Method for removing silicon oxide layer on surface of silicon substrate and contact hole forming

A silicon oxide layer, silicon substrate technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as damage to the pattern shape, damage to the surface of the silicon substrate, etc., and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

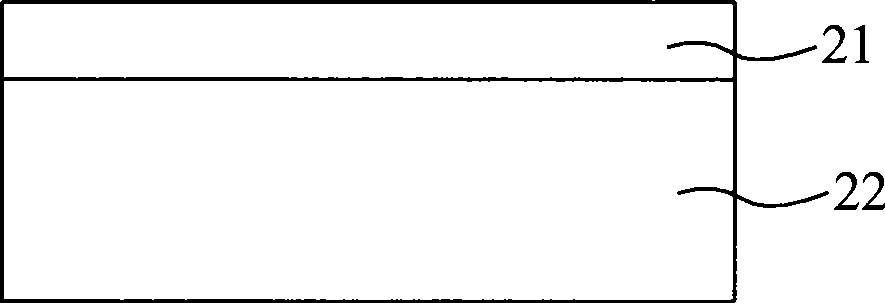

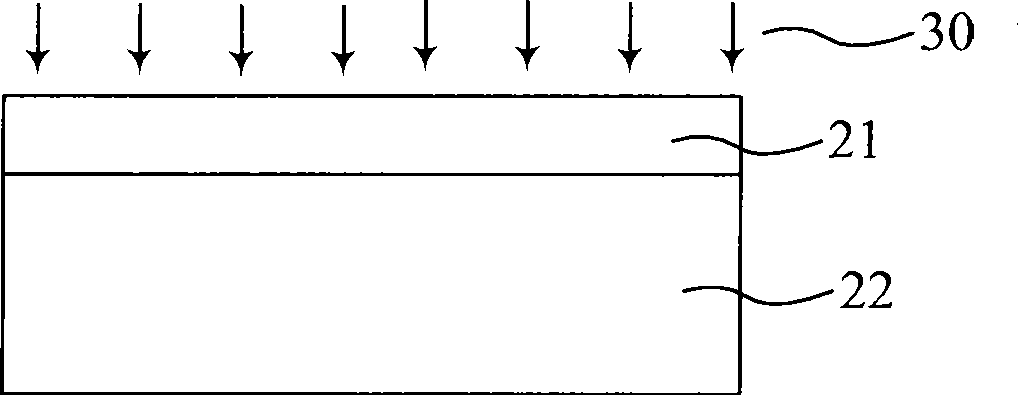

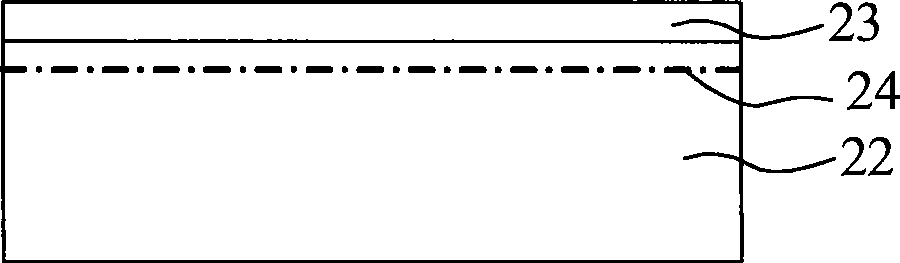

[0034] The invention provides a method for removing the silicon oxide layer on the surface of a silicon substrate, by converting the natural silicon oxide layer on the surface of the silicon substrate into ammonium fluorosilicate to passivate the surface of the silicon substrate, and then heating to make the ammonia fluorosilicate Chemicalization, the gas of ammonium fluorosilicate is pumped away, and the silicon oxide layer on the surface of the silicon substrate is removed.

[0035] refer to Figure 6 , the present invention at first provides a kind of method for removing silicon oxide layer on silicon substrate surface, comprises the steps:

[0036] Execute step S101, put the silicon substrate with the silicon oxide layer into the etching equipment, the silicon oxide layer is formed on the surface of the silicon substrate, and the NH 4 F atomic group, which reacts with the silicon oxide layer on the surface of the silicon substrate to form a solid state (NH 4 ) 2 SiF 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com