Method for removing porcelain by hydrofluoric acid and co-producing white carbon black

A technology of hydrofluoric acid and white carbon black, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems that the enamel cannot be completely removed, cannot be recycled and reused, and the blank is easy to deform, so as to achieve reasonable acid utilization and low production cost , the effect of short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

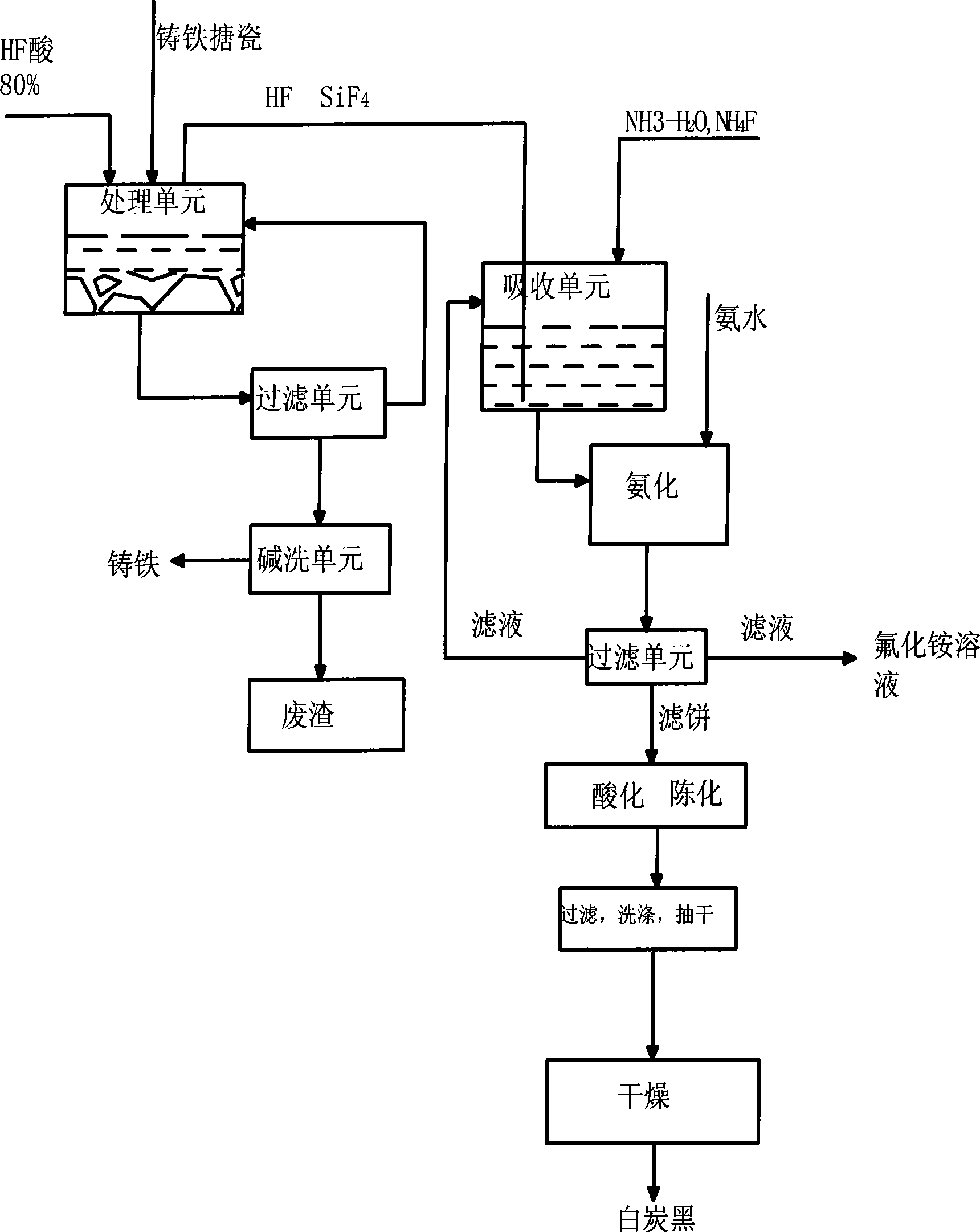

Image

Examples

Embodiment 1

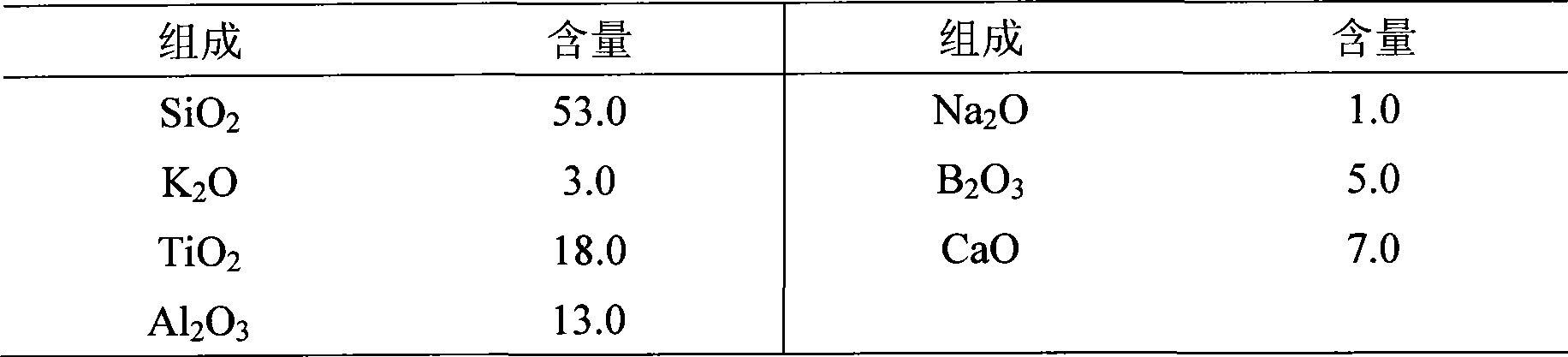

[0018] (1) Taking gray cast iron enamel as an example, the formula of gray cast iron enamel (w%)

[0019]

[0020] In the enamel composition, SiO 2 It is a matrix agent that can form the skeleton of enamel. SiO 2 At least a certain content in the composition of enamel raw materials can maintain the structure of enamel. In most enamel materials SiO 2 The content is more than 50wt.%. Immerse the defective cast iron enamel in a reaction kettle filled with a hydrofluoric acid aqueous solution with a mass fraction of 85%, heat it indirectly with water vapor, and react at 70°C for 2 hours, and silicon tetrafluoride gas will be generated. The responses are:

[0021] Na 2 O+2HF=2NaF+H 2 o

[0022] K 2 O+2HF=2KF+H 2 o

[0023] SiO 2 +4HF=SiF 4 ↑+H 2 o

[0024] SiF 4 +2HF=H 2 SiO 6

[0025] CaO+2HF=CaF 2 ↓+H 2 o

[0026] Al 2 o 3 +6HF=2AIF 3 +3H 2 o

[0027] TiO 2 +6HF=H 2 TiF 6 +2H 2 o

[0028] B 2 o 3 +6HF=2BF 3 +3H 2 o

[0029] In the reaction,...

Embodiment 2

[0044] The method that hydrofluoric acid removes porcelain and co-produces white carbon black, comprises the steps:

[0045](1) Immerse the cast iron enamel defective product in the reaction kettle that filled the hydrofluoric acid aqueous solution of 75% by mass fraction, indirect heating, at 80 ℃, react 1h, have silicon tetrafluoride gas to generate, described reaction Filtrate the liquid in the kettle, re-input the filtrate into the reaction kettle, wash the remaining substances with 15% sodium hydroxide aqueous solution, reclaim the cast iron, and further process the waste residue;

[0046] (2) Use ammonia water with a mass fraction of 25% to simultaneously absorb silicon tetrafluoride gas and volatilized hydrogen fluoride gas with a molar ratio of 1:2, the amount of ammonia water added is 1.2 times the theoretical amount, and 30% fluorine The ammonium chloride aqueous solution absorbs silicon tetrafluoride gas that has not been absorbed, and the solution is heated to boil...

Embodiment 3

[0049] The method for hydrofluoric acid porcelain removal and co-production of white carbon black is characterized in that it comprises the steps:

[0050] (1) Immerse the cast iron enamel defective product in the reactor of the hydrofluoric acid aqueous solution of 95% in full bloom by mass fraction, indirect heating, at 60 ℃, react 3h, have silicon tetrafluoride gas to generate, described reaction Filtrate the liquid in the kettle, re-input the filtrate into the reaction kettle, wash the rest of the material with 10% sodium hydroxide aqueous solution, recover the cast iron, and further process the waste residue;

[0051] (2) Use ammonia water with a mass fraction of 20% to simultaneously absorb silicon tetrafluoride gas and volatilized hydrogen fluoride gas with a molar ratio of 1:2, the amount of ammonia water added is 1.5 times the theoretical amount, and 20% fluorine The ammonium chloride aqueous solution absorbs silicon tetrafluoride gas that has not been absorbed, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com