less than 200 meshes, and ball milled for 2h under the condition of argon atmosphere with a ball-to-battery ratio of 20:1. Then the powder obtained by ball milling is placed in Sieverts-type (Western In the Fitz type) device, activate 4 times at a temperature of 400°C and a hydrogen pressure of 4 MPa, and then absorb hydrogen for 24 hours to obtain magnesium-calcium-based hydride powder. The SEM image is shown in figure 1 , Of which magnesium calcium hydride Ca 4 Mg 3 H 14 50.2wt%, magnesium hydride MgH 2 It is 47.3wt%, and the balance Mg is 2.5wt%.

[0035] Take 0.2g of the prepared magnesium-calcium-based hydride powder and place it in a reactor at a constant temperature of 0°C, and inject 10ml of distilled water at a temperature of 0°C for the reaction, and collect the hydrogen by the drainage gas collection method and react for 60 minutes. The conversion yields 775ml of hydrogen per g...

Embodiment 2

[0037] The magnesium-calcium alloy containing 25wt% calcium and 75wt% magnesium is crushed to less than 300 mesh, and ball milled for 3h under the conditions of argon atmosphere and ball-to-battery ratio of 20:1, and then the powder obtained by ball milling is placed in Sieverts-type (Western In the Fitz type) device, activate 4 times at a temperature of 400°C and a hydrogen pressure of 4.5 MPa, and then absorb hydrogen for 6 hours to obtain a magnesium-calcium-based hydride powder, in which the magnesium-calcium hydride Ca 4 Mg 3 H 14 35.8wt%, magnesium hydride MgH 2 It is 61.5wt%, and the balance Mg is 2.7wt%.

[0038] Take 0.2g of the prepared magnesium calcium-based hydride powder and place it in a reactor at a constant temperature of 10°C, and inject 10ml of distilled water at a temperature of 10°C for reaction, and collect hydrogen by the drainage gas collection method, and react for 60 minutes. The conversion yields 585ml of hydrogen per gram of the above materials.

Embodiment 3

[0040] (1) The magnesium-calcium alloy containing 35wt% calcium and 65wt% magnesium is crushed to less than 100 mesh, and ball milled for 1h under the conditions of argon atmosphere and ball-to-battery ratio of 8:1, and then the powder obtained by ball milling is placed in Sieverts -type (Siffertz type) device, activated once at a temperature of 400°C and a hydrogen pressure of 3.5MPa, and then hydrogenated for 24 hours to obtain magnesium-calcium-based hydride powder, of which the magnesium-calcium hydride Ca 4 Mg 3 H 14 50.2wt%, magnesium hydride MgH 2 It is 34.8wt%, and the balance Mg is 15.0wt%.

[0041] (2) The obtained magnesium-calcium-based hydride powder is mechanically ball-milled in a ball mill under an argon atmosphere with a ball-to-material ratio of 2:1 for 10 hours.

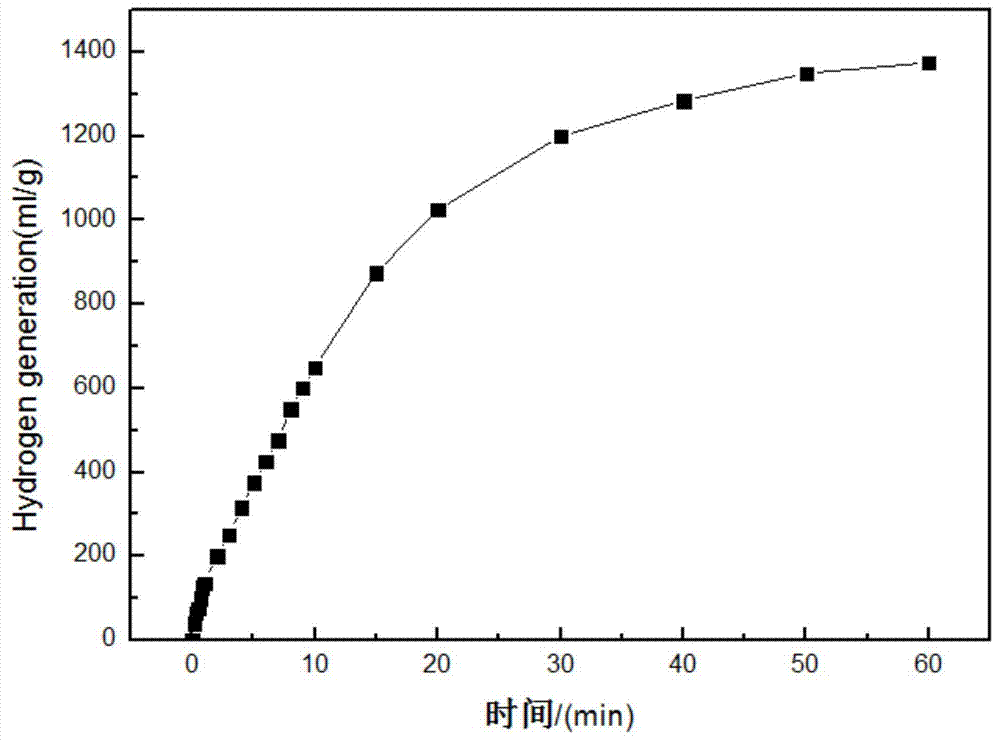

[0042] Take 0.2g of the prepared magnesium-calcium-based hydride powder and place it in a reactor at a constant temperature of 25°C, and inject 10ml of distilled water at a temperature of 25°C for reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com