Method for recovering silicon carbide in waste cutting mortar by using ammonium bifluoride

A technology of ammonium bifluoride and cutting waste sand, which is applied in the fields of monocrystalline silicon or polycrystalline silicon processing, environment and chemical industry, can solve the problem that waste mortar cannot be processed in a timely and effective manner, achieve obvious economic and social benefits, and is simple to operate and easy to process. Achieve the effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

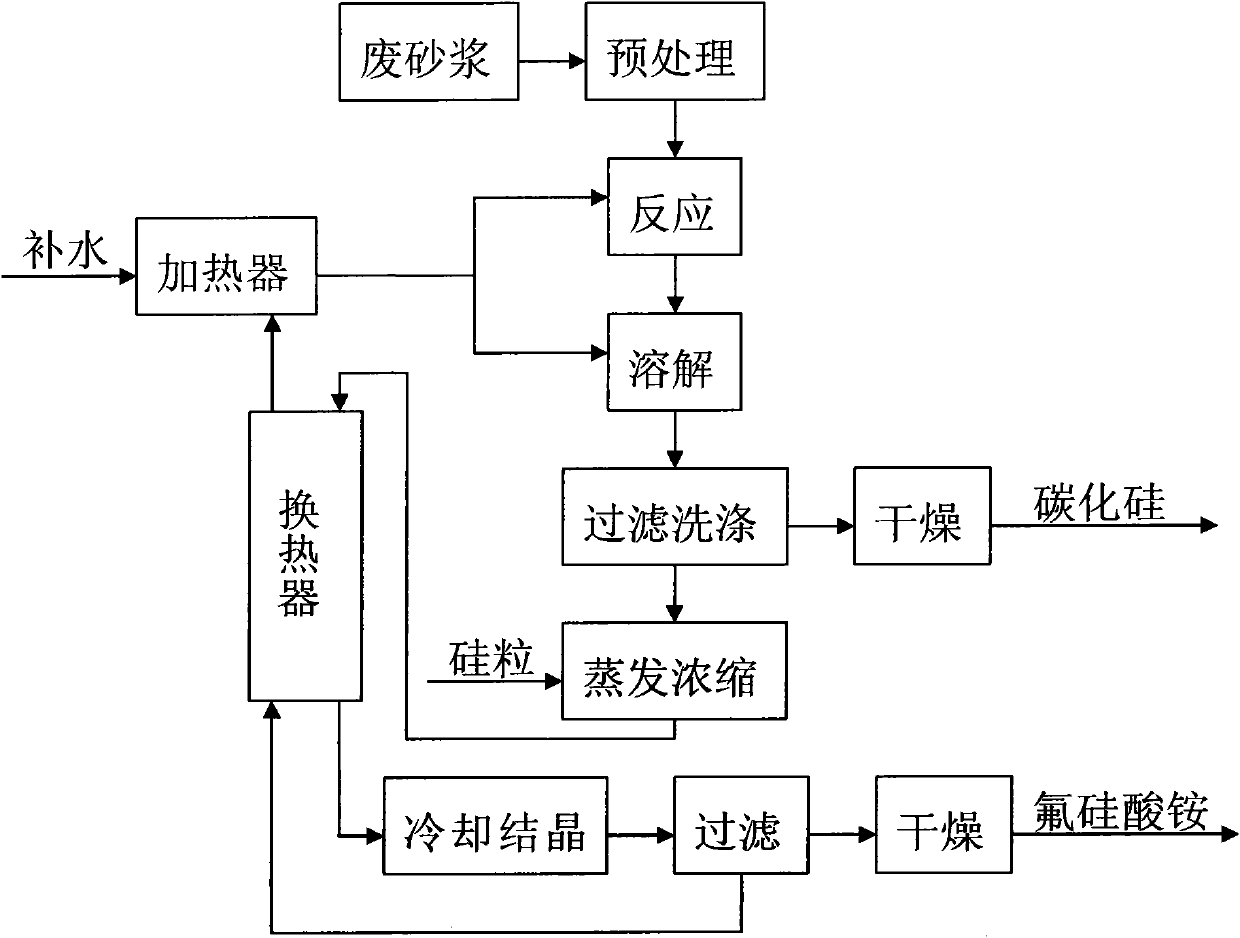

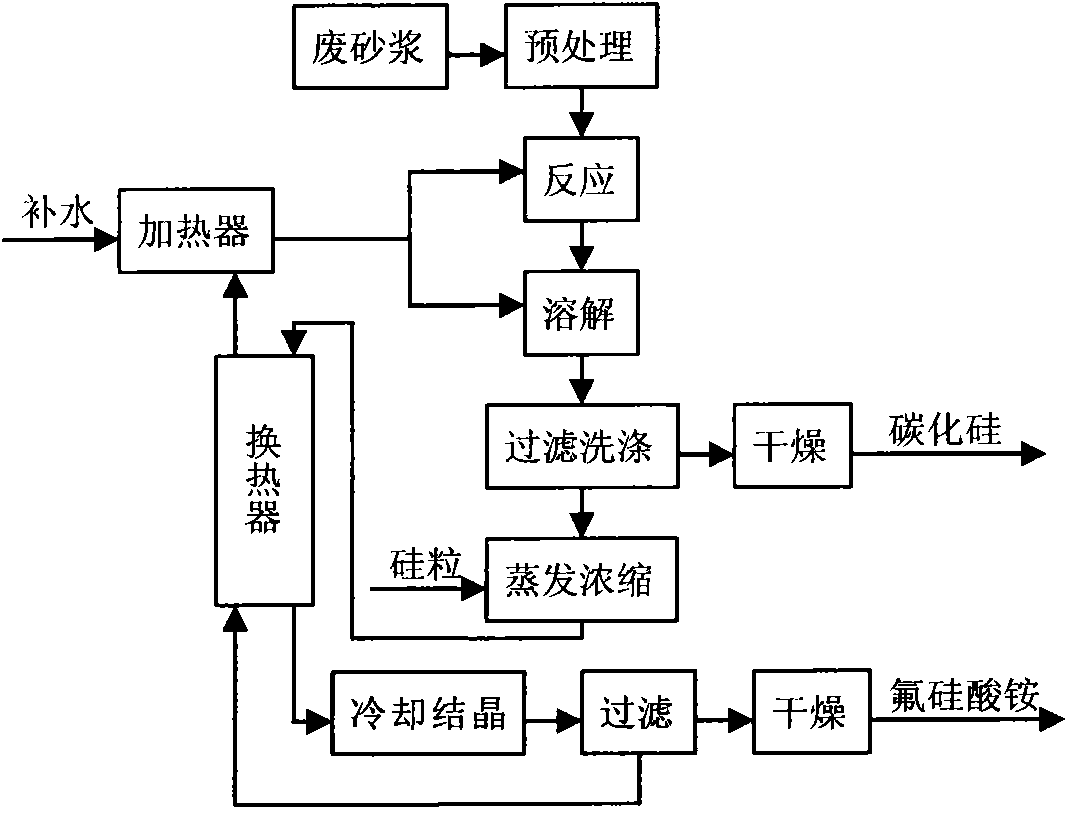

Image

Examples

Embodiment 1

[0019] During the silicon wafer processing of substrates such as solar cells or integrated circuits (semiconductors and liquid crystal displays, etc.), the waste mortar generated is pretreated to remove oil-based dispersants (such as polyethylene glycol, etc.) and a small amount of impurities (such as iron etc.), put 30 kg of sand powder (silicon carbide 86.6%, silicon 13.4%) into the container after pretreatment, and add 13 kg of ammonium bifluoride, stir evenly, add water to disperse and dissolve ammonium bifluoride gradually while reacting, to avoid becoming solid Shape, react at 50°C for 1.2 hours, add about 100 g of deionized distilled water to dissolve the reaction product ammonium fluorosilicate, control the concentration close to the saturated concentration, filter and separate, wash the solid three times to obtain 27.8 kg of wet silicon carbide, and pass through Dry to obtain finished silicon carbide; add 0.5 kg of large-grained high-purity silicon to the filtrate and ...

Embodiment 2

[0021] During the silicon wafer processing of substrates such as solar cells or integrated circuits (semiconductors and liquid crystal displays, etc.), the waste mortar generated is pretreated to remove oil-based dispersants (such as polyethylene glycol, etc.) and a small amount of impurities (such as iron etc.), put 30 kg of pretreated sand powder (silicon carbide 82.1%, silicon 17.9%) into the container, and add 17.5 kg of ammonium bifluoride, stir evenly, gradually add water to disperse and dissolve ammonium bifluoride while reacting, to avoid solidification Shape, react at 60°C for 1 hour, add deionized distilled water at about 100°C to dissolve the reaction product ammonium fluorosilicate, control the concentration close to the saturated concentration, filter and separate, and wash the solid three times to obtain 26.3 kg of wet silicon carbide. After drying, the finished silicon carbide is obtained; 0.5 kg of large-grained high-purity silicon is added to the filtrate and w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com