Method for preparing MCM-22 molecular sieve in high silicon

A technology of MCM-22 and molecular sieves, applied in molecular sieves and base exchange compounds, chemical instruments and methods, inorganic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] 1) The silicon-aluminum ratio is Si / Al 2 The former powder of MCM-22 molecular sieve of =27 is roasted at 500°C to remove the template agent, and it is converted into an intermediate ammonium form by ammonium ion exchange method; ammonium ion source NH 4 NO 3 , Ammonium ion exchange conditions: ammonium ion concentration 0.2mol / L, volume liquid-solid ratio 5, temperature 20°C.

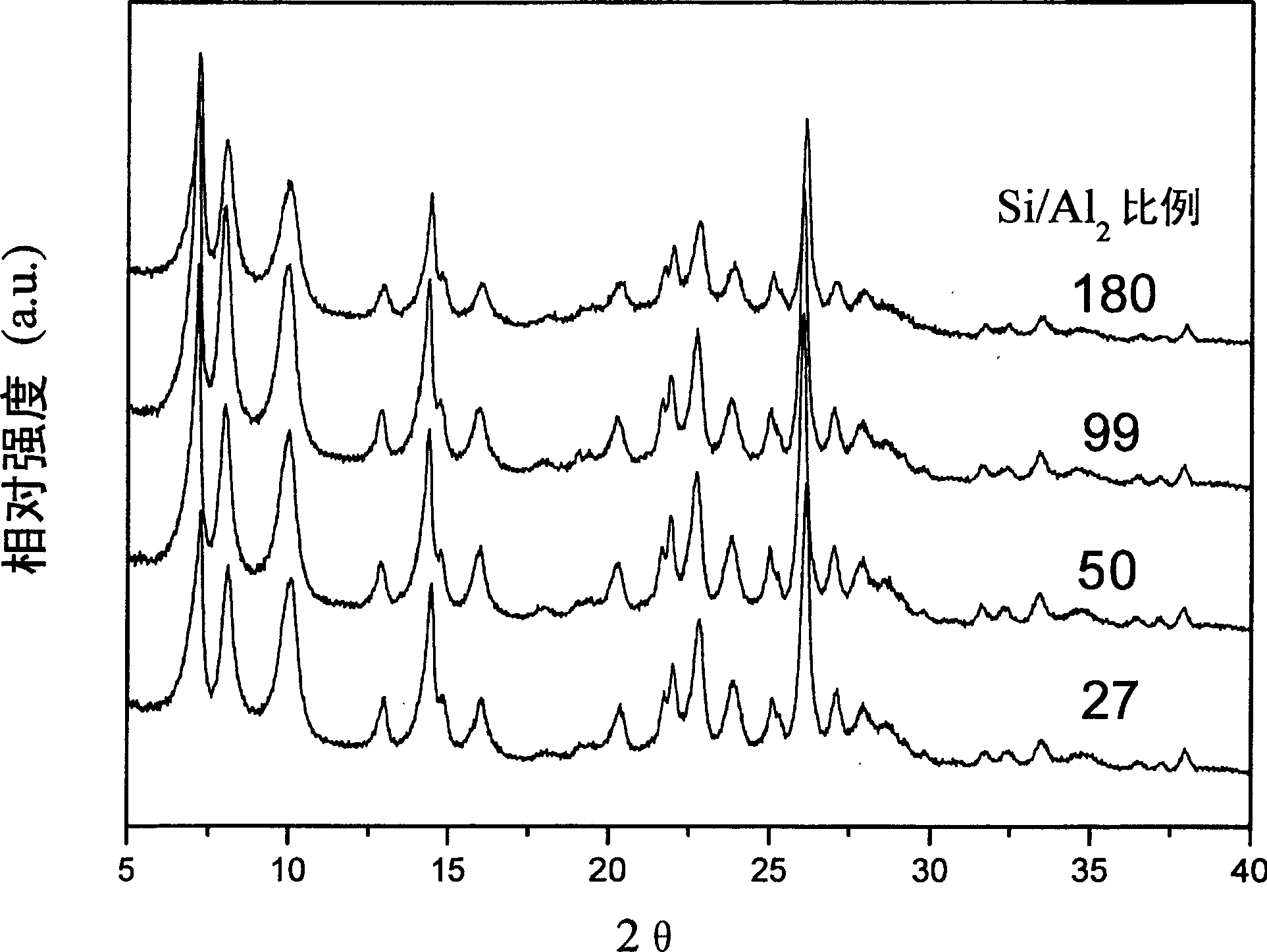

[0014] 2) Treat the molecular sieve obtained in step 1 with 0.01mol / L ammonium fluorosilicate solution under reflux at room temperature for 0.5h, wash with deionized water three times, dry at 100-120°C, and dry at 550°C. ℃, the resulting MCM-22 molecular sieve has a silicon-aluminum ratio of 50, a relative crystallinity of >99%, and no other crystal phases, see attached figure 1 .

Embodiment 2

[0016] The preparation method of ammonium type molecular sieve is the same as embodiment 1, ammonium ion source NH 4 Cl, ammonium ion exchange conditions: ammonium ion concentration 1mol / L, volume liquid-solid ratio 10, temperature 80°C. The obtained ammonium molecular sieve was treated with 0.03mol / L ammonium fluorosilicate solution under reflux at 70°C for 10 hours, washed repeatedly with deionized water three times, dried at 100-120°C, and calcined at 600°C to obtain MCM-22 Molecular sieve has a silicon-aluminum ratio of 99, a relative crystallinity of >99%, and no other crystalline phases, see attached figure 1 .

Embodiment 3

[0018] The preparation method of ammonium type molecular sieve is the same as embodiment 1, ammonium ion source (NH 4 ) SO 4 , Ammonium ion exchange conditions: ammonium ion concentration 1.2mol / L, volume liquid-solid ratio 5, temperature 100°C. The obtained ammonium molecular sieve was treated with 0.8mol / L ammonium fluorosilicate solution at 100°C for 48 hours under reflux, washed three times with deionized water, dried at 100-120°C, and calcined at 400°C to obtain MCM-22 Molecular sieve has a silicon-aluminum ratio of 180, a relative crystallinity > 80%, and no other crystal phases, see attached figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com