Start-up activation method for hydrogenation cracking process

A technology for hydrocracking and start-up activation, which is used in hydrotreating process, petroleum industry, processing of hydrocarbon oil, etc., can solve the problem of no further optimization of the activation process of the pre-sulfurized catalyst loaded into the reactor, etc., and achieves considerable economy and efficiency. Social benefits, reduced usage, simple process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

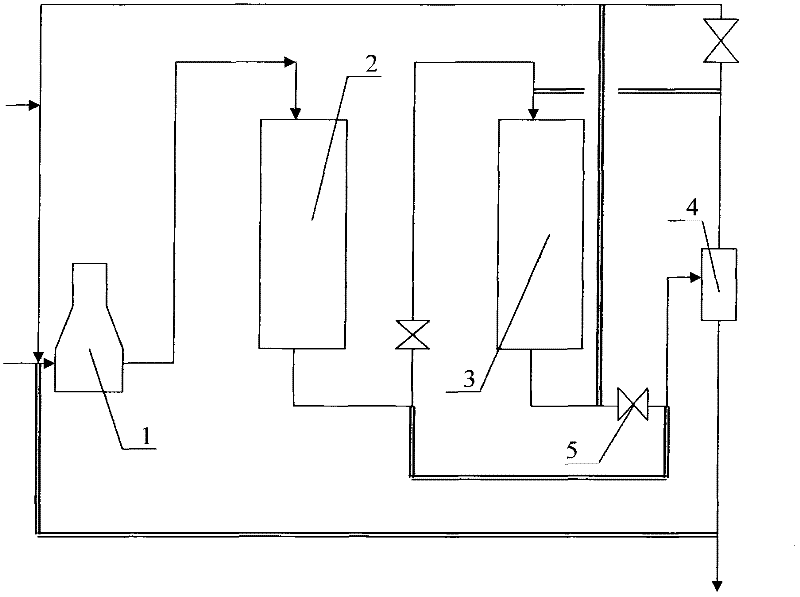

[0048] EPFF-36 and EPFC-32 are respectively loaded into their respective reactors and made airtight. After the airtightness is qualified, the hydrogen partial pressure is adjusted to 14.0MPa, the temperature is adjusted to 100°C, and the activated oil is introduced (the activated oil is straight-run kerosene), and the volume space velocity of the activated oil is 2h -1 , the volume ratio of hydrogen to oil is 1000. The process is as figure 1 According to the formula (the laboratory pilot plant is used, the reactor is a salt bath isothermal reactor, the main equipment of the following examples is the same, and the process is slightly changed), hydrogen and activated oil are mixed and enter the heating furnace 1, and then enter the hydrogenation after heating Cracking pre-refining reactor 2, the outflow gas-liquid enters the high-pressure gas-liquid separator 4 for gas-liquid separation, the separated gas enters the hydrocracking reactor 3, returns to the heating furnace 1 afte...

Embodiment 2

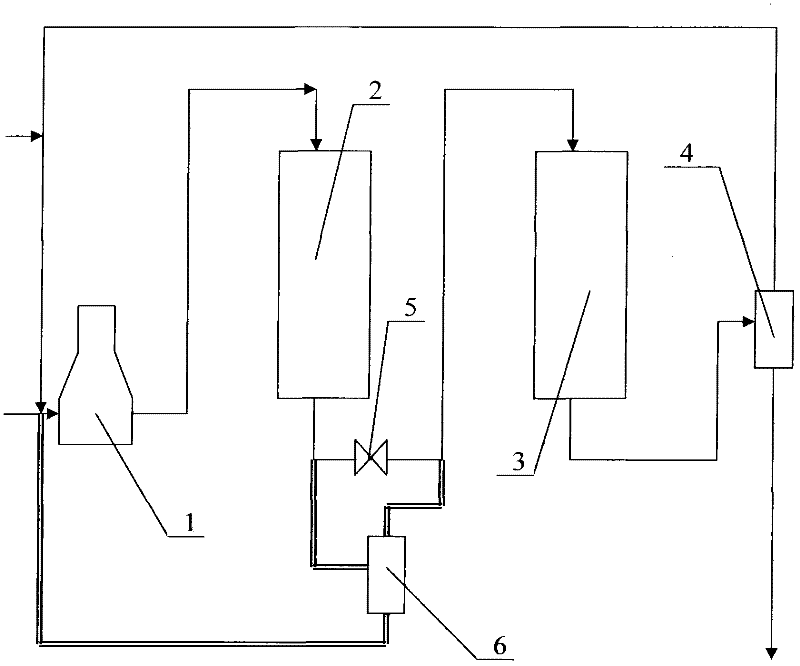

[0050] EPFF-36 and EPFC-32 are respectively loaded into their respective reactors and made airtight. After the airtightness is qualified, the hydrogen partial pressure is adjusted to 14.0MPa, the temperature is adjusted to 100°C, and the activated oil is introduced (the activated oil is straight-run kerosene), and the volume space velocity of the activated oil is 2h -1 , the volume ratio of hydrogen to oil is 1000. The process is as figure 2 As shown, the hydrogen and activated oil are mixed and enter the heating furnace 1, and then enter the hydrocracking pre-refining reactor 2 after heating, and the outflow gas-liquid enters the gas-liquid separator 6 for gas-liquid separation, and the separated gas enters the hydrocracking Reactor 3 returns to heating furnace 1 after passing through high-pressure gas-liquid separator 4, (or directly returns to heating furnace 1 without passing through high-pressure gas-liquid separator 4.) And before entering heating furnace 1, it is comb...

Embodiment 3

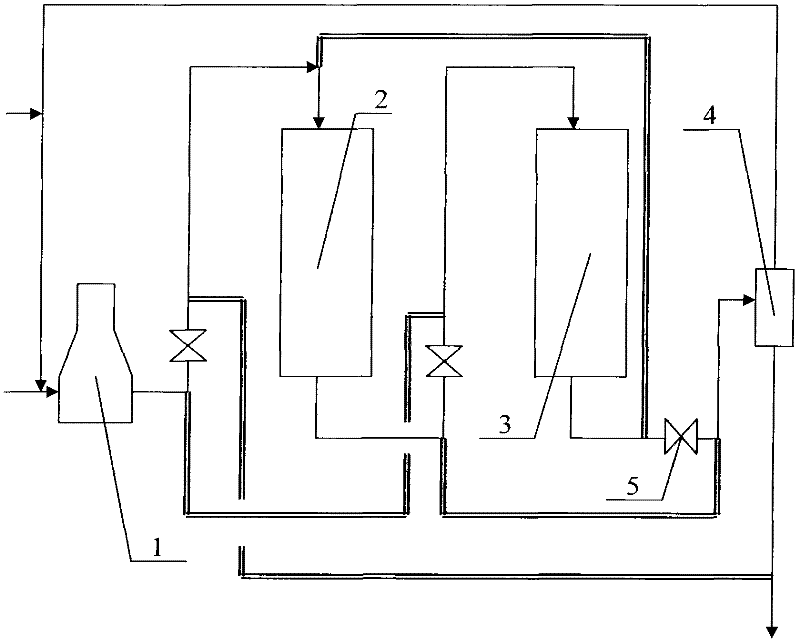

[0052] EPFF-36 and EPFC-32 are respectively loaded into their respective reactors and made airtight. After the airtightness is qualified, the hydrogen partial pressure is adjusted to 14.0MPa, the temperature is adjusted to 100°C, and the activated oil is introduced (the activated oil is straight-run kerosene), and the volume space velocity of the activated oil is 2h -1 , the volume ratio of hydrogen to oil is 1000. The process is as image 3 As shown, the gas and activated oil are mixed and enter the hydrocracking pre-refining reactor 2, and the gas and liquid in the hydrocracking pre-refining reactor 2 enter the high-pressure gas-liquid separator 4 for gas-liquid separation, and the separated gas is returned to the heating furnace 1. After heating, it enters the hydrocracking reactor 3, returns to the hydrocracking pre-refining reactor 2 after passing through the hydrocracking reactor 3, and before entering the hydrocracking pre-refining reactor 2, it is separated from the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com